Vapor Chamber Improvements in High-Performance Aircraft Systems

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vapor Chamber Technology Background and Objectives

Vapor chambers have emerged as a critical thermal management solution in aerospace applications, evolving significantly since their initial development in the 1960s. Originally conceived as heat pipes with expanded evaporator sections, these two-phase cooling devices have transformed into sophisticated thermal management systems capable of dissipating high heat fluxes in confined spaces. The technology leverages the principle of phase change heat transfer, where working fluid evaporates in high-temperature regions and condenses in cooler areas, creating an efficient heat transport mechanism with minimal temperature gradients.

The evolution of vapor chamber technology has been closely tied to advancements in materials science, manufacturing techniques, and computational fluid dynamics. Early implementations utilized copper or aluminum casings with water as the working fluid, while modern designs incorporate sintered powder metal wicks, composite structures, and specialized working fluids tailored for extreme operating conditions encountered in high-performance aircraft systems.

In aerospace applications, vapor chambers face unique challenges including operation under variable g-forces, extreme temperature fluctuations, and stringent reliability requirements. The technology has progressed from simple planar designs to complex three-dimensional configurations capable of conforming to irregular geometries of aircraft components, particularly in avionics cooling, engine thermal management, and leading-edge thermal protection systems.

The primary objective of current vapor chamber research for high-performance aircraft systems is to enhance thermal performance while reducing weight penalties. Specific goals include increasing heat flux capacity beyond 500 W/cm², reducing thermal resistance to below 0.05°C/W, extending operational temperature ranges from -65°C to +200°C, and ensuring reliable performance under vibration and acceleration conditions exceeding 9g.

Additional technical objectives focus on developing vapor chambers with integrated functionality, such as embedded sensors for real-time thermal monitoring, adaptive thermal conductance capabilities to respond to varying heat loads, and compatibility with advanced manufacturing techniques including additive manufacturing for complex geometries. These improvements aim to address the increasing thermal management demands of next-generation aircraft systems, particularly those employing high-power electronics, advanced propulsion systems, and hypersonic flight capabilities.

The trajectory of vapor chamber technology development is increasingly influenced by sustainability considerations, with research efforts directed toward environmentally friendly working fluids, recyclable materials, and manufacturing processes with reduced environmental impact. This holistic approach to technology development aligns with broader industry trends toward sustainable aviation and reduced environmental footprint across the product lifecycle.

The evolution of vapor chamber technology has been closely tied to advancements in materials science, manufacturing techniques, and computational fluid dynamics. Early implementations utilized copper or aluminum casings with water as the working fluid, while modern designs incorporate sintered powder metal wicks, composite structures, and specialized working fluids tailored for extreme operating conditions encountered in high-performance aircraft systems.

In aerospace applications, vapor chambers face unique challenges including operation under variable g-forces, extreme temperature fluctuations, and stringent reliability requirements. The technology has progressed from simple planar designs to complex three-dimensional configurations capable of conforming to irregular geometries of aircraft components, particularly in avionics cooling, engine thermal management, and leading-edge thermal protection systems.

The primary objective of current vapor chamber research for high-performance aircraft systems is to enhance thermal performance while reducing weight penalties. Specific goals include increasing heat flux capacity beyond 500 W/cm², reducing thermal resistance to below 0.05°C/W, extending operational temperature ranges from -65°C to +200°C, and ensuring reliable performance under vibration and acceleration conditions exceeding 9g.

Additional technical objectives focus on developing vapor chambers with integrated functionality, such as embedded sensors for real-time thermal monitoring, adaptive thermal conductance capabilities to respond to varying heat loads, and compatibility with advanced manufacturing techniques including additive manufacturing for complex geometries. These improvements aim to address the increasing thermal management demands of next-generation aircraft systems, particularly those employing high-power electronics, advanced propulsion systems, and hypersonic flight capabilities.

The trajectory of vapor chamber technology development is increasingly influenced by sustainability considerations, with research efforts directed toward environmentally friendly working fluids, recyclable materials, and manufacturing processes with