The Convergence of Cellophane with Smart Material Growth

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cellophane-Smart Material Convergence Background

The convergence of cellophane with smart material growth represents a fascinating intersection of traditional materials science and cutting-edge technology. Cellophane, a thin, transparent sheet made from regenerated cellulose, has been in use for over a century, primarily in packaging and industrial applications. Its journey from a simple wrapping material to a potential component in smart materials exemplifies the continuous evolution of materials science.

The development of cellophane dates back to 1900 when Jacques E. Brandenberger, a Swiss textile engineer, conceived the idea of creating a clear, impermeable coating for cloth. After years of experimentation, he successfully produced the first cellophane sheet in 1908. This invention marked a significant milestone in packaging technology, offering a transparent, moisture-resistant material that quickly found applications in food preservation and product display.

As materials science progressed, the potential for enhancing cellophane's properties became apparent. The advent of nanotechnology and smart materials in the late 20th and early 21st centuries opened new avenues for cellophane's evolution. Smart materials, capable of changing their properties in response to external stimuli, presented an opportunity to imbue cellophane with advanced functionalities.

The convergence of cellophane with smart material growth is driven by several factors. First, the increasing demand for sustainable and biodegradable materials aligns well with cellophane's cellulose-based composition. Second, the push for more interactive and responsive packaging solutions in various industries has created a need for materials that can adapt to environmental changes or user interactions.

This technological fusion aims to create a new class of materials that combine the biodegradability and transparency of cellophane with the responsive properties of smart materials. Potential applications range from advanced food packaging that can indicate freshness to interactive displays and even biomedical devices that respond to physiological changes.

The journey towards this convergence involves overcoming several challenges. These include developing methods to incorporate smart material properties into cellophane without compromising its inherent characteristics, ensuring the stability and longevity of the combined material, and scaling up production processes for commercial viability.

As research in this field progresses, we anticipate seeing cellophane-based smart materials that can change color, alter their permeability, or even release substances in response to specific triggers. This evolution represents not just an advancement in materials science but a paradigm shift in how we perceive and interact with everyday materials.

The development of cellophane dates back to 1900 when Jacques E. Brandenberger, a Swiss textile engineer, conceived the idea of creating a clear, impermeable coating for cloth. After years of experimentation, he successfully produced the first cellophane sheet in 1908. This invention marked a significant milestone in packaging technology, offering a transparent, moisture-resistant material that quickly found applications in food preservation and product display.

As materials science progressed, the potential for enhancing cellophane's properties became apparent. The advent of nanotechnology and smart materials in the late 20th and early 21st centuries opened new avenues for cellophane's evolution. Smart materials, capable of changing their properties in response to external stimuli, presented an opportunity to imbue cellophane with advanced functionalities.

The convergence of cellophane with smart material growth is driven by several factors. First, the increasing demand for sustainable and biodegradable materials aligns well with cellophane's cellulose-based composition. Second, the push for more interactive and responsive packaging solutions in various industries has created a need for materials that can adapt to environmental changes or user interactions.

This technological fusion aims to create a new class of materials that combine the biodegradability and transparency of cellophane with the responsive properties of smart materials. Potential applications range from advanced food packaging that can indicate freshness to interactive displays and even biomedical devices that respond to physiological changes.

The journey towards this convergence involves overcoming several challenges. These include developing methods to incorporate smart material properties into cellophane without compromising its inherent characteristics, ensuring the stability and longevity of the combined material, and scaling up production processes for commercial viability.

As research in this field progresses, we anticipate seeing cellophane-based smart materials that can change color, alter their permeability, or even release substances in response to specific triggers. This evolution represents not just an advancement in materials science but a paradigm shift in how we perceive and interact with everyday materials.

Market Potential Analysis

The convergence of cellophane with smart material growth presents a significant market opportunity across various industries. This innovative combination leverages the traditional benefits of cellophane, such as its transparency, flexibility, and barrier properties, while incorporating advanced smart material technologies to create responsive and adaptive packaging solutions.

In the food packaging sector, smart cellophane materials show immense potential. The global food packaging market, valued at $303.26 billion in 2019, is projected to reach $463.65 billion by 2027, with a CAGR of 5.9%. Smart cellophane packaging could capture a substantial portion of this growth by offering features like real-time freshness monitoring, temperature-sensitive color changes, and biodegradability.

