Vapor Chamber Applications in Next-Generation EV Batteries

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vapor Chamber Technology Evolution in EV Battery Cooling

Vapor chamber technology has undergone significant evolution in its application to EV battery cooling systems. Initially developed for electronics cooling in consumer devices, vapor chambers have transitioned into automotive applications over the past decade. The first-generation implementations around 2015 were primarily experimental, featuring simple flat-plate designs with limited heat transfer capacity of 50-100 W/cm². These early systems demonstrated the basic concept but lacked the sophistication needed for large-scale battery packs.

By 2018, second-generation vapor chambers emerged with improved wick structures and working fluids specifically engineered for the temperature ranges common in EV batteries (20-60°C). These systems incorporated sintered copper powder wicks that enhanced capillary action and heat transfer capabilities, pushing performance to 150-200 W/cm². This period marked the transition from laboratory testing to limited production implementations in premium electric vehicles.

The current third-generation technology (2020-2023) features advanced vapor chamber designs with integrated multi-directional heat spreading capabilities and thermal conductivities exceeding 3000 W/m·K—significantly outperforming traditional cooling methods. These systems incorporate composite wick structures and custom-engineered working fluids that maintain performance across wider temperature ranges (-20°C to 80°C), addressing the challenging thermal conditions of fast-charging scenarios.

A notable technological milestone occurred in 2021 when manufacturers developed ultra-thin vapor chambers (under 1.5mm thickness) that could be directly integrated into battery module structures, eliminating thermal interface materials and reducing thermal resistance. This innovation decreased thermal gradients within battery packs by up to 40% compared to conventional liquid cooling systems.

Recent developments in 2022-2023 have focused on vapor chambers with variable conductance features that provide adaptive cooling based on battery load conditions. These systems incorporate smart materials that modify heat transfer characteristics in response to temperature changes, optimizing cooling efficiency across diverse operating scenarios from slow urban driving to high-speed highway conditions and rapid charging events.

The technology roadmap indicates continued evolution toward fully integrated thermal management systems where vapor chambers work in conjunction with phase change materials and active cooling systems. Research trends suggest future vapor chambers will likely incorporate nanostructured wicks and environmentally friendly working fluids to replace traditional options with high global warming potential, aligning with sustainability goals while maintaining or improving thermal performance.

By 2018, second-generation vapor chambers emerged with improved wick structures and working fluids specifically engineered for the temperature ranges common in EV batteries (20-60°C). These systems incorporated sintered copper powder wicks that enhanced capillary action and heat transfer capabilities, pushing performance to 150-200 W/cm². This period marked the transition from laboratory testing to limited production implementations in premium electric vehicles.

The current third-generation technology (2020-2023) features advanced vapor chamber designs with integrated multi-directional heat spreading capabilities and thermal conductivities exceeding 3000 W/m·K—significantly outperforming traditional cooling methods. These systems incorporate composite wick structures and custom-engineered working fluids that maintain performance across wider temperature ranges (-20°C to 80°C), addressing the challenging thermal conditions of fast-charging scenarios.

A notable technological milestone occurred in 2021 when manufacturers developed ultra-thin vapor chambers (under 1.5mm thickness) that could be directly integrated into battery module structures, eliminating thermal interface materials and reducing thermal resistance. This innovation decreased thermal gradients within battery packs by up to 40% compared to conventional liquid cooling systems.

Recent developments in 2022-2023 have focused on vapor chambers with variable conductance features that provide adaptive cooling based on battery load conditions. These systems incorporate smart materials that modify heat transfer characteristics in response to temperature changes, optimizing cooling efficiency across diverse operating scenarios from slow urban driving to high-speed highway conditions and rapid charging events.

The technology roadmap indicates continued evolution toward fully integrated thermal management systems where vapor chambers work in conjunction with phase change materials and active cooling systems. Research trends suggest future vapor chambers will likely incorporate nanostructured wicks and environmentally friendly working fluids to replace traditional options with high global warming potential, aligning with sustainability goals while maintaining or improving thermal performance.

