Thermal Stability in Microinjection Molding: Techniques and Outcomes

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microinjection Molding Thermal Stability Background and Objectives

Microinjection molding emerged in the late 1980s as a specialized manufacturing process designed to produce miniature plastic components with high precision. This technology evolved from conventional injection molding but addresses the unique challenges presented by micro-scale production. The evolution of this field has been driven by increasing demands in industries such as medical devices, electronics, and microfluidics, where components with microscale features are essential.

The thermal stability aspect of microinjection molding represents one of the most critical parameters affecting product quality and process reliability. Historically, thermal management in microinjection molding has progressed from basic temperature control systems to sophisticated multi-zone heating arrangements with precise monitoring capabilities. This progression reflects the growing understanding that thermal gradients and fluctuations significantly impact the filling behavior, solidification patterns, and ultimately the dimensional accuracy of micro-molded parts.

Recent technological trends indicate a shift toward more integrated thermal management systems that combine real-time monitoring with adaptive control algorithms. The miniaturization trend continues to push the boundaries of what is achievable, with feature sizes now regularly reaching sub-micron levels, placing even greater demands on thermal stability control.

The primary objective of thermal stability research in microinjection molding is to establish robust processing windows that ensure consistent part quality despite the inherent challenges of working at the micro scale. This includes developing methodologies to maintain uniform temperature distributions throughout the mold cavity during the entire molding cycle, from injection through packing and cooling phases.

Secondary objectives include minimizing cycle times while maintaining thermal stability, reducing energy consumption through more efficient heating and cooling strategies, and developing predictive models that can anticipate thermal behavior under various processing conditions. These models aim to reduce the empirical nature of process optimization that currently dominates the industry.

Another crucial goal is to understand the relationship between thermal stability and material behavior at the micro scale, where conventional polymer flow models often fail to accurately predict actual outcomes. This includes investigating how thermal conditions affect phenomena such as wall slip, surface tension effects, and viscosity changes in confined spaces.

The technological trajectory suggests that future developments will likely focus on more precise localized heating techniques, advanced thermal isolation strategies, and the integration of smart materials that can actively respond to thermal fluctuations. These advancements will be essential to meet the increasingly stringent requirements for micro-components across various high-value applications.

The thermal stability aspect of microinjection molding represents one of the most critical parameters affecting product quality and process reliability. Historically, thermal management in microinjection molding has progressed from basic temperature control systems to sophisticated multi-zone heating arrangements with precise monitoring capabilities. This progression reflects the growing understanding that thermal gradients and fluctuations significantly impact the filling behavior, solidification patterns, and ultimately the dimensional accuracy of micro-molded parts.

Recent technological trends indicate a shift toward more integrated thermal management systems that combine real-time monitoring with adaptive control algorithms. The miniaturization trend continues to push the boundaries of what is achievable, with feature sizes now regularly reaching sub-micron levels, placing even greater demands on thermal stability control.

The primary objective of thermal stability research in microinjection molding is to establish robust processing windows that ensure consistent part quality despite the inherent challenges of working at the micro scale. This includes developing methodologies to maintain uniform temperature distributions throughout the mold cavity during the entire molding cycle, from injection through packing and cooling phases.

Secondary objectives include minimizing cycle times while maintaining thermal stability, reducing energy consumption through more efficient heating and cooling strategies, and developing predictive models that can anticipate thermal behavior under various processing conditions. These models aim to reduce the empirical nature of process optimization that currently dominates the industry.

Another crucial goal is to understand the relationship between thermal stability and material behavior at the micro scale, where conventional polymer flow models often fail to accurately predict actual outcomes. This includes investigating how thermal conditions affect phenomena such as wall slip, surface tension effects, and viscosity changes in confined spaces.

The technological trajectory suggests that future developments will likely focus on more precise localized heating techniques, advanced thermal isolation strategies, and the integration of smart materials that can actively respond to thermal fluctuations. These advancements will be essential to meet the increasingly stringent requirements for micro-components across various high-value applications.

Market Demand Analysis for Thermally Stable Microinjection Components

The microinjection molding market is experiencing significant growth driven by increasing demand for miniaturized components across multiple industries. The global market for microinjection molded parts was valued at approximately $1.2 billion in 2022 and is projected to reach $2.1 billion by 2028, representing a compound annual growth rate of 9.8%. This growth trajectory is primarily fueled by expanding applications in medical devices, electronics, automotive systems, and telecommunications.

