Vapor Chamber Application in Efficient Spacecraft Thermal Management

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Spacecraft Thermal Management Background and Objectives

Spacecraft thermal management represents a critical engineering challenge in the space industry, as vehicles must maintain operational temperatures while navigating the extreme thermal environment of space. The vacuum of space presents a unique thermal condition where radiation becomes the primary heat transfer mechanism, unlike Earth-based systems that can utilize convection. This fundamental difference necessitates specialized thermal control solutions for spacecraft to ensure mission success and equipment longevity.

The evolution of spacecraft thermal management has progressed from passive systems in early satellites to increasingly sophisticated active and semi-active solutions in modern spacecraft. Early thermal control relied primarily on surface coatings and simple radiators, while contemporary systems incorporate multiple technologies including fluid loops, heat pipes, and advanced materials. This progression has been driven by increasing power densities in spacecraft electronics and more demanding mission requirements.

Current spacecraft thermal management systems face significant limitations in terms of mass, power consumption, and thermal capacity. Traditional systems often contribute substantially to overall spacecraft mass, reducing payload capacity and increasing launch costs. Additionally, as spacecraft electronics become more powerful and compact, localized heat fluxes continue to rise, challenging conventional thermal solutions.

Vapor chambers represent a promising technology for addressing these challenges. These two-phase heat transfer devices utilize the phase change of a working fluid to efficiently transport heat from sources to radiating surfaces with minimal temperature gradients. The fundamental operating principle involves evaporation of the working fluid at heat sources and condensation at heat sinks, creating a highly efficient thermal transport mechanism with no moving parts.

The primary objectives of implementing vapor chamber technology in spacecraft thermal management include: reducing overall thermal control system mass while maintaining or improving thermal performance; enabling more efficient management of high heat flux components; increasing system reliability through passive operation; and accommodating the thermal demands of next-generation spacecraft electronics and power systems.

Research and development in this field aims to overcome several technical hurdles, including material compatibility with space environments, long-term reliability under microgravity conditions, and integration challenges with existing spacecraft systems. Additionally, optimization of vapor chamber designs specifically for space applications requires addressing unique constraints such as launch vibration tolerance and radiation resistance.

The successful implementation of vapor chamber technology in spacecraft thermal management could significantly impact future mission capabilities, enabling more compact and powerful electronics systems while reducing overall spacecraft mass and improving reliability in the harsh environment of space.

The evolution of spacecraft thermal management has progressed from passive systems in early satellites to increasingly sophisticated active and semi-active solutions in modern spacecraft. Early thermal control relied primarily on surface coatings and simple radiators, while contemporary systems incorporate multiple technologies including fluid loops, heat pipes, and advanced materials. This progression has been driven by increasing power densities in spacecraft electronics and more demanding mission requirements.

Current spacecraft thermal management systems face significant limitations in terms of mass, power consumption, and thermal capacity. Traditional systems often contribute substantially to overall spacecraft mass, reducing payload capacity and increasing launch costs. Additionally, as spacecraft electronics become more powerful and compact, localized heat fluxes continue to rise, challenging conventional thermal solutions.

Vapor chambers represent a promising technology for addressing these challenges. These two-phase heat transfer devices utilize the phase change of a working fluid to efficiently transport heat from sources to radiating surfaces with minimal temperature gradients. The fundamental operating principle involves evaporation of the working fluid at heat sources and condensation at heat sinks, creating a highly efficient thermal transport mechanism with no moving parts.

The primary objectives of implementing vapor chamber technology in spacecraft thermal management include: reducing overall thermal control system mass while maintaining or improving thermal performance; enabling more efficient management of high heat flux components; increasing system reliability through passive operation; and accommodating the thermal demands of next-generation spacecraft electronics and power systems.

Research and development in this field aims to overcome several technical hurdles, including material compatibility with space environments, long-term reliability under microgravity conditions, and integration challenges with existing spacecraft systems. Additionally, optimization of vapor chamber designs specifically for space applications requires addressing unique constraints such as launch vibration tolerance and radiation resistance.

