Vapor Chamber Applications in Enhancing Device Lifespan

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vapor Chamber Technology Evolution and Objectives

Vapor chamber technology has evolved significantly over the past three decades, transforming from a niche cooling solution to a mainstream thermal management technology. Initially developed for aerospace applications in the 1990s, vapor chambers have undergone substantial miniaturization and efficiency improvements to become integral components in consumer electronics. The fundamental operating principle—utilizing phase change processes to transfer heat rapidly across a sealed chamber—has remained consistent, while manufacturing techniques and materials have advanced considerably.

The evolution trajectory shows three distinct phases: early development (1990-2005) focused on proof-of-concept and industrial applications; mainstream adoption (2006-2015) saw integration into high-performance computing systems; and current optimization phase (2016-present) emphasizes ultra-thin designs and enhanced thermal efficiency for mobile devices. This progression reflects the technology's adaptation to increasingly demanding thermal management requirements in progressively smaller form factors.

Material science breakthroughs have been pivotal in this evolution. The transition from copper-based chambers to composite materials incorporating graphene, sintered powder wicks, and advanced working fluids has dramatically improved thermal conductivity while reducing thickness. Modern vapor chambers achieve thermal conductivity values exceeding 3000 W/m·K, significantly outperforming traditional copper heat spreaders limited to approximately 400 W/m·K.

The primary objective of vapor chamber technology in device lifespan enhancement is multifaceted. First, it aims to maintain optimal operating temperatures for sensitive electronic components, particularly in high-performance processors and graphics units where thermal throttling can significantly impact performance and longevity. Research indicates that maintaining temperatures below critical thresholds can extend semiconductor lifespan by 30-50% through reduction of electromigration and thermal stress.

Secondary objectives include enabling sustained performance under heavy computational loads, facilitating passive cooling designs that eliminate moving parts (enhancing reliability), and supporting device miniaturization without thermal compromises. The technology also seeks to address hotspot management—a critical factor in preventing premature component failure—by distributing heat more uniformly across the device chassis.

Future development goals focus on further thickness reduction (sub-0.3mm chambers), integration with emerging semiconductor technologies, enhanced manufacturing scalability, and cost reduction to enable broader adoption across consumer electronics categories. Environmental considerations are increasingly important, with research directed toward eco-friendly working fluids and recyclable construction materials that maintain thermal performance while reducing environmental impact.

The evolution trajectory shows three distinct phases: early development (1990-2005) focused on proof-of-concept and industrial applications; mainstream adoption (2006-2015) saw integration into high-performance computing systems; and current optimization phase (2016-present) emphasizes ultra-thin designs and enhanced thermal efficiency for mobile devices. This progression reflects the technology's adaptation to increasingly demanding thermal management requirements in progressively smaller form factors.

Material science breakthroughs have been pivotal in this evolution. The transition from copper-based chambers to composite materials incorporating graphene, sintered powder wicks, and advanced working fluids has dramatically improved thermal conductivity while reducing thickness. Modern vapor chambers achieve thermal conductivity values exceeding 3000 W/m·K, significantly outperforming traditional copper heat spreaders limited to approximately 400 W/m·K.

The primary objective of vapor chamber technology in device lifespan enhancement is multifaceted. First, it aims to maintain optimal operating temperatures for sensitive electronic components, particularly in high-performance processors and graphics units where thermal throttling can significantly impact performance and longevity. Research indicates that maintaining temperatures below critical thresholds can extend semiconductor lifespan by 30-50% through reduction of electromigration and thermal stress.

Secondary objectives include enabling sustained performance under heavy computational loads, facilitating passive cooling designs that eliminate moving parts (enhancing reliability), and supporting device miniaturization without thermal compromises. The technology also seeks to address hotspot management—a critical factor in preventing premature component failure—by distributing heat more uniformly across the device chassis.

