The Transition of Cellophane from Basic to Advanced Material

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cellophane Evolution

Cellophane, a transparent film made from regenerated cellulose, has undergone a remarkable evolution since its accidental discovery in 1908 by Swiss chemist Jacques Brandenberger. Initially conceived as a protective coating for tablecloths, cellophane's journey from a basic material to an advanced one spans over a century of technological advancements and innovative applications.

In its early stages, cellophane was primarily used for packaging due to its transparency and moisture resistance. The 1920s and 1930s saw a surge in its popularity, particularly in the food industry, where it revolutionized product display and preservation. This period marked the beginning of cellophane's transition from a simple wrapping material to a more versatile product with expanding applications.

The mid-20th century brought significant improvements in cellophane production techniques. The introduction of plasticizers and coatings enhanced its properties, making it more flexible, heat-sealable, and resistant to moisture. These advancements broadened cellophane's utility across various industries, including textiles, pharmaceuticals, and electronics.

The late 20th century witnessed a shift in focus towards the environmental aspects of cellophane. As a biodegradable material derived from renewable resources, cellophane gained renewed interest in the context of sustainable packaging solutions. This period saw intensive research into improving its eco-friendly characteristics while maintaining its functional properties.

In recent decades, the evolution of cellophane has accelerated with the integration of nanotechnology and advanced material science. Researchers have explored ways to incorporate nanoparticles and novel coatings to enhance cellophane's barrier properties, mechanical strength, and functionality. These developments have positioned cellophane as a potential candidate for high-tech applications in fields such as flexible electronics and biomedical devices.

The 21st century has seen cellophane evolve into a smart material platform. Innovations include the development of cellophane-based sensors, actuators, and even energy storage devices. These advancements leverage cellophane's unique properties, such as its transparency and flexibility, combined with cutting-edge material modifications to create multifunctional films with capabilities far beyond simple packaging.

Today, cellophane stands at the intersection of traditional materials and advanced technologies. Its journey from a basic packaging material to a sophisticated, multifunctional film exemplifies the potential for reinventing conventional materials through continuous innovation and cross-disciplinary research. As we look to the future, cellophane's evolution continues, promising new applications in areas such as wearable technology, environmental monitoring, and advanced medical treatments.

In its early stages, cellophane was primarily used for packaging due to its transparency and moisture resistance. The 1920s and 1930s saw a surge in its popularity, particularly in the food industry, where it revolutionized product display and preservation. This period marked the beginning of cellophane's transition from a simple wrapping material to a more versatile product with expanding applications.

The mid-20th century brought significant improvements in cellophane production techniques. The introduction of plasticizers and coatings enhanced its properties, making it more flexible, heat-sealable, and resistant to moisture. These advancements broadened cellophane's utility across various industries, including textiles, pharmaceuticals, and electronics.

The late 20th century witnessed a shift in focus towards the environmental aspects of cellophane. As a biodegradable material derived from renewable resources, cellophane gained renewed interest in the context of sustainable packaging solutions. This period saw intensive research into improving its eco-friendly characteristics while maintaining its functional properties.

In recent decades, the evolution of cellophane has accelerated with the integration of nanotechnology and advanced material science. Researchers have explored ways to incorporate nanoparticles and novel coatings to enhance cellophane's barrier properties, mechanical strength, and functionality. These developments have positioned cellophane as a potential candidate for high-tech applications in fields such as flexible electronics and biomedical devices.

The 21st century has seen cellophane evolve into a smart material platform. Innovations include the development of cellophane-based sensors, actuators, and even energy storage devices. These advancements leverage cellophane's unique properties, such as its transparency and flexibility, combined with cutting-edge material modifications to create multifunctional films with capabilities far beyond simple packaging.

Today, cellophane stands at the intersection of traditional materials and advanced technologies. Its journey from a basic packaging material to a sophisticated, multifunctional film exemplifies the potential for reinventing conventional materials through continuous innovation and cross-disciplinary research. As we look to the future, cellophane's evolution continues, promising new applications in areas such as wearable technology, environmental monitoring, and advanced medical treatments.

Market Applications

Cellophane has undergone a remarkable transformation from a basic packaging material to an advanced material with diverse applications across multiple industries. The market for cellophane has expanded significantly, driven by its unique properties and adaptability to various technological advancements.

