The Role of Hydroxyapatite in Stabilizing Biodegradable Polymers

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydroxyapatite-Polymer Evolution and Objectives

The evolution of hydroxyapatite-polymer composites represents a significant advancement in the field of biomaterials, particularly in the context of biodegradable polymers. This technological progression has been driven by the need for materials that can provide both structural support and bioactivity in medical applications. The journey began with the recognition of hydroxyapatite's potential to enhance the mechanical and biological properties of polymeric materials.

Initially, researchers focused on simple blending techniques to incorporate hydroxyapatite into polymer matrices. However, these early attempts often resulted in poor dispersion and limited interaction between the two components. As the field progressed, more sophisticated methods were developed, including in situ precipitation of hydroxyapatite within polymer networks and surface modification of hydroxyapatite particles to improve their compatibility with polymers.

The evolution of these composites has been marked by several key milestones. The development of nanoscale hydroxyapatite particles significantly improved the interfacial bonding with polymers, leading to enhanced mechanical properties. Additionally, the introduction of controlled release systems, where hydroxyapatite serves as both a reinforcing agent and a drug carrier, opened new avenues for therapeutic applications.

Recent advancements have focused on creating hierarchical structures that mimic natural bone tissue more closely. This includes the development of 3D-printed scaffolds with precise control over pore size and distribution, as well as the incorporation of growth factors and other bioactive molecules to promote tissue regeneration.

The primary objective of hydroxyapatite-polymer composite research is to create materials that can effectively stabilize biodegradable polymers while maintaining their biocompatibility and osteoconductivity. This involves optimizing the interface between hydroxyapatite and the polymer matrix to achieve synergistic effects in terms of mechanical strength, degradation rate, and biological response.

Future goals include developing smart composites that can respond to physiological stimuli, improving the long-term performance of these materials in vivo, and expanding their application to a wider range of medical devices and tissue engineering constructs. Additionally, there is a growing emphasis on sustainable production methods and the use of naturally derived polymers to create more environmentally friendly composites.

As research in this field continues to evolve, the ultimate aim is to create biomaterials that can seamlessly integrate with the human body, promote natural healing processes, and eventually be replaced by native tissue without adverse effects. This ambitious objective drives ongoing efforts to refine the synthesis, characterization, and application of hydroxyapatite-polymer composites in the biomedical field.

Initially, researchers focused on simple blending techniques to incorporate hydroxyapatite into polymer matrices. However, these early attempts often resulted in poor dispersion and limited interaction between the two components. As the field progressed, more sophisticated methods were developed, including in situ precipitation of hydroxyapatite within polymer networks and surface modification of hydroxyapatite particles to improve their compatibility with polymers.

The evolution of these composites has been marked by several key milestones. The development of nanoscale hydroxyapatite particles significantly improved the interfacial bonding with polymers, leading to enhanced mechanical properties. Additionally, the introduction of controlled release systems, where hydroxyapatite serves as both a reinforcing agent and a drug carrier, opened new avenues for therapeutic applications.

Recent advancements have focused on creating hierarchical structures that mimic natural bone tissue more closely. This includes the development of 3D-printed scaffolds with precise control over pore size and distribution, as well as the incorporation of growth factors and other bioactive molecules to promote tissue regeneration.

The primary objective of hydroxyapatite-polymer composite research is to create materials that can effectively stabilize biodegradable polymers while maintaining their biocompatibility and osteoconductivity. This involves optimizing the interface between hydroxyapatite and the polymer matrix to achieve synergistic effects in terms of mechanical strength, degradation rate, and biological response.

Future goals include developing smart composites that can respond to physiological stimuli, improving the long-term performance of these materials in vivo, and expanding their application to a wider range of medical devices and tissue engineering constructs. Additionally, there is a growing emphasis on sustainable production methods and the use of naturally derived polymers to create more environmentally friendly composites.

