Thermal Properties of Materials in Microinjection Molding Processes

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microinjection Molding Thermal Properties Background

Microinjection molding (μIM) has emerged as a pivotal manufacturing technology for producing miniaturized plastic components with high precision and complex geometries. The evolution of this technology can be traced back to the late 1980s when conventional injection molding techniques were adapted to accommodate smaller part dimensions. The fundamental difference between conventional injection molding and μIM lies in the scale of operation, with μIM typically dealing with part weights below 1 gram and feature dimensions in the micrometer range.

The thermal properties of materials play a crucial role in the μIM process, significantly influencing the flow behavior, solidification patterns, and ultimate quality of the molded components. As the part dimensions decrease, the surface-to-volume ratio increases dramatically, leading to accelerated cooling rates that fundamentally alter the material behavior compared to conventional molding processes. This rapid thermal transition creates unique challenges in process control and material selection.

Historically, the development of μIM has been driven by increasing demands from industries such as medical devices, electronics, and microfluidics, where miniaturization continues to push the boundaries of manufacturing capabilities. The technology has evolved from simple adaptations of conventional equipment to specialized systems designed specifically for micro-scale processing, with significant advancements in heating systems, injection control, and mold design.

The thermal behavior of polymers in μIM exhibits distinct characteristics due to the high shear rates and temperature gradients involved. Polymers commonly used in μIM include engineering thermoplastics such as polyoxymethylene (POM), polyamide (PA), liquid crystal polymers (LCP), and high-performance materials like polyetheretherketone (PEEK). Each material presents unique thermal properties that must be carefully considered during process design.

Recent technological trends in μIM focus on enhancing thermal management through innovations in mold design, such as conformal cooling channels, variotherm processes, and advanced heating technologies. These developments aim to address the challenges of short filling times, premature solidification, and inconsistent part quality that often result from the complex thermal dynamics in micro-scale molding.

The scientific understanding of thermal phenomena in μIM continues to evolve, with research increasingly focused on the characterization of polymer behavior under extreme processing conditions. Advanced simulation tools now incorporate micro-scale effects such as wall slip, surface tension, and non-Newtonian flow behavior, enabling more accurate prediction of material flow and cooling patterns.

As the industry moves toward even smaller components and more complex geometries, the precise control of thermal properties becomes increasingly critical to achieving consistent quality and performance in micro-molded parts. This technological trajectory points toward a future where material science and process engineering must converge to overcome the inherent challenges of manufacturing at the micro scale.

The thermal properties of materials play a crucial role in the μIM process, significantly influencing the flow behavior, solidification patterns, and ultimate quality of the molded components. As the part dimensions decrease, the surface-to-volume ratio increases dramatically, leading to accelerated cooling rates that fundamentally alter the material behavior compared to conventional molding processes. This rapid thermal transition creates unique challenges in process control and material selection.

Historically, the development of μIM has been driven by increasing demands from industries such as medical devices, electronics, and microfluidics, where miniaturization continues to push the boundaries of manufacturing capabilities. The technology has evolved from simple adaptations of conventional equipment to specialized systems designed specifically for micro-scale processing, with significant advancements in heating systems, injection control, and mold design.

The thermal behavior of polymers in μIM exhibits distinct characteristics due to the high shear rates and temperature gradients involved. Polymers commonly used in μIM include engineering thermoplastics such as polyoxymethylene (POM), polyamide (PA), liquid crystal polymers (LCP), and high-performance materials like polyetheretherketone (PEEK). Each material presents unique thermal properties that must be carefully considered during process design.

Recent technological trends in μIM focus on enhancing thermal management through innovations in mold design, such as conformal cooling channels, variotherm processes, and advanced heating technologies. These developments aim to address the challenges of short filling times, premature solidification, and inconsistent part quality that often result from the complex thermal dynamics in micro-scale molding.

The scientific understanding of thermal phenomena in μIM continues to evolve, with research increasingly focused on the characterization of polymer behavior under extreme processing conditions. Advanced simulation tools now incorporate micro-scale effects such as wall slip, surface tension, and non-Newtonian flow behavior, enabling more accurate prediction of material flow and cooling patterns.

As the industry moves toward even smaller components and more complex geometries, the precise control of thermal properties becomes increasingly critical to achieving consistent quality and performance in micro-molded parts. This technological trajectory points toward a future where material science and process engineering must converge to overcome the inherent challenges of manufacturing at the micro scale.