In the food packaging industry, cellophane continues to be a popular choice due to its excellent barrier properties against moisture, gases, and bacteria. The material's transparency allows for clear product visibility, enhancing consumer appeal. As consumers become more environmentally conscious, the biodegradable nature of cellophane has become a significant selling point, aligning with the growing demand for sustainable packaging solutions.

The pharmaceutical sector has also embraced cellophane for its sterility and protective qualities. It is widely used in blister packaging for tablets and capsules, ensuring product integrity and extending shelf life. The material's compatibility with various sterilization methods makes it ideal for medical device packaging as well.

In the electronics industry, cellophane has found applications in the production of flexible displays and touchscreens. Its high transparency and flexibility allow for the creation of bendable and foldable electronic devices, contributing to the development of next-generation smartphones and wearable technology.

The textile industry has incorporated cellophane into fabric production, creating innovative materials with unique properties. Cellophane fibers are used to produce moisture-wicking fabrics for sportswear and to enhance the durability and appearance of certain textiles. The material's ability to accept dyes easily has also made it popular in the fashion industry for creating shimmering, translucent fabrics.

Cellophane's application in the automotive sector has grown, particularly in the development of lightweight, eco-friendly components. It is used in the production of composite materials that offer strength and durability while reducing overall vehicle weight, contributing to improved fuel efficiency and reduced emissions.

In the construction industry, cellophane-based materials are being explored for their potential in creating energy-efficient building envelopes. The material's insulating properties and ability to be modified for specific light transmission characteristics make it an attractive option for advanced glazing systems and smart windows.

The cosmetics industry has also found innovative uses for cellophane, incorporating it into packaging designs that offer both functionality and visual appeal. Its use in creating biodegradable glitter and special effects makeup demonstrates the material's versatility in meeting consumer demands for both performance and sustainability.

As research continues, new applications for cellophane are emerging in fields such as biomedical engineering, where it is being explored for use in tissue engineering scaffolds and drug delivery systems. The material's biocompatibility and ability to be modified at the molecular level open up possibilities for advanced medical applications.

In the food packaging industry, cellophane continues to be a popular choice due to its excellent barrier properties against moisture, gases, and bacteria. The material's transparency allows for clear product visibility, enhancing consumer appeal. As consumers become more environmentally conscious, the biodegradable nature of cellophane has become a significant selling point, aligning with the growing demand for sustainable packaging solutions.

The pharmaceutical sector has also embraced cellophane for its sterility and protective qualities. It is widely used in blister packaging for tablets and capsules, ensuring product integrity and extending shelf life. The material's compatibility with various sterilization methods makes it ideal for medical device packaging as well.

In the electronics industry, cellophane has found applications in the production of flexible displays and touchscreens. Its high transparency and flexibility allow for the creation of bendable and foldable electronic devices, contributing to the development of next-generation smartphones and wearable technology.

The textile industry has incorporated cellophane into fabric production, creating innovative materials with unique properties. Cellophane fibers are used to produce moisture-wicking fabrics for sportswear and to enhance the durability and appearance of certain textiles. The material's ability to accept dyes easily has also made it popular in the fashion industry for creating shimmering, translucent fabrics.

Cellophane's application in the automotive sector has grown, particularly in the development of lightweight, eco-friendly components. It is used in the production of composite materials that offer strength and durability while reducing overall vehicle weight, contributing to improved fuel efficiency and reduced emissions.

In the construction industry, cellophane-based materials are being explored for their potential in creating energy-efficient building envelopes. The material's insulating properties and ability to be modified for specific light transmission characteristics make it an attractive option for advanced glazing systems and smart windows.

The cosmetics industry has also found innovative uses for cellophane, incorporating it into packaging designs that offer both functionality and visual appeal. Its use in creating biodegradable glitter and special effects makeup demonstrates the material's versatility in meeting consumer demands for both performance and sustainability.

As research continues, new applications for cellophane are emerging in fields such as biomedical engineering, where it is being explored for use in tissue engineering scaffolds and drug delivery systems. The material's biocompatibility and ability to be modified at the molecular level open up possibilities for advanced medical applications.

Technical Challenges

The transition of cellophane from a basic to an advanced material faces several significant technical challenges. One of the primary obstacles is improving the material's barrier properties while maintaining its biodegradability. Traditional cellophane, while biodegradable, lacks the high-performance barrier characteristics required for many modern applications, particularly in food packaging and electronics.