Future development goals focus on further thickness reduction (sub-0.3mm chambers), integration with emerging semiconductor technologies, enhanced manufacturing scalability, and cost reduction to enable broader adoption across consumer electronics categories. Environmental considerations are increasingly important, with research directed toward eco-friendly working fluids and recyclable construction materials that maintain thermal performance while reducing environmental impact.

Market Demand for Enhanced Thermal Management Solutions

The thermal management solutions market is experiencing unprecedented growth driven by the increasing power density and miniaturization of electronic devices. According to industry reports, the global thermal management market is projected to reach $16.2 billion by 2026, growing at a CAGR of 8.2% from 2021. This growth is particularly pronounced in sectors such as consumer electronics, telecommunications, automotive electronics, and data centers, where device performance and longevity are directly impacted by thermal efficiency.

Consumer electronics manufacturers are facing mounting pressure to develop thinner, lighter, and more powerful devices while simultaneously extending product lifespan. This contradiction has created significant demand for advanced thermal solutions like Vapor Chamber technology, which offers superior heat dissipation capabilities compared to traditional cooling methods. Market research indicates that smartphones incorporating Vapor Chamber technology demonstrate 15-20% lower operating temperatures, resulting in extended component lifespan and improved performance stability.

The data center industry represents another substantial market segment driving demand for enhanced thermal management. With the exponential growth in cloud computing and data processing requirements, data centers face critical challenges in managing heat generated by densely packed server racks. Studies show that for every 10°C increase in operating temperature, electronic component failure rates double, highlighting the direct correlation between thermal management and device longevity.

Automotive electronics present a rapidly expanding market for advanced thermal solutions. The transition toward electric vehicles and autonomous driving systems has introduced complex thermal challenges, as these vehicles contain significantly more electronic components operating in harsh environmental conditions. Industry analysts report that the automotive thermal management market segment alone is expected to grow at 9.7% CAGR through 2026, with Vapor Chamber technology increasingly being adopted in battery thermal management systems and power electronics cooling.

The telecommunications sector, particularly with the global rollout of 5G infrastructure, represents another significant market driver. 5G equipment generates substantially more heat than previous generations due to higher processing requirements and power consumption. Network equipment manufacturers are actively seeking thermal solutions that can ensure the reliability and longevity of base station components, with Vapor Chamber technology emerging as a preferred solution for its passive operation and high thermal conductivity.

Market surveys indicate that end-users are increasingly willing to pay premium prices for devices with demonstrably better thermal management, recognizing the direct relationship between operating temperature and device lifespan. This consumer awareness has created a competitive advantage for manufacturers implementing advanced cooling technologies like Vapor Chambers in their product designs.

Consumer electronics manufacturers are facing mounting pressure to develop thinner, lighter, and more powerful devices while simultaneously extending product lifespan. This contradiction has created significant demand for advanced thermal solutions like Vapor Chamber technology, which offers superior heat dissipation capabilities compared to traditional cooling methods. Market research indicates that smartphones incorporating Vapor Chamber technology demonstrate 15-20% lower operating temperatures, resulting in extended component lifespan and improved performance stability.

The data center industry represents another substantial market segment driving demand for enhanced thermal management. With the exponential growth in cloud computing and data processing requirements, data centers face critical challenges in managing heat generated by densely packed server racks. Studies show that for every 10°C increase in operating temperature, electronic component failure rates double, highlighting the direct correlation between thermal management and device longevity.

Automotive electronics present a rapidly expanding market for advanced thermal solutions. The transition toward electric vehicles and autonomous driving systems has introduced complex thermal challenges, as these vehicles contain significantly more electronic components operating in harsh environmental conditions. Industry analysts report that the automotive thermal management market segment alone is expected to grow at 9.7% CAGR through 2026, with Vapor Chamber technology increasingly being adopted in battery thermal management systems and power electronics cooling.