Market Analysis for Microinjection Molded Components

The global market for microinjection molded components has experienced substantial growth in recent years, driven primarily by increasing demand in medical devices, electronics, automotive applications, and consumer products. The market size was valued at approximately $1.2 billion in 2022 and is projected to reach $1.8 billion by 2027, representing a compound annual growth rate (CAGR) of 8.5%.

Medical and healthcare sectors currently dominate the microinjection molding market, accounting for nearly 40% of the total market share. This dominance is attributed to the growing need for miniaturized medical devices, implants, drug delivery systems, and diagnostic equipment. The precision and material compatibility offered by microinjection molding processes make them ideal for these applications where dimensional accuracy and biocompatibility are critical.

The electronics industry represents the second-largest application segment, constituting about 30% of the market. With the continuous trend toward miniaturization in consumer electronics, demand for micro-components such as connectors, switches, and housings has surged. The automotive sector follows at approximately 15%, where microinjection molded parts are increasingly used in sensors, control systems, and interior components.

Regional analysis reveals that North America and Europe currently lead the market with combined shares of approximately 60%, primarily due to advanced healthcare infrastructure and strong presence of medical device manufacturers. However, the Asia-Pacific region is expected to witness the fastest growth rate of 10.2% during the forecast period, driven by expanding electronics manufacturing capabilities in China, Japan, South Korea, and emerging economies like India and Vietnam.

Material selection for microinjection molding is heavily influenced by thermal properties, with engineering thermoplastics dominating the material landscape. High-performance polymers like PEEK, LCP, and PPS are gaining traction due to their superior thermal stability and mechanical properties. The market for these specialty materials is growing at 12% annually, outpacing conventional thermoplastics.

Customer demands are increasingly focused on components that can withstand extreme thermal conditions while maintaining dimensional stability. This trend is particularly evident in automotive and aerospace applications where operating temperatures can fluctuate dramatically. Consequently, material suppliers are investing heavily in developing new polymer formulations with enhanced thermal conductivity and reduced thermal expansion coefficients.

Market challenges include high initial investment costs for precision equipment, complex process optimization requirements, and increasing competition from alternative manufacturing technologies such as micro-3D printing. However, the superior surface finish, material versatility, and production efficiency of microinjection molding continue to provide competitive advantages for high-volume applications.

Medical and healthcare sectors currently dominate the microinjection molding market, accounting for nearly 40% of the total market share. This dominance is attributed to the growing need for miniaturized medical devices, implants, drug delivery systems, and diagnostic equipment. The precision and material compatibility offered by microinjection molding processes make them ideal for these applications where dimensional accuracy and biocompatibility are critical.

The electronics industry represents the second-largest application segment, constituting about 30% of the market. With the continuous trend toward miniaturization in consumer electronics, demand for micro-components such as connectors, switches, and housings has surged. The automotive sector follows at approximately 15%, where microinjection molded parts are increasingly used in sensors, control systems, and interior components.

Regional analysis reveals that North America and Europe currently lead the market with combined shares of approximately 60%, primarily due to advanced healthcare infrastructure and strong presence of medical device manufacturers. However, the Asia-Pacific region is expected to witness the fastest growth rate of 10.2% during the forecast period, driven by expanding electronics manufacturing capabilities in China, Japan, South Korea, and emerging economies like India and Vietnam.

Material selection for microinjection molding is heavily influenced by thermal properties, with engineering thermoplastics dominating the material landscape. High-performance polymers like PEEK, LCP, and PPS are gaining traction due to their superior thermal stability and mechanical properties. The market for these specialty materials is growing at 12% annually, outpacing conventional thermoplastics.

Customer demands are increasingly focused on components that can withstand extreme thermal conditions while maintaining dimensional stability. This trend is particularly evident in automotive and aerospace applications where operating temperatures can fluctuate dramatically. Consequently, material suppliers are investing heavily in developing new polymer formulations with enhanced thermal conductivity and reduced thermal expansion coefficients.

Market challenges include high initial investment costs for precision equipment, complex process optimization requirements, and increasing competition from alternative manufacturing technologies such as micro-3D printing. However, the superior surface finish, material versatility, and production efficiency of microinjection molding continue to provide competitive advantages for high-volume applications.