In the medical sector, demand for thermally stable microinjection components has surged due to the proliferation of minimally invasive surgical procedures, point-of-care diagnostic devices, and implantable medical technologies. These applications require components that maintain dimensional stability and mechanical properties under sterilization processes that often involve high temperatures. The medical microinjection molding segment alone is expected to grow at 11.3% annually through 2028.

The electronics industry represents another significant market driver, with manufacturers seeking thermally resistant microcomponents for smartphones, wearable devices, and IoT applications. As electronic devices continue to shrink while operating at higher temperatures, the need for thermally stable polymer components has become critical. Industry analysts report that approximately 42% of microinjection molding applications now require thermal stability ratings above 150°C, compared to just 28% five years ago.

Automotive applications present a rapidly expanding market segment, particularly with the transition toward electric vehicles. These vehicles require numerous microcomponents that can withstand the higher operating temperatures associated with battery systems and power electronics. The automotive microinjection molding market segment is projected to grow at 10.5% annually, with thermal stability being cited as a primary requirement by 78% of tier-one suppliers.

Consumer preferences are increasingly favoring smaller, more portable devices across all product categories, further driving demand for miniaturized components. This trend is particularly evident in wearable technology, where the market for thermally stable microinjection components is growing at 13.7% annually.

Regional analysis indicates that Asia-Pacific dominates the market with 43% share, followed by North America (27%) and Europe (22%). However, the fastest growth is occurring in emerging markets where manufacturing capabilities are rapidly advancing. These regions are showing 14-16% annual growth rates in the adoption of thermally stable microinjection molding technologies.

Industry surveys reveal that manufacturers are willing to pay premium prices for microinjection components with enhanced thermal stability, with 67% of procurement specialists indicating they would accept a 15-20% price premium for components that demonstrate superior thermal performance and reliability.

In the medical sector, demand for thermally stable microinjection components has surged due to the proliferation of minimally invasive surgical procedures, point-of-care diagnostic devices, and implantable medical technologies. These applications require components that maintain dimensional stability and mechanical properties under sterilization processes that often involve high temperatures. The medical microinjection molding segment alone is expected to grow at 11.3% annually through 2028.

The electronics industry represents another significant market driver, with manufacturers seeking thermally resistant microcomponents for smartphones, wearable devices, and IoT applications. As electronic devices continue to shrink while operating at higher temperatures, the need for thermally stable polymer components has become critical. Industry analysts report that approximately 42% of microinjection molding applications now require thermal stability ratings above 150°C, compared to just 28% five years ago.

Automotive applications present a rapidly expanding market segment, particularly with the transition toward electric vehicles. These vehicles require numerous microcomponents that can withstand the higher operating temperatures associated with battery systems and power electronics. The automotive microinjection molding market segment is projected to grow at 10.5% annually, with thermal stability being cited as a primary requirement by 78% of tier-one suppliers.

Consumer preferences are increasingly favoring smaller, more portable devices across all product categories, further driving demand for miniaturized components. This trend is particularly evident in wearable technology, where the market for thermally stable microinjection components is growing at 13.7% annually.

Regional analysis indicates that Asia-Pacific dominates the market with 43% share, followed by North America (27%) and Europe (22%). However, the fastest growth is occurring in emerging markets where manufacturing capabilities are rapidly advancing. These regions are showing 14-16% annual growth rates in the adoption of thermally stable microinjection molding technologies.

Industry surveys reveal that manufacturers are willing to pay premium prices for microinjection components with enhanced thermal stability, with 67% of procurement specialists indicating they would accept a 15-20% price premium for components that demonstrate superior thermal performance and reliability.

Current Thermal Control Challenges in Microinjection Molding

Microinjection molding processes face significant thermal control challenges that directly impact product quality, production efficiency, and material performance. The primary challenge lies in maintaining precise temperature distribution throughout the entire molding cycle. Temperature variations as small as 5-10°C can lead to defects such as short shots, sink marks, warpage, and internal stresses in micro-components, where dimensional tolerances are often in the micrometer range.

The miniaturized nature of microinjection molding equipment creates inherent thermal management difficulties. Heat transfer dynamics in micro-scale cavities differ substantially from conventional molding, with higher cooling rates and more pronounced thermal gradients. These conditions make it exceptionally difficult to achieve uniform temperature profiles across micro-features with varying geometries and wall thicknesses.