The successful implementation of vapor chamber technology in spacecraft thermal management could significantly impact future mission capabilities, enabling more compact and powerful electronics systems while reducing overall spacecraft mass and improving reliability in the harsh environment of space.

Market Analysis for Space Thermal Control Systems

The space thermal control systems market is experiencing robust growth, driven by increasing satellite deployments and space exploration missions. Current market valuations indicate the global space thermal management sector reached approximately $2.3 billion in 2022, with projections suggesting growth to $3.5 billion by 2027, representing a compound annual growth rate of 8.7%. This expansion is primarily fueled by the proliferation of small satellites and constellations, which require advanced thermal management solutions despite their compact form factors.

Demand analysis reveals distinct market segments with varying requirements. Commercial satellite operators prioritize cost-effective, reliable thermal solutions with extended operational lifespans, while military and defense applications emphasize performance under extreme conditions and resilience against environmental stressors. Scientific missions, particularly those involving sensitive instrumentation, require precision temperature control with minimal fluctuations.

Geographically, North America dominates the market with approximately 40% share, benefiting from established aerospace infrastructure and substantial government funding. Europe follows at 30%, with significant contributions from ESA programs and commercial ventures. The Asia-Pacific region represents the fastest-growing market segment at 15% annual growth, driven by ambitious space programs in China, India, and Japan.

Customer pain points center around several key challenges: mass constraints that limit thermal system allocation to 10-15% of total spacecraft mass; power efficiency requirements as thermal management typically consumes 20-30% of onboard power; reliability concerns for missions extending beyond 10-15 years; and cost pressures as launch expenses remain substantial despite recent reductions.

Vapor chamber technology addresses these market needs by offering superior thermal conductivity (10-200 times that of solid aluminum) while maintaining relatively low mass. Market adoption analysis indicates vapor chambers are increasingly specified in next-generation satellite designs, with implementation growing at approximately 25% annually in new spacecraft thermal management systems.

The competitive landscape features traditional aerospace contractors offering conventional heat pipe solutions alongside newer entrants specializing in advanced thermal technologies. Price sensitivity varies significantly by application, with commercial operators demonstrating higher price elasticity than government or military customers. The latter segment values performance and reliability over cost considerations, creating distinct market approaches for suppliers.

Demand analysis reveals distinct market segments with varying requirements. Commercial satellite operators prioritize cost-effective, reliable thermal solutions with extended operational lifespans, while military and defense applications emphasize performance under extreme conditions and resilience against environmental stressors. Scientific missions, particularly those involving sensitive instrumentation, require precision temperature control with minimal fluctuations.

Geographically, North America dominates the market with approximately 40% share, benefiting from established aerospace infrastructure and substantial government funding. Europe follows at 30%, with significant contributions from ESA programs and commercial ventures. The Asia-Pacific region represents the fastest-growing market segment at 15% annual growth, driven by ambitious space programs in China, India, and Japan.

Customer pain points center around several key challenges: mass constraints that limit thermal system allocation to 10-15% of total spacecraft mass; power efficiency requirements as thermal management typically consumes 20-30% of onboard power; reliability concerns for missions extending beyond 10-15 years; and cost pressures as launch expenses remain substantial despite recent reductions.

Vapor chamber technology addresses these market needs by offering superior thermal conductivity (10-200 times that of solid aluminum) while maintaining relatively low mass. Market adoption analysis indicates vapor chambers are increasingly specified in next-generation satellite designs, with implementation growing at approximately 25% annually in new spacecraft thermal management systems.

The competitive landscape features traditional aerospace contractors offering conventional heat pipe solutions alongside newer entrants specializing in advanced thermal technologies. Price sensitivity varies significantly by application, with commercial operators demonstrating higher price elasticity than government or military customers. The latter segment values performance and reliability over cost considerations, creating distinct market approaches for suppliers.