Current Thermal Challenges in Microinjection Molding

Microinjection molding processes face significant thermal challenges that directly impact product quality, process efficiency, and material performance. The primary challenge stems from the rapid cooling rates inherent in the process, which can be up to 10,000°C/s compared to conventional injection molding's 100-1000°C/s. This extreme thermal gradient creates substantial difficulties in maintaining consistent material properties throughout the molded microparts.

Temperature control precision represents another critical challenge. In microinjection molding, even minor temperature fluctuations of 2-5°C can significantly affect material flow behavior and final part properties. The miniaturized mold cavities and thin wall sections (often below 100 μm) exacerbate this issue, as heat dissipation occurs extremely rapidly and unevenly across the part geometry.

Material-specific thermal behavior adds complexity to the process. Polymers commonly used in microinjection molding exhibit pronounced thermal sensitivity, with their viscosity changing exponentially with temperature variations. This sensitivity is particularly problematic for high-performance engineering polymers like PEEK, PEI, and LCP, which require precise processing windows to achieve optimal mechanical properties and dimensional stability.

The interface between polymer melts and mold surfaces presents additional thermal management challenges. Heat transfer coefficients at these interfaces can vary significantly based on surface roughness, coating materials, and processing conditions. Research indicates that these coefficients can differ by factors of 2-5× depending on specific material-mold combinations, creating unpredictable cooling patterns.

Thermal-induced residual stresses constitute another significant issue in microinjection molded parts. The extreme cooling rates create frozen-in molecular orientations and internal stresses that can lead to post-molding warpage, dimensional instability, and mechanical property anisotropy. These effects are particularly pronounced in microparts with high aspect ratios or complex geometries.

Energy efficiency concerns also emerge in current microinjection molding processes. The need for high mold temperatures (often 80-150°C) to facilitate proper filling of microscale features, followed by rapid cooling, creates substantial energy demands. Current systems typically operate at 15-30% thermal efficiency, significantly lower than conventional molding processes.

Advanced simulation capabilities for predicting thermal behavior at the microscale remain limited. Existing computational fluid dynamics and heat transfer models struggle to accurately capture the complex non-Newtonian flow behavior and heat transfer mechanisms at microscale dimensions, particularly when dealing with filled polymers or multi-material systems.

Temperature control precision represents another critical challenge. In microinjection molding, even minor temperature fluctuations of 2-5°C can significantly affect material flow behavior and final part properties. The miniaturized mold cavities and thin wall sections (often below 100 μm) exacerbate this issue, as heat dissipation occurs extremely rapidly and unevenly across the part geometry.

Material-specific thermal behavior adds complexity to the process. Polymers commonly used in microinjection molding exhibit pronounced thermal sensitivity, with their viscosity changing exponentially with temperature variations. This sensitivity is particularly problematic for high-performance engineering polymers like PEEK, PEI, and LCP, which require precise processing windows to achieve optimal mechanical properties and dimensional stability.

The interface between polymer melts and mold surfaces presents additional thermal management challenges. Heat transfer coefficients at these interfaces can vary significantly based on surface roughness, coating materials, and processing conditions. Research indicates that these coefficients can differ by factors of 2-5× depending on specific material-mold combinations, creating unpredictable cooling patterns.

Thermal-induced residual stresses constitute another significant issue in microinjection molded parts. The extreme cooling rates create frozen-in molecular orientations and internal stresses that can lead to post-molding warpage, dimensional instability, and mechanical property anisotropy. These effects are particularly pronounced in microparts with high aspect ratios or complex geometries.

Energy efficiency concerns also emerge in current microinjection molding processes. The need for high mold temperatures (often 80-150°C) to facilitate proper filling of microscale features, followed by rapid cooling, creates substantial energy demands. Current systems typically operate at 15-30% thermal efficiency, significantly lower than conventional molding processes.

Advanced simulation capabilities for predicting thermal behavior at the microscale remain limited. Existing computational fluid dynamics and heat transfer models struggle to accurately capture the complex non-Newtonian flow behavior and heat transfer mechanisms at microscale dimensions, particularly when dealing with filled polymers or multi-material systems.