Enhancing the moisture barrier properties of cellophane without compromising its inherent biodegradability presents a complex challenge. Researchers are exploring various surface modification techniques and coating technologies to achieve this balance. However, finding eco-friendly additives that can effectively improve moisture resistance without altering the material's end-of-life decomposition remains a hurdle.

Another critical challenge lies in improving the mechanical properties of cellophane to expand its application range. While cellophane possesses good tensile strength, its relatively low tear resistance and impact strength limit its use in certain high-performance applications. Developing methods to enhance these properties without sacrificing transparency or increasing production costs is an ongoing area of research.

The production process of advanced cellophane also presents technical difficulties. Traditional cellophane manufacturing involves the use of carbon disulfide, a toxic and environmentally harmful chemical. Developing greener production methods that eliminate or significantly reduce the use of such chemicals, while maintaining product quality and cost-effectiveness, is a major focus for researchers and manufacturers alike.

Scalability and cost-effectiveness in producing advanced cellophane variants pose additional challenges. Many laboratory-scale improvements in cellophane properties have been achieved, but translating these advancements to industrial-scale production while keeping costs competitive with synthetic plastics remains a significant hurdle.

Furthermore, achieving consistent quality in advanced cellophane production across large batches is technically demanding. The natural variability in cellulose sources and the complexity of modification processes can lead to inconsistencies in the final product, which is unacceptable for many high-tech applications.

Lastly, the development of multi-functional cellophane that combines advanced properties such as antimicrobial activity, controlled permeability, and smart responsiveness to environmental stimuli represents a frontier in material science. Integrating these functionalities while preserving the material's core characteristics and eco-friendliness is a complex challenge that requires interdisciplinary research and innovation.

Enhancing the moisture barrier properties of cellophane without compromising its inherent biodegradability presents a complex challenge. Researchers are exploring various surface modification techniques and coating technologies to achieve this balance. However, finding eco-friendly additives that can effectively improve moisture resistance without altering the material's end-of-life decomposition remains a hurdle.

Another critical challenge lies in improving the mechanical properties of cellophane to expand its application range. While cellophane possesses good tensile strength, its relatively low tear resistance and impact strength limit its use in certain high-performance applications. Developing methods to enhance these properties without sacrificing transparency or increasing production costs is an ongoing area of research.

The production process of advanced cellophane also presents technical difficulties. Traditional cellophane manufacturing involves the use of carbon disulfide, a toxic and environmentally harmful chemical. Developing greener production methods that eliminate or significantly reduce the use of such chemicals, while maintaining product quality and cost-effectiveness, is a major focus for researchers and manufacturers alike.

Scalability and cost-effectiveness in producing advanced cellophane variants pose additional challenges. Many laboratory-scale improvements in cellophane properties have been achieved, but translating these advancements to industrial-scale production while keeping costs competitive with synthetic plastics remains a significant hurdle.

Furthermore, achieving consistent quality in advanced cellophane production across large batches is technically demanding. The natural variability in cellulose sources and the complexity of modification processes can lead to inconsistencies in the final product, which is unacceptable for many high-tech applications.

Lastly, the development of multi-functional cellophane that combines advanced properties such as antimicrobial activity, controlled permeability, and smart responsiveness to environmental stimuli represents a frontier in material science. Integrating these functionalities while preserving the material's core characteristics and eco-friendliness is a complex challenge that requires interdisciplinary research and innovation.

Current Solutions

01 Cellophane in packaging applications

Cellophane is widely used in packaging applications due to its transparency, flexibility, and barrier properties. It is particularly useful for food packaging, providing protection against moisture and gases while allowing visibility of the product. Cellophane can be combined with other materials to enhance its properties for specific packaging needs.- Cellophane in packaging applications: Cellophane is widely used in packaging applications due to its transparency, flexibility, and barrier properties. It is particularly useful for food packaging, providing protection against moisture and gases while allowing visibility of the product. Cellophane can be combined with other materials to enhance its properties for specific packaging needs.

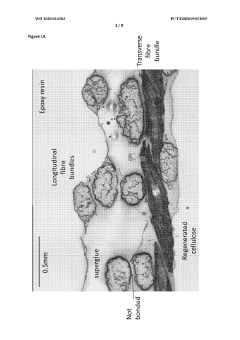

- Cellophane in biotechnology and medical applications: Cellophane membranes are utilized in various biotechnology and medical applications. They can be used for cell culture, dialysis, and as a support material for tissue engineering. The biocompatibility and semi-permeable nature of cellophane make it suitable for these applications.