Market Demand Analysis for Advanced EV Thermal Management

The electric vehicle (EV) market is experiencing unprecedented growth, with global sales projected to reach 14 million units in 2023, representing a 35% year-over-year increase. This rapid expansion is driving significant demand for advanced thermal management solutions, particularly as battery technology evolves toward higher energy densities and faster charging capabilities. Thermal management has emerged as a critical factor in EV performance, safety, and longevity, creating a substantial market opportunity for innovative cooling technologies like vapor chambers.

Current market analysis indicates that the global EV thermal management system market is valued at approximately $3.5 billion in 2023 and is expected to grow at a CAGR of 22% through 2030. This growth is primarily driven by increasing consumer demands for extended range, faster charging times, and enhanced battery longevity - all factors directly impacted by thermal management efficiency.

Consumer expectations are shifting dramatically, with surveys indicating that 78% of potential EV buyers consider fast charging capabilities essential, while 65% express concerns about battery degradation over time. These consumer priorities are creating market pressure for more sophisticated thermal solutions that can maintain optimal battery temperatures during high-power charging and discharge cycles.

Regulatory frameworks are further accelerating market demand, with several jurisdictions implementing stringent safety standards for EV batteries. The EU Battery Regulation and similar frameworks in North America and Asia are establishing temperature management requirements that conventional cooling systems struggle to meet cost-effectively, creating market pull for vapor chamber technology.

Industry stakeholders, including major automotive OEMs and tier-one suppliers, are increasingly recognizing thermal management as a competitive differentiator. Market research indicates that 82% of automotive executives consider advanced thermal management a high or critical priority for their EV development programs, up from just 45% three years ago.

The market landscape shows significant regional variations, with the Asia-Pacific region currently leading adoption of advanced thermal solutions due to its dominant position in battery manufacturing. However, North American and European markets are showing the fastest growth rates in premium thermal management adoption as they compete to establish domestic EV supply chains.

Economic factors are also driving market demand, with analysis showing that advanced thermal management systems can reduce battery pack costs by 8-12% over vehicle lifetime through improved longevity and reduced warranty claims. This cost-benefit equation is becoming increasingly favorable as vapor chamber manufacturing scales and technology matures.

Current market analysis indicates that the global EV thermal management system market is valued at approximately $3.5 billion in 2023 and is expected to grow at a CAGR of 22% through 2030. This growth is primarily driven by increasing consumer demands for extended range, faster charging times, and enhanced battery longevity - all factors directly impacted by thermal management efficiency.

Consumer expectations are shifting dramatically, with surveys indicating that 78% of potential EV buyers consider fast charging capabilities essential, while 65% express concerns about battery degradation over time. These consumer priorities are creating market pressure for more sophisticated thermal solutions that can maintain optimal battery temperatures during high-power charging and discharge cycles.

Regulatory frameworks are further accelerating market demand, with several jurisdictions implementing stringent safety standards for EV batteries. The EU Battery Regulation and similar frameworks in North America and Asia are establishing temperature management requirements that conventional cooling systems struggle to meet cost-effectively, creating market pull for vapor chamber technology.

Industry stakeholders, including major automotive OEMs and tier-one suppliers, are increasingly recognizing thermal management as a competitive differentiator. Market research indicates that 82% of automotive executives consider advanced thermal management a high or critical priority for their EV development programs, up from just 45% three years ago.

The market landscape shows significant regional variations, with the Asia-Pacific region currently leading adoption of advanced thermal solutions due to its dominant position in battery manufacturing. However, North American and European markets are showing the fastest growth rates in premium thermal management adoption as they compete to establish domestic EV supply chains.

Economic factors are also driving market demand, with analysis showing that advanced thermal management systems can reduce battery pack costs by 8-12% over vehicle lifetime through improved longevity and reduced warranty claims. This cost-benefit equation is becoming increasingly favorable as vapor chamber manufacturing scales and technology matures.

Current Challenges in EV Battery Thermal Management

Electric vehicle (EV) battery thermal management systems face significant challenges in maintaining optimal operating temperatures across diverse conditions. Current lithium-ion battery technologies operate efficiently within a narrow temperature range (20-40°C), with performance degradation and safety risks occurring outside this window. Thermal runaway remains a critical concern, where uncontrolled temperature increases can trigger catastrophic chain reactions within battery packs.