Existing Thermal Control Solutions for Microinjection Molding

01 Polymer materials with optimized thermal properties

Various polymer materials are specifically formulated for microinjection molding with optimized thermal properties. These materials include thermoplastic polymers with enhanced heat resistance, thermal stability, and controlled crystallization behavior. The thermal conductivity and specific heat capacity of these polymers are carefully engineered to ensure proper flow during the molding process and dimensional stability of the final parts. These materials often incorporate additives that improve their thermal performance during the high-temperature processing conditions of microinjection molding.- Polymer materials with optimized thermal properties for microinjection molding: Various polymer materials have been developed specifically for microinjection molding applications with optimized thermal properties. These materials exhibit controlled thermal expansion, improved heat resistance, and enhanced flow characteristics at processing temperatures. The thermal conductivity and specific heat capacity of these polymers are carefully engineered to ensure rapid and uniform cooling during the molding process, which is critical for maintaining dimensional accuracy in micro-scale components.

- Ceramic and metal-based materials for high temperature microinjection applications: Ceramic and metal-based materials are increasingly used in microinjection molding for applications requiring high temperature resistance. These materials offer superior thermal stability, reduced thermal expansion, and excellent heat dissipation properties compared to conventional polymers. Metal-ceramic composites combine the processability of metals with the thermal resistance of ceramics, making them suitable for microcomponents that operate in extreme thermal environments. The thermal conductivity of these materials helps achieve faster cycle times and more uniform cooling.

- Thermal analysis techniques for microinjection molding materials: Advanced thermal analysis techniques are essential for characterizing materials used in microinjection molding. These include differential scanning calorimetry (DSC), thermogravimetric analysis (TGA), and dynamic mechanical analysis (DMA) to determine key thermal properties such as glass transition temperature, melting point, crystallization behavior, and thermal degradation. These analytical methods help optimize processing parameters and predict material behavior during the molding process, ensuring consistent quality of microinjected components.

- Thermally conductive additives and fillers for enhanced heat transfer: Incorporating thermally conductive additives and fillers into base polymers significantly improves the thermal properties of materials used in microinjection molding. Additives such as carbon nanotubes, graphene, metallic particles, and ceramic fillers enhance heat dissipation during processing and in the final product. These modified materials exhibit reduced cycle times due to faster cooling, improved dimensional stability, and better resistance to thermal degradation, making them ideal for precision microcomponents that require efficient heat management.

- Thermal simulation and modeling for microinjection molding process optimization: Thermal simulation and modeling tools are crucial for predicting material behavior during microinjection molding processes. These computational methods analyze heat transfer, thermal gradients, and cooling rates to optimize mold design and processing parameters. Accurate thermal modeling helps prevent defects such as warpage, sink marks, and residual stresses by simulating how different materials respond to thermal conditions during filling, packing, and cooling phases. This approach enables the selection of appropriate materials based on their thermal properties for specific microinjection applications.

02 Ceramic and metal-based materials for microinjection molding

Ceramic and metal-based materials are used in microinjection molding applications requiring high thermal stability and conductivity. These materials include ceramic powders, metal powders, and metal-ceramic composites that can be formulated into feedstocks suitable for microinjection molding. The thermal properties of these materials, such as high melting points, excellent thermal conductivity, and low thermal expansion coefficients, make them ideal for applications requiring thermal resistance and precise dimensional control. Special binder systems are developed to facilitate the molding process while maintaining the thermal characteristics of the base materials.Expand Specific Solutions03 Thermal analysis methods for microinjection molding materials

Various thermal analysis methods are employed to characterize materials used in microinjection molding. These techniques include differential scanning calorimetry (DSC), thermogravimetric analysis (TGA), dynamic mechanical analysis (DMA), and thermal conductivity measurements. These methods help determine critical thermal properties such as glass transition temperature, melting point, crystallization behavior, thermal degradation temperature, and heat capacity. The thermal analysis data is essential for optimizing processing parameters, predicting material behavior during molding, and ensuring the quality of the final microinjected components.Expand Specific Solutions04 Composite materials with enhanced thermal performance

Composite materials are developed for microinjection molding to achieve enhanced thermal performance. These composites typically consist of a polymer matrix reinforced with fillers such as carbon fibers, glass fibers, or nanoparticles. The incorporation of these fillers significantly improves thermal properties including thermal conductivity, heat deflection temperature, and dimensional stability under thermal stress. The composite materials are specially formulated to maintain good flow properties during the microinjection process while providing superior thermal performance in the final molded parts.Expand Specific Solutions05 Bio-based and biodegradable materials with controlled thermal properties

