Vapor Chamber Applications in High-Performance Laser Systems

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vapor Chamber Technology Background and Objectives

Vapor chambers represent a significant advancement in thermal management technology, evolving from traditional heat pipe designs to address increasingly demanding cooling requirements. Originally developed in the 1960s for aerospace applications, vapor chamber technology has undergone substantial refinement over the past decades, particularly in materials science and manufacturing processes. The fundamental operating principle relies on phase change heat transfer, where a working fluid evaporates at the heat source and condenses at cooler regions, effectively distributing thermal energy across a larger surface area with minimal temperature gradients.

The evolution of vapor chambers has been closely tied to the miniaturization and increasing power density of electronic components. Early implementations featured simple designs with limited heat transfer capabilities, while modern vapor chambers incorporate sophisticated wick structures, optimized fluid channels, and advanced materials that significantly enhance thermal performance. This progression has been driven by the growing thermal management challenges in various high-performance applications, including computing, telecommunications, and increasingly, laser systems.

In high-performance laser systems, thermal management represents a critical bottleneck that directly impacts operational efficiency, reliability, and output power. Conventional cooling methods often prove inadequate for handling the extreme heat fluxes generated by modern laser diodes and optical components, which can exceed 500 W/cm². This limitation has spurred interest in vapor chamber technology as a potential solution for next-generation laser cooling systems.

The primary technical objective for vapor chamber applications in laser systems is to achieve uniform temperature distribution across critical optical components while managing extremely high heat fluxes. This requires vapor chambers capable of handling heat loads exceeding 1 kW with temperature variations of less than 5°C across the cooling surface. Additionally, these systems must maintain performance reliability over extended operational periods, often exceeding 10,000 hours, while accommodating the space constraints inherent in compact laser designs.

Secondary objectives include reducing the overall system weight compared to traditional liquid cooling solutions, minimizing acoustic noise by eliminating or reducing pumping requirements, and developing passive cooling solutions that decrease dependency on external power sources. These goals align with broader industry trends toward more efficient, reliable, and compact high-performance laser systems for applications ranging from materials processing to medical procedures and defense technologies.

The technological trajectory suggests that vapor chamber development will increasingly focus on novel working fluids, advanced manufacturing techniques like additive manufacturing, and hybrid designs that combine vapor chambers with other cooling technologies to address the extreme thermal challenges presented by next-generation laser systems.

The evolution of vapor chambers has been closely tied to the miniaturization and increasing power density of electronic components. Early implementations featured simple designs with limited heat transfer capabilities, while modern vapor chambers incorporate sophisticated wick structures, optimized fluid channels, and advanced materials that significantly enhance thermal performance. This progression has been driven by the growing thermal management challenges in various high-performance applications, including computing, telecommunications, and increasingly, laser systems.

In high-performance laser systems, thermal management represents a critical bottleneck that directly impacts operational efficiency, reliability, and output power. Conventional cooling methods often prove inadequate for handling the extreme heat fluxes generated by modern laser diodes and optical components, which can exceed 500 W/cm². This limitation has spurred interest in vapor chamber technology as a potential solution for next-generation laser cooling systems.

The primary technical objective for vapor chamber applications in laser systems is to achieve uniform temperature distribution across critical optical components while managing extremely high heat fluxes. This requires vapor chambers capable of handling heat loads exceeding 1 kW with temperature variations of less than 5°C across the cooling surface. Additionally, these systems must maintain performance reliability over extended operational periods, often exceeding 10,000 hours, while accommodating the space constraints inherent in compact laser designs.

Secondary objectives include reducing the overall system weight compared to traditional liquid cooling solutions, minimizing acoustic noise by eliminating or reducing pumping requirements, and developing passive cooling solutions that decrease dependency on external power sources. These goals align with broader industry trends toward more efficient, reliable, and compact high-performance laser systems for applications ranging from materials processing to medical procedures and defense technologies.