Material-specific thermal challenges further complicate the process. High-performance polymers commonly used in microinjection molding, such as PEEK, LCP, and PEI, require processing temperatures exceeding 300°C, pushing heating systems to their limits. The narrow processing windows of these materials leave minimal margin for temperature fluctuations, creating a delicate balance between achieving proper flow and preventing material degradation.

Cycle time optimization presents another significant thermal control challenge. The industry demands increasingly shorter cycle times, yet rapid cooling can induce excessive internal stresses and compromise part quality. Conversely, insufficient cooling time leads to ejection issues and dimensional instability. Finding the optimal thermal cycle that balances productivity with quality remains elusive for many manufacturers.

Energy efficiency concerns have also emerged as critical challenges. Traditional thermal management systems in microinjection molding are often energy-intensive, with significant heat losses occurring throughout the process. The industry faces mounting pressure to develop more sustainable thermal control solutions that reduce energy consumption while maintaining precise temperature control.

Sensor integration and real-time thermal monitoring present technical hurdles due to space constraints in micro-molds. Conventional temperature sensors are often too large for micro-cavities, limiting the ability to gather accurate thermal data during the molding process. This information gap hampers the development of advanced control algorithms that could potentially address many thermal stability issues.

The increasing complexity of micro-components, particularly those with multi-material compositions or embedded electronics, introduces additional thermal management complications. Different materials exhibit varying thermal expansion coefficients and cooling behaviors, creating internal stresses at material interfaces. Controlling these thermal interactions remains one of the most challenging aspects of advanced microinjection molding applications.

The miniaturized nature of microinjection molding equipment creates inherent thermal management difficulties. Heat transfer dynamics in micro-scale cavities differ substantially from conventional molding, with higher cooling rates and more pronounced thermal gradients. These conditions make it exceptionally difficult to achieve uniform temperature profiles across micro-features with varying geometries and wall thicknesses.

Material-specific thermal challenges further complicate the process. High-performance polymers commonly used in microinjection molding, such as PEEK, LCP, and PEI, require processing temperatures exceeding 300°C, pushing heating systems to their limits. The narrow processing windows of these materials leave minimal margin for temperature fluctuations, creating a delicate balance between achieving proper flow and preventing material degradation.

Cycle time optimization presents another significant thermal control challenge. The industry demands increasingly shorter cycle times, yet rapid cooling can induce excessive internal stresses and compromise part quality. Conversely, insufficient cooling time leads to ejection issues and dimensional instability. Finding the optimal thermal cycle that balances productivity with quality remains elusive for many manufacturers.

Energy efficiency concerns have also emerged as critical challenges. Traditional thermal management systems in microinjection molding are often energy-intensive, with significant heat losses occurring throughout the process. The industry faces mounting pressure to develop more sustainable thermal control solutions that reduce energy consumption while maintaining precise temperature control.

Sensor integration and real-time thermal monitoring present technical hurdles due to space constraints in micro-molds. Conventional temperature sensors are often too large for micro-cavities, limiting the ability to gather accurate thermal data during the molding process. This information gap hampers the development of advanced control algorithms that could potentially address many thermal stability issues.

The increasing complexity of micro-components, particularly those with multi-material compositions or embedded electronics, introduces additional thermal management complications. Different materials exhibit varying thermal expansion coefficients and cooling behaviors, creating internal stresses at material interfaces. Controlling these thermal interactions remains one of the most challenging aspects of advanced microinjection molding applications.

Current Thermal Stability Solutions and Implementation Methods

01 Material selection for thermal stability in microinjection molding

Selecting thermally stable materials is crucial for microinjection molding processes. Materials with high thermal resistance can withstand the temperature fluctuations during the molding process without degradation. Polymers with high glass transition temperatures and thermal stability modifiers can be incorporated to enhance the thermal performance of the final molded components. These materials maintain their structural integrity and mechanical properties even under elevated processing temperatures.- Material selection for thermal stability in microinjection molding: Selecting thermally stable materials is crucial for microinjection molding processes. Polymers with high thermal resistance and stability can withstand the processing temperatures without degradation. Materials such as high-performance thermoplastics, specialty blends, and composites with thermal stabilizers help maintain dimensional accuracy and prevent warping during the molding cycle. These materials ensure consistent part quality and extended mold life in high-temperature applications.