Vapor Chamber Technology Status and Challenges

Vapor chamber technology has evolved significantly over the past decade, with current global development showing varied levels of maturity across different regions. In the United States, NASA and commercial space companies have made substantial progress in developing vapor chamber solutions specifically designed for spacecraft thermal management. The European Space Agency has similarly invested in advanced two-phase heat transfer technologies, while Japan and China have demonstrated growing capabilities in miniaturized vapor chamber systems for satellite applications.

Despite these advancements, several critical technical challenges persist in adapting vapor chamber technology for spacecraft thermal management. The primary limitation involves the development of ultra-thin vapor chambers that maintain high thermal performance while meeting stringent weight requirements for space applications. Current vapor chambers typically range from 3-5mm in thickness, whereas spacecraft applications ideally require thicknesses below 2mm without compromising thermal conductivity.

Material compatibility presents another significant challenge, as spacecraft vapor chambers must withstand extreme temperature fluctuations ranging from -150°C to +150°C depending on orbital position and mission parameters. Conventional wick structures and working fluids often fail to perform consistently across this temperature range, leading to potential thermal management system failures.

Long-term reliability remains problematic in the vacuum and microgravity environment of space. Traditional vapor chamber designs rely partially on gravity for fluid return in the wick structure, necessitating specialized designs for space applications. Additionally, radiation exposure can degrade material properties and working fluid characteristics over extended missions, an issue that has not been fully resolved in current implementations.

Manufacturing complexity further constrains widespread adoption, as spacecraft-grade vapor chambers require extremely high precision in wick structure fabrication and hermetic sealing. Current production techniques struggle to maintain consistent quality at the required scale, resulting in high unit costs and limited availability for spacecraft thermal management systems.

The geographical distribution of vapor chamber technology expertise shows concentration in aerospace hubs within the United States, Europe, and increasingly in Asia. However, significant knowledge gaps exist between theoretical research and practical implementation, particularly regarding space-qualified designs that can withstand launch vibrations and long-duration exposure to the space environment.

Recent testing aboard the International Space Station has validated some vapor chamber designs for short-duration missions, but data on multi-year performance remains limited. This knowledge gap represents one of the most significant barriers to widespread adoption in long-duration spacecraft missions where thermal management system reliability is mission-critical.

Despite these advancements, several critical technical challenges persist in adapting vapor chamber technology for spacecraft thermal management. The primary limitation involves the development of ultra-thin vapor chambers that maintain high thermal performance while meeting stringent weight requirements for space applications. Current vapor chambers typically range from 3-5mm in thickness, whereas spacecraft applications ideally require thicknesses below 2mm without compromising thermal conductivity.

Material compatibility presents another significant challenge, as spacecraft vapor chambers must withstand extreme temperature fluctuations ranging from -150°C to +150°C depending on orbital position and mission parameters. Conventional wick structures and working fluids often fail to perform consistently across this temperature range, leading to potential thermal management system failures.

Long-term reliability remains problematic in the vacuum and microgravity environment of space. Traditional vapor chamber designs rely partially on gravity for fluid return in the wick structure, necessitating specialized designs for space applications. Additionally, radiation exposure can degrade material properties and working fluid characteristics over extended missions, an issue that has not been fully resolved in current implementations.

Manufacturing complexity further constrains widespread adoption, as spacecraft-grade vapor chambers require extremely high precision in wick structure fabrication and hermetic sealing. Current production techniques struggle to maintain consistent quality at the required scale, resulting in high unit costs and limited availability for spacecraft thermal management systems.

The geographical distribution of vapor chamber technology expertise shows concentration in aerospace hubs within the United States, Europe, and increasingly in Asia. However, significant knowledge gaps exist between theoretical research and practical implementation, particularly regarding space-qualified designs that can withstand launch vibrations and long-duration exposure to the space environment.