The pharmaceutical industry also stands to benefit greatly from this convergence. With the global pharmaceutical packaging market expected to reach $153.93 billion by 2027, growing at a CAGR of 8.5%, smart cellophane packaging could revolutionize drug delivery systems and improve medication adherence. Features such as time-release mechanisms and environmental responsiveness could enhance drug efficacy and patient outcomes.

In the consumer electronics sector, where packaging plays a crucial role in product protection and brand perception, smart cellophane materials could offer innovative solutions. The global electronics packaging market, valued at $37.12 billion in 2019, is projected to reach $61.05 billion by 2027. Smart cellophane packaging could provide enhanced protection against moisture and static electricity while offering interactive features for consumers.

The cosmetics and personal care industry presents another lucrative market for smart cellophane materials. With the global cosmetic packaging market expected to reach $40.96 billion by 2025, growing at a CAGR of 4.3%, smart cellophane packaging could offer unique selling propositions such as customizable fragrance release or UV protection indicators.

Environmental concerns and sustainability trends further bolster the market potential for smart cellophane materials. As consumers and regulators push for more eco-friendly packaging solutions, the biodegradable properties of cellophane combined with smart material technologies could position these products as a preferred choice across industries.

The convergence of cellophane with smart material growth also aligns with the broader trend of Industry 4.0 and the Internet of Things (IoT). As supply chains become more digitized and interconnected, smart packaging materials that can communicate with inventory systems and provide real-time data on product conditions will become increasingly valuable.

In the food packaging sector, smart cellophane materials show immense potential. The global food packaging market, valued at $303.26 billion in 2019, is projected to reach $463.65 billion by 2027, with a CAGR of 5.9%. Smart cellophane packaging could capture a substantial portion of this growth by offering features like real-time freshness monitoring, temperature-sensitive color changes, and biodegradability.

The pharmaceutical industry also stands to benefit greatly from this convergence. With the global pharmaceutical packaging market expected to reach $153.93 billion by 2027, growing at a CAGR of 8.5%, smart cellophane packaging could revolutionize drug delivery systems and improve medication adherence. Features such as time-release mechanisms and environmental responsiveness could enhance drug efficacy and patient outcomes.

In the consumer electronics sector, where packaging plays a crucial role in product protection and brand perception, smart cellophane materials could offer innovative solutions. The global electronics packaging market, valued at $37.12 billion in 2019, is projected to reach $61.05 billion by 2027. Smart cellophane packaging could provide enhanced protection against moisture and static electricity while offering interactive features for consumers.

The cosmetics and personal care industry presents another lucrative market for smart cellophane materials. With the global cosmetic packaging market expected to reach $40.96 billion by 2025, growing at a CAGR of 4.3%, smart cellophane packaging could offer unique selling propositions such as customizable fragrance release or UV protection indicators.

Environmental concerns and sustainability trends further bolster the market potential for smart cellophane materials. As consumers and regulators push for more eco-friendly packaging solutions, the biodegradable properties of cellophane combined with smart material technologies could position these products as a preferred choice across industries.

The convergence of cellophane with smart material growth also aligns with the broader trend of Industry 4.0 and the Internet of Things (IoT). As supply chains become more digitized and interconnected, smart packaging materials that can communicate with inventory systems and provide real-time data on product conditions will become increasingly valuable.

Current Challenges in Integration

The integration of cellophane with smart material growth presents several significant challenges that researchers and engineers must overcome. One of the primary obstacles is achieving seamless compatibility between the traditional cellophane substrate and the advanced smart materials. The inherent properties of cellophane, such as its moisture sensitivity and limited thermal stability, can interfere with the growth and performance of smart materials.

Another major challenge lies in maintaining the desirable characteristics of cellophane while incorporating smart functionalities. Cellophane is valued for its transparency, flexibility, and biodegradability. However, the addition of smart materials may compromise these properties, potentially altering the optical clarity or mechanical flexibility of the resulting composite. Striking a balance between preserving cellophane's inherent qualities and enhancing its capabilities through smart material integration remains a complex task.

The scalability of the integration process poses yet another hurdle. While laboratory-scale experiments may yield promising results, translating these findings into large-scale, commercially viable production methods presents significant technical and economic challenges. The development of cost-effective and efficient manufacturing processes that can consistently produce high-quality smart cellophane composites is crucial for widespread adoption.