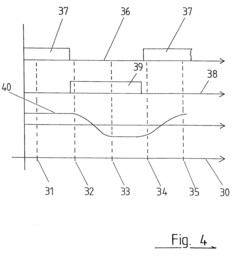

- Process parameter optimization for thermal stability: Optimizing process parameters is essential for maintaining thermal stability during microinjection molding. Parameters such as melt temperature, injection speed, holding pressure, and cooling time significantly impact the thermal behavior of the molded parts. Precise control of these parameters helps prevent thermal degradation, ensures uniform material flow, and minimizes residual stresses. Advanced process monitoring and adaptive control systems can be implemented to maintain consistent thermal conditions throughout the molding cycle.

- Mold design considerations for thermal management: Effective mold design is critical for thermal management in microinjection molding. Features such as conformal cooling channels, optimized gate locations, and balanced runner systems help maintain uniform temperature distribution. Thermal sensors integrated into the mold cavity provide real-time temperature monitoring. Materials with high thermal conductivity for mold construction facilitate rapid and uniform heat transfer, reducing cycle times while maintaining thermal stability throughout the molding process.

- Additives and modifiers for enhanced thermal stability: Various additives and modifiers can be incorporated into polymer formulations to enhance thermal stability during microinjection molding. Heat stabilizers, antioxidants, and nucleating agents help prevent polymer degradation at high processing temperatures. Nanofillers and reinforcing agents can improve the thermal resistance of the base polymer. These additives not only protect the material during processing but also enhance the thermal performance of the final molded components in high-temperature applications.

- Simulation and modeling techniques for thermal analysis: Advanced simulation and modeling techniques are employed to predict and analyze thermal behavior during microinjection molding. Computational fluid dynamics (CFD) and finite element analysis (FEA) help visualize melt flow, temperature distribution, and cooling patterns. These simulations enable optimization of process parameters and mold design before physical implementation. Predictive modeling of thermal stresses and warpage allows for proactive design modifications, reducing development time and ensuring thermal stability in the final molded parts.

02 Process parameter optimization for thermal stability

Optimizing process parameters such as injection speed, pressure, temperature, and cooling time significantly impacts the thermal stability of microinjection molded parts. Controlled heating and cooling rates prevent thermal degradation and ensure dimensional stability. Advanced process monitoring systems can be implemented to maintain consistent thermal conditions throughout the molding cycle, resulting in higher quality microparts with improved thermal resistance and reduced internal stresses.Expand Specific Solutions03 Mold design considerations for thermal management

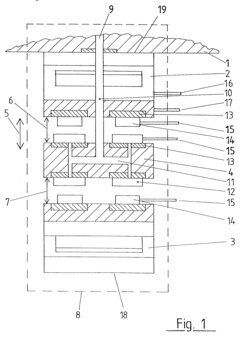

Specialized mold designs incorporating efficient cooling channels and thermal management systems are essential for maintaining thermal stability during microinjection molding. Conformal cooling designs, thermally conductive mold materials, and precise temperature control zones help achieve uniform heat distribution and rapid cooling. These design elements minimize thermal gradients within the mold cavity, reducing warpage and enhancing the dimensional accuracy of microinjected components.Expand Specific Solutions04 Thermal stability additives and reinforcements

Incorporating thermal stability additives and reinforcements into polymer formulations enhances the heat resistance of microinjection molded parts. Additives such as antioxidants, heat stabilizers, and nucleating agents prevent thermal degradation during processing. Reinforcing materials like glass fibers, carbon nanotubes, and mineral fillers improve the thermal performance of the base polymer. These additives and reinforcements extend the service temperature range of the final components and maintain mechanical properties under thermal stress.Expand Specific Solutions05 Simulation and modeling for thermal stability prediction

Advanced simulation and modeling techniques help predict thermal behavior during microinjection molding processes. Computational fluid dynamics and finite element analysis enable visualization of temperature distributions, cooling patterns, and potential thermal issues before actual production. These predictive tools allow for optimization of process parameters and mold designs to achieve optimal thermal stability. Simulation-based approaches reduce development time and costs while improving the thermal performance of microinjected components.Expand Specific Solutions