- Cellophane in textile and fiber production: Cellophane is used in the production of certain textiles and fibers. It can be processed into thin filaments or incorporated into composite materials to create fabrics with unique properties. The material's ability to be dyed and its moisture-resistant characteristics make it valuable in this field.

- Cellophane in electronic and energy applications: Cellophane finds applications in electronic and energy-related fields. It can be used as a substrate or component in flexible electronics, capacitors, and certain types of batteries. The material's dielectric properties and ability to be modified make it suitable for these advanced applications.

- Cellophane processing and modification techniques: Various techniques are employed to process and modify cellophane for specific applications. These include chemical treatments to alter surface properties, lamination with other materials, and the incorporation of additives to enhance functionality. Such modifications can improve the material's strength, barrier properties, or introduce new features like antimicrobial activity.

02 Cellophane in biotechnology and medical applications

Cellophane membranes are utilized in various biotechnology and medical applications. They can be used for cell culture, dialysis, and as a support material for tissue engineering. The biocompatibility and semi-permeable nature of cellophane make it suitable for these applications.Expand Specific Solutions03 Cellophane in textile and fiber production

Cellophane is used in the production of certain textiles and fibers. It can be processed into thin filaments or incorporated into composite materials to create fabrics with unique properties. The material's ability to be dyed and its moisture-resistant characteristics make it valuable in this field.Expand Specific Solutions04 Cellophane in electronic and energy applications

Cellophane finds applications in electronic and energy-related fields. It can be used as a dielectric material in capacitors, as a separator in batteries, or as a substrate for flexible electronic devices. Its electrical insulation properties and thin film form make it suitable for these purposes.Expand Specific Solutions05 Cellophane production and modification techniques

Various techniques are employed to produce and modify cellophane to enhance its properties or create specialized forms. These may include chemical treatments, surface modifications, or the incorporation of additives. Such processes aim to improve the material's strength, barrier properties, or compatibility with other substances.Expand Specific Solutions

Industry Leaders

The transition of cellophane from a basic to an advanced material represents a dynamic shift in the packaging industry. This evolution is characterized by a mature market with established players like W. L. Gore & Associates and Bayer AG, alongside emerging innovators such as Resonac Corp. and Neste Oyj. The market is experiencing steady growth, driven by increasing demand for sustainable and high-performance packaging solutions. Technological advancements are focusing on enhancing cellophane's properties, including improved barrier functions, biodegradability, and compatibility with smart packaging technologies. Companies like FUJIFILM Corp. and Idemitsu Kosan Co., Ltd. are investing in research and development to create value-added cellophane products, indicating a trend towards more sophisticated applications in various industries.

W. L. Gore & Associates, Inc.

Technical Solution: W. L. Gore & Associates, Inc. has applied its materials science expertise to transform cellophane into advanced functional materials. Their approach focuses on creating microporous cellophane structures with unique properties. Gore has developed a proprietary stretching and thermal treatment process that introduces a controlled network of micropores into the cellophane structure, significantly enhancing its breathability while maintaining excellent barrier properties against liquids[11]. They have also developed techniques for selectively functionalizing these micropores, allowing for the creation of cellophane membranes with specific molecular filtration capabilities[13]. Additionally, Gore has explored the use of cellophane in composite materials, combining it with their ePTFE technology to create hybrid materials with exceptional durability and chemical resistance[15].

Strengths: Unique microporous structures, advanced filtration capabilities, and potential for high-performance composites. Weaknesses: Specialized manufacturing requirements and potentially limited applications outside of niche markets.

FUJIFILM Corp.

Technical Solution: FUJIFILM Corp. has leveraged its expertise in film technology to advance cellophane into high-performance materials. Their approach focuses on creating multi-layered cellophane structures with enhanced functionalities. FUJIFILM has developed a proprietary lamination process that allows for the precise layering of different cellophane variants, each optimized for specific properties such as gas barrier, moisture resistance, or mechanical strength[8]. They have also incorporated functional nanoparticles into the cellophane matrix, enabling properties such as UV protection, antimicrobial activity, and even photocatalytic self-cleaning capabilities[10]. Additionally, FUJIFILM has developed cellophane-based flexible electronics, using their expertise in thin-film coating to create transparent conductive layers on cellophane substrates[12].