Recent testing aboard the International Space Station has validated some vapor chamber designs for short-duration missions, but data on multi-year performance remains limited. This knowledge gap represents one of the most significant barriers to widespread adoption in long-duration spacecraft missions where thermal management system reliability is mission-critical.

Current Vapor Chamber Implementation in Spacecraft

01 Vapor chamber structure and design

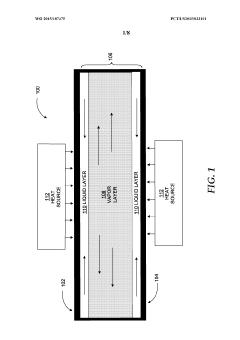

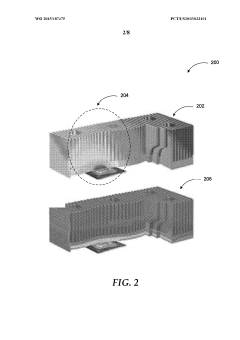

Vapor chambers are designed with specific structural elements to enhance thermal management. These designs include optimized internal structures, wick materials, and vapor flow channels that facilitate efficient heat transfer. The chambers are typically flat and thin, allowing for effective heat spreading across electronic devices. Advanced designs incorporate features like multiple chambers, specialized sealing methods, and integrated heat pipes to maximize thermal performance in limited spaces.- Vapor chamber structure and materials: Vapor chambers are designed with specific structural elements and materials to optimize thermal management. These structures typically include a sealed chamber with a working fluid, wicks for capillary action, and thermally conductive walls. Advanced materials such as copper, aluminum, or composite materials are used to enhance heat transfer efficiency. The internal structure may include posts, pillars, or mesh designs to support the chamber walls while facilitating vapor flow.

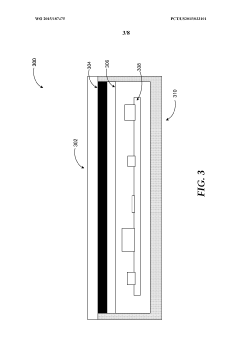

- Integration with electronic devices: Vapor chambers are integrated into electronic devices to manage thermal loads from components such as processors, graphics cards, and power modules. The integration involves designing vapor chambers that conform to the specific form factors of devices while maintaining optimal thermal contact with heat-generating components. This approach allows for efficient heat dissipation in compact electronic devices like smartphones, laptops, and telecommunications equipment.

- Working fluid selection and circulation: The selection of appropriate working fluids is critical for vapor chamber performance. These fluids undergo phase changes (evaporation and condensation) to transfer heat efficiently. Common working fluids include water, alcohols, refrigerants, or engineered fluids with specific thermophysical properties. The circulation system within the vapor chamber is designed to ensure continuous fluid movement through evaporation at hot spots and condensation at cooler regions, creating an efficient heat transfer cycle.

- Thermal management systems with multiple components: Advanced thermal management systems incorporate vapor chambers as part of a comprehensive cooling solution. These systems may combine vapor chambers with heat sinks, fans, thermoelectric coolers, or liquid cooling components to create multi-stage cooling architectures. The integration of vapor chambers with other thermal management technologies allows for more effective heat dissipation in high-power applications and ensures stable operation under varying thermal loads.

- Manufacturing and fabrication techniques: Specialized manufacturing techniques are employed to produce effective vapor chambers. These include precision stamping, diffusion bonding, sintering of porous structures, and advanced welding methods to create sealed chambers. The fabrication process must ensure proper internal structure formation, wick implementation, and vacuum sealing before charging with the working fluid. Novel manufacturing approaches focus on reducing thermal resistance at interfaces and improving overall thermal conductivity of the system.