Existing cooling solutions predominantly rely on liquid cooling systems that circulate coolant through channels adjacent to battery cells. While effective, these systems add considerable weight, complexity, and cost to EV designs. Air cooling alternatives, though simpler, lack sufficient cooling capacity for high-performance applications and rapid charging scenarios. Both approaches struggle with thermal gradient issues, where temperature differences across the battery pack lead to uneven aging and performance.

Fast charging capabilities, increasingly demanded by consumers, generate substantial heat that current systems struggle to dissipate efficiently. This limitation forces manufacturers to implement charging speed restrictions that hamper user experience. Additionally, extreme ambient conditions—particularly cold environments—necessitate energy-intensive heating systems that significantly reduce vehicle range.

Space constraints within modern EV designs further complicate thermal management implementation, as packaging requirements become increasingly stringent. The industry also faces challenges in balancing thermal management effectiveness against energy consumption, as parasitic losses from pumps, fans, and control systems can reduce overall vehicle efficiency by 1-5%.

Reliability concerns persist across thermal management systems, with potential points of failure including pumps, valves, sensors, and seals. These components must maintain performance over the vehicle's lifetime while withstanding vibration, temperature cycling, and environmental exposure. Maintenance accessibility remains problematic in many designs, complicating service procedures.

Cost pressures represent another significant hurdle, as advanced thermal management solutions must achieve price points compatible with mass-market adoption. Current systems typically account for 10-15% of total battery pack costs, creating tension between performance requirements and economic viability.

Environmental considerations add further complexity, with regulations increasingly restricting refrigerant types and mandating recyclability. The industry must develop solutions that minimize environmental impact throughout the product lifecycle while maintaining thermal performance. These multifaceted challenges highlight the need for innovative approaches like vapor chamber technology that can address thermal management requirements more effectively than conventional methods.

Existing cooling solutions predominantly rely on liquid cooling systems that circulate coolant through channels adjacent to battery cells. While effective, these systems add considerable weight, complexity, and cost to EV designs. Air cooling alternatives, though simpler, lack sufficient cooling capacity for high-performance applications and rapid charging scenarios. Both approaches struggle with thermal gradient issues, where temperature differences across the battery pack lead to uneven aging and performance.

Fast charging capabilities, increasingly demanded by consumers, generate substantial heat that current systems struggle to dissipate efficiently. This limitation forces manufacturers to implement charging speed restrictions that hamper user experience. Additionally, extreme ambient conditions—particularly cold environments—necessitate energy-intensive heating systems that significantly reduce vehicle range.

Space constraints within modern EV designs further complicate thermal management implementation, as packaging requirements become increasingly stringent. The industry also faces challenges in balancing thermal management effectiveness against energy consumption, as parasitic losses from pumps, fans, and control systems can reduce overall vehicle efficiency by 1-5%.

Reliability concerns persist across thermal management systems, with potential points of failure including pumps, valves, sensors, and seals. These components must maintain performance over the vehicle's lifetime while withstanding vibration, temperature cycling, and environmental exposure. Maintenance accessibility remains problematic in many designs, complicating service procedures.

Cost pressures represent another significant hurdle, as advanced thermal management solutions must achieve price points compatible with mass-market adoption. Current systems typically account for 10-15% of total battery pack costs, creating tension between performance requirements and economic viability.

Environmental considerations add further complexity, with regulations increasingly restricting refrigerant types and mandating recyclability. The industry must develop solutions that minimize environmental impact throughout the product lifecycle while maintaining thermal performance. These multifaceted challenges highlight the need for innovative approaches like vapor chamber technology that can address thermal management requirements more effectively than conventional methods.