Bio-based and biodegradable materials are increasingly being developed for microinjection molding with carefully controlled thermal properties. These materials include modified polylactic acid (PLA), polyhydroxyalkanoates (PHA), thermoplastic starch, and cellulose derivatives. The thermal properties of these materials, such as crystallization behavior, melting temperature, and thermal degradation profile, are optimized through various formulation strategies to make them suitable for microinjection molding processes. These materials offer environmentally friendly alternatives while maintaining the thermal performance required for specific applications.Expand Specific Solutions

Key Industry Players in Microinjection Molding Technology

The microinjection molding thermal properties market is in a growth phase, with increasing demand driven by miniaturization trends across industries. The competitive landscape features established chemical giants like Mitsui Chemicals, Toray Industries, and Mitsubishi Engineering-Plastics dominating material development, while specialized players such as iMFLUX (P&G subsidiary) focus on process innovations. Academic institutions including Sichuan University and Dalian University of Technology contribute significant research advancements. The technology maturity varies across applications, with automotive and electronics sectors (supported by Bosch and Kingfa) showing higher maturity levels than emerging medical applications (where Celanese and Capsugel are active). Material thermal characterization capabilities and simulation accuracy remain key competitive differentiators as the industry advances toward more precise micro-scale applications.

Mitsui Chemicals, Inc.

Technical Solution: Mitsui Chemicals has developed advanced polymer formulations specifically engineered for microinjection molding processes with optimized thermal properties. Their technology focuses on high-performance engineering plastics with precisely controlled crystallization behavior and thermal conductivity. They've pioneered the development of specialized polypropylene and polyolefin compounds with modified thermal expansion coefficients that maintain dimensional stability during the rapid heating and cooling cycles characteristic of microinjection molding. Their materials incorporate proprietary additives that enhance heat transfer during processing while maintaining excellent flow properties at reduced wall thicknesses. Mitsui's thermal management approach includes the integration of nano-fillers that create pathways for efficient heat dissipation without compromising the mechanical properties of the final parts, enabling cycle time reductions of up to 25% compared to conventional materials.

Strengths: Superior thermal stability during high-shear processing conditions; excellent dimensional control in micro-features; reduced cycle times through optimized crystallization kinetics. Weaknesses: Higher material costs compared to standard resins; may require specialized processing equipment for optimal performance; limited compatibility with certain colorants and additives.

Toray Industries, Inc.

Technical Solution: Toray Industries has developed a comprehensive thermal management solution for microinjection molding through their advanced polymer science expertise. Their approach centers on engineered thermoplastics with precisely controlled melt flow characteristics and thermal conductivity profiles. Toray's proprietary technology incorporates specially formulated liquid crystal polymers (LCPs) and polyamide compounds that maintain exceptional dimensional stability under the extreme thermal gradients encountered in microinjection processes. Their materials feature modified crystallization kinetics that allow for rapid solidification without warpage, even in parts with wall thicknesses below 100 microns. Toray has also pioneered the integration of thermally conductive fillers at the nanoscale level, creating materials that facilitate faster heat transfer during both the filling and cooling phases of the molding cycle, resulting in reported cycle time reductions of up to 30% while maintaining tight tolerances in micro-features.

Strengths: Exceptional flow properties at low processing temperatures; superior dimensional stability in high-precision applications; excellent thermal conductivity allowing for faster cycle times. Weaknesses: Premium pricing compared to standard engineering plastics; requires specialized processing knowledge; limited color options due to the presence of thermal additives.

Critical Material Science Innovations for Thermal Optimization

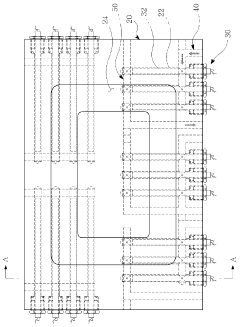

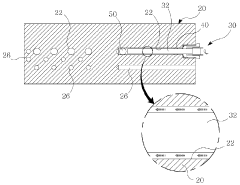

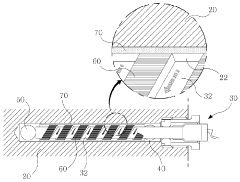

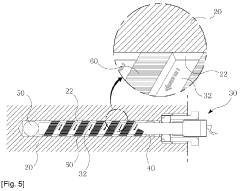

Apparatus for quick heating and cooling a injection mold and method of controlling temperature of the injection mold

PatentWO2009084762A1

Innovation

- An apparatus with electric heater cartridges, a fluid supply and passage system, and temperature sensors that allow for direct heating and cooling of the mold, along with heat-transfer plates and tubes to ensure uniform temperature distribution, and a temperature controller to manage power to the heaters based on detected temperatures.