Leading Manufacturers and Technology Providers in Microinjection Molding

The thermal stability in microinjection molding market is currently in a growth phase, with increasing demand driven by miniaturization trends in electronics, medical devices, and automotive components. The global market size is estimated to exceed $1.5 billion, expanding at approximately 8-10% CAGR. Technologically, the field shows moderate maturity with ongoing innovations in process control and material science. Leading players include Nissei Plastic Industrial and The Japan Steel Works, who have developed advanced thermal management systems, while TOYO INNOVEX and Niigata Machine Techno focus on precision control technologies. Companies like Mitsubishi Engineering-Plastics and Toray Industries are advancing high-performance polymers specifically designed for thermal stability challenges in microinjection applications, creating a competitive landscape balanced between equipment manufacturers and material suppliers.

Nissei Plastic Industrial Co., Ltd.

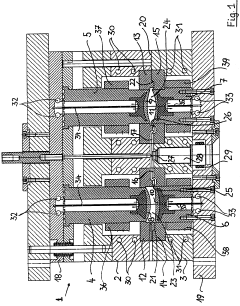

Technical Solution: Nissei Plastic Industrial has developed advanced thermal management systems for microinjection molding that incorporate precise temperature control algorithms and specialized heating elements. Their X-Mold technology utilizes a multi-zone heating approach with independent temperature controllers that can maintain thermal stability within ±0.1°C during the entire molding cycle. The system employs integrated thermal sensors strategically positioned throughout the mold cavity to provide real-time feedback for dynamic temperature adjustments. Nissei's proprietary heat distribution technology ensures uniform temperature profiles across complex micro-features, significantly reducing internal stresses and warpage in final parts. Their system also incorporates rapid heating and cooling transitions (RHCT) that can achieve heating rates of 15°C/second and cooling rates of 40°C/second, enabling precise control of crystallization processes in semi-crystalline polymers during microinjection molding.

Strengths: Superior temperature uniformity across complex micro-geometries, exceptional cycle-to-cycle repeatability, and integrated quality monitoring systems that detect thermal anomalies. Weaknesses: Higher initial equipment investment compared to conventional systems, requires specialized operator training, and the sophisticated control systems may introduce additional maintenance requirements.

Dalian University of Technology

Technical Solution: Dalian University of Technology has developed an innovative thermal stability solution for microinjection molding that combines ultrasonic-assisted heating with precision thermal monitoring. Their system utilizes focused ultrasonic energy to generate localized heating precisely where needed in the mold cavity, achieving temperature increases of up to 40°C within milliseconds. This approach enables highly controlled melting behavior without overheating the bulk material. The university's research team has implemented a multi-physics simulation model that predicts thermal gradients during the filling phase with accuracy within 2.5% of experimental measurements. Their technology incorporates nano-composite mold coatings with tailored thermal conductivity properties that can be adjusted based on specific polymer requirements. The system also features a novel thermal imaging array that provides real-time temperature mapping across the entire mold surface with resolution down to 50μm. This comprehensive thermal monitoring enables closed-loop control that automatically adjusts process parameters to maintain optimal thermal conditions throughout the molding cycle, even when processing heat-sensitive biopolymers and pharmaceutical compounds.

Strengths: Exceptional control over localized heating, minimal thermal degradation of sensitive materials, and comprehensive real-time monitoring capabilities. Weaknesses: Currently limited to laboratory and small-scale production environments, requires specialized equipment integration, and higher implementation complexity compared to conventional systems.

Key Thermal Control Patents and Technical Innovations

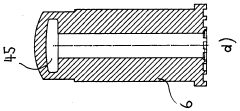

Method and apparatus for injection moulding

PatentInactiveEP0748679A1

Innovation

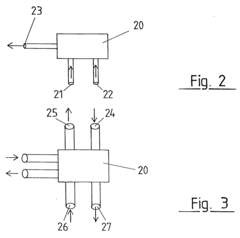

- Thermal insulation of mold inserts relative to the tool block, with a switchover element for controlled supply of temperature media, allowing for rapid temperature changes and reduced energy use by using a solenoid valve to alternate between heating and cooling media.

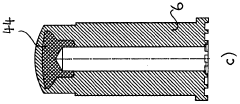

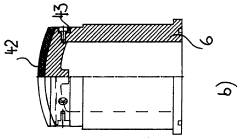

Injection moulding device and method for preparing precision-optical and precision-mechanical parts from a thermoplastic

PatentWO2000051805A1

Innovation

- The solution involves an injection molding device and method that maintains thermal equilibrium between the injection molding compound and the mold cavity, minimizes flow orientation and shear, and optimizes cooling and heating processes to prevent the formation of injection skin, using interchangeable mold parts, thermally conductive materials, and anti-stick coatings to ensure precise temperature control and reduced adhesion.