Current Vapor Chamber Implementation Strategies

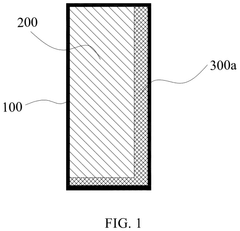

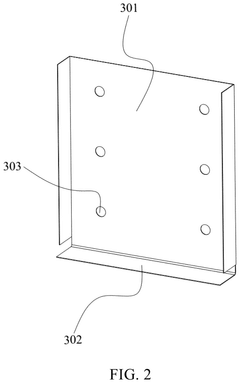

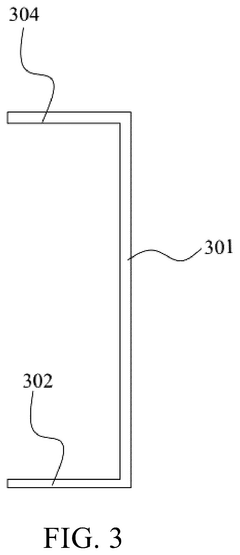

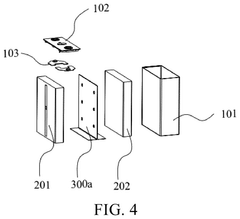

01 Vapor chamber structure and design

Vapor chambers are designed with specific structural elements to enhance heat dissipation. These designs include various internal configurations, wick structures, and vapor flow channels that optimize thermal performance. The chambers typically consist of a sealed container with a working fluid that evaporates at the heat source and condenses at cooler areas, effectively transferring heat across the device.- Vapor chamber structure and design: Vapor chambers are designed with specific structural elements to enhance heat dissipation. These designs include various internal configurations, wick structures, and vapor flow channels that optimize thermal performance. The chambers typically consist of a sealed container with a working fluid that evaporates at the heat source and condenses at cooler areas, effectively transferring heat across the device.

- Vapor chamber applications in electronic devices: Vapor chambers are widely implemented in electronic devices for thermal management. They are particularly valuable in compact devices like smartphones, tablets, and laptops where space is limited but heat dissipation is critical. These thermal solutions help maintain optimal operating temperatures for processors and other heat-generating components, improving device performance and longevity.

- Advanced materials for vapor chamber efficiency: The efficiency of vapor chambers is significantly influenced by the materials used in their construction. Advanced materials with high thermal conductivity are employed for the chamber walls, while specialized wicking materials enhance capillary action. Innovative working fluids with optimal phase-change properties are also developed to maximize heat transfer capacity and overall thermal performance.

- Integration of vapor chambers in cooling systems: Vapor chambers are often integrated with other cooling components to create comprehensive thermal management systems. These integrations may include combinations with heat sinks, fans, thermal interface materials, and liquid cooling solutions. Such hybrid approaches maximize cooling efficiency in high-performance computing systems, telecommunications equipment, and other applications with significant thermal challenges.

- Manufacturing techniques for vapor chambers: Specialized manufacturing techniques are employed to produce effective vapor chambers. These include precision welding, sintering processes for wick structures, vacuum sealing methods, and working fluid charging procedures. Advanced fabrication approaches enable the creation of ultra-thin vapor chambers, three-dimensional designs, and customized shapes to meet specific application requirements while maintaining optimal thermal performance.

02 Vapor chamber cooling solutions for electronic devices

Vapor chambers are implemented in electronic devices to manage thermal issues. These cooling solutions are particularly valuable in compact devices like smartphones, tablets, and laptops where traditional cooling methods are limited by space constraints. The vapor chamber technology allows for efficient heat spreading across the device, preventing hotspots and maintaining optimal operating temperatures for sensitive components.Expand Specific Solutions03 Wireless communication systems with vapor chamber cooling

Telecommunications equipment and wireless communication systems incorporate vapor chamber cooling to manage heat generated by high-power transmission components. These systems benefit from the efficient thermal management provided by vapor chambers, allowing for more reliable operation of base stations, network equipment, and other communication infrastructure. The cooling technology helps maintain signal integrity and extends the operational lifespan of these systems.Expand Specific Solutions04 Manufacturing methods for vapor chambers

