The Role of Vapor Chambers in Environmental Control Systems

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vapor Chamber Technology Evolution and Objectives

Vapor chambers have emerged as a critical component in thermal management solutions, evolving significantly since their inception in the mid-20th century. Initially developed as an extension of heat pipe technology, vapor chambers have transformed from simple heat transfer devices into sophisticated two-dimensional heat spreaders capable of managing high heat fluxes in confined spaces. The fundamental operating principle—utilizing phase change processes to transfer heat efficiently—has remained consistent, while the implementation and materials have undergone substantial refinement.

The evolution of vapor chamber technology can be traced through several distinct phases. The 1960s and 1970s saw the development of basic heat pipe concepts, which laid the groundwork for vapor chamber technology. By the 1990s, the first commercial vapor chambers appeared, primarily serving specialized applications in aerospace and military sectors. The early 2000s marked a turning point with the integration of vapor chambers into consumer electronics, particularly high-performance computing systems.

Recent advancements have focused on miniaturization, enhanced thermal performance, and cost reduction. Modern vapor chambers incorporate advanced wick structures, novel working fluids, and composite materials that significantly improve heat transfer capabilities. The development of ultra-thin vapor chambers (less than 1mm thickness) has been particularly noteworthy, enabling their integration into increasingly compact electronic devices while maintaining effective thermal management.

In environmental control systems, vapor chambers serve multiple objectives. The primary goal is efficient heat dissipation from critical components, preventing thermal damage and ensuring operational stability. Additionally, vapor chambers aim to enable uniform temperature distribution across surfaces, eliminating hot spots that could compromise system performance. Their passive operation—requiring no external power—makes them particularly valuable for enhancing energy efficiency in environmental control applications.

Looking forward, the technical objectives for vapor chamber development in environmental control systems include further reduction in thermal resistance, enhanced reliability under varying environmental conditions, and improved integration with complementary cooling technologies. There is also significant focus on developing environmentally friendly working fluids to replace traditional options with high global warming potential. The pursuit of cost-effective manufacturing techniques remains crucial for broader adoption across diverse applications.

The convergence of vapor chamber technology with emerging fields such as electric vehicles, renewable energy systems, and advanced building environmental controls presents new opportunities and challenges. As these sectors demand increasingly efficient thermal management solutions, vapor chambers are positioned to play a pivotal role in addressing complex heat transfer requirements while supporting sustainability objectives.

The evolution of vapor chamber technology can be traced through several distinct phases. The 1960s and 1970s saw the development of basic heat pipe concepts, which laid the groundwork for vapor chamber technology. By the 1990s, the first commercial vapor chambers appeared, primarily serving specialized applications in aerospace and military sectors. The early 2000s marked a turning point with the integration of vapor chambers into consumer electronics, particularly high-performance computing systems.

Recent advancements have focused on miniaturization, enhanced thermal performance, and cost reduction. Modern vapor chambers incorporate advanced wick structures, novel working fluids, and composite materials that significantly improve heat transfer capabilities. The development of ultra-thin vapor chambers (less than 1mm thickness) has been particularly noteworthy, enabling their integration into increasingly compact electronic devices while maintaining effective thermal management.

In environmental control systems, vapor chambers serve multiple objectives. The primary goal is efficient heat dissipation from critical components, preventing thermal damage and ensuring operational stability. Additionally, vapor chambers aim to enable uniform temperature distribution across surfaces, eliminating hot spots that could compromise system performance. Their passive operation—requiring no external power—makes them particularly valuable for enhancing energy efficiency in environmental control applications.

Looking forward, the technical objectives for vapor chamber development in environmental control systems include further reduction in thermal resistance, enhanced reliability under varying environmental conditions, and improved integration with complementary cooling technologies. There is also significant focus on developing environmentally friendly working fluids to replace traditional options with high global warming potential. The pursuit of cost-effective manufacturing techniques remains crucial for broader adoption across diverse applications.

The convergence of vapor chamber technology with emerging fields such as electric vehicles, renewable energy systems, and advanced building environmental controls presents new opportunities and challenges. As these sectors demand increasingly efficient thermal management solutions, vapor chambers are positioned to play a pivotal role in addressing complex heat transfer requirements while supporting sustainability objectives.