Furthermore, ensuring the long-term stability and durability of the integrated smart materials on the cellophane substrate is a critical concern. Environmental factors such as humidity, temperature fluctuations, and mechanical stress can potentially degrade the performance of smart materials or cause delamination from the cellophane base. Developing robust bonding techniques and protective measures to maintain the integrity of the smart functionalities over extended periods is essential.

The integration process also faces challenges related to the precise control and uniformity of smart material growth on the cellophane surface. Achieving consistent coverage and performance across large areas of cellophane requires advanced deposition techniques and careful optimization of growth parameters. Additionally, the potential for unintended interactions between the cellophane substrate and the precursors or growth conditions of smart materials must be carefully managed to prevent adverse effects on either component.

Lastly, the multidisciplinary nature of this integration effort necessitates collaboration between experts in diverse fields, including materials science, chemistry, and engineering. Coordinating research efforts and bridging knowledge gaps between these disciplines can be challenging but is crucial for overcoming the technical hurdles and driving innovation in smart cellophane composites.

Another major challenge lies in maintaining the desirable characteristics of cellophane while incorporating smart functionalities. Cellophane is valued for its transparency, flexibility, and biodegradability. However, the addition of smart materials may compromise these properties, potentially altering the optical clarity or mechanical flexibility of the resulting composite. Striking a balance between preserving cellophane's inherent qualities and enhancing its capabilities through smart material integration remains a complex task.

The scalability of the integration process poses yet another hurdle. While laboratory-scale experiments may yield promising results, translating these findings into large-scale, commercially viable production methods presents significant technical and economic challenges. The development of cost-effective and efficient manufacturing processes that can consistently produce high-quality smart cellophane composites is crucial for widespread adoption.

Furthermore, ensuring the long-term stability and durability of the integrated smart materials on the cellophane substrate is a critical concern. Environmental factors such as humidity, temperature fluctuations, and mechanical stress can potentially degrade the performance of smart materials or cause delamination from the cellophane base. Developing robust bonding techniques and protective measures to maintain the integrity of the smart functionalities over extended periods is essential.

The integration process also faces challenges related to the precise control and uniformity of smart material growth on the cellophane surface. Achieving consistent coverage and performance across large areas of cellophane requires advanced deposition techniques and careful optimization of growth parameters. Additionally, the potential for unintended interactions between the cellophane substrate and the precursors or growth conditions of smart materials must be carefully managed to prevent adverse effects on either component.

Lastly, the multidisciplinary nature of this integration effort necessitates collaboration between experts in diverse fields, including materials science, chemistry, and engineering. Coordinating research efforts and bridging knowledge gaps between these disciplines can be challenging but is crucial for overcoming the technical hurdles and driving innovation in smart cellophane composites.

Existing Convergence Solutions

01 Cellophane in packaging applications

Cellophane is widely used in packaging applications due to its transparency, flexibility, and barrier properties. It is particularly useful for food packaging, providing protection against moisture and gases while allowing visibility of the product. Cellophane can be combined with other materials to enhance its properties for specific packaging needs.- Cellophane production methods: Various methods for producing cellophane, including improvements in the manufacturing process to enhance its properties. These methods may involve different chemical treatments, extrusion techniques, or modifications to the cellulose base material to create cellophane with specific characteristics.

- Cellophane packaging applications: Utilization of cellophane in packaging solutions, particularly for food and consumer products. This includes the development of cellophane-based packaging materials with improved barrier properties, transparency, and sealability. Innovations in this area focus on enhancing the functionality and sustainability of cellophane packaging.

- Cellophane-based composite materials: Creation of composite materials incorporating cellophane to enhance their properties. These composites may combine cellophane with other materials to improve strength, flexibility, or other desirable characteristics. Applications of these composites range from industrial uses to consumer products.

- Cellophane modification techniques: Methods for modifying cellophane to impart specific properties or functionalities. This includes surface treatments, chemical modifications, or the incorporation of additives to enhance characteristics such as moisture resistance, heat sealability, or biodegradability. These techniques aim to expand the range of applications for cellophane.

- Cellophane-based devices and structures: Development of various devices and structures utilizing cellophane as a key component. This includes the use of cellophane in filters, membranes, or as a substrate for electronic or optical applications. Innovations in this area focus on leveraging the unique properties of cellophane to create novel functional devices.