As research in this field continues to evolve, the ultimate aim is to create biomaterials that can seamlessly integrate with the human body, promote natural healing processes, and eventually be replaced by native tissue without adverse effects. This ambitious objective drives ongoing efforts to refine the synthesis, characterization, and application of hydroxyapatite-polymer composites in the biomedical field.

Market Analysis for Biodegradable Composites

The market for biodegradable composites incorporating hydroxyapatite (HA) and biodegradable polymers is experiencing significant growth, driven by increasing environmental concerns and the demand for sustainable materials across various industries. This market segment is particularly promising in the biomedical field, where these composites find applications in tissue engineering, drug delivery systems, and orthopedic implants.

In the healthcare sector, the global market for biodegradable implants is projected to reach substantial figures in the coming years, with a considerable portion attributed to HA-polymer composites. The orthopedic segment, in particular, shows strong potential due to the rising incidence of bone-related disorders and the aging population in many developed countries.

Beyond healthcare, these composites are gaining traction in packaging and consumer goods industries. The global biodegradable plastics market, which includes HA-polymer composites, is expanding rapidly as companies seek alternatives to traditional petroleum-based plastics. This growth is fueled by stringent environmental regulations and changing consumer preferences towards eco-friendly products.

Regionally, North America and Europe currently dominate the market for biodegradable composites, owing to advanced healthcare infrastructure and stringent environmental policies. However, Asia-Pacific is emerging as a lucrative market, driven by rapid industrialization, increasing healthcare expenditure, and growing awareness of environmental issues.

Key market drivers include technological advancements in material science, increasing research and development activities, and the expanding applications of these composites in various end-use industries. The ability of HA to enhance the mechanical properties and biocompatibility of biodegradable polymers is a significant factor contributing to market growth.

Challenges in the market include the higher cost of production compared to conventional materials and the need for further research to improve the performance and versatility of these composites. Additionally, regulatory hurdles and the lack of standardized quality control measures pose obstacles to market expansion.

Despite these challenges, the market outlook remains positive. The increasing focus on circular economy principles and the push towards sustainable development goals are expected to drive further adoption of HA-stabilized biodegradable polymer composites across industries. As research continues to advance and production costs decrease, these materials are poised to capture a larger share of the global materials market, offering environmentally friendly alternatives to traditional plastics and composites.

In the healthcare sector, the global market for biodegradable implants is projected to reach substantial figures in the coming years, with a considerable portion attributed to HA-polymer composites. The orthopedic segment, in particular, shows strong potential due to the rising incidence of bone-related disorders and the aging population in many developed countries.

Beyond healthcare, these composites are gaining traction in packaging and consumer goods industries. The global biodegradable plastics market, which includes HA-polymer composites, is expanding rapidly as companies seek alternatives to traditional petroleum-based plastics. This growth is fueled by stringent environmental regulations and changing consumer preferences towards eco-friendly products.

Regionally, North America and Europe currently dominate the market for biodegradable composites, owing to advanced healthcare infrastructure and stringent environmental policies. However, Asia-Pacific is emerging as a lucrative market, driven by rapid industrialization, increasing healthcare expenditure, and growing awareness of environmental issues.

Key market drivers include technological advancements in material science, increasing research and development activities, and the expanding applications of these composites in various end-use industries. The ability of HA to enhance the mechanical properties and biocompatibility of biodegradable polymers is a significant factor contributing to market growth.

Challenges in the market include the higher cost of production compared to conventional materials and the need for further research to improve the performance and versatility of these composites. Additionally, regulatory hurdles and the lack of standardized quality control measures pose obstacles to market expansion.

Despite these challenges, the market outlook remains positive. The increasing focus on circular economy principles and the push towards sustainable development goals are expected to drive further adoption of HA-stabilized biodegradable polymer composites across industries. As research continues to advance and production costs decrease, these materials are poised to capture a larger share of the global materials market, offering environmentally friendly alternatives to traditional plastics and composites.