The telecommunications sector, particularly with the global rollout of 5G infrastructure, represents another significant market driver. 5G equipment generates substantially more heat than previous generations due to higher processing requirements and power consumption. Network equipment manufacturers are actively seeking thermal solutions that can ensure the reliability and longevity of base station components, with Vapor Chamber technology emerging as a preferred solution for its passive operation and high thermal conductivity.

Market surveys indicate that end-users are increasingly willing to pay premium prices for devices with demonstrably better thermal management, recognizing the direct relationship between operating temperature and device lifespan. This consumer awareness has created a competitive advantage for manufacturers implementing advanced cooling technologies like Vapor Chambers in their product designs.

Current State and Challenges in Vapor Chamber Technology

Vapor chamber technology has evolved significantly over the past decade, establishing itself as a critical thermal management solution across multiple industries. Currently, vapor chambers are widely deployed in high-performance computing devices, smartphones, and other electronic systems where thermal management directly impacts device longevity. The global market adoption has accelerated, with Asia-Pacific manufacturers dominating production capacity, while North American and European companies focus on advanced design innovations.

The current state of vapor chamber technology features several key advancements. Ultra-thin vapor chambers, measuring less than 0.3mm in thickness, have enabled integration into increasingly compact devices. Multi-layer wick structures have improved capillary action efficiency, enhancing heat transfer capabilities by up to 30% compared to previous generations. Additionally, composite materials incorporating copper, aluminum, and specialized alloys have optimized thermal conductivity while reducing weight.

Despite these advancements, significant technical challenges persist. Thermal interface resistance remains a critical bottleneck, with contact points between vapor chambers and heat-generating components still causing efficiency losses of 15-20%. Manufacturing consistency presents another major hurdle, as production yield rates for ultra-thin chambers typically hover around 70-80%, increasing costs and limiting mass adoption.

Reliability under extreme operating conditions continues to challenge engineers, particularly in applications experiencing frequent thermal cycling or mechanical stress. Current vapor chambers show performance degradation of approximately 10-15% after 5,000 thermal cycles, falling short of the ideal lifespan requirements for many consumer electronics. This degradation primarily stems from working fluid depletion and internal structure deformation over time.

Material limitations further constrain innovation, as conventional copper-based chambers face corrosion issues when exposed to certain environmental conditions. Additionally, the environmental impact of manufacturing processes and materials used in vapor chambers has come under increasing scrutiny, with regulatory pressures mounting in key markets.

Integration complexity represents another significant barrier, particularly for devices with irregular form factors or multiple heat sources. Current design methodologies struggle to optimize vapor chamber placement for devices with distributed thermal loads, resulting in suboptimal cooling performance and reduced device longevity.

The geographical distribution of vapor chamber technology development shows concentration in East Asia for manufacturing capacity, while research advancements are more evenly distributed across North America, Europe, and Asia. This distribution creates both collaboration opportunities and intellectual property challenges for global technology deployment.

The current state of vapor chamber technology features several key advancements. Ultra-thin vapor chambers, measuring less than 0.3mm in thickness, have enabled integration into increasingly compact devices. Multi-layer wick structures have improved capillary action efficiency, enhancing heat transfer capabilities by up to 30% compared to previous generations. Additionally, composite materials incorporating copper, aluminum, and specialized alloys have optimized thermal conductivity while reducing weight.

Despite these advancements, significant technical challenges persist. Thermal interface resistance remains a critical bottleneck, with contact points between vapor chambers and heat-generating components still causing efficiency losses of 15-20%. Manufacturing consistency presents another major hurdle, as production yield rates for ultra-thin chambers typically hover around 70-80%, increasing costs and limiting mass adoption.

Reliability under extreme operating conditions continues to challenge engineers, particularly in applications experiencing frequent thermal cycling or mechanical stress. Current vapor chambers show performance degradation of approximately 10-15% after 5,000 thermal cycles, falling short of the ideal lifespan requirements for many consumer electronics. This degradation primarily stems from working fluid depletion and internal structure deformation over time.