Process for producing injection molded product

PatentInactiveTW200730329A

Innovation

- Incorporating polyolefin wax into the thermoplastic resin mixture, specifically using a metallocene-based catalyst to produce polyethylene wax, enhances flow length and mold release properties without compromising the characteristics of the molded product.

Sustainability Aspects of Thermal Materials in Microinjection

The sustainability aspects of thermal materials in microinjection molding processes have become increasingly critical as environmental concerns gain prominence across manufacturing industries. The thermal properties of materials directly impact energy consumption, material efficiency, and overall environmental footprint of microinjection molding operations.

Energy efficiency represents a primary sustainability concern, as the heating and cooling phases of microinjection molding account for approximately 30-40% of the total energy consumption. Materials with optimized thermal conductivity and specific heat capacity can significantly reduce cycle times and energy requirements. Recent advancements in bio-based polymer composites have demonstrated potential energy savings of up to 25% compared to conventional petroleum-based alternatives.

Material waste reduction constitutes another crucial sustainability dimension. The thermal degradation of polymers during processing leads to material wastage and quality issues. Thermally stable materials that maintain their properties across multiple processing cycles enable increased use of recycled content without compromising product integrity. Studies indicate that thermally enhanced recycled polymers can achieve up to 95% of virgin material performance when properly formulated.

Carbon footprint considerations extend beyond the processing phase to encompass the entire lifecycle of thermal materials. Bio-based alternatives to traditional fillers and additives have emerged as promising solutions. For instance, natural fiber reinforcements derived from agricultural waste streams offer comparable thermal performance while reducing embodied carbon by 40-60% compared to glass or carbon fiber reinforcements.

Water consumption in cooling systems presents additional sustainability challenges. Advanced thermal management materials that enable more efficient heat transfer can reduce cooling water requirements by up to 35%. Closed-loop cooling systems, when paired with thermally optimized materials, further minimize environmental impact through reduced water consumption and treatment needs.

Regulatory compliance and market demands increasingly drive sustainability innovations in thermal materials. The European Union's Circular Economy Action Plan and similar initiatives worldwide have accelerated research into recyclable and biodegradable materials with appropriate thermal characteristics for microinjection applications. Materials that maintain thermal stability while offering end-of-life biodegradability represent a growing market segment, projected to expand at 12% annually through 2030.

Economic sustainability must balance with environmental considerations. The development of cost-effective sustainable thermal materials remains challenging, with bio-based alternatives typically commanding a 15-30% price premium. However, lifecycle cost analyses increasingly demonstrate long-term economic benefits through energy savings, waste reduction, and regulatory compliance advantages.

Energy efficiency represents a primary sustainability concern, as the heating and cooling phases of microinjection molding account for approximately 30-40% of the total energy consumption. Materials with optimized thermal conductivity and specific heat capacity can significantly reduce cycle times and energy requirements. Recent advancements in bio-based polymer composites have demonstrated potential energy savings of up to 25% compared to conventional petroleum-based alternatives.

Material waste reduction constitutes another crucial sustainability dimension. The thermal degradation of polymers during processing leads to material wastage and quality issues. Thermally stable materials that maintain their properties across multiple processing cycles enable increased use of recycled content without compromising product integrity. Studies indicate that thermally enhanced recycled polymers can achieve up to 95% of virgin material performance when properly formulated.

Carbon footprint considerations extend beyond the processing phase to encompass the entire lifecycle of thermal materials. Bio-based alternatives to traditional fillers and additives have emerged as promising solutions. For instance, natural fiber reinforcements derived from agricultural waste streams offer comparable thermal performance while reducing embodied carbon by 40-60% compared to glass or carbon fiber reinforcements.

Water consumption in cooling systems presents additional sustainability challenges. Advanced thermal management materials that enable more efficient heat transfer can reduce cooling water requirements by up to 35%. Closed-loop cooling systems, when paired with thermally optimized materials, further minimize environmental impact through reduced water consumption and treatment needs.

Regulatory compliance and market demands increasingly drive sustainability innovations in thermal materials. The European Union's Circular Economy Action Plan and similar initiatives worldwide have accelerated research into recyclable and biodegradable materials with appropriate thermal characteristics for microinjection applications. Materials that maintain thermal stability while offering end-of-life biodegradability represent a growing market segment, projected to expand at 12% annually through 2030.