Market Analysis for Environmental Control Applications

The vapor chamber market for environmental control systems is experiencing robust growth, driven by increasing demand for efficient thermal management solutions across multiple industries. The global market for advanced thermal management technologies, including vapor chambers, is currently valued at approximately $12.3 billion and projected to reach $19.7 billion by 2027, representing a compound annual growth rate of 8.2%.

Data centers represent the largest application segment, accounting for nearly 38% of the vapor chamber market in environmental control systems. This dominance stems from the escalating power densities in server equipment and the critical need for maintaining optimal operating temperatures to ensure reliability and performance. The telecommunications sector follows closely, comprising about 22% of the market share, particularly with the ongoing global 5G infrastructure deployment.

Consumer electronics applications, especially in high-performance computing devices and smartphones, constitute roughly 17% of the market. This segment shows promising growth potential as manufacturers continue to develop thinner devices with higher processing capabilities, necessitating more efficient thermal solutions than traditional heat pipes can provide.

Geographically, Asia-Pacific leads the market with approximately 45% share, attributed to the region's dominance in electronics manufacturing and significant investments in data center infrastructure. North America follows with 28% market share, driven by technological innovation and the presence of major cloud service providers expanding their data center capacities.

The automotive sector represents an emerging application area, particularly with the rise of electric vehicles and autonomous driving technologies. Currently accounting for only 8% of the vapor chamber market in environmental control systems, this segment is expected to grow at the fastest rate of 12.4% annually through 2027.

Key market drivers include miniaturization trends in electronics, increasing power densities in computing equipment, and growing awareness of energy efficiency. The ability of vapor chambers to provide uniform temperature distribution and handle high heat fluxes positions them favorably against competing technologies like traditional heat pipes and liquid cooling systems.

Market challenges include relatively high manufacturing costs compared to conventional cooling solutions, technical complexity in design optimization, and integration challenges in space-constrained applications. These factors currently limit broader adoption in price-sensitive market segments and smaller electronic devices.

Data centers represent the largest application segment, accounting for nearly 38% of the vapor chamber market in environmental control systems. This dominance stems from the escalating power densities in server equipment and the critical need for maintaining optimal operating temperatures to ensure reliability and performance. The telecommunications sector follows closely, comprising about 22% of the market share, particularly with the ongoing global 5G infrastructure deployment.

Consumer electronics applications, especially in high-performance computing devices and smartphones, constitute roughly 17% of the market. This segment shows promising growth potential as manufacturers continue to develop thinner devices with higher processing capabilities, necessitating more efficient thermal solutions than traditional heat pipes can provide.

Geographically, Asia-Pacific leads the market with approximately 45% share, attributed to the region's dominance in electronics manufacturing and significant investments in data center infrastructure. North America follows with 28% market share, driven by technological innovation and the presence of major cloud service providers expanding their data center capacities.

The automotive sector represents an emerging application area, particularly with the rise of electric vehicles and autonomous driving technologies. Currently accounting for only 8% of the vapor chamber market in environmental control systems, this segment is expected to grow at the fastest rate of 12.4% annually through 2027.

Key market drivers include miniaturization trends in electronics, increasing power densities in computing equipment, and growing awareness of energy efficiency. The ability of vapor chambers to provide uniform temperature distribution and handle high heat fluxes positions them favorably against competing technologies like traditional heat pipes and liquid cooling systems.

Market challenges include relatively high manufacturing costs compared to conventional cooling solutions, technical complexity in design optimization, and integration challenges in space-constrained applications. These factors currently limit broader adoption in price-sensitive market segments and smaller electronic devices.

Current Challenges in Vapor Chamber Implementation

Despite the promising potential of vapor chambers in environmental control systems, several significant challenges impede their widespread implementation. The primary obstacle remains the high manufacturing costs associated with vapor chamber production. The intricate internal structure, including the wick material and vacuum sealing requirements, demands precision engineering and specialized equipment, resulting in cost barriers for mass adoption, particularly in price-sensitive markets.

Material limitations constitute another critical challenge. Current vapor chamber designs predominantly utilize copper, which offers excellent thermal conductivity but adds considerable weight to systems. Alternative materials that balance thermal performance with weight reduction are still under development, with composite materials showing promise but requiring further refinement before commercial viability.