Material limitations further constrain innovation, as conventional copper-based chambers face corrosion issues when exposed to certain environmental conditions. Additionally, the environmental impact of manufacturing processes and materials used in vapor chambers has come under increasing scrutiny, with regulatory pressures mounting in key markets.

Integration complexity represents another significant barrier, particularly for devices with irregular form factors or multiple heat sources. Current design methodologies struggle to optimize vapor chamber placement for devices with distributed thermal loads, resulting in suboptimal cooling performance and reduced device longevity.

The geographical distribution of vapor chamber technology development shows concentration in East Asia for manufacturing capacity, while research advancements are more evenly distributed across North America, Europe, and Asia. This distribution creates both collaboration opportunities and intellectual property challenges for global technology deployment.

Current Vapor Chamber Implementation Strategies

01 Factors affecting vapor chamber lifespan

Various factors can significantly impact the operational lifespan of vapor chamber devices. These include the quality of materials used in construction, working fluid purity, internal vacuum integrity, and manufacturing processes. Environmental conditions such as temperature cycling, humidity, and mechanical stress also play crucial roles in determining how long these thermal management solutions remain effective. Proper sealing techniques and corrosion resistance of internal components are particularly important for preventing premature failure.- Factors affecting vapor chamber lifespan: Various factors can significantly impact the operational lifespan of vapor chamber devices. These include the quality of materials used in construction, operating temperature ranges, working fluid selection, and environmental conditions. The integrity of the vapor chamber's sealed structure is crucial for preventing leakage and maintaining proper functionality over time. Design considerations such as wall thickness, internal structure, and wick material selection also play important roles in determining how long these thermal management solutions remain effective.

- Working fluid selection and maintenance: The choice of working fluid within vapor chambers significantly affects their operational lifespan. Optimal working fluids must maintain stable properties over extended periods, resist degradation, and remain compatible with the chamber materials. Non-condensable gases that form over time can reduce thermal performance and shorten device lifespan. Advanced fluid formulations may include additives that prevent corrosion and extend operational life. Regular monitoring of fluid properties and potential replenishment systems can help maintain performance throughout the intended service life.

- Structural integrity and reliability enhancements: Enhancing the structural integrity of vapor chambers is essential for extending their operational lifespan. This includes reinforced sealing methods to prevent working fluid leakage, optimized internal support structures to withstand thermal cycling, and specialized surface treatments to minimize corrosion. Advanced manufacturing techniques can reduce potential failure points and improve overall reliability. Stress testing under extreme conditions helps identify potential weaknesses, while innovative materials such as composite structures or specialized alloys can significantly extend the functional lifetime of vapor chamber devices.

- Thermal cycling and performance degradation: Repeated thermal cycling can lead to performance degradation in vapor chamber devices over time. This includes potential issues such as wick structure deterioration, seal integrity compromise, and working fluid property changes. The rate of performance decline depends on operating conditions, with more extreme temperature fluctuations accelerating aging effects. Monitoring systems can track performance metrics to predict remaining useful life. Design optimizations that accommodate thermal expansion differences between materials can minimize stress-related failures and extend the functional lifespan of vapor chamber cooling solutions.

- Lifespan testing and prediction methodologies: Accurate prediction of vapor chamber device lifespan requires comprehensive testing methodologies. Accelerated aging tests subject devices to intensified conditions to simulate long-term use in compressed timeframes. Computational models can predict failure modes and estimate service life based on material properties and operating parameters. Non-destructive evaluation techniques allow for ongoing monitoring of device integrity without compromising functionality. Statistical reliability analyses from field data help manufacturers establish realistic lifespan expectations and warranty periods for vapor chamber cooling solutions in various application environments.