Material Science Advancements for Thermal-Resistant Microcomponents

Recent advancements in material science have significantly contributed to overcoming thermal stability challenges in microinjection molding processes. High-performance polymers such as polyetheretherketone (PEEK), polyetherimide (PEI), and liquid crystal polymers (LCPs) have emerged as frontrunners for thermal-resistant microcomponents. These materials demonstrate exceptional thermal stability with glass transition temperatures exceeding 140°C and continuous service temperatures above 200°C, making them suitable for demanding applications in medical devices, automotive sensors, and aerospace components.

Nanocomposite materials represent another breakthrough, incorporating nanoscale fillers like carbon nanotubes, graphene, and ceramic nanoparticles into polymer matrices. These additives enhance thermal conductivity by 40-200% while simultaneously improving dimensional stability during thermal cycling. Research indicates that even at low loading levels (0.5-5 wt%), these nanofillers can significantly alter the crystallization behavior and thermal degradation pathways of the base polymers.

Surface modification techniques have evolved to address the interface challenges between polymer matrices and reinforcement materials. Chemical functionalization methods, including silane coupling agents and plasma treatments, have demonstrated up to 30% improvement in interfacial adhesion, resulting in microcomponents with enhanced thermal resistance and mechanical integrity. These treatments modify the surface energy characteristics, promoting better wetting and chemical bonding between dissimilar materials.

Bioinspired materials design approaches have introduced novel hierarchical structures mimicking natural thermal-resistant systems. Biomimetic composites with layered architectures similar to nacre or wood have shown remarkable thermal stability improvements of 25-45% compared to conventional composites. These structures effectively dissipate thermal energy through their complex interfaces while maintaining structural integrity under thermal stress.

Smart responsive materials incorporating shape memory polymers and thermochromic additives represent the cutting edge of thermal-resistant microcomponents. These materials can actively respond to temperature changes, providing adaptive thermal management capabilities. For instance, phase-change materials embedded within polymer matrices can absorb excess heat during temperature spikes, releasing it gradually during cooling cycles, effectively dampening thermal fluctuations by up to 60%.

Computational materials science has accelerated development through molecular dynamics simulations and machine learning algorithms that predict thermal behavior of novel material combinations. These digital tools have reduced experimental iterations by approximately 40%, enabling faster identification of promising material formulations with optimal thermal resistance properties for specific microinjection molding applications.

Nanocomposite materials represent another breakthrough, incorporating nanoscale fillers like carbon nanotubes, graphene, and ceramic nanoparticles into polymer matrices. These additives enhance thermal conductivity by 40-200% while simultaneously improving dimensional stability during thermal cycling. Research indicates that even at low loading levels (0.5-5 wt%), these nanofillers can significantly alter the crystallization behavior and thermal degradation pathways of the base polymers.

Surface modification techniques have evolved to address the interface challenges between polymer matrices and reinforcement materials. Chemical functionalization methods, including silane coupling agents and plasma treatments, have demonstrated up to 30% improvement in interfacial adhesion, resulting in microcomponents with enhanced thermal resistance and mechanical integrity. These treatments modify the surface energy characteristics, promoting better wetting and chemical bonding between dissimilar materials.

Bioinspired materials design approaches have introduced novel hierarchical structures mimicking natural thermal-resistant systems. Biomimetic composites with layered architectures similar to nacre or wood have shown remarkable thermal stability improvements of 25-45% compared to conventional composites. These structures effectively dissipate thermal energy through their complex interfaces while maintaining structural integrity under thermal stress.

Smart responsive materials incorporating shape memory polymers and thermochromic additives represent the cutting edge of thermal-resistant microcomponents. These materials can actively respond to temperature changes, providing adaptive thermal management capabilities. For instance, phase-change materials embedded within polymer matrices can absorb excess heat during temperature spikes, releasing it gradually during cooling cycles, effectively dampening thermal fluctuations by up to 60%.