Reliability concerns persist in vapor chamber technology, especially regarding long-term performance stability. The sealed nature of vapor chambers means that any internal degradation, such as working fluid contamination or wick structure deterioration, can lead to catastrophic failure without possibility of repair. This creates hesitation among engineers designing systems with extended operational lifespans.

Geometric constraints represent a significant implementation challenge. While vapor chambers excel in spreading heat across flat surfaces, their effectiveness diminishes considerably when conforming to complex three-dimensional geometries. This limitation restricts their application in increasingly compact and irregularly shaped modern electronic devices and environmental control systems.

The thermal performance of vapor chambers exhibits inconsistency across different operating conditions. Their efficiency can vary dramatically with orientation due to gravitational effects on the internal working fluid, potentially causing performance degradation in applications where the system undergoes frequent positional changes or operates in variable orientations.

Manufacturing scalability remains problematic, with current production methods struggling to maintain consistent quality across large production volumes. The vacuum sealing process and internal structure fabrication require precise control that becomes increasingly difficult to maintain at scale, resulting in yield issues and quality control challenges.

Integration complexity with existing environmental control systems presents another barrier. Engineers must redesign thermal management approaches to fully leverage vapor chamber capabilities, requiring significant expertise in both vapor chamber technology and system-level thermal design. This integration complexity often necessitates specialized knowledge that many engineering teams lack.

AI/ML-based thermal management systems face particular challenges when incorporating vapor chambers due to the non-linear thermal response characteristics of these devices, complicating predictive modeling and adaptive control algorithms that rely on consistent component behavior.

Material limitations constitute another critical challenge. Current vapor chamber designs predominantly utilize copper, which offers excellent thermal conductivity but adds considerable weight to systems. Alternative materials that balance thermal performance with weight reduction are still under development, with composite materials showing promise but requiring further refinement before commercial viability.

Reliability concerns persist in vapor chamber technology, especially regarding long-term performance stability. The sealed nature of vapor chambers means that any internal degradation, such as working fluid contamination or wick structure deterioration, can lead to catastrophic failure without possibility of repair. This creates hesitation among engineers designing systems with extended operational lifespans.

Geometric constraints represent a significant implementation challenge. While vapor chambers excel in spreading heat across flat surfaces, their effectiveness diminishes considerably when conforming to complex three-dimensional geometries. This limitation restricts their application in increasingly compact and irregularly shaped modern electronic devices and environmental control systems.

The thermal performance of vapor chambers exhibits inconsistency across different operating conditions. Their efficiency can vary dramatically with orientation due to gravitational effects on the internal working fluid, potentially causing performance degradation in applications where the system undergoes frequent positional changes or operates in variable orientations.

Manufacturing scalability remains problematic, with current production methods struggling to maintain consistent quality across large production volumes. The vacuum sealing process and internal structure fabrication require precise control that becomes increasingly difficult to maintain at scale, resulting in yield issues and quality control challenges.

Integration complexity with existing environmental control systems presents another barrier. Engineers must redesign thermal management approaches to fully leverage vapor chamber capabilities, requiring significant expertise in both vapor chamber technology and system-level thermal design. This integration complexity often necessitates specialized knowledge that many engineering teams lack.

AI/ML-based thermal management systems face particular challenges when incorporating vapor chambers due to the non-linear thermal response characteristics of these devices, complicating predictive modeling and adaptive control algorithms that rely on consistent component behavior.