Current Challenges in Polymer Stabilization

The stabilization of biodegradable polymers remains a significant challenge in the field of biomaterials. Despite their promising potential in various applications, these polymers often suffer from rapid degradation rates and poor mechanical properties, limiting their long-term functionality. One of the primary issues is the uncontrolled hydrolysis of polymer chains, which can lead to premature material failure and unpredictable release of degradation products.

The incorporation of hydroxyapatite (HA) into biodegradable polymer matrices has emerged as a potential solution to address these stability concerns. However, several challenges persist in achieving optimal polymer-HA composites. The dispersion of HA particles within the polymer matrix is often non-uniform, leading to inconsistent mechanical properties and degradation rates across the material. This heterogeneity can result in localized stress concentrations and accelerated degradation in certain regions of the composite.

Another significant challenge is the interfacial adhesion between the HA particles and the polymer matrix. Poor adhesion can lead to particle agglomeration and the formation of micro-voids, compromising the overall structural integrity of the composite. These interfacial issues not only affect the mechanical properties but also influence the degradation kinetics of the polymer, potentially leading to unpredictable material behavior in vivo.

The control of HA particle size and morphology presents an additional hurdle in polymer stabilization. Nano-sized HA particles are often preferred due to their higher surface area and potential for improved interaction with the polymer matrix. However, the synthesis and incorporation of uniformly sized nanoparticles without agglomeration remain technically challenging. The particle size distribution can significantly impact the composite's properties, affecting both its mechanical strength and degradation profile.

Furthermore, the optimization of HA content within the polymer matrix is a delicate balance. While higher HA concentrations may improve mechanical properties and potentially slow down degradation rates, excessive amounts can lead to brittleness and reduced ductility of the composite. Determining the optimal HA concentration that enhances stability without compromising other essential material properties is an ongoing area of research.

The long-term stability of HA-polymer composites in physiological environments is another critical concern. The dynamic nature of the in vivo environment, including fluctuations in pH, temperature, and the presence of enzymes, can affect the degradation behavior of these composites in ways that are difficult to predict from in vitro studies. Developing accurate models and testing protocols that can reliably simulate long-term in vivo performance remains a significant challenge in the field.

The incorporation of hydroxyapatite (HA) into biodegradable polymer matrices has emerged as a potential solution to address these stability concerns. However, several challenges persist in achieving optimal polymer-HA composites. The dispersion of HA particles within the polymer matrix is often non-uniform, leading to inconsistent mechanical properties and degradation rates across the material. This heterogeneity can result in localized stress concentrations and accelerated degradation in certain regions of the composite.

Another significant challenge is the interfacial adhesion between the HA particles and the polymer matrix. Poor adhesion can lead to particle agglomeration and the formation of micro-voids, compromising the overall structural integrity of the composite. These interfacial issues not only affect the mechanical properties but also influence the degradation kinetics of the polymer, potentially leading to unpredictable material behavior in vivo.

The control of HA particle size and morphology presents an additional hurdle in polymer stabilization. Nano-sized HA particles are often preferred due to their higher surface area and potential for improved interaction with the polymer matrix. However, the synthesis and incorporation of uniformly sized nanoparticles without agglomeration remain technically challenging. The particle size distribution can significantly impact the composite's properties, affecting both its mechanical strength and degradation profile.

Furthermore, the optimization of HA content within the polymer matrix is a delicate balance. While higher HA concentrations may improve mechanical properties and potentially slow down degradation rates, excessive amounts can lead to brittleness and reduced ductility of the composite. Determining the optimal HA concentration that enhances stability without compromising other essential material properties is an ongoing area of research.

The long-term stability of HA-polymer composites in physiological environments is another critical concern. The dynamic nature of the in vivo environment, including fluctuations in pH, temperature, and the presence of enzymes, can affect the degradation behavior of these composites in ways that are difficult to predict from in vitro studies. Developing accurate models and testing protocols that can reliably simulate long-term in vivo performance remains a significant challenge in the field.