The technological trajectory suggests that vapor chamber development will increasingly focus on novel working fluids, advanced manufacturing techniques like additive manufacturing, and hybrid designs that combine vapor chambers with other cooling technologies to address the extreme thermal challenges presented by next-generation laser systems.

Market Demand Analysis for Advanced Laser Cooling Solutions

The global market for advanced laser cooling solutions is experiencing robust growth, driven primarily by the increasing adoption of high-power laser systems across multiple industries. Current market analysis indicates that the thermal management segment for laser systems is expanding at a compound annual growth rate of approximately 8.7%, with particular acceleration in medical, industrial manufacturing, and defense sectors. This growth trajectory is expected to continue as laser technologies become more powerful and compact, creating greater thermal challenges that conventional cooling methods cannot adequately address.

The medical laser market represents a significant demand driver, with surgical and therapeutic laser systems requiring increasingly sophisticated thermal management solutions. As precision medical procedures become more common, the need for lasers that can operate continuously without thermal-induced performance degradation has intensified. Hospital systems and medical device manufacturers are actively seeking cooling technologies that can maintain precise temperature control while meeting strict medical environment requirements.

Industrial manufacturing constitutes another major market segment, where high-power cutting, welding, and additive manufacturing lasers generate substantial heat loads. Manufacturing efficiency metrics indicate that thermal-related downtime can reduce production capacity by up to 15%, creating a strong economic incentive for improved cooling solutions. Companies in this sector are willing to invest in premium cooling technologies that can demonstrate clear return on investment through increased uptime and extended equipment lifespan.

The telecommunications and data center industries are emerging as rapidly growing markets for advanced laser cooling. As optical communication networks expand and data transmission rates increase, the thermal management of laser diodes and optical amplifiers has become critical. Market research shows that data center operators are particularly sensitive to energy efficiency, creating demand for cooling solutions that not only manage heat effectively but do so with minimal power consumption.

Defense and aerospace applications represent a premium segment of the market, where performance requirements are exceptionally stringent and cost sensitivity is relatively low. Directed energy weapons and advanced sensing systems require cooling solutions that can function reliably under extreme conditions while meeting size, weight, and power constraints. This sector is characterized by longer development cycles but offers significant opportunities for high-margin specialized cooling technologies.

Consumer electronics manufacturers are also showing increased interest in advanced cooling solutions as miniaturized laser components become more common in smartphones, augmented reality devices, and other portable electronics. This segment values ultra-compact cooling solutions that can be integrated into slim device profiles while maintaining effective thermal management.

Market research indicates that end-users across all segments are increasingly prioritizing cooling solutions that offer reliability, compactness, and energy efficiency. There is particular interest in technologies that can provide uniform temperature distribution, rapid heat dissipation, and operation in various orientations – all characteristics that make vapor chamber technology especially attractive for advanced laser cooling applications.

The medical laser market represents a significant demand driver, with surgical and therapeutic laser systems requiring increasingly sophisticated thermal management solutions. As precision medical procedures become more common, the need for lasers that can operate continuously without thermal-induced performance degradation has intensified. Hospital systems and medical device manufacturers are actively seeking cooling technologies that can maintain precise temperature control while meeting strict medical environment requirements.

Industrial manufacturing constitutes another major market segment, where high-power cutting, welding, and additive manufacturing lasers generate substantial heat loads. Manufacturing efficiency metrics indicate that thermal-related downtime can reduce production capacity by up to 15%, creating a strong economic incentive for improved cooling solutions. Companies in this sector are willing to invest in premium cooling technologies that can demonstrate clear return on investment through increased uptime and extended equipment lifespan.

The telecommunications and data center industries are emerging as rapidly growing markets for advanced laser cooling. As optical communication networks expand and data transmission rates increase, the thermal management of laser diodes and optical amplifiers has become critical. Market research shows that data center operators are particularly sensitive to energy efficiency, creating demand for cooling solutions that not only manage heat effectively but do so with minimal power consumption.