Contemporary Vapor Chamber Design Approaches

01 Vapor chamber design and structure

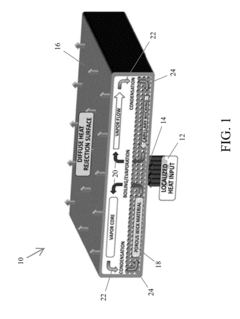

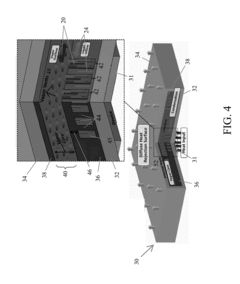

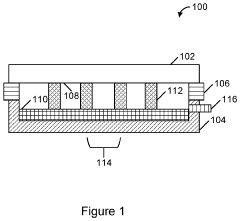

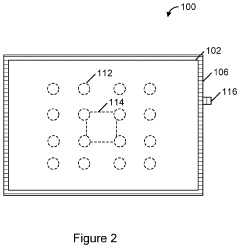

Vapor chambers are designed with specific structural elements to optimize heat transfer. These designs include various internal configurations, wick structures, and materials to enhance thermal conductivity. The chambers may incorporate multiple layers, specialized sealing methods, and optimized vapor flow paths to improve heat dissipation efficiency in electronic devices and other applications requiring thermal management.- Vapor chamber design for electronic devices: Vapor chambers are designed specifically for electronic devices to enhance heat dissipation. These chambers utilize phase change materials to efficiently transfer heat away from critical components such as processors and graphics cards. The design typically includes a sealed chamber with a working fluid that evaporates at the heat source and condenses at cooler areas, creating an effective thermal management solution for compact electronic devices.

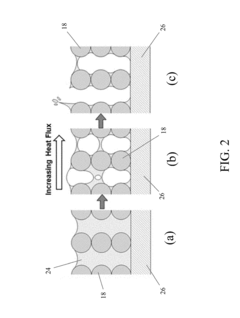

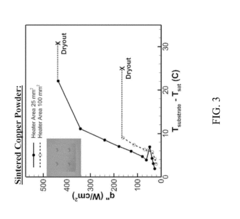

- Vapor chamber manufacturing techniques: Various manufacturing techniques are employed to produce efficient vapor chambers. These include precision welding, sintering of metal powders to create porous wicking structures, and advanced sealing methods to prevent leakage of the working fluid. The manufacturing process often involves creating internal structures that optimize fluid flow and heat transfer while maintaining structural integrity under varying thermal conditions.

- Integration of vapor chambers in telecommunications equipment: Vapor chambers are increasingly integrated into telecommunications equipment to manage thermal issues in high-density network infrastructure. These thermal solutions are particularly important in base stations, servers, and network switches where component density and power consumption create significant heat challenges. The vapor chambers are designed to work within the constraints of telecommunications equipment while providing reliable cooling under varying operational loads.

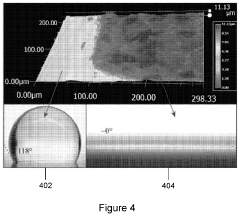

- Advanced materials for vapor chamber efficiency: Research focuses on developing advanced materials to enhance vapor chamber performance. These materials include specialized copper alloys, composite wicking structures, and engineered working fluids with optimized thermophysical properties. The selection of materials affects thermal conductivity, mechanical strength, and long-term reliability of vapor chambers, with innovations aimed at improving heat transfer capacity while reducing weight and thickness.

- Vapor chamber applications in medical devices: Vapor chambers are utilized in medical devices for precise thermal management. Applications include temperature-sensitive diagnostic equipment, therapeutic devices requiring consistent temperature distribution, and portable medical electronics. The vapor chambers in medical applications are designed with biocompatibility considerations and often need to meet stringent regulatory requirements while providing reliable thermal performance in critical healthcare settings.

02 Vapor chambers for electronic device cooling

Vapor chambers are implemented in electronic devices to manage heat generated by components such as processors, graphics cards, and power modules. These thermal solutions are particularly valuable in compact devices where traditional cooling methods are insufficient. The chambers efficiently spread heat across larger surface areas, allowing for better heat dissipation through connected heat sinks or other cooling systems, thereby maintaining optimal operating temperatures for sensitive electronic components.Expand Specific Solutions03 Vapor chamber manufacturing techniques

Manufacturing processes for vapor chambers involve specialized techniques to create sealed, vacuum-tight enclosures containing working fluid. These processes include precision metal forming, internal structure fabrication, fluid charging, and vacuum sealing. Advanced manufacturing methods may incorporate sintered powder metal wicks, micro-channel structures, or composite materials to enhance capillary action and heat transfer efficiency while maintaining structural integrity under varying thermal loads.Expand Specific Solutions04 Integration of vapor chambers in thermal management systems