Existing Hydroxyapatite Stabilization Methods

01 Synthesis methods for stable hydroxyapatite

Various synthesis methods are employed to produce stable hydroxyapatite, including sol-gel processes, hydrothermal techniques, and precipitation methods. These approaches aim to control particle size, crystallinity, and composition, which are crucial factors in determining the stability of hydroxyapatite. Optimizing synthesis parameters such as temperature, pH, and precursor concentrations can lead to more stable hydroxyapatite structures.- Synthesis methods for stable hydroxyapatite: Various synthesis methods are employed to produce stable hydroxyapatite, including sol-gel processes, hydrothermal techniques, and precipitation methods. These approaches aim to control particle size, morphology, and crystallinity, which are crucial factors in determining the stability of hydroxyapatite. Optimizing reaction conditions such as temperature, pH, and precursor concentrations can lead to more stable hydroxyapatite structures.

- Surface modification to enhance hydroxyapatite stability: Surface modification techniques are used to improve the stability of hydroxyapatite. These methods include coating with polymers, functionalization with organic molecules, or incorporation of metal ions. Such modifications can enhance the resistance of hydroxyapatite to dissolution, improve its mechanical properties, and increase its biocompatibility for various applications.

- Thermal stability of hydroxyapatite: The thermal stability of hydroxyapatite is crucial for high-temperature applications and processing. Research focuses on understanding and improving the thermal behavior of hydroxyapatite, including phase transitions, decomposition temperatures, and structural changes under heat treatment. Strategies to enhance thermal stability include doping with various elements or creating composite materials.

- Hydroxyapatite stability in biological environments: The stability of hydroxyapatite in biological environments is essential for its use in biomedical applications. Studies investigate the behavior of hydroxyapatite under physiological conditions, including its dissolution rate, interaction with proteins and cells, and long-term stability in vivo. Factors such as crystallinity, porosity, and chemical composition are optimized to achieve desired stability profiles for specific biomedical applications.

- Composite materials for improved hydroxyapatite stability: Composite materials incorporating hydroxyapatite are developed to enhance its overall stability. These composites often combine hydroxyapatite with polymers, ceramics, or other bioactive materials. The resulting composites can exhibit improved mechanical properties, controlled degradation rates, and enhanced biological performance compared to pure hydroxyapatite, making them suitable for various applications in tissue engineering and regenerative medicine.

02 Surface modification to enhance stability

Surface modification techniques are used to improve the stability of hydroxyapatite. This can involve coating the hydroxyapatite particles with polymers, incorporating ions such as fluoride or strontium, or grafting functional groups onto the surface. These modifications can enhance the resistance to dissolution, improve mechanical properties, and increase biocompatibility, thereby increasing overall stability.Expand Specific Solutions03 Thermal stability of hydroxyapatite

The thermal stability of hydroxyapatite is crucial for its applications in high-temperature environments. Research focuses on understanding and improving the thermal behavior of hydroxyapatite, including phase transitions, decomposition temperatures, and structural changes under heat. Methods to enhance thermal stability include doping with various elements and controlling the stoichiometry of the hydroxyapatite.Expand Specific Solutions04 Stability in physiological environments

Maintaining stability in physiological environments is essential for biomedical applications of hydroxyapatite. This involves studying the behavior of hydroxyapatite under various pH conditions, in the presence of proteins and other biomolecules, and in simulated body fluids. Strategies to improve stability in these conditions include controlling the Ca/P ratio, incorporating carbonate ions, and developing composite materials with enhanced biological properties.Expand Specific Solutions05 Characterization techniques for stability assessment

Advanced characterization techniques are employed to assess the stability of hydroxyapatite. These include X-ray diffraction (XRD) for crystalline structure analysis, scanning electron microscopy (SEM) for morphology studies, and various spectroscopic methods for chemical composition analysis. In vitro dissolution tests and long-term stability studies are also conducted to evaluate the performance of hydroxyapatite under different conditions.Expand Specific Solutions