02 Cellophane in biotechnology and medical applications

Cellophane membranes are utilized in various biotechnology and medical applications. They can be used for cell culture, dialysis, and as a support material for tissue engineering. The semi-permeable nature of cellophane allows for controlled diffusion of molecules, making it suitable for certain biomedical processes.Expand Specific Solutions03 Modifications and improvements to cellophane

Research focuses on modifying cellophane to enhance its properties or add new functionalities. This includes chemical treatments to improve moisture resistance, incorporation of antimicrobial agents, and development of biodegradable variants. These modifications aim to expand the range of applications for cellophane in various industries.Expand Specific Solutions04 Cellophane in textile and fiber applications

Cellophane finds use in textile and fiber applications, particularly in the production of regenerated cellulose fibers. It can be processed into fibers or films for use in clothing, upholstery, and other textile products. The material's properties, such as its ability to accept dyes and its strength, make it suitable for various textile applications.Expand Specific Solutions05 Cellophane in electronic and energy applications

Emerging research explores the use of cellophane in electronic and energy-related applications. This includes its potential as a substrate for flexible electronics, as a component in energy storage devices, or as a separator in batteries. The material's properties, such as flexibility and ion permeability, make it interesting for these novel applications.Expand Specific Solutions

Key Industry Players

The convergence of cellophane with smart material growth is in an early developmental stage, characterized by emerging research and limited commercial applications. The market size is relatively small but growing, driven by increasing interest in sustainable and functional materials. Technologically, this field is still evolving, with varying levels of maturity among key players. Companies like China Petroleum & Chemical Corp. and BASF Corp. are leveraging their expertise in materials science to explore potential applications. Academic institutions such as the University of Washington and Harbin Institute of Technology are conducting fundamental research to advance the technology. Startups like Bolt Threads, Inc. are pioneering innovative approaches to bio-based smart materials, potentially disrupting traditional cellophane production methods.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a novel approach to integrate cellophane with smart materials. Their research focuses on creating bio-based cellophane films infused with responsive polymers. These films can change properties in response to environmental stimuli such as temperature, pH, or light. Sinopec's method involves incorporating nanoparticles into the cellophane matrix during production, enabling the film to exhibit smart behaviors while maintaining biodegradability[1]. The company has also explored adding conductive materials to cellophane, creating flexible and transparent electrodes for potential use in smart packaging or wearable electronics[3].

Strengths: Leverages existing cellophane production infrastructure; combines biodegradability with smart functionalities. Weaknesses: May face challenges in scaling up production; potential increase in production costs.

Dow Silicones Corp.

Technical Solution: Dow Silicones Corp. has developed an innovative approach to integrating cellophane with smart materials, focusing on the incorporation of silicone-based smart polymers. Their technology involves creating a hybrid material that combines the biodegradability of cellophane with the responsive properties of silicone elastomers. This results in a flexible, transparent film that can change its mechanical properties in response to electrical stimuli[7]. Dow's smart cellophane can transition from rigid to soft states, opening up possibilities for adaptive packaging and shape-changing consumer products. The company has also explored adding piezoelectric properties to cellophane, enabling energy harvesting capabilities in flexible, bio-based materials[8].

Strengths: Combines biodegradability with advanced responsive properties; potential for energy harvesting applications. Weaknesses: May face challenges in achieving full biodegradability due to silicone content; higher production costs compared to traditional cellophane.

Innovative Approaches Analysis

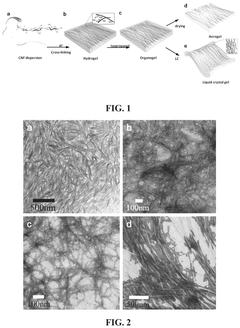

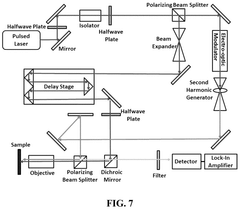

Cellulose-enabled orientationally ordered flexible gels

PatentActiveUS12129353B2

Innovation

- The development of cellulose-based flexible gels containing cellulose nanorods, ribbons, and fibers, which can be aligned to form ordered liquid crystal phases, allowing for the adjustment of optical transmissivity, thermal conductivity, and mechanical stiffness through the use of polysiloxane composites and surface modification agents.