Various manufacturing techniques are employed to produce vapor chambers with optimal performance characteristics. These methods include specialized bonding processes, working fluid selection and filling procedures, and wick structure fabrication. Advanced manufacturing approaches enable the creation of ultra-thin vapor chambers, custom shapes, and designs tailored to specific thermal management requirements across different applications.Expand Specific Solutions05 Medical and healthcare applications of vapor chambers

Vapor chamber technology is utilized in medical devices and healthcare applications for temperature regulation and thermal management. These applications include temperature-controlled drug delivery systems, medical imaging equipment cooling, and therapeutic devices that require precise thermal control. The efficient heat transfer capabilities of vapor chambers enable more compact and reliable medical equipment design.Expand Specific Solutions

Key Industry Players in EV Thermal Management Solutions

The vapor chamber technology in next-generation EV batteries is currently in an early growth phase, with the market expected to expand significantly as EV adoption accelerates globally. The competitive landscape is characterized by major battery manufacturers and automotive companies investing in thermal management solutions. LG Energy Solution, SAMSUNG SDI, and Panasonic Holdings lead in commercial applications, while automotive giants like Toyota, Honda, and SAIC Motor are integrating these technologies into their EV platforms. Chinese companies including Hubei Yiwei Power and Beijing Electric Vehicle are rapidly advancing their capabilities. Research institutions such as South China University of Technology and University of Michigan are developing next-generation vapor chamber designs, indicating the technology is transitioning from research to commercial implementation with significant potential for thermal efficiency improvements in high-performance EV battery systems.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed an innovative vapor chamber cooling system specifically designed for high-energy-density EV battery packs. Their technology features a multi-layered vapor chamber architecture that sandwiches between battery cells, creating an efficient thermal interface with minimal thermal resistance. The system incorporates a novel composite wick structure combining sintered metal powder and mesh designs to optimize fluid circulation across different operating conditions. LG's vapor chambers utilize proprietary working fluids with customized boiling points matched to typical EV battery operating temperatures (20-45°C). The chambers are integrated into a comprehensive battery thermal management system that includes intelligent thermal routing to prioritize cooling for cells experiencing higher temperatures. This approach has demonstrated the ability to reduce maximum temperature differences between cells by up to 40% compared to conventional cooling methods, while also enabling faster charging capabilities without thermal degradation.

Strengths: Excellent thermal uniformity across large battery packs, reduced system complexity compared to liquid cooling, and compatibility with various cell form factors. Weaknesses: Manufacturing complexity requiring specialized equipment, potential for performance degradation over extended vehicle lifetime, and higher material costs.

Honda Motor Co., Ltd.

Technical Solution: Honda has developed an advanced vapor chamber cooling system for EV batteries that focuses on weight reduction and thermal efficiency. Their design features an aluminum-silicon alloy vapor chamber with internal pillar structures that provide mechanical strength while maintaining optimal vapor flow paths. The system incorporates a hybrid wick structure that combines mesh and grooved surfaces to enhance fluid circulation across various operating orientations and g-forces experienced in automotive applications. Honda's implementation integrates the vapor chambers directly into the battery module frame, reducing thermal interfaces and improving overall system efficiency. Their technology utilizes a proprietary working fluid formulation that maintains consistent performance across the wide temperature range experienced in automotive environments (-30°C to 60°C). The system includes pressure relief mechanisms to ensure safety during extreme conditions and has demonstrated the ability to handle rapid temperature fluctuations during aggressive driving cycles and fast-charging scenarios.

Strengths: Lightweight design optimized for automotive applications, excellent thermal response during dynamic load changes, and seamless integration with existing battery architectures. Weaknesses: Higher initial production costs, more complex manufacturing process requiring specialized equipment, and potential challenges with long-term reliability verification.

Critical Patents and Innovations in Vapor Chamber Technology

Battery and battery pack

PatentPendingUS20250158167A1

Innovation

- The proposed solution involves a battery design that includes a housing with an accommodating cavity for an electrode assembly, and a vapor chamber with a first side plate part attached to the side wall of the electrode assembly and a first bottom plate part between the electrode assembly and the housing. This configuration allows for effective heat transfer and dissipation through a cooling plate, reducing temperature differences within the battery cell.