Key Players in Biocomposite Industry

The field of hydroxyapatite in stabilizing biodegradable polymers is in a growth phase, with increasing market size and technological advancements. The global market for this technology is expanding due to rising demand in biomedical applications, particularly in tissue engineering and drug delivery systems. While the technology is maturing, there is still room for innovation and improvement. Key players like UCL Business Ltd., Chongqing University, and Mayo Foundation for Medical Education & Research are driving research and development in this area. Companies such as ArBlast Co., Ltd. and LG Chem Ltd. are also contributing to the commercialization of these materials. The competitive landscape is characterized by a mix of academic institutions, research organizations, and industrial players, indicating a collaborative yet competitive environment for technological advancement.

Kyoto University

Technical Solution: Kyoto University has made significant advancements in the field of hydroxyapatite (HA) stabilized biodegradable polymers. Their research team has developed a unique approach that involves the in-situ precipitation of HA nanoparticles within biodegradable polymer matrices. This method ensures a more uniform distribution of HA throughout the polymer, resulting in improved mechanical properties and biocompatibility. The university's studies have shown that this technique can enhance the osteoconductivity of the composite materials, making them particularly suitable for bone tissue engineering applications[6]. Additionally, Kyoto University researchers have explored the use of HA-polymer composites for controlled drug release systems, demonstrating the potential for these materials in therapeutic applications[7]. Their work also includes the development of 3D-printable HA-polymer composites, opening up new possibilities for personalized implant manufacturing[8].

Strengths: Uniform HA distribution, enhanced osteoconductivity, potential for controlled drug release, and 3D-printability. Weaknesses: Possible limitations in controlling the HA precipitation process and potential effects on polymer degradation kinetics.

Sichuan University

Technical Solution: Sichuan University has developed a novel approach to stabilize biodegradable polymers using hydroxyapatite (HA). Their method involves creating a nanocomposite material by incorporating HA nanoparticles into biodegradable polymer matrices. This technique enhances the mechanical properties and biocompatibility of the resulting material. The university's research has shown that the addition of HA can significantly improve the compressive strength and elastic modulus of biodegradable polymers, making them more suitable for bone tissue engineering applications[1]. Additionally, they have explored the use of surface-modified HA to improve the interfacial bonding between the HA particles and the polymer matrix, resulting in better dispersion and enhanced overall performance of the composite[3].

Strengths: Improved mechanical properties, enhanced biocompatibility, and better suitability for bone tissue engineering. Weaknesses: Potential challenges in achieving uniform dispersion of HA nanoparticles and controlling the degradation rate of the composite.

Innovative Hydroxyapatite-Polymer Interfaces

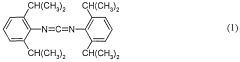

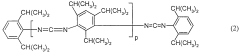

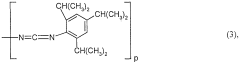

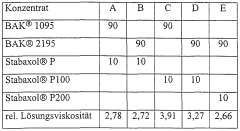

Stabilized molding compounds comprised of biologically degradable materials

PatentWO1999029768A1

Innovation

- Incorporating stabilizers such as N,N'-dicyclohexylcarbodiimide, polyfunctional oxazolines, and microbe protection agents into biodegradable polymers to delay degradation, thereby enhancing storage stability and extending the usability of biodegradable molding compositions.

Patent

Innovation

- Incorporation of hydroxyapatite nanoparticles into biodegradable polymer matrices to enhance mechanical properties and slow degradation rates.

- Use of hydroxyapatite as a pH buffering agent to neutralize acidic degradation products of biodegradable polymers and maintain a more stable local environment.

- Development of hydroxyapatite-polymer nanocomposites with improved bioactivity and osteoconductivity for bone tissue engineering applications.