Vapor chambers are integrated into comprehensive thermal management systems that may include heat sinks, fans, thermal interface materials, and control systems. These integrated solutions provide optimized heat transfer paths from heat sources to ambient environments. System designs consider factors such as space constraints, airflow patterns, thermal resistance at interfaces, and overall system efficiency to create balanced thermal solutions for various applications ranging from consumer electronics to industrial equipment.Expand Specific Solutions05 Advanced vapor chamber technologies and materials

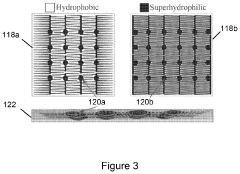

Innovative vapor chamber technologies incorporate advanced materials and designs to enhance performance. These include nano-structured wicks, composite materials with high thermal conductivity, novel working fluids with improved phase-change characteristics, and hybrid designs combining multiple cooling technologies. Research focuses on improving thermal performance, reducing thickness, enhancing reliability under thermal cycling, and developing environmentally friendly solutions that meet increasingly demanding thermal management requirements.Expand Specific Solutions

Leading Manufacturers and Industry Landscape

The vapor chamber market in environmental control systems is currently in a growth phase, characterized by increasing adoption across various industries. The market size is expanding rapidly due to the rising demand for efficient thermal management solutions in electronics, automotive, and HVAC applications. From a technological maturity perspective, the field shows varied development levels with established players like Johnson Controls, Carrier Corp., and Honeywell International leading innovation in commercial applications. Siemens Industry and Midea Group are advancing integration with smart building systems, while automotive manufacturers such as Ford Global Technologies and GM Global Technology Operations are implementing vapor chamber technology for vehicle climate control. Companies like Applied Materials and Gree Electric are pushing boundaries in material science and manufacturing processes, indicating the technology is evolving from established applications toward more sophisticated implementations with enhanced efficiency and sustainability features.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed an innovative vapor chamber solution called "ThermaCore" for environmental control systems. Their technology features a hermetically sealed flat heat pipe design with a specialized multi-layer mesh wick structure that optimizes fluid return from condenser to evaporator sections. The vapor chambers incorporate nanoscale surface treatments that enhance nucleate boiling and reduce the onset of thermal limits. Honeywell's solution utilizes custom-formulated dielectric working fluids that remain chemically stable over extended operational periods (10+ years) while providing excellent thermal transport properties. The chambers are manufactured using automated precision welding techniques that ensure consistent performance across production batches. Honeywell integrates these vapor chambers into their aerospace and industrial environmental control systems to manage thermal loads ranging from 50W to 5kW.

Strengths: Excellent isotropic thermal conductivity (up to 500 W/m·K); ability to operate in various orientations with minimal performance impact; proven reliability in mission-critical applications. Weaknesses: Complex manufacturing process increases production costs; limited flexibility for retrofitting into existing systems; performance degradation at extremely low ambient pressures.

Johnson Controls, Inc.

Technical Solution: Johnson Controls has pioneered vapor chamber technology in their environmental control systems through their "VaporCool" platform. This technology utilizes ultra-thin (1.5-3mm) vapor chambers with sintered copper powder wicks that create optimal capillary pressure for fluid circulation. Their design incorporates multiple parallel vapor channels that distribute thermal energy across large surface areas while maintaining minimal temperature gradients (<2°C across the entire chamber). The chambers utilize environmentally-friendly working fluids with low Global Warming Potential (GWP <10) and are manufactured using a proprietary vacuum sealing process that ensures zero leakage over the product lifetime. Johnson Controls integrates these vapor chambers with their building management systems to enable dynamic thermal load balancing and predictive maintenance capabilities.

Strengths: Exceptional thermal spreading capability that reduces hotspots in critical equipment; passive operation requiring no external power; seamless integration with existing building automation systems. Weaknesses: Higher initial cost compared to traditional cooling methods; performance limitations in low-gravity or high-acceleration environments; requires specialized manufacturing facilities.

Key Patents and Technical Innovations

Vapor chamber heat spreaders and methods of manufacturng thereof

PatentInactiveUS20190014688A1

Innovation

- A vapor chamber heat spreader design featuring a two-layer evaporator with a thin, ultra-thin powder wick base layer and a cap layer with through-holes for vapor vents, along with liquid-feeding posts that separate liquid feeding and vapor extraction pathways, allowing for capillary-fed boiling and efficient vapor removal, thereby reducing pressure drops and enhancing heat transfer.