Design and analysis of copper made vapour chamber for electric vehicle cooling system

PatentPendingIN202341050402A

Innovation

- A copper-based brazing material with specific alloy compositions, including 20-35% nickel, 5-20% zinc, 5-20% manganese, 1-10% chromium, 0.1-5% silicon, and 0-7% molybdenum, which offers improved oxidation resistance, corrosion resistance, and deformability, allowing for induction brazing with a melting point below 1150°C and excellent wetting behavior on stainless steel surfaces.

Safety Standards and Compliance for EV Thermal Systems

The integration of Vapor Chamber technology in next-generation EV batteries necessitates rigorous adherence to evolving safety standards and compliance frameworks. Current regulatory bodies, including the International Electrotechnical Commission (IEC), Society of Automotive Engineers (SAE), and United Nations Economic Commission for Europe (UNECE), have established comprehensive guidelines specifically addressing thermal management systems in electric vehicles.

IEC 62660 and SAE J2929 standards explicitly outline thermal runaway prevention requirements, with recent amendments incorporating specific provisions for advanced cooling technologies like Vapor Chambers. These standards mandate thermal isolation between cells, maximum temperature gradient specifications, and thermal propagation prevention measures—all areas where Vapor Chamber technology must demonstrate compliance.

Regulatory frameworks across major markets show notable variations. The European Union's ECE R100 regulation has recently updated its thermal management requirements, while China's GB/T 31467 standard now includes specific clauses for vapor-based cooling systems. The United States NHTSA guidelines emphasize performance-based approaches rather than prescriptive requirements for thermal management technologies.

Testing protocols for Vapor Chamber implementations in EV batteries require specialized methodologies beyond conventional thermal management systems. These include thermal cycling under extreme conditions (-40°C to +85°C), vibration resistance testing specific to vapor-based systems, and thermal runaway containment verification. The UN38.3 test procedure has been adapted to address the unique characteristics of vapor chamber cooling systems.

Certification processes for Vapor Chamber-equipped battery systems involve multi-stage validation, including computational fluid dynamics (CFD) simulation validation, physical prototype testing, and accelerated aging assessments. Third-party certification bodies have developed specialized testing protocols for vapor-based cooling technologies in automotive applications.

Future regulatory trends indicate increasing stringency in thermal management requirements, with particular focus on thermal propagation prevention and rapid heat dissipation capabilities—areas where Vapor Chamber technology offers significant advantages. The upcoming ISO 21782 standard is expected to include specific provisions for advanced cooling technologies, potentially creating a more standardized global framework for Vapor Chamber implementation in EV batteries.

IEC 62660 and SAE J2929 standards explicitly outline thermal runaway prevention requirements, with recent amendments incorporating specific provisions for advanced cooling technologies like Vapor Chambers. These standards mandate thermal isolation between cells, maximum temperature gradient specifications, and thermal propagation prevention measures—all areas where Vapor Chamber technology must demonstrate compliance.

Regulatory frameworks across major markets show notable variations. The European Union's ECE R100 regulation has recently updated its thermal management requirements, while China's GB/T 31467 standard now includes specific clauses for vapor-based cooling systems. The United States NHTSA guidelines emphasize performance-based approaches rather than prescriptive requirements for thermal management technologies.

Testing protocols for Vapor Chamber implementations in EV batteries require specialized methodologies beyond conventional thermal management systems. These include thermal cycling under extreme conditions (-40°C to +85°C), vibration resistance testing specific to vapor-based systems, and thermal runaway containment verification. The UN38.3 test procedure has been adapted to address the unique characteristics of vapor chamber cooling systems.

Certification processes for Vapor Chamber-equipped battery systems involve multi-stage validation, including computational fluid dynamics (CFD) simulation validation, physical prototype testing, and accelerated aging assessments. Third-party certification bodies have developed specialized testing protocols for vapor-based cooling technologies in automotive applications.