02 Integration with electronic devices

Vapor chambers are integrated into various electronic devices to manage thermal issues. They are commonly incorporated into smartphones, computers, and telecommunications equipment where space constraints and high heat generation are concerns. The integration involves strategic placement of the vapor chamber between heat sources (like processors) and heat dissipation components. This approach allows for efficient thermal management while maintaining the compact form factor required in modern electronic devices.Expand Specific Solutions03 Advanced materials for enhanced thermal conductivity

The performance of vapor chambers is significantly influenced by the materials used in their construction. Advanced materials with high thermal conductivity are employed for the chamber walls, wicks, and working fluids. These materials include copper, aluminum alloys, sintered metal powders, and specialized composites. The selection of appropriate materials enhances heat transfer efficiency, reduces thermal resistance, and improves the overall thermal management capability of the vapor chamber system.Expand Specific Solutions04 Working fluid selection and management

The choice and management of working fluids within vapor chambers are critical for optimal thermal performance. Various fluids with appropriate boiling points and thermodynamic properties are selected based on the operating temperature range of the application. The fluid management system includes mechanisms for proper distribution, circulation, and phase change processes. Advanced vapor chambers incorporate techniques to prevent dry-out conditions, manage pressure variations, and ensure consistent heat transfer across different operating conditions.Expand Specific Solutions05 Manufacturing techniques and quality control

Specialized manufacturing techniques are employed to produce high-performance vapor chambers. These include precision stamping, diffusion bonding, vacuum sealing, and advanced welding methods. Quality control processes ensure proper chamber sealing, wick saturation, and absence of non-condensable gases that could impair performance. Manufacturing innovations focus on reducing thickness, increasing reliability, and enabling mass production while maintaining consistent thermal performance across produced units.Expand Specific Solutions

Leading Organizations in Space Thermal Control Industry

The vapor chamber technology for spacecraft thermal management is in a growth phase, with the market expanding due to increasing satellite deployments and space missions. The global market for advanced thermal management solutions in aerospace is projected to reach significant scale as spacecraft complexity increases. Technologically, vapor chambers are maturing rapidly with key players demonstrating varying levels of expertise. Beijing Institute of Spacecraft System Engineering and Japan Aerospace Exploration Agency lead in space-specific applications, while Razer and Cooler Master bring consumer electronics cooling expertise. Thales SA and Furukawa Electric contribute advanced materials research, with Beihang University and Harbin Institute of Technology providing academic innovation. The competitive landscape shows a mix of aerospace specialists, electronics manufacturers, and research institutions collaborating to overcome the unique challenges of space thermal management.

Beijing Institute of Spacecraft System Engineering

Technical Solution: Beijing Institute of Spacecraft System Engineering has developed advanced vapor chamber thermal management systems specifically designed for spacecraft applications. Their technology utilizes ultra-thin vapor chambers with specialized working fluids that maintain optimal performance in microgravity environments. The institute has implemented a multi-layer wick structure design that enhances capillary action and fluid circulation without relying on gravity, crucial for space applications. Their vapor chambers incorporate composite materials that offer superior thermal conductivity (>1500 W/m·K) while maintaining structural integrity under launch vibrations and thermal cycling conditions. The institute has also pioneered integration techniques that allow vapor chambers to be embedded directly into satellite structural panels, reducing overall mass while maximizing thermal dissipation capabilities. Their systems have demonstrated effective heat spreading capabilities across temperature ranges from -100°C to +150°C, addressing the extreme thermal environments encountered in space.

Strengths: Specialized design for microgravity environments; high thermal conductivity-to-weight ratio; proven reliability in actual space missions; integration capability with existing spacecraft structures. Weaknesses: Higher production costs compared to conventional cooling solutions; limited scalability for very small satellites; requires specialized manufacturing facilities and expertise.