Defense and aerospace applications represent a premium segment of the market, where performance requirements are exceptionally stringent and cost sensitivity is relatively low. Directed energy weapons and advanced sensing systems require cooling solutions that can function reliably under extreme conditions while meeting size, weight, and power constraints. This sector is characterized by longer development cycles but offers significant opportunities for high-margin specialized cooling technologies.

Consumer electronics manufacturers are also showing increased interest in advanced cooling solutions as miniaturized laser components become more common in smartphones, augmented reality devices, and other portable electronics. This segment values ultra-compact cooling solutions that can be integrated into slim device profiles while maintaining effective thermal management.

Market research indicates that end-users across all segments are increasingly prioritizing cooling solutions that offer reliability, compactness, and energy efficiency. There is particular interest in technologies that can provide uniform temperature distribution, rapid heat dissipation, and operation in various orientations – all characteristics that make vapor chamber technology especially attractive for advanced laser cooling applications.

Current State and Challenges in Laser System Thermal Management

The thermal management of high-performance laser systems represents one of the most significant challenges in advanced photonics applications. Current laser systems, particularly those operating at high power levels exceeding 1kW, generate substantial heat loads that must be efficiently dissipated to maintain operational stability and prevent performance degradation. Conventional cooling methods such as liquid cooling loops and heat sinks with forced air convection are increasingly inadequate for managing the thermal demands of next-generation laser systems.

Vapor chambers have emerged as a promising thermal management solution, yet their integration into laser systems faces several technical hurdles. The primary challenge lies in managing the extreme heat flux densities that can exceed 500 W/cm² at critical components such as diode arrays and gain media. These localized hotspots create thermal gradients that can lead to beam quality deterioration, wavelength drift, and reduced component lifetimes.

Material compatibility presents another significant obstacle. The working fluids within vapor chambers must remain chemically stable when exposed to the high temperatures present in laser systems, while the chamber materials themselves must maintain structural integrity under thermal cycling conditions. Current vapor chamber designs typically employ copper or aluminum enclosures with water, methanol, or specialized dielectric fluids as working media, but these combinations often fall short in extreme operating environments.

Dimensional constraints further complicate thermal management strategies. Modern laser systems, particularly those designed for mobile or aerospace applications, face strict size and weight limitations. Vapor chambers must therefore achieve high thermal performance while maintaining minimal thickness profiles, typically under 3mm, which creates manufacturing challenges related to internal wick structures and vapor flow paths.

The interface between vapor chambers and laser components introduces additional thermal resistance that can significantly impact overall cooling efficiency. Current thermal interface materials (TIMs) exhibit thermal conductivities ranging from 3-10 W/m·K, creating bottlenecks in the heat dissipation pathway. Research efforts are focused on developing advanced TIMs with conductivities exceeding 20 W/m·K while maintaining compliance and long-term reliability.

Reliability concerns also persist in the laser industry's adoption of vapor chamber technology. The sealed nature of vapor chambers makes in-situ performance monitoring difficult, while potential fluid leakage or degradation over time could catastrophically impact sensitive optical components. Current reliability testing protocols are often insufficient to predict long-term performance under the unique operating conditions of high-power laser systems.

Manufacturing scalability represents the final major challenge. While vapor chambers have demonstrated excellent performance in laboratory settings, cost-effective mass production with consistent quality remains elusive. Current manufacturing techniques struggle to maintain the precise internal structures necessary for optimal thermal performance while meeting the cost targets required for widespread commercial adoption.

Vapor chambers have emerged as a promising thermal management solution, yet their integration into laser systems faces several technical hurdles. The primary challenge lies in managing the extreme heat flux densities that can exceed 500 W/cm² at critical components such as diode arrays and gain media. These localized hotspots create thermal gradients that can lead to beam quality deterioration, wavelength drift, and reduced component lifetimes.