02 Wick structure design for extended lifespan

The design and implementation of wick structures within vapor chambers significantly influence device longevity. Advanced wick designs incorporate optimized porosity, thickness, and material composition to ensure efficient capillary action throughout the device's operational life. Multi-layer wick structures with varying pore sizes can maintain performance even as some degradation occurs over time. Innovations in sintering processes and composite wick materials help resist clogging and structural breakdown, which are common failure mechanisms in vapor chamber devices.Expand Specific Solutions03 Working fluid selection and maintenance

The selection of appropriate working fluids is critical for vapor chamber longevity. Fluids must maintain stable thermophysical properties over extended periods while resisting decomposition and chemical reactions with chamber materials. Non-condensable gas generation, which can significantly reduce thermal performance over time, must be minimized through proper fluid purification and chamber preparation. Some advanced designs incorporate fluid reservoirs or regeneration systems to compensate for minimal fluid loss during extended operation, thereby extending the functional lifespan of the device.Expand Specific Solutions04 Monitoring and predictive maintenance systems

Integrated monitoring systems can significantly extend vapor chamber lifespan by detecting early signs of performance degradation. These systems may include temperature sensors, pressure monitors, and performance analytics that track changes in thermal conductivity over time. Predictive maintenance algorithms can analyze operational data to forecast potential failures before they occur, allowing for timely intervention. Some advanced vapor chamber designs incorporate self-diagnostic capabilities that can alert users to maintenance needs or impending failure conditions.Expand Specific Solutions05 Reliability testing and lifespan certification

Standardized testing protocols have been developed to accurately predict and certify vapor chamber device lifespans. These include accelerated aging tests, thermal cycling, mechanical stress testing, and long-term performance monitoring under various operating conditions. Reliability models based on these tests help manufacturers provide accurate lifespan estimates and warranty periods. Advanced simulation techniques can predict failure modes and optimize designs to extend operational life before physical prototyping, reducing development time and improving final product reliability.Expand Specific Solutions

Key Industry Players in Vapor Chamber Manufacturing

Vapor Chamber technology for device lifespan enhancement is currently in a growth phase, with the market expanding rapidly due to increasing demand for thermal management solutions in electronics. The global market size is projected to reach significant scale as consumer electronics, automotive, and telecommunications sectors adopt this technology. In terms of technical maturity, industry leaders like Samsung Electronics, Intel, and Xiaomi have made substantial advancements in vapor chamber implementation, while specialized thermal solution providers such as Cooler Master, Delta Electronics, and Asia Vital Components offer sophisticated designs. Companies like Murata Manufacturing and DuPont contribute advanced materials expertise, creating a competitive landscape where established electronics manufacturers collaborate with thermal management specialists to develop increasingly efficient vapor chamber solutions for extending device longevity.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed advanced vapor chamber cooling solutions for their premium smartphones and other electronic devices. Their technology utilizes a two-phase cooling system where a working fluid inside a sealed copper chamber evaporates when heated, moves to cooler areas where it condenses, and returns to the heat source through capillary action in a wick structure. Samsung's latest vapor chambers feature ultra-thin designs (less than 0.35mm) with optimized internal structures that maximize heat spreading efficiency[1]. They've implemented multi-directional vapor chambers that can dissipate heat across different components simultaneously, significantly reducing thermal throttling in their flagship devices. Samsung has also integrated vapor chambers with graphite sheets and thermal interface materials to create comprehensive thermal management systems that extend device lifespan by maintaining optimal operating temperatures under sustained loads[3].

Strengths: Samsung's vapor chambers demonstrate excellent thermal conductivity (up to 1500-2000 W/m·K) compared to traditional cooling solutions, allowing for more efficient heat dissipation in compact devices. Their ultra-thin design enables implementation in slim form factors without compromising cooling performance. Weaknesses: Higher manufacturing costs compared to traditional cooling solutions, and potential reliability concerns with long-term use due to the risk of working fluid depletion over extended device lifespans.

Intel Corp.