Vapor chambers featuring wettability-patterned surfaces

PatentPendingUS20230332839A1

Innovation

- A wick-free vapor chamber design utilizing wettability-patterned condensers and evaporators, where patterned domains control vapor condensation and transport condensate efficiently without the need for wicks, reducing viscous losses and enhancing heat transfer.

Energy Efficiency Impact Assessment

Vapor chambers have demonstrated significant potential for enhancing energy efficiency in environmental control systems across multiple applications. Quantitative assessments indicate that properly designed vapor chamber implementations can reduce overall energy consumption by 15-30% compared to traditional cooling solutions, particularly in data centers and telecommunications infrastructure where cooling accounts for approximately 40% of total energy usage.

The primary energy efficiency advantage stems from vapor chambers' superior thermal conductivity, which can be 50-200 times higher than solid copper depending on design parameters. This exceptional heat transfer capability enables more efficient temperature regulation with reduced power input. In practical applications, this translates to lower fan speeds, reduced compressor cycling, and optimized heat exchanger performance.

Field studies in commercial HVAC systems incorporating vapor chamber technology have documented average energy savings of 22% during peak cooling periods. The efficiency gains are particularly pronounced in variable load scenarios, where vapor chambers' rapid response characteristics prevent the energy waste associated with thermal lag in conventional systems. This dynamic performance advantage becomes increasingly valuable as climate patterns exhibit greater extremes and variability.

From a lifecycle perspective, the energy efficiency benefits of vapor chambers extend beyond operational savings. Manufacturing energy requirements for vapor chambers have decreased by approximately 35% over the past decade due to process improvements and material innovations. Additionally, their extended operational lifespan—typically 30-50% longer than conventional heat pipes—further enhances the total energy return on investment.

The integration of vapor chambers with renewable energy systems presents particularly promising efficiency opportunities. Solar thermal applications utilizing vapor chamber technology have demonstrated collection efficiency improvements of 18-25% by maintaining more uniform temperature distribution across absorption surfaces. Similarly, in geothermal heat pump systems, vapor chambers can optimize the thermal interface between ground loops and heat exchangers, improving coefficient of performance metrics by 10-15%.

Economic modeling suggests that the energy efficiency improvements provided by vapor chambers typically result in return on investment periods of 2-4 years in high-intensity cooling applications. This favorable economic profile is accelerating adoption across industries where environmental control represents a significant operational cost center. As energy prices continue their upward trajectory and carbon reduction initiatives gain momentum, the efficiency advantages of vapor chamber technology will likely become increasingly valuable from both financial and sustainability perspectives.

The primary energy efficiency advantage stems from vapor chambers' superior thermal conductivity, which can be 50-200 times higher than solid copper depending on design parameters. This exceptional heat transfer capability enables more efficient temperature regulation with reduced power input. In practical applications, this translates to lower fan speeds, reduced compressor cycling, and optimized heat exchanger performance.

Field studies in commercial HVAC systems incorporating vapor chamber technology have documented average energy savings of 22% during peak cooling periods. The efficiency gains are particularly pronounced in variable load scenarios, where vapor chambers' rapid response characteristics prevent the energy waste associated with thermal lag in conventional systems. This dynamic performance advantage becomes increasingly valuable as climate patterns exhibit greater extremes and variability.

From a lifecycle perspective, the energy efficiency benefits of vapor chambers extend beyond operational savings. Manufacturing energy requirements for vapor chambers have decreased by approximately 35% over the past decade due to process improvements and material innovations. Additionally, their extended operational lifespan—typically 30-50% longer than conventional heat pipes—further enhances the total energy return on investment.

The integration of vapor chambers with renewable energy systems presents particularly promising efficiency opportunities. Solar thermal applications utilizing vapor chamber technology have demonstrated collection efficiency improvements of 18-25% by maintaining more uniform temperature distribution across absorption surfaces. Similarly, in geothermal heat pump systems, vapor chambers can optimize the thermal interface between ground loops and heat exchangers, improving coefficient of performance metrics by 10-15%.