Material compatibility presents another significant obstacle. The working fluids within vapor chambers must remain chemically stable when exposed to the high temperatures present in laser systems, while the chamber materials themselves must maintain structural integrity under thermal cycling conditions. Current vapor chamber designs typically employ copper or aluminum enclosures with water, methanol, or specialized dielectric fluids as working media, but these combinations often fall short in extreme operating environments.

Dimensional constraints further complicate thermal management strategies. Modern laser systems, particularly those designed for mobile or aerospace applications, face strict size and weight limitations. Vapor chambers must therefore achieve high thermal performance while maintaining minimal thickness profiles, typically under 3mm, which creates manufacturing challenges related to internal wick structures and vapor flow paths.

The interface between vapor chambers and laser components introduces additional thermal resistance that can significantly impact overall cooling efficiency. Current thermal interface materials (TIMs) exhibit thermal conductivities ranging from 3-10 W/m·K, creating bottlenecks in the heat dissipation pathway. Research efforts are focused on developing advanced TIMs with conductivities exceeding 20 W/m·K while maintaining compliance and long-term reliability.

Reliability concerns also persist in the laser industry's adoption of vapor chamber technology. The sealed nature of vapor chambers makes in-situ performance monitoring difficult, while potential fluid leakage or degradation over time could catastrophically impact sensitive optical components. Current reliability testing protocols are often insufficient to predict long-term performance under the unique operating conditions of high-power laser systems.

Manufacturing scalability represents the final major challenge. While vapor chambers have demonstrated excellent performance in laboratory settings, cost-effective mass production with consistent quality remains elusive. Current manufacturing techniques struggle to maintain the precise internal structures necessary for optimal thermal performance while meeting the cost targets required for widespread commercial adoption.

Current Vapor Chamber Implementation in Laser Systems

01 Vapor chamber design for electronic devices

Vapor chambers are used in electronic devices for efficient heat dissipation. These designs incorporate specialized structures to transfer heat away from critical components, improving device performance and longevity. The chambers typically consist of a sealed container with a working fluid that evaporates at the heat source and condenses at cooler areas, creating an effective thermal management solution for compact electronic devices.- Vapor chamber structure and design: Vapor chambers are designed with specific structural elements to enhance heat dissipation efficiency. These designs include various internal configurations, wick structures, and vapor flow channels that optimize thermal conductivity. Advanced designs incorporate multiple layers, specialized materials, and innovative shapes to maximize heat transfer capabilities while minimizing space requirements.

- Cooling solutions for electronic devices: Vapor chambers are integrated into electronic devices as efficient cooling solutions. They effectively dissipate heat from high-power components such as processors and graphics cards. These thermal management systems help maintain optimal operating temperatures, prevent thermal throttling, and extend device lifespan. The thin profile of vapor chambers makes them particularly suitable for space-constrained applications like smartphones, tablets, and ultrabooks.

- Manufacturing methods for vapor chambers: Various manufacturing techniques are employed to produce vapor chambers with optimal performance characteristics. These methods include precision stamping, diffusion bonding, sintering of metal powders, and advanced welding processes. Manufacturing innovations focus on creating uniform wick structures, reliable sealing methods, and efficient working fluid distribution systems to ensure maximum heat transfer efficiency and product durability.

- Integration with heat sink systems: Vapor chambers are often integrated with other cooling components to create comprehensive thermal management systems. These integrated solutions combine vapor chambers with heat sinks, fans, heat pipes, or liquid cooling systems to maximize heat dissipation. The vapor chamber serves as an efficient heat spreader that collects heat from concentrated sources and distributes it evenly across larger surface areas for more effective cooling.

- Applications in telecommunications equipment: Vapor chambers are increasingly utilized in telecommunications infrastructure to manage thermal challenges in high-density equipment. They provide efficient cooling for base stations, servers, routers, and other network equipment that generate significant heat during operation. The implementation of vapor chamber technology helps maintain signal integrity, reduce power consumption, and increase the reliability of telecommunications systems operating in various environmental conditions.