Economic sustainability must balance with environmental considerations. The development of cost-effective sustainable thermal materials remains challenging, with bio-based alternatives typically commanding a 15-30% price premium. However, lifecycle cost analyses increasingly demonstrate long-term economic benefits through energy savings, waste reduction, and regulatory compliance advantages.

Quality Assurance Standards for Thermal Performance

Quality assurance for thermal performance in microinjection molding processes requires rigorous standards to ensure consistent material behavior and final product quality. These standards must address the complex thermal interactions that occur during the molding cycle, where materials experience rapid temperature changes that significantly affect their properties.

International standards organizations, including ISO and ASTM, have developed specific protocols for evaluating thermal performance in polymer processing. ISO 17744 and ASTM D3418 provide guidelines for thermal analysis techniques such as Differential Scanning Calorimetry (DSC), which is essential for characterizing the thermal transitions of polymers used in microinjection molding. These standards ensure that measurements of glass transition temperature, crystallization behavior, and melting points are conducted with appropriate precision and reproducibility.

Temperature monitoring and control systems within microinjection molding equipment must meet standards such as ISO 13485 for medical applications or IATF 16949 for automotive components. These standards mandate calibration procedures, measurement accuracy requirements, and documentation protocols that ensure thermal parameters remain within specified tolerances throughout production runs.

Material-specific thermal performance standards have been established for commonly used polymers in microinjection molding. For example, standards for thermal stability testing (ISO 11357) help manufacturers predict how materials will behave under processing conditions and identify potential degradation issues before they affect production quality. These standards typically specify test conditions, sample preparation methods, and acceptance criteria for various thermal properties.

Quality assurance protocols must include validation of thermal simulation models against actual process measurements. Standards such as ASME V&V 10-2006 provide frameworks for verification and validation of computational simulations, ensuring that thermal predictions accurately reflect real-world behavior in microinjection molding processes.

Documentation requirements form another critical component of thermal performance standards. Manufacturers must maintain detailed records of thermal process parameters, material lot testing results, and equipment calibration data. These records must demonstrate traceability and compliance with relevant industry standards, particularly for applications in regulated industries such as medical devices or aerospace components.

Emerging standards are beginning to address advanced thermal management techniques in microinjection molding, including conformal cooling channel design, variotherm processing, and induction heating systems. These standards aim to establish best practices for implementing these technologies while ensuring consistent thermal performance across production batches.

International standards organizations, including ISO and ASTM, have developed specific protocols for evaluating thermal performance in polymer processing. ISO 17744 and ASTM D3418 provide guidelines for thermal analysis techniques such as Differential Scanning Calorimetry (DSC), which is essential for characterizing the thermal transitions of polymers used in microinjection molding. These standards ensure that measurements of glass transition temperature, crystallization behavior, and melting points are conducted with appropriate precision and reproducibility.

Temperature monitoring and control systems within microinjection molding equipment must meet standards such as ISO 13485 for medical applications or IATF 16949 for automotive components. These standards mandate calibration procedures, measurement accuracy requirements, and documentation protocols that ensure thermal parameters remain within specified tolerances throughout production runs.

Material-specific thermal performance standards have been established for commonly used polymers in microinjection molding. For example, standards for thermal stability testing (ISO 11357) help manufacturers predict how materials will behave under processing conditions and identify potential degradation issues before they affect production quality. These standards typically specify test conditions, sample preparation methods, and acceptance criteria for various thermal properties.

Quality assurance protocols must include validation of thermal simulation models against actual process measurements. Standards such as ASME V&V 10-2006 provide frameworks for verification and validation of computational simulations, ensuring that thermal predictions accurately reflect real-world behavior in microinjection molding processes.

Documentation requirements form another critical component of thermal performance standards. Manufacturers must maintain detailed records of thermal process parameters, material lot testing results, and equipment calibration data. These records must demonstrate traceability and compliance with relevant industry standards, particularly for applications in regulated industries such as medical devices or aerospace components.

Emerging standards are beginning to address advanced thermal management techniques in microinjection molding, including conformal cooling channel design, variotherm processing, and induction heating systems. These standards aim to establish best practices for implementing these technologies while ensuring consistent thermal performance across production batches.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!