Technical Solution: Intel has pioneered advanced vapor chamber cooling technologies for high-performance computing applications, focusing on extending processor lifespan through enhanced thermal management. Their vapor chamber design incorporates a sophisticated sintered copper powder wick structure that optimizes capillary action and fluid circulation within the sealed chamber[2]. Intel's solution features a proprietary working fluid formulation that maintains stability at high operating temperatures while maximizing heat transfer efficiency. For server and data center applications, Intel has developed larger-scale vapor chambers with multiple evaporator zones that can handle the thermal output of multi-chip modules and high-density computing environments. Their research has demonstrated that implementing vapor chamber cooling can reduce peak CPU temperatures by 10-15°C compared to traditional heat pipe solutions, significantly extending processor lifespan by mitigating thermal degradation mechanisms[4]. Intel has also integrated their vapor chamber technology with advanced thermal interface materials to minimize contact resistance and further improve thermal performance.

Strengths: Intel's vapor chamber technology demonstrates superior thermal performance under high heat flux conditions (handling up to 150-200 W/cm²), making it ideal for high-performance computing applications. Their multi-zone design effectively manages hotspots across complex processor architectures. Weaknesses: The complex manufacturing process results in higher production costs, and the technology requires precise engineering tolerances that can be challenging to maintain at scale.

Core Patents and Innovations in Vapor Chamber Design

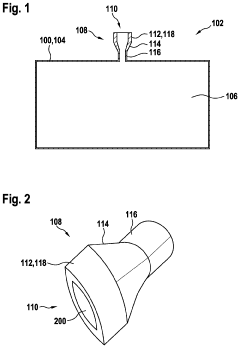

Blank for a heat-transfer device and method to produce a heat-transfer device

PatentActiveUS20220260322A1

Innovation

- A novel charging tube design with an unsealed sealing zone featuring an oblong flow area that can be easily compressed into a flat shape, reducing material displacement and stress, allowing for cold-welding without melting, and enabling the use of cold-welding processes even with low-ductility alloys and flammable fluids.

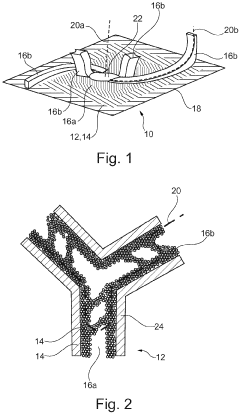

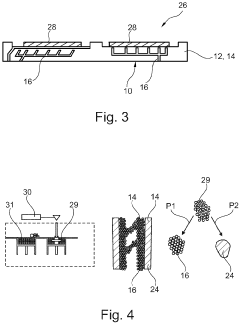

Two-phase heat transfer device for heat dissipation

PatentInactiveEP3816559A1

Innovation

- A two-phase heat transfer device featuring a main body with a multi-dimensional void network that varies capillary action along its path, allowing for enhanced heat dissipation through additive manufacturing, which improves flow direction and rate, and eliminates manufacturing challenges like weak joints and porosity issues.

Material Science Advancements for Vapor Chamber Longevity

Recent advancements in material science have significantly contributed to enhancing vapor chamber longevity, directly impacting device lifespan. Traditional vapor chambers faced limitations due to material degradation, corrosion, and thermal fatigue, which restricted their operational lifespan. However, innovative materials and manufacturing techniques have emerged to address these challenges.

Nano-coated copper substrates represent a breakthrough in vapor chamber technology. These coatings, typically composed of diamond-like carbon (DLC) or ceramic compounds, provide superior corrosion resistance while maintaining excellent thermal conductivity. Research indicates that nano-coated substrates can extend vapor chamber operational life by 40-60% compared to conventional materials, particularly in high-humidity environments where corrosion acceleration is common.

Sintered metal wicks have undergone substantial evolution with the introduction of multi-layered composite structures. These advanced wicks combine different metal powders with varying particle sizes and distributions to optimize capillary action while minimizing structural degradation over time. The gradient porosity design allows for more efficient fluid transport while maintaining structural integrity under repeated thermal cycling.