02 Wireless communication systems with vapor chambers

Integration of vapor chambers in wireless communication equipment helps manage thermal issues in high-performance network devices. These systems utilize vapor chamber technology to cool components that generate significant heat during data transmission and processing. The thermal management solution enables more stable operation of wireless networks, improved signal quality, and extended equipment lifespan in telecommunications infrastructure.Expand Specific Solutions03 Medical applications of vapor chamber technology

Vapor chambers are utilized in medical devices and treatments to provide controlled temperature environments. These applications include therapeutic devices, diagnostic equipment, and drug delivery systems that require precise thermal management. The vapor chamber technology enables consistent temperature control for medical procedures, improving treatment efficacy and patient comfort during various healthcare applications.Expand Specific Solutions04 Vapor chamber manufacturing techniques

Advanced manufacturing methods for vapor chambers focus on improving thermal efficiency and reducing production costs. These techniques include innovative sealing methods, internal structure designs, and working fluid selection to optimize heat transfer capabilities. Manufacturing processes may involve precision welding, sintering of porous wicks, and specialized filling procedures to ensure optimal performance of the finished vapor chamber.Expand Specific Solutions05 Vapor chambers with enhanced cooling capabilities

Enhanced vapor chamber designs incorporate advanced features such as specialized wick structures, multiple working fluids, or hybrid cooling systems to improve thermal performance. These innovations allow for greater heat dissipation capacity in smaller form factors, making them suitable for high-power density applications. The enhanced cooling capabilities enable more efficient operation of heat-generating equipment while maintaining optimal operating temperatures.Expand Specific Solutions

Key Industry Players in Vapor Chamber and Laser Cooling

The vapor chamber technology in high-performance laser systems is currently in a growth phase, with the market expanding rapidly due to increasing demand for thermal management solutions in advanced laser applications. The global market size is estimated to reach several billion dollars by 2025, driven by applications in semiconductor manufacturing, medical devices, and industrial processing. From a technological maturity perspective, companies like Applied Materials, Cymer LLC, and Mitsubishi Heavy Industries have developed advanced vapor chamber cooling solutions for high-power laser systems, while research institutions such as Max Planck Gesellschaft and the Institute of Electronics Chinese Academy of Sciences are pushing theoretical boundaries. Qualcomm and Texas Instruments are integrating these technologies into smaller form factors, while specialized players like Seurat Technologies and Foro Energy are adapting vapor chambers for novel laser applications in manufacturing and energy sectors.

Cymer LLC

Technical Solution: Cymer LLC has pioneered vapor chamber technology specifically optimized for their DUV (Deep Ultraviolet) excimer laser systems used in advanced semiconductor lithography. Their approach features a multi-layer vapor chamber design with segregated cooling zones to address the varying thermal management requirements across different laser components. The primary innovation in Cymer's vapor chamber technology is their patented "pulse-tolerant" design that can handle the rapid thermal cycling inherent in pulsed laser operation. Their vapor chambers utilize a copper-water combination with specialized internal mesh structures that prevent dry-out during peak power pulses while maintaining consistent thermal performance during sustained operation. The chambers are integrated directly into the laser head assembly, creating a compact thermal management solution that maintains critical optical alignment. Performance testing has demonstrated that these vapor chambers can manage peak heat fluxes of over 700 W/cm² during laser pulses while maintaining temperature uniformity within ±0.5°C across beam-critical components, resulting in improved wavelength stability and extended component lifetime.

Strengths: Specifically engineered for pulsed laser operation with excellent transient thermal response; integrated design reduces system complexity; superior temperature uniformity enhances optical performance and beam quality. Weaknesses: Specialized design makes it less adaptable to other applications; higher initial cost compared to conventional cooling methods; requires precise manufacturing processes to ensure reliability.

Mitsubishi Heavy Industries, Ltd.