Beijing Space Electromechanical Research Institute

Technical Solution: Beijing Space Electromechanical Research Institute has developed proprietary vapor chamber technology specifically engineered for spacecraft thermal management challenges. Their approach features ultra-thin vapor chambers (less than 1.5mm thickness) with specialized sintered copper wicks that maintain fluid circulation in zero-gravity conditions. The institute has created custom working fluid formulations that remain stable under radiation exposure and extreme temperature cycling. Their vapor chambers incorporate multiple redundant fluid pathways to ensure continued operation even if partial blockage occurs during long-duration missions. The institute has also pioneered integration methods that allow vapor chambers to be directly bonded to high-heat-generating components like communication amplifiers and processors, reducing thermal resistance at interfaces. Their systems have been flight-qualified through extensive testing in thermal vacuum chambers and have demonstrated reliable performance on multiple satellite platforms, maintaining electronic components within 5°C of optimal operating temperatures despite external temperature fluctuations of over 200°C.

Strengths: Radiation-resistant design suitable for long-duration space missions; ultra-thin profile minimizing mass penalties; proven reliability through multiple space deployments; excellent thermal performance in vacuum conditions. Weaknesses: Higher manufacturing complexity leading to increased production time; limited flexibility for design modifications after production; requires specialized testing facilities to validate performance.

Key Patents and Research in Vapor Chamber Technology

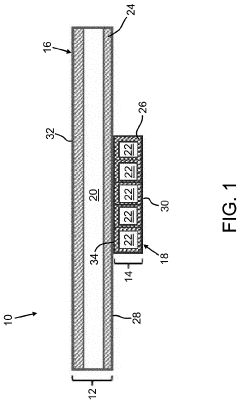

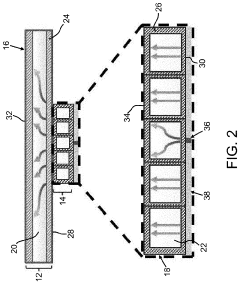

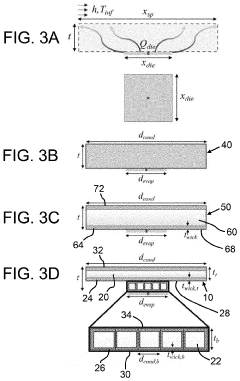

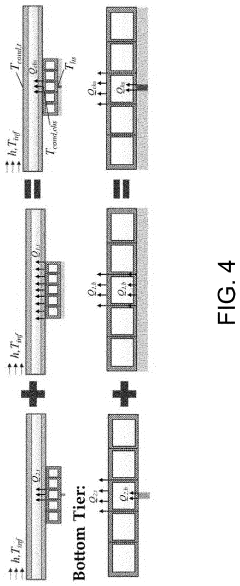

Vapor chamber devices and methods of dissipating heat therewith

PatentActiveUS20210372709A1

Innovation

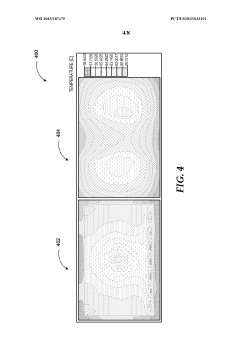

- A cascaded multi-core vapor chamber device with a top-tier subunit for bulk heat spreading and a bottom-tier subunit with multiple vapor cores to attenuate high heat flux hotspots, decoupling the spreading of total background power from individual hotspots and reducing conduction resistance.

Integrated vapor chamber for thermal management of computing devices

PatentWO2015187475A1

Innovation

- Integration of a fluid-filled vapor chamber with upper and lower portions and an annular space into computing device components, such as a touch display module or back case, which absorbs heat and facilitates uniform heat transfer through phase changes of the fluid, optimizing dynamic viscosity and thermal conductivity for efficient heat dissipation.

Space Qualification Standards and Testing Protocols

Space qualification standards for vapor chamber technology in spacecraft thermal management systems are governed by rigorous protocols established by major space agencies like NASA, ESA, and JAXA. These standards primarily focus on ensuring reliability under extreme space conditions, including vacuum, radiation, and thermal cycling. The NASA-STD-5012 and ECSS-Q-ST-70 standards specifically address thermal control systems, requiring vapor chambers to maintain performance integrity throughout the mission lifecycle.