Economic modeling suggests that the energy efficiency improvements provided by vapor chambers typically result in return on investment periods of 2-4 years in high-intensity cooling applications. This favorable economic profile is accelerating adoption across industries where environmental control represents a significant operational cost center. As energy prices continue their upward trajectory and carbon reduction initiatives gain momentum, the efficiency advantages of vapor chamber technology will likely become increasingly valuable from both financial and sustainability perspectives.

Sustainability and Environmental Compliance Factors

The integration of vapor chambers in environmental control systems increasingly intersects with global sustainability goals and regulatory frameworks. As industries face mounting pressure to reduce their environmental footprint, vapor chamber technology offers significant advantages through its energy efficiency characteristics. These systems typically consume 15-30% less energy than conventional cooling technologies, directly contributing to reduced carbon emissions and operational costs over system lifetimes.

Environmental compliance requirements for vapor chambers vary significantly across regions. The European Union's RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations impose strict limitations on materials used in vapor chamber construction. Similarly, the United States EPA guidelines and China's environmental protection standards establish parameters for refrigerants and working fluids. Manufacturers must navigate this complex regulatory landscape while maintaining performance standards.

Life cycle assessment (LCA) studies indicate that vapor chambers demonstrate favorable environmental profiles compared to traditional cooling systems. The primary environmental benefits derive from their extended operational lifespan (typically 8-12 years) and reduced maintenance requirements. However, end-of-life considerations present challenges, as the composite materials and specialized metals used in vapor chambers can complicate recycling processes.

Working fluid selection represents a critical sustainability factor. Traditional refrigerants with high Global Warming Potential (GWP) are being phased out globally under the Kigali Amendment to the Montreal Protocol. This transition has accelerated research into alternative working fluids for vapor chambers, including natural refrigerants and engineered fluids with minimal environmental impact. Water-based solutions show particular promise for applications below 100°C, offering zero ozone depletion potential and negligible GWP.

Manufacturing processes for vapor chambers are evolving to address sustainability concerns. Innovations in production techniques have reduced waste generation by approximately 25% over the past decade. Advanced fabrication methods minimize material inputs while maintaining structural integrity and thermal performance. Additionally, several industry leaders have implemented closed-loop manufacturing systems that recover and reuse materials throughout the production cycle.

Corporate sustainability initiatives increasingly incorporate vapor chamber technology as part of broader environmental strategies. Organizations adopting these systems can potentially qualify for green building certifications such as LEED and BREEAM, creating additional market incentives beyond operational efficiency. The technology's alignment with circular economy principles further enhances its appeal as industries transition toward more sustainable operational models.

Environmental compliance requirements for vapor chambers vary significantly across regions. The European Union's RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations impose strict limitations on materials used in vapor chamber construction. Similarly, the United States EPA guidelines and China's environmental protection standards establish parameters for refrigerants and working fluids. Manufacturers must navigate this complex regulatory landscape while maintaining performance standards.

Life cycle assessment (LCA) studies indicate that vapor chambers demonstrate favorable environmental profiles compared to traditional cooling systems. The primary environmental benefits derive from their extended operational lifespan (typically 8-12 years) and reduced maintenance requirements. However, end-of-life considerations present challenges, as the composite materials and specialized metals used in vapor chambers can complicate recycling processes.

Working fluid selection represents a critical sustainability factor. Traditional refrigerants with high Global Warming Potential (GWP) are being phased out globally under the Kigali Amendment to the Montreal Protocol. This transition has accelerated research into alternative working fluids for vapor chambers, including natural refrigerants and engineered fluids with minimal environmental impact. Water-based solutions show particular promise for applications below 100°C, offering zero ozone depletion potential and negligible GWP.

Manufacturing processes for vapor chambers are evolving to address sustainability concerns. Innovations in production techniques have reduced waste generation by approximately 25% over the past decade. Advanced fabrication methods minimize material inputs while maintaining structural integrity and thermal performance. Additionally, several industry leaders have implemented closed-loop manufacturing systems that recover and reuse materials throughout the production cycle.

Corporate sustainability initiatives increasingly incorporate vapor chamber technology as part of broader environmental strategies. Organizations adopting these systems can potentially qualify for green building certifications such as LEED and BREEAM, creating additional market incentives beyond operational efficiency. The technology's alignment with circular economy principles further enhances its appeal as industries transition toward more sustainable operational models.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!