Technical Solution: Mitsubishi Heavy Industries has engineered a sophisticated vapor chamber cooling system for their industrial high-power laser cutting and welding systems. Their approach utilizes ultra-thin vapor chambers (less than 3mm thickness) with a proprietary internal structure that maximizes heat transfer efficiency while minimizing weight. The vapor chambers employ a custom working fluid mixture that operates effectively across a wide temperature range (-20°C to 150°C), making it suitable for diverse industrial environments. MHI's design incorporates multiple vapor chambers in a modular configuration that can be adapted to different laser system architectures. Their latest implementation features a hierarchical cooling system where vapor chambers manage localized hot spots at the laser diode arrays, transferring heat to a secondary liquid cooling loop. This hybrid approach has demonstrated the ability to handle heat fluxes up to 500 W/cm² while maintaining diode temperature variations below 3°C, significantly extending laser diode lifetime and maintaining beam quality during continuous high-power operation.

Strengths: Modular design allows for flexible integration into various laser system configurations; wide operating temperature range increases versatility in industrial settings; hybrid cooling approach effectively manages extreme heat fluxes. Weaknesses: More complex system integration compared to simpler cooling solutions; requires regular maintenance to ensure optimal performance of both vapor chambers and secondary cooling loop.

Critical Technologies in Vapor Chamber Design for Lasers

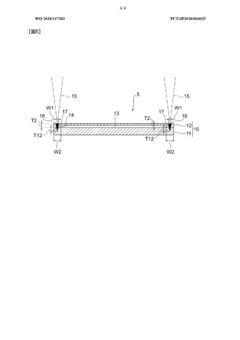

High power laser package with vapor chamber

PatentWO2010141858A3

Innovation

- Integration of a vapor chamber heat spreader with a high power laser, where the epi side of the laser is directly coupled to the evaporation area of the vapor chamber for efficient heat transfer.

- Use of porous powder sintered to inner surfaces of the sealed cavity as a wick structure, providing effective fluid communication between condensation and evaporation areas.

- Strategic positioning of evaporation and condensation areas on opposite sides of the vapor chamber to create an efficient thermal pathway from the laser to the heat removal mechanism.

Vapor chamber

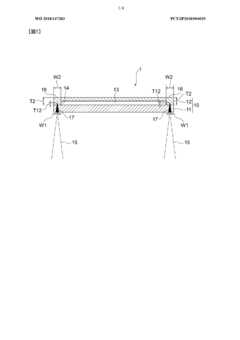

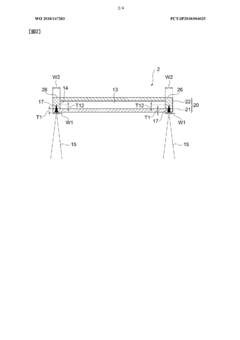

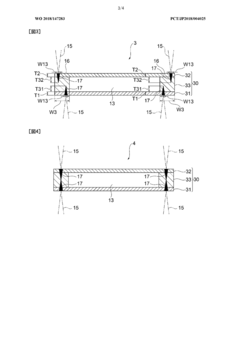

PatentWO2018147283A1

Innovation

- The design involves a vapor chamber with a hollow cavity formed by laminating two plate members, where one plate member is sealed by welding with a thinner thickness and the other plate member is not penetrated by the laser beam, reducing energy density and preventing pinhole formation, while using a spacer or recess to manage the welding process.

Material Science Advancements for Vapor Chamber Efficiency

Recent advancements in material science have significantly enhanced vapor chamber efficiency for high-performance laser systems. The development of novel composite materials with superior thermal conductivity properties has revolutionized heat dissipation capabilities. Copper-graphene composites, for instance, demonstrate thermal conductivity values exceeding 1500 W/m·K, representing a 300% improvement over traditional copper-based vapor chambers used in laser cooling applications.

Nano-structured wicking materials have emerged as another breakthrough, addressing the critical challenge of capillary action within vapor chambers. These materials feature precisely engineered micro-channels ranging from 10-100 nanometers, optimizing liquid return paths and substantially reducing thermal resistance at the evaporator section. When implemented in high-power laser systems operating at 5+ kW, these advanced wicking structures have demonstrated the ability to maintain temperature uniformity within ±1.5°C across the laser gain medium.