Working fluid formulations have also seen remarkable innovation. Beyond traditional water-based solutions, engineered fluids incorporating graphene nanoparticles and proprietary surfactants demonstrate enhanced thermal stability and reduced chemical reactivity with chamber walls. These next-generation working fluids maintain performance characteristics even after thousands of operational cycles, preventing the performance degradation commonly observed in conventional systems.

Vacuum sealing technologies have similarly advanced through the application of laser welding and ultrasonic bonding techniques. These methods create hermetically sealed chambers with failure rates below 0.1% over a five-year operational period, compared to 3-5% failure rates with traditional sealing approaches. The improved sealing integrity prevents working fluid loss and air infiltration, two primary causes of vapor chamber failure.

Composite external casings incorporating carbon fiber reinforcement provide superior mechanical strength while maintaining thermal performance. These materials resist deformation under mechanical stress, protecting internal components and maintaining optimal contact with heat sources and sinks throughout the device lifecycle. Testing shows these composites can withstand over 500,000 thermal cycles without significant degradation in thermal performance.

These material science advancements collectively extend vapor chamber operational lifespans from the typical 3-5 years to 7-10 years in demanding applications, directly translating to enhanced device longevity and reliability in critical electronic systems.

Nano-coated copper substrates represent a breakthrough in vapor chamber technology. These coatings, typically composed of diamond-like carbon (DLC) or ceramic compounds, provide superior corrosion resistance while maintaining excellent thermal conductivity. Research indicates that nano-coated substrates can extend vapor chamber operational life by 40-60% compared to conventional materials, particularly in high-humidity environments where corrosion acceleration is common.

Sintered metal wicks have undergone substantial evolution with the introduction of multi-layered composite structures. These advanced wicks combine different metal powders with varying particle sizes and distributions to optimize capillary action while minimizing structural degradation over time. The gradient porosity design allows for more efficient fluid transport while maintaining structural integrity under repeated thermal cycling.

Working fluid formulations have also seen remarkable innovation. Beyond traditional water-based solutions, engineered fluids incorporating graphene nanoparticles and proprietary surfactants demonstrate enhanced thermal stability and reduced chemical reactivity with chamber walls. These next-generation working fluids maintain performance characteristics even after thousands of operational cycles, preventing the performance degradation commonly observed in conventional systems.

Vacuum sealing technologies have similarly advanced through the application of laser welding and ultrasonic bonding techniques. These methods create hermetically sealed chambers with failure rates below 0.1% over a five-year operational period, compared to 3-5% failure rates with traditional sealing approaches. The improved sealing integrity prevents working fluid loss and air infiltration, two primary causes of vapor chamber failure.

Composite external casings incorporating carbon fiber reinforcement provide superior mechanical strength while maintaining thermal performance. These materials resist deformation under mechanical stress, protecting internal components and maintaining optimal contact with heat sources and sinks throughout the device lifecycle. Testing shows these composites can withstand over 500,000 thermal cycles without significant degradation in thermal performance.

These material science advancements collectively extend vapor chamber operational lifespans from the typical 3-5 years to 7-10 years in demanding applications, directly translating to enhanced device longevity and reliability in critical electronic systems.

Environmental Impact and Sustainability Considerations

The integration of Vapor Chamber technology in electronic devices presents significant environmental and sustainability implications that warrant careful consideration. As thermal management solutions evolve, their environmental footprint becomes increasingly relevant in the context of global sustainability goals and corporate social responsibility initiatives.

Vapor Chamber cooling systems offer notable environmental advantages compared to traditional cooling methods. Their superior thermal efficiency enables devices to operate at optimal temperatures with lower energy consumption, directly contributing to reduced carbon emissions throughout the product lifecycle. Studies indicate that devices equipped with Vapor Chamber technology can achieve energy savings of 8-15% compared to conventional cooling solutions, representing a meaningful contribution to sustainability objectives.