Strengths: Versatile multi-functional materials, potential for high-tech applications. Weaknesses: Complex manufacturing process and potentially high production costs.

Key Innovations

Composite materials

PatentWO2020016583A1

Innovation

- A composite material is formed by alternately layering a cellulose-based textile with a cellulose-based sheet or film, eliminating the need for casting and reducing ionic liquid usage, and enhancing mechanical properties through a reinforcement network and improved peel strength by using a solvent and regeneration process.

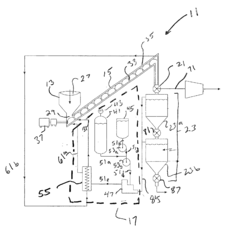

Methods and apparatus for processing cellulosic biomass

PatentActiveUS20110287502A1

Innovation

- An apparatus and method utilizing supercritical, critical, or near critical fluids, such as carbon dioxide with entrainers and modifiers, to process cellulosic biomass in a continuous or near continuous process, involving a first vessel for receiving biomass, conveying means for mixing with the fluid, and a second vessel for hydrolysis and fermentation to produce ethanol, bio-fuels, and higher value materials, with gas recycling and kinetic energy recovery.

Environmental Impact

The environmental impact of cellophane's transition from a basic to an advanced material is multifaceted and significant. Initially, traditional cellophane production relied heavily on wood pulp and chemical processes, contributing to deforestation and water pollution. However, as the material evolved, so did its environmental footprint.

Modern cellophane manufacturing has seen substantial improvements in resource efficiency and waste reduction. Advanced production techniques have reduced water consumption and implemented closed-loop systems, minimizing the release of harmful chemicals into the environment. Additionally, the shift towards using renewable resources, such as sustainably sourced wood or agricultural by-products, has helped mitigate the material's impact on forests.

The biodegradability of cellophane remains one of its key environmental advantages. Unlike many synthetic plastics, cellophane can decompose naturally, reducing long-term environmental accumulation. However, the addition of coatings and treatments to enhance cellophane's properties has introduced new environmental considerations. While these modifications improve functionality, they may also affect the material's biodegradability and recyclability.

Energy consumption in cellophane production has been a focus of environmental concern. The transition to advanced manufacturing processes has led to more energy-efficient operations, with some facilities adopting renewable energy sources. This shift has contributed to reducing the carbon footprint associated with cellophane production.

The end-of-life management of cellophane products has also evolved. Improved recycling technologies and increased consumer awareness have led to better collection and processing of cellophane waste. However, challenges remain in separating cellophane from other materials in mixed waste streams, highlighting the need for continued innovation in recycling infrastructure.

As cellophane transitions into more advanced applications, its environmental impact extends to new areas. For instance, its use in smart packaging and electronic components raises questions about electronic waste management and the potential for releasing nanomaterials into the environment. These emerging concerns underscore the importance of life cycle assessments and sustainable design principles in the ongoing development of cellophane-based products.

The shift towards bio-based and compostable cellophane variants represents a promising direction for further reducing environmental impact. These innovations aim to address concerns about fossil fuel dependency and plastic pollution while maintaining the material's desirable properties. However, the scalability and true environmental benefits of these alternatives are still subjects of ongoing research and debate.

Modern cellophane manufacturing has seen substantial improvements in resource efficiency and waste reduction. Advanced production techniques have reduced water consumption and implemented closed-loop systems, minimizing the release of harmful chemicals into the environment. Additionally, the shift towards using renewable resources, such as sustainably sourced wood or agricultural by-products, has helped mitigate the material's impact on forests.

The biodegradability of cellophane remains one of its key environmental advantages. Unlike many synthetic plastics, cellophane can decompose naturally, reducing long-term environmental accumulation. However, the addition of coatings and treatments to enhance cellophane's properties has introduced new environmental considerations. While these modifications improve functionality, they may also affect the material's biodegradability and recyclability.

Energy consumption in cellophane production has been a focus of environmental concern. The transition to advanced manufacturing processes has led to more energy-efficient operations, with some facilities adopting renewable energy sources. This shift has contributed to reducing the carbon footprint associated with cellophane production.

The end-of-life management of cellophane products has also evolved. Improved recycling technologies and increased consumer awareness have led to better collection and processing of cellophane waste. However, challenges remain in separating cellophane from other materials in mixed waste streams, highlighting the need for continued innovation in recycling infrastructure.