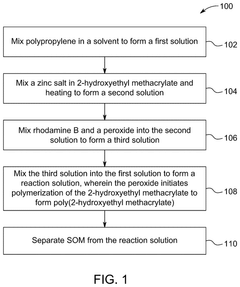

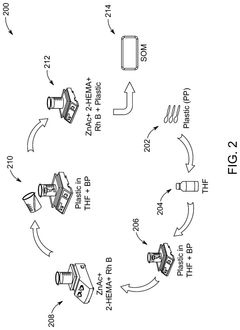

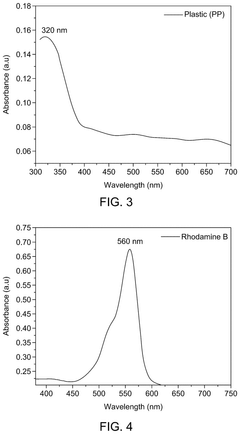

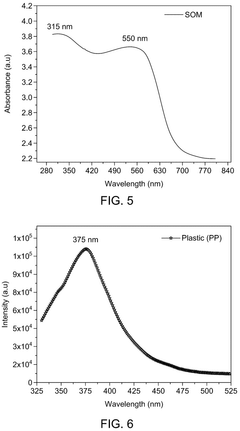

Smart optical material and method of making thereof

PatentActiveUS12110350B1

Innovation

- A method involving the synthesis of smart optical materials by mixing polypropylene with a solvent, a zinc salt, and rhodamine B, followed by polymerization using a peroxide, to create a composite material with dual optical bandgaps and improved impedance characteristics, suitable for laser and optoelectronic applications.

Environmental Impact Assessment

The convergence of cellophane with smart material growth presents both opportunities and challenges from an environmental perspective. This innovative technology has the potential to revolutionize packaging and material science, but its environmental impact must be carefully assessed.

The production process of smart cellophane materials may require additional energy and resources compared to traditional cellophane manufacturing. However, the enhanced functionality and durability of these materials could lead to reduced waste and longer product lifecycles. This trade-off necessitates a comprehensive life cycle analysis to determine the net environmental impact.

One of the key environmental benefits of smart cellophane materials is their potential for biodegradability. By incorporating smart growth techniques into cellophane production, it may be possible to create materials that break down more efficiently in natural environments, reducing long-term pollution and microplastic accumulation in ecosystems.

The use of smart cellophane materials in packaging applications could significantly reduce food waste by extending shelf life and improving preservation. This would have a positive cascading effect on resource consumption and greenhouse gas emissions associated with food production and disposal.

However, the introduction of new chemical compounds and nanoparticles in smart cellophane materials raises concerns about their potential impact on soil and water systems. Rigorous testing and long-term studies are necessary to ensure these materials do not introduce harmful substances into the environment upon degradation.

The recyclability of smart cellophane materials is another crucial factor to consider. While traditional cellophane is generally recyclable, the addition of smart components may complicate recycling processes. Developing effective recycling methods for these hybrid materials will be essential to minimize their environmental footprint.

The potential for smart cellophane materials to replace less environmentally friendly alternatives, such as certain plastics, could lead to a net positive impact on the environment. However, this substitution effect must be carefully evaluated across different applications and industries to ensure genuine environmental benefits.

In conclusion, the environmental impact of converging cellophane with smart material growth is complex and multifaceted. While the technology shows promise in areas such as waste reduction and improved resource efficiency, careful consideration must be given to production processes, material lifecycle, and end-of-life management to ensure a positive environmental outcome.

The production process of smart cellophane materials may require additional energy and resources compared to traditional cellophane manufacturing. However, the enhanced functionality and durability of these materials could lead to reduced waste and longer product lifecycles. This trade-off necessitates a comprehensive life cycle analysis to determine the net environmental impact.

One of the key environmental benefits of smart cellophane materials is their potential for biodegradability. By incorporating smart growth techniques into cellophane production, it may be possible to create materials that break down more efficiently in natural environments, reducing long-term pollution and microplastic accumulation in ecosystems.

The use of smart cellophane materials in packaging applications could significantly reduce food waste by extending shelf life and improving preservation. This would have a positive cascading effect on resource consumption and greenhouse gas emissions associated with food production and disposal.

However, the introduction of new chemical compounds and nanoparticles in smart cellophane materials raises concerns about their potential impact on soil and water systems. Rigorous testing and long-term studies are necessary to ensure these materials do not introduce harmful substances into the environment upon degradation.

The recyclability of smart cellophane materials is another crucial factor to consider. While traditional cellophane is generally recyclable, the addition of smart components may complicate recycling processes. Developing effective recycling methods for these hybrid materials will be essential to minimize their environmental footprint.