Testing protocols for vapor chamber qualification typically involve a multi-phase approach. Initial screening includes material compatibility tests to verify that working fluids and chamber materials will not degrade or react adversely in space environments. Vacuum compatibility testing is particularly critical, as vapor chambers must function efficiently in the absence of atmospheric pressure. This involves extended operation in vacuum chambers that simulate space conditions, with performance metrics carefully monitored.

Thermal cycling tests represent another crucial qualification phase, where vapor chambers undergo repeated exposure to temperature extremes ranging from -150°C to +150°C. These tests verify structural integrity and consistent thermal performance across operational temperature ranges. Vibration and shock testing protocols, aligned with standards like MIL-STD-810, subject vapor chambers to launch-level mechanical stresses to ensure they can withstand the violent conditions of rocket ascent.

Radiation hardness testing evaluates the vapor chamber's resilience to space radiation, including galactic cosmic rays and solar particle events. This involves exposing prototypes to controlled radiation environments and measuring subsequent performance degradation. Long-duration life testing, often accelerated through increased cycling frequency, verifies that vapor chambers can meet or exceed mission lifetime requirements, typically ranging from 5 to 15 years.

Qualification standards also address manufacturing consistency through batch testing protocols. Statistical sampling methods ensure that production vapor chambers maintain consistent performance characteristics. Documentation requirements are extensive, with full material traceability, manufacturing process controls, and test results required for flight certification.

Recent developments in qualification standards have begun incorporating specific provisions for additive manufacturing techniques used in advanced vapor chamber designs. These include additional X-ray and CT scan inspections to verify internal structure integrity and specialized leak testing protocols for complex geometries that cannot be adequately evaluated using traditional methods.

Testing protocols for vapor chamber qualification typically involve a multi-phase approach. Initial screening includes material compatibility tests to verify that working fluids and chamber materials will not degrade or react adversely in space environments. Vacuum compatibility testing is particularly critical, as vapor chambers must function efficiently in the absence of atmospheric pressure. This involves extended operation in vacuum chambers that simulate space conditions, with performance metrics carefully monitored.

Thermal cycling tests represent another crucial qualification phase, where vapor chambers undergo repeated exposure to temperature extremes ranging from -150°C to +150°C. These tests verify structural integrity and consistent thermal performance across operational temperature ranges. Vibration and shock testing protocols, aligned with standards like MIL-STD-810, subject vapor chambers to launch-level mechanical stresses to ensure they can withstand the violent conditions of rocket ascent.

Radiation hardness testing evaluates the vapor chamber's resilience to space radiation, including galactic cosmic rays and solar particle events. This involves exposing prototypes to controlled radiation environments and measuring subsequent performance degradation. Long-duration life testing, often accelerated through increased cycling frequency, verifies that vapor chambers can meet or exceed mission lifetime requirements, typically ranging from 5 to 15 years.

Qualification standards also address manufacturing consistency through batch testing protocols. Statistical sampling methods ensure that production vapor chambers maintain consistent performance characteristics. Documentation requirements are extensive, with full material traceability, manufacturing process controls, and test results required for flight certification.

Recent developments in qualification standards have begun incorporating specific provisions for additive manufacturing techniques used in advanced vapor chamber designs. These include additional X-ray and CT scan inspections to verify internal structure integrity and specialized leak testing protocols for complex geometries that cannot be adequately evaluated using traditional methods.

Microgravity Effects on Vapor Chamber Performance

The unique environment of microgravity presents significant challenges for vapor chamber operation in spacecraft thermal management systems. In Earth's gravitational field, vapor chambers rely on gravity to return condensed working fluid to the evaporator section. However, in the microgravity conditions of space, this natural return mechanism is compromised, potentially reducing thermal performance and reliability.