As cellophane transitions into more advanced applications, its environmental impact extends to new areas. For instance, its use in smart packaging and electronic components raises questions about electronic waste management and the potential for releasing nanomaterials into the environment. These emerging concerns underscore the importance of life cycle assessments and sustainable design principles in the ongoing development of cellophane-based products.

The shift towards bio-based and compostable cellophane variants represents a promising direction for further reducing environmental impact. These innovations aim to address concerns about fossil fuel dependency and plastic pollution while maintaining the material's desirable properties. However, the scalability and true environmental benefits of these alternatives are still subjects of ongoing research and debate.

Regulatory Framework

The regulatory framework surrounding cellophane has evolved significantly as the material transitioned from a basic packaging solution to an advanced material with diverse applications. Initially, regulations primarily focused on food safety and packaging standards. The U.S. Food and Drug Administration (FDA) played a crucial role in establishing guidelines for cellophane's use in food contact applications, ensuring its safety for consumers.

As cellophane's applications expanded, regulatory bodies worldwide began to address its environmental impact. The European Union, for instance, introduced directives on packaging and packaging waste, which influenced the production and disposal of cellophane products. These regulations aimed to reduce waste and promote recycling, pushing manufacturers to develop more sustainable cellophane formulations.

The transition of cellophane into advanced materials has necessitated new regulatory considerations. Agencies such as the Environmental Protection Agency (EPA) and the European Chemicals Agency (ECHA) have implemented stricter controls on the chemicals used in cellophane production, particularly focusing on potential health and environmental hazards. This has led to the development of safer, more environmentally friendly cellophane variants.

Intellectual property regulations have also played a significant role in cellophane's evolution. As companies invest in research and development to enhance cellophane's properties, patent laws have become increasingly important. These regulations protect innovations in cellophane technology, encouraging further advancements while ensuring fair competition in the market.

International trade regulations have further shaped the cellophane industry. Tariffs, import/export restrictions, and trade agreements have influenced the global distribution of cellophane products and raw materials. As cellophane becomes more specialized, these regulations have adapted to accommodate its changing status from a basic commodity to a high-value material.

The emergence of biodegradable and compostable cellophane variants has prompted the development of new certification standards. Organizations such as the Biodegradable Products Institute (BPI) and TÜV Austria have established criteria for certifying biodegradable and compostable materials, including cellophane. These standards ensure that advanced cellophane products meet specific environmental performance criteria.

As cellophane continues to evolve, regulatory frameworks are likely to adapt further. Future regulations may focus on lifecycle assessments, carbon footprint reduction, and the integration of cellophane into circular economy models. This ongoing regulatory evolution will continue to shape the development and application of cellophane as an advanced material.

As cellophane's applications expanded, regulatory bodies worldwide began to address its environmental impact. The European Union, for instance, introduced directives on packaging and packaging waste, which influenced the production and disposal of cellophane products. These regulations aimed to reduce waste and promote recycling, pushing manufacturers to develop more sustainable cellophane formulations.

The transition of cellophane into advanced materials has necessitated new regulatory considerations. Agencies such as the Environmental Protection Agency (EPA) and the European Chemicals Agency (ECHA) have implemented stricter controls on the chemicals used in cellophane production, particularly focusing on potential health and environmental hazards. This has led to the development of safer, more environmentally friendly cellophane variants.

Intellectual property regulations have also played a significant role in cellophane's evolution. As companies invest in research and development to enhance cellophane's properties, patent laws have become increasingly important. These regulations protect innovations in cellophane technology, encouraging further advancements while ensuring fair competition in the market.

International trade regulations have further shaped the cellophane industry. Tariffs, import/export restrictions, and trade agreements have influenced the global distribution of cellophane products and raw materials. As cellophane becomes more specialized, these regulations have adapted to accommodate its changing status from a basic commodity to a high-value material.

The emergence of biodegradable and compostable cellophane variants has prompted the development of new certification standards. Organizations such as the Biodegradable Products Institute (BPI) and TÜV Austria have established criteria for certifying biodegradable and compostable materials, including cellophane. These standards ensure that advanced cellophane products meet specific environmental performance criteria.

As cellophane continues to evolve, regulatory frameworks are likely to adapt further. Future regulations may focus on lifecycle assessments, carbon footprint reduction, and the integration of cellophane into circular economy models. This ongoing regulatory evolution will continue to shape the development and application of cellophane as an advanced material.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!