Biocompatibility and Safety Considerations

The biocompatibility and safety considerations of hydroxyapatite (HA) in stabilizing biodegradable polymers are crucial aspects that require thorough examination. HA, being a naturally occurring mineral component of bone and teeth, exhibits excellent biocompatibility and osteoconductive properties, making it an ideal candidate for biomedical applications.

When incorporated into biodegradable polymers, HA not only enhances the mechanical properties but also improves the overall biocompatibility of the composite material. The presence of HA can promote cell adhesion, proliferation, and differentiation, particularly for osteoblasts and other bone-forming cells. This synergistic effect between HA and biodegradable polymers creates a more favorable environment for tissue regeneration and integration.

Safety considerations for HA-polymer composites primarily focus on the potential release of particles or degradation products. While HA is generally considered safe, the size and morphology of HA particles can influence their biological interactions. Nano-sized HA particles may exhibit different cellular uptake and distribution patterns compared to micro-sized particles, potentially affecting their safety profile.

The degradation kinetics of the polymer matrix play a crucial role in the safety assessment of these composites. Ideally, the degradation rate should match the rate of new tissue formation to ensure a smooth transition and minimize the risk of inflammatory responses. The release of HA particles during polymer degradation must be carefully controlled to prevent any adverse effects on surrounding tissues.

Long-term biocompatibility studies are essential to evaluate the potential for chronic inflammation or foreign body reactions. While short-term studies often show promising results, the extended presence of HA-polymer composites in the body may lead to unforeseen complications. Comprehensive in vivo studies are necessary to assess the long-term safety and efficacy of these materials.

The processing methods used to incorporate HA into biodegradable polymers can also impact biocompatibility and safety. Techniques such as solvent casting, melt blending, or in situ precipitation may introduce residual solvents or alter the surface properties of the composite, potentially affecting cellular interactions and tissue response.

Regulatory considerations for HA-polymer composites must address both the individual components and the final composite material. Standardized testing protocols and guidelines for evaluating the safety and efficacy of these composites are crucial for their successful translation into clinical applications.

When incorporated into biodegradable polymers, HA not only enhances the mechanical properties but also improves the overall biocompatibility of the composite material. The presence of HA can promote cell adhesion, proliferation, and differentiation, particularly for osteoblasts and other bone-forming cells. This synergistic effect between HA and biodegradable polymers creates a more favorable environment for tissue regeneration and integration.

Safety considerations for HA-polymer composites primarily focus on the potential release of particles or degradation products. While HA is generally considered safe, the size and morphology of HA particles can influence their biological interactions. Nano-sized HA particles may exhibit different cellular uptake and distribution patterns compared to micro-sized particles, potentially affecting their safety profile.

The degradation kinetics of the polymer matrix play a crucial role in the safety assessment of these composites. Ideally, the degradation rate should match the rate of new tissue formation to ensure a smooth transition and minimize the risk of inflammatory responses. The release of HA particles during polymer degradation must be carefully controlled to prevent any adverse effects on surrounding tissues.

Long-term biocompatibility studies are essential to evaluate the potential for chronic inflammation or foreign body reactions. While short-term studies often show promising results, the extended presence of HA-polymer composites in the body may lead to unforeseen complications. Comprehensive in vivo studies are necessary to assess the long-term safety and efficacy of these materials.

The processing methods used to incorporate HA into biodegradable polymers can also impact biocompatibility and safety. Techniques such as solvent casting, melt blending, or in situ precipitation may introduce residual solvents or alter the surface properties of the composite, potentially affecting cellular interactions and tissue response.

Regulatory considerations for HA-polymer composites must address both the individual components and the final composite material. Standardized testing protocols and guidelines for evaluating the safety and efficacy of these composites are crucial for their successful translation into clinical applications.

Environmental Impact Assessment

The incorporation of hydroxyapatite (HA) into biodegradable polymers has significant environmental implications that warrant careful consideration. As these composite materials gain traction in various applications, particularly in the biomedical field, their environmental impact throughout their lifecycle becomes increasingly important.