Research conducted by NASA and international space agencies has demonstrated that conventional vapor chamber designs experience up to 40% reduction in heat transfer capacity when operating in microgravity. This performance degradation stems from the absence of gravitational forces that normally assist in fluid distribution and return within the chamber structure.

Several microgravity-specific phenomena affect vapor chamber performance. Fluid pooling becomes a critical issue, with working fluid tending to form large aggregations rather than distributing evenly across wicking structures. This leads to dry-out conditions in evaporator regions and subsequent hotspots that can compromise electronic component reliability. Additionally, bubble formation and entrapment within the working fluid occurs more readily in microgravity, creating thermal barriers that impede efficient heat transfer.

Advanced visualization experiments conducted aboard the International Space Station have revealed altered phase-change dynamics in microgravity environments. The evaporation-condensation cycle exhibits different characteristics, with surface tension forces becoming the dominant mechanism for fluid transport rather than gravitational forces. This shift fundamentally changes the operational parameters of vapor chambers designed for terrestrial applications.

To address these challenges, specialized wick structures have been developed for space-based vapor chambers. These include arterial wicks, sintered metal powders with optimized porosity gradients, and hybrid structures combining multiple capillary transport mechanisms. Testing has shown that properly designed microgravity-optimized vapor chambers can recover up to 85% of the thermal performance observed in terrestrial conditions.

Long-duration microgravity testing remains a significant challenge for vapor chamber development. Ground-based facilities such as drop towers and parabolic flights provide only brief periods of microgravity exposure, insufficient for comprehensive thermal cycling evaluation. This limitation has led to conservative design approaches that often sacrifice optimal performance for reliability, resulting in oversized thermal management systems that increase spacecraft mass.

Recent advancements in computational fluid dynamics modeling have improved the prediction of vapor chamber performance in microgravity, allowing designers to simulate long-term operation without extensive space-based testing. These models incorporate complex multiphase flow physics and have been validated against available experimental data from space missions, providing a valuable tool for future spacecraft thermal management system development.

Research conducted by NASA and international space agencies has demonstrated that conventional vapor chamber designs experience up to 40% reduction in heat transfer capacity when operating in microgravity. This performance degradation stems from the absence of gravitational forces that normally assist in fluid distribution and return within the chamber structure.

Several microgravity-specific phenomena affect vapor chamber performance. Fluid pooling becomes a critical issue, with working fluid tending to form large aggregations rather than distributing evenly across wicking structures. This leads to dry-out conditions in evaporator regions and subsequent hotspots that can compromise electronic component reliability. Additionally, bubble formation and entrapment within the working fluid occurs more readily in microgravity, creating thermal barriers that impede efficient heat transfer.

Advanced visualization experiments conducted aboard the International Space Station have revealed altered phase-change dynamics in microgravity environments. The evaporation-condensation cycle exhibits different characteristics, with surface tension forces becoming the dominant mechanism for fluid transport rather than gravitational forces. This shift fundamentally changes the operational parameters of vapor chambers designed for terrestrial applications.

To address these challenges, specialized wick structures have been developed for space-based vapor chambers. These include arterial wicks, sintered metal powders with optimized porosity gradients, and hybrid structures combining multiple capillary transport mechanisms. Testing has shown that properly designed microgravity-optimized vapor chambers can recover up to 85% of the thermal performance observed in terrestrial conditions.

Long-duration microgravity testing remains a significant challenge for vapor chamber development. Ground-based facilities such as drop towers and parabolic flights provide only brief periods of microgravity exposure, insufficient for comprehensive thermal cycling evaluation. This limitation has led to conservative design approaches that often sacrifice optimal performance for reliability, resulting in oversized thermal management systems that increase spacecraft mass.

Recent advancements in computational fluid dynamics modeling have improved the prediction of vapor chamber performance in microgravity, allowing designers to simulate long-term operation without extensive space-based testing. These models incorporate complex multiphase flow physics and have been validated against available experimental data from space missions, providing a valuable tool for future spacecraft thermal management system development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!