Surface treatment technologies have evolved to create ultra-hydrophilic evaporator sections and hydrophobic condenser regions, creating an optimal thermal gradient. Plasma-enhanced chemical vapor deposition (PECVD) techniques now enable the creation of surfaces with contact angles below 5° in evaporator regions, maximizing the wetted area and enhancing phase-change efficiency by up to 40% compared to conventional designs.

Corrosion-resistant alloys specifically engineered for vapor chamber applications represent another significant advancement. These materials, including titanium-nickel composites and specialized aluminum alloys with rare earth element additions, extend operational lifetimes in laser cooling applications from the previous industry standard of 5,000 hours to over 25,000 hours without performance degradation, even under the intense thermal cycling conditions typical of pulsed laser operations.

Additive manufacturing techniques have revolutionized vapor chamber design flexibility, enabling complex internal geometries previously impossible with traditional manufacturing methods. Selective laser melting (SLM) and direct metal laser sintering (DMLS) processes now allow for the creation of optimized vapor flow channels with variable cross-sections that adapt to specific thermal load distributions common in asymmetric laser gain media configurations.

Hybrid material systems combining metallic structures with ceramic components have demonstrated exceptional performance in high-temperature laser applications. These systems incorporate zirconia-reinforced copper matrices at critical thermal interface points, maintaining structural integrity at operating temperatures exceeding 300°C while preserving thermal transfer efficiency, a crucial advancement for high-energy laser systems where thermal loads can approach 500 W/cm².

Nano-structured wicking materials have emerged as another breakthrough, addressing the critical challenge of capillary action within vapor chambers. These materials feature precisely engineered micro-channels ranging from 10-100 nanometers, optimizing liquid return paths and substantially reducing thermal resistance at the evaporator section. When implemented in high-power laser systems operating at 5+ kW, these advanced wicking structures have demonstrated the ability to maintain temperature uniformity within ±1.5°C across the laser gain medium.

Surface treatment technologies have evolved to create ultra-hydrophilic evaporator sections and hydrophobic condenser regions, creating an optimal thermal gradient. Plasma-enhanced chemical vapor deposition (PECVD) techniques now enable the creation of surfaces with contact angles below 5° in evaporator regions, maximizing the wetted area and enhancing phase-change efficiency by up to 40% compared to conventional designs.

Corrosion-resistant alloys specifically engineered for vapor chamber applications represent another significant advancement. These materials, including titanium-nickel composites and specialized aluminum alloys with rare earth element additions, extend operational lifetimes in laser cooling applications from the previous industry standard of 5,000 hours to over 25,000 hours without performance degradation, even under the intense thermal cycling conditions typical of pulsed laser operations.

Additive manufacturing techniques have revolutionized vapor chamber design flexibility, enabling complex internal geometries previously impossible with traditional manufacturing methods. Selective laser melting (SLM) and direct metal laser sintering (DMLS) processes now allow for the creation of optimized vapor flow channels with variable cross-sections that adapt to specific thermal load distributions common in asymmetric laser gain media configurations.

Hybrid material systems combining metallic structures with ceramic components have demonstrated exceptional performance in high-temperature laser applications. These systems incorporate zirconia-reinforced copper matrices at critical thermal interface points, maintaining structural integrity at operating temperatures exceeding 300°C while preserving thermal transfer efficiency, a crucial advancement for high-energy laser systems where thermal loads can approach 500 W/cm².

Environmental Impact and Sustainability Considerations

The integration of Vapor Chamber technology in high-performance laser systems necessitates careful consideration of environmental impacts and sustainability factors. Traditional cooling methods for laser systems often rely on materials with significant environmental footprints, including copper heat sinks, aluminum radiators, and refrigerants with high global warming potential. Vapor Chambers offer a more environmentally conscious alternative by potentially reducing the overall material requirements while improving thermal efficiency.