Computational materials science has accelerated development through molecular dynamics simulations and machine learning algorithms that predict thermal behavior of novel material combinations. These digital tools have reduced experimental iterations by approximately 40%, enabling faster identification of promising material formulations with optimal thermal resistance properties for specific microinjection molding applications.

Quality Assurance Standards for Thermally Stable Microinjection Products

Establishing quality assurance standards for thermally stable microinjection molded products requires a comprehensive framework that addresses the unique challenges of microscale manufacturing. The International Organization for Standardization (ISO) has developed several standards specifically applicable to microinjection molding, including ISO 20457 for dimensional tolerances and ISO 14644 for cleanroom environments often necessary for micro-manufacturing processes.

Temperature control during the molding process represents a critical quality parameter that must be monitored and documented according to established protocols. Quality assurance systems typically mandate temperature variation limits of ±2°C throughout the entire molding cycle, with more stringent requirements of ±0.5°C for high-precision medical or optical components. These standards necessitate implementation of advanced thermal monitoring systems with calibration traceability to national measurement institutes.

Material certification processes form another essential component of quality assurance standards. Polymer materials used in microinjection molding must undergo rigorous testing for thermal degradation characteristics, with documentation of melt flow indices before and after processing. The American Society for Testing and Materials (ASTM) D1238 standard provides the methodology for these measurements, while ASTM D3418 governs differential scanning calorimetry testing to verify thermal transition temperatures.

Process validation protocols specifically addressing thermal stability have evolved significantly in recent years. The current best practice involves a three-phase approach: Installation Qualification (IQ) verifying proper temperature control system installation, Operational Qualification (OQ) confirming temperature uniformity across the mold cavity, and Performance Qualification (PQ) demonstrating consistent part quality under varying production conditions. Statistical Process Control (SPC) methodologies, particularly those outlined in ISO 13485 for medical devices, provide the framework for ongoing monitoring.

Non-destructive testing standards for thermally-induced defects have also advanced considerably. Micro-computed tomography (micro-CT) scanning protocols now exist with standardized resolution requirements of 1-5 μm for detecting internal voids or material inconsistencies resulting from thermal instability. These inspection standards typically mandate 100% inspection for critical components and statistical sampling plans based on ANSI/ASQ Z1.4 for non-critical applications.

Traceability requirements within quality assurance standards ensure that thermal history data for each production batch is maintained and retrievable. Modern standards increasingly incorporate digital twin concepts, where virtual models maintain complete thermal histories of physical products throughout their lifecycle, facilitating root cause analysis when thermal-related defects emerge in field applications.

Temperature control during the molding process represents a critical quality parameter that must be monitored and documented according to established protocols. Quality assurance systems typically mandate temperature variation limits of ±2°C throughout the entire molding cycle, with more stringent requirements of ±0.5°C for high-precision medical or optical components. These standards necessitate implementation of advanced thermal monitoring systems with calibration traceability to national measurement institutes.

Material certification processes form another essential component of quality assurance standards. Polymer materials used in microinjection molding must undergo rigorous testing for thermal degradation characteristics, with documentation of melt flow indices before and after processing. The American Society for Testing and Materials (ASTM) D1238 standard provides the methodology for these measurements, while ASTM D3418 governs differential scanning calorimetry testing to verify thermal transition temperatures.

Process validation protocols specifically addressing thermal stability have evolved significantly in recent years. The current best practice involves a three-phase approach: Installation Qualification (IQ) verifying proper temperature control system installation, Operational Qualification (OQ) confirming temperature uniformity across the mold cavity, and Performance Qualification (PQ) demonstrating consistent part quality under varying production conditions. Statistical Process Control (SPC) methodologies, particularly those outlined in ISO 13485 for medical devices, provide the framework for ongoing monitoring.

Non-destructive testing standards for thermally-induced defects have also advanced considerably. Micro-computed tomography (micro-CT) scanning protocols now exist with standardized resolution requirements of 1-5 μm for detecting internal voids or material inconsistencies resulting from thermal instability. These inspection standards typically mandate 100% inspection for critical components and statistical sampling plans based on ANSI/ASQ Z1.4 for non-critical applications.

Traceability requirements within quality assurance standards ensure that thermal history data for each production batch is maintained and retrievable. Modern standards increasingly incorporate digital twin concepts, where virtual models maintain complete thermal histories of physical products throughout their lifecycle, facilitating root cause analysis when thermal-related defects emerge in field applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!