One of the primary environmental benefits of using HA in biodegradable polymers is the potential reduction in overall material consumption. By enhancing the mechanical properties and stability of biodegradable polymers, HA allows for the creation of more durable and long-lasting products. This increased longevity can lead to a decrease in the frequency of product replacement, ultimately reducing waste generation and resource consumption.

However, the production of HA itself requires careful scrutiny from an environmental perspective. The synthesis of HA often involves energy-intensive processes and the use of chemical precursors. While natural sources of HA exist, such as those derived from fish bones or eggshells, the scalability and consistency of these sources may present challenges for large-scale industrial applications.

The biodegradation process of HA-reinforced polymers also merits attention. While biodegradable polymers are designed to break down in natural environments, the presence of HA may alter the degradation kinetics and pathways. This could potentially lead to the release of HA particles into ecosystems, necessitating studies on their potential impact on soil and aquatic environments.

On a positive note, the biocompatibility of HA suggests that its environmental impact may be less severe compared to other synthetic reinforcing materials. As a naturally occurring mineral in bone and teeth, HA is less likely to pose significant toxicological risks to flora and fauna. Nevertheless, comprehensive ecotoxicological studies are essential to confirm this assumption across various ecosystems and exposure scenarios.

The end-of-life management of HA-reinforced biodegradable polymers presents both challenges and opportunities. While the biodegradable nature of the polymer matrix facilitates its breakdown, the fate of the HA component requires consideration. Ideally, recycling or upcycling processes should be developed to recover and repurpose the HA, minimizing waste and promoting a circular economy approach.

In conclusion, the environmental impact of using HA to stabilize biodegradable polymers is multifaceted. While it offers potential benefits in terms of material efficiency and product longevity, careful consideration must be given to the entire lifecycle of these composites. Future research should focus on optimizing production processes, understanding degradation mechanisms in various environments, and developing effective end-of-life management strategies to ensure that the environmental benefits of these materials are fully realized.

One of the primary environmental benefits of using HA in biodegradable polymers is the potential reduction in overall material consumption. By enhancing the mechanical properties and stability of biodegradable polymers, HA allows for the creation of more durable and long-lasting products. This increased longevity can lead to a decrease in the frequency of product replacement, ultimately reducing waste generation and resource consumption.

However, the production of HA itself requires careful scrutiny from an environmental perspective. The synthesis of HA often involves energy-intensive processes and the use of chemical precursors. While natural sources of HA exist, such as those derived from fish bones or eggshells, the scalability and consistency of these sources may present challenges for large-scale industrial applications.

The biodegradation process of HA-reinforced polymers also merits attention. While biodegradable polymers are designed to break down in natural environments, the presence of HA may alter the degradation kinetics and pathways. This could potentially lead to the release of HA particles into ecosystems, necessitating studies on their potential impact on soil and aquatic environments.

On a positive note, the biocompatibility of HA suggests that its environmental impact may be less severe compared to other synthetic reinforcing materials. As a naturally occurring mineral in bone and teeth, HA is less likely to pose significant toxicological risks to flora and fauna. Nevertheless, comprehensive ecotoxicological studies are essential to confirm this assumption across various ecosystems and exposure scenarios.

The end-of-life management of HA-reinforced biodegradable polymers presents both challenges and opportunities. While the biodegradable nature of the polymer matrix facilitates its breakdown, the fate of the HA component requires consideration. Ideally, recycling or upcycling processes should be developed to recover and repurpose the HA, minimizing waste and promoting a circular economy approach.

In conclusion, the environmental impact of using HA to stabilize biodegradable polymers is multifaceted. While it offers potential benefits in terms of material efficiency and product longevity, careful consideration must be given to the entire lifecycle of these composites. Future research should focus on optimizing production processes, understanding degradation mechanisms in various environments, and developing effective end-of-life management strategies to ensure that the environmental benefits of these materials are fully realized.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!