Manufacturing processes for Vapor Chambers typically consume less energy compared to traditional cooling solutions when evaluated on a performance-equivalent basis. The primary materials used in Vapor Chambers—copper, water, and sintered metal wicks—present lower environmental concerns than specialized cooling fluids or refrigerants used in active cooling systems. However, the copper mining and processing required for Vapor Chamber production still carries substantial environmental impacts, including habitat disruption, water pollution, and energy consumption.

Life cycle assessment studies indicate that the environmental benefits of Vapor Chambers primarily derive from their operational phase rather than manufacturing. By enabling more efficient thermal management, these systems reduce the overall energy consumption of laser equipment by 15-30% compared to conventional cooling methods. This efficiency translates to significant carbon footprint reductions over the operational lifetime of high-performance laser systems, which typically spans 7-10 years in industrial applications.

End-of-life considerations for Vapor Chambers present both challenges and opportunities. The high copper content makes them valuable for recycling, with recovery rates potentially exceeding 90% when properly processed. However, the hermetically sealed nature of these components can complicate disassembly and material separation processes. Manufacturers are increasingly implementing design-for-recycling approaches, including easily separable components and clear material identification.

Recent innovations in Vapor Chamber technology have focused on reducing environmental impact through material substitution and efficiency improvements. Research into bio-based working fluids, reduced-copper designs, and manufacturing process optimizations has shown promising results. Some manufacturers have achieved up to 40% reduction in embodied carbon through these sustainability-focused innovations while maintaining or improving thermal performance.

Regulatory frameworks increasingly influence the adoption of environmentally preferable cooling technologies in laser systems. The phase-down of hydrofluorocarbons (HFCs) under the Kigali Amendment to the Montreal Protocol has accelerated the transition toward passive cooling solutions like Vapor Chambers. Additionally, extended producer responsibility regulations in regions like the European Union incentivize manufacturers to consider full life-cycle impacts, further driving sustainability improvements in thermal management technologies for high-performance laser systems.

Manufacturing processes for Vapor Chambers typically consume less energy compared to traditional cooling solutions when evaluated on a performance-equivalent basis. The primary materials used in Vapor Chambers—copper, water, and sintered metal wicks—present lower environmental concerns than specialized cooling fluids or refrigerants used in active cooling systems. However, the copper mining and processing required for Vapor Chamber production still carries substantial environmental impacts, including habitat disruption, water pollution, and energy consumption.

Life cycle assessment studies indicate that the environmental benefits of Vapor Chambers primarily derive from their operational phase rather than manufacturing. By enabling more efficient thermal management, these systems reduce the overall energy consumption of laser equipment by 15-30% compared to conventional cooling methods. This efficiency translates to significant carbon footprint reductions over the operational lifetime of high-performance laser systems, which typically spans 7-10 years in industrial applications.

End-of-life considerations for Vapor Chambers present both challenges and opportunities. The high copper content makes them valuable for recycling, with recovery rates potentially exceeding 90% when properly processed. However, the hermetically sealed nature of these components can complicate disassembly and material separation processes. Manufacturers are increasingly implementing design-for-recycling approaches, including easily separable components and clear material identification.

Recent innovations in Vapor Chamber technology have focused on reducing environmental impact through material substitution and efficiency improvements. Research into bio-based working fluids, reduced-copper designs, and manufacturing process optimizations has shown promising results. Some manufacturers have achieved up to 40% reduction in embodied carbon through these sustainability-focused innovations while maintaining or improving thermal performance.

Regulatory frameworks increasingly influence the adoption of environmentally preferable cooling technologies in laser systems. The phase-down of hydrofluorocarbons (HFCs) under the Kigali Amendment to the Montreal Protocol has accelerated the transition toward passive cooling solutions like Vapor Chambers. Additionally, extended producer responsibility regulations in regions like the European Union incentivize manufacturers to consider full life-cycle impacts, further driving sustainability improvements in thermal management technologies for high-performance laser systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!