Future regulatory trends indicate increasing stringency in thermal management requirements, with particular focus on thermal propagation prevention and rapid heat dissipation capabilities—areas where Vapor Chamber technology offers significant advantages. The upcoming ISO 21782 standard is expected to include specific provisions for advanced cooling technologies, potentially creating a more standardized global framework for Vapor Chamber implementation in EV batteries.

Environmental Impact and Sustainability Considerations

The integration of Vapor Chamber technology in next-generation EV batteries presents significant environmental implications that warrant careful consideration. The manufacturing process of vapor chambers typically involves metals like copper, aluminum, and stainless steel, which require substantial energy for extraction and processing. However, when compared to traditional thermal management systems, vapor chambers offer a more resource-efficient alternative due to their lightweight design and reduced material requirements.

From a lifecycle perspective, vapor chambers contribute to extended battery longevity by maintaining optimal operating temperatures, thereby reducing the frequency of battery replacements. This extension of battery service life directly translates to decreased raw material extraction and processing needs over time, mitigating the environmental footprint associated with battery production and disposal.

Energy efficiency represents another critical environmental dimension of vapor chamber implementation. By enhancing thermal management efficiency, these systems enable batteries to operate closer to their ideal temperature range, reducing energy losses during charging and discharging cycles. This improved efficiency cascades through the entire vehicle system, potentially decreasing overall energy consumption and associated greenhouse gas emissions throughout the vehicle's operational lifespan.

End-of-life considerations reveal both challenges and opportunities. While vapor chambers introduce additional materials into the battery system, their predominantly metallic composition facilitates recycling processes. The high thermal conductivity metals used in vapor chambers maintain significant value in secondary material markets, creating economic incentives for proper recycling rather than disposal.

Water usage in vapor chamber manufacturing presents a notable environmental concern, particularly in regions experiencing water scarcity. The production process requires ultrapure water for cleaning and testing phases, necessitating water treatment systems that may increase the technology's environmental footprint in water-stressed areas.

Regulatory compliance frameworks increasingly emphasize lifecycle environmental impact assessments for automotive components. Vapor chamber manufacturers must navigate evolving standards regarding material selection, manufacturing processes, and end-of-life management. Forward-thinking companies are proactively developing environmental product declarations (EPDs) to quantify and communicate the environmental performance of their vapor chamber technologies.

The transition toward more sustainable vapor chamber designs represents an active area of innovation, with research focusing on bio-based working fluids, recycled metal content, and design optimizations that minimize material usage while maintaining thermal performance.

From a lifecycle perspective, vapor chambers contribute to extended battery longevity by maintaining optimal operating temperatures, thereby reducing the frequency of battery replacements. This extension of battery service life directly translates to decreased raw material extraction and processing needs over time, mitigating the environmental footprint associated with battery production and disposal.

Energy efficiency represents another critical environmental dimension of vapor chamber implementation. By enhancing thermal management efficiency, these systems enable batteries to operate closer to their ideal temperature range, reducing energy losses during charging and discharging cycles. This improved efficiency cascades through the entire vehicle system, potentially decreasing overall energy consumption and associated greenhouse gas emissions throughout the vehicle's operational lifespan.

End-of-life considerations reveal both challenges and opportunities. While vapor chambers introduce additional materials into the battery system, their predominantly metallic composition facilitates recycling processes. The high thermal conductivity metals used in vapor chambers maintain significant value in secondary material markets, creating economic incentives for proper recycling rather than disposal.

Water usage in vapor chamber manufacturing presents a notable environmental concern, particularly in regions experiencing water scarcity. The production process requires ultrapure water for cleaning and testing phases, necessitating water treatment systems that may increase the technology's environmental footprint in water-stressed areas.

Regulatory compliance frameworks increasingly emphasize lifecycle environmental impact assessments for automotive components. Vapor chamber manufacturers must navigate evolving standards regarding material selection, manufacturing processes, and end-of-life management. Forward-thinking companies are proactively developing environmental product declarations (EPDs) to quantify and communicate the environmental performance of their vapor chamber technologies.

The transition toward more sustainable vapor chamber designs represents an active area of innovation, with research focusing on bio-based working fluids, recycled metal content, and design optimizations that minimize material usage while maintaining thermal performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!