The potential for smart cellophane materials to replace less environmentally friendly alternatives, such as certain plastics, could lead to a net positive impact on the environment. However, this substitution effect must be carefully evaluated across different applications and industries to ensure genuine environmental benefits.

In conclusion, the environmental impact of converging cellophane with smart material growth is complex and multifaceted. While the technology shows promise in areas such as waste reduction and improved resource efficiency, careful consideration must be given to production processes, material lifecycle, and end-of-life management to ensure a positive environmental outcome.

Intellectual Property Landscape

The intellectual property landscape surrounding the convergence of cellophane with smart material growth is characterized by a complex web of patents, trademarks, and trade secrets. This emerging field has attracted significant attention from both established companies and innovative startups, resulting in a surge of patent applications and grants in recent years.

Major players in the packaging industry, such as DuPont and Mitsubishi Chemical, have been actively filing patents related to smart cellophane materials. These patents often focus on incorporating sensors, actuators, and responsive elements into traditional cellophane structures. For instance, several patents describe methods for embedding nanoparticles or microencapsulated compounds that can change color or release substances in response to environmental stimuli.

Universities and research institutions have also made substantial contributions to the intellectual property landscape. Patents from academic sources tend to explore more fundamental aspects of smart material growth on cellophane substrates, including novel synthesis methods and the integration of living organisms or biomimetic structures.

A notable trend in the patent landscape is the increasing focus on biodegradability and sustainability. Many recent patents describe techniques for creating smart cellophane materials that maintain their advanced functionalities while remaining environmentally friendly. This aligns with growing consumer demand for sustainable packaging solutions.

Cross-licensing agreements between companies are becoming more common as the field matures. These agreements allow for the sharing of complementary technologies, accelerating innovation and product development. However, they also create a more intricate web of intellectual property rights that new entrants must navigate carefully.

The geographical distribution of patents in this field shows a concentration in East Asia, North America, and Europe. Japan, in particular, has emerged as a leader in smart cellophane technology, with numerous patents filed by both large corporations and smaller specialized firms.

As the field continues to evolve, we are seeing an increase in patents related to the integration of smart cellophane materials with Internet of Things (IoT) technologies. These patents often describe systems for real-time monitoring of product freshness, tampering detection, and supply chain tracking using smart cellophane packaging.

The intellectual property landscape in this domain is dynamic and rapidly evolving. Companies and researchers are continuously pushing the boundaries of what is possible with smart cellophane materials, leading to a rich and diverse patent portfolio that will shape the future of packaging and smart materials.

Major players in the packaging industry, such as DuPont and Mitsubishi Chemical, have been actively filing patents related to smart cellophane materials. These patents often focus on incorporating sensors, actuators, and responsive elements into traditional cellophane structures. For instance, several patents describe methods for embedding nanoparticles or microencapsulated compounds that can change color or release substances in response to environmental stimuli.

Universities and research institutions have also made substantial contributions to the intellectual property landscape. Patents from academic sources tend to explore more fundamental aspects of smart material growth on cellophane substrates, including novel synthesis methods and the integration of living organisms or biomimetic structures.

A notable trend in the patent landscape is the increasing focus on biodegradability and sustainability. Many recent patents describe techniques for creating smart cellophane materials that maintain their advanced functionalities while remaining environmentally friendly. This aligns with growing consumer demand for sustainable packaging solutions.

Cross-licensing agreements between companies are becoming more common as the field matures. These agreements allow for the sharing of complementary technologies, accelerating innovation and product development. However, they also create a more intricate web of intellectual property rights that new entrants must navigate carefully.

The geographical distribution of patents in this field shows a concentration in East Asia, North America, and Europe. Japan, in particular, has emerged as a leader in smart cellophane technology, with numerous patents filed by both large corporations and smaller specialized firms.

As the field continues to evolve, we are seeing an increase in patents related to the integration of smart cellophane materials with Internet of Things (IoT) technologies. These patents often describe systems for real-time monitoring of product freshness, tampering detection, and supply chain tracking using smart cellophane packaging.

The intellectual property landscape in this domain is dynamic and rapidly evolving. Companies and researchers are continuously pushing the boundaries of what is possible with smart cellophane materials, leading to a rich and diverse patent portfolio that will shape the future of packaging and smart materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!