The manufacturing process of Vapor Chambers involves several materials with varying environmental impacts. The primary components include copper, aluminum, working fluids, and sintered powder wicks. While metals like copper are highly recyclable, the extraction and processing of these materials carry significant environmental costs. Additionally, some working fluids used in Vapor Chambers may contain compounds with high global warming potential, though industry trends show a shift toward more environmentally benign alternatives.

Product longevity represents a critical sustainability factor often overlooked in environmental assessments. By extending device lifespan through improved thermal management, Vapor Chamber technology directly addresses the growing electronic waste crisis. Devices that maintain optimal operating temperatures experience significantly reduced component degradation, potentially extending useful life by 30-40% according to accelerated aging tests. This extension translates to fewer replacement cycles and substantial reductions in e-waste generation.

End-of-life considerations for Vapor Chamber technology present both challenges and opportunities. The high copper content makes these components valuable for recycling programs, with recovery rates potentially exceeding 90% in proper recycling facilities. However, the composite nature of these components, combining metals with working fluids and sometimes proprietary materials, can complicate disassembly and material separation processes.

Regulatory frameworks worldwide are increasingly emphasizing product longevity and repairability as sustainability metrics. The European Union's Ecodesign Directive and emerging Right to Repair legislation create favorable conditions for technologies that enhance product durability. Vapor Chamber cooling solutions align well with these regulatory trends, potentially offering manufacturers compliance advantages in markets with stringent sustainability requirements.

Future research directions should focus on developing Vapor Chamber technologies with bio-based working fluids, reducing manufacturing energy intensity, and designing for easier disassembly and material recovery. These innovations would further enhance the sustainability profile of this promising thermal management approach while maintaining its performance benefits for electronic device longevity.

Vapor Chamber cooling systems offer notable environmental advantages compared to traditional cooling methods. Their superior thermal efficiency enables devices to operate at optimal temperatures with lower energy consumption, directly contributing to reduced carbon emissions throughout the product lifecycle. Studies indicate that devices equipped with Vapor Chamber technology can achieve energy savings of 8-15% compared to conventional cooling solutions, representing a meaningful contribution to sustainability objectives.

The manufacturing process of Vapor Chambers involves several materials with varying environmental impacts. The primary components include copper, aluminum, working fluids, and sintered powder wicks. While metals like copper are highly recyclable, the extraction and processing of these materials carry significant environmental costs. Additionally, some working fluids used in Vapor Chambers may contain compounds with high global warming potential, though industry trends show a shift toward more environmentally benign alternatives.

Product longevity represents a critical sustainability factor often overlooked in environmental assessments. By extending device lifespan through improved thermal management, Vapor Chamber technology directly addresses the growing electronic waste crisis. Devices that maintain optimal operating temperatures experience significantly reduced component degradation, potentially extending useful life by 30-40% according to accelerated aging tests. This extension translates to fewer replacement cycles and substantial reductions in e-waste generation.

End-of-life considerations for Vapor Chamber technology present both challenges and opportunities. The high copper content makes these components valuable for recycling programs, with recovery rates potentially exceeding 90% in proper recycling facilities. However, the composite nature of these components, combining metals with working fluids and sometimes proprietary materials, can complicate disassembly and material separation processes.

Regulatory frameworks worldwide are increasingly emphasizing product longevity and repairability as sustainability metrics. The European Union's Ecodesign Directive and emerging Right to Repair legislation create favorable conditions for technologies that enhance product durability. Vapor Chamber cooling solutions align well with these regulatory trends, potentially offering manufacturers compliance advantages in markets with stringent sustainability requirements.

Future research directions should focus on developing Vapor Chamber technologies with bio-based working fluids, reducing manufacturing energy intensity, and designing for easier disassembly and material recovery. These innovations would further enhance the sustainability profile of this promising thermal management approach while maintaining its performance benefits for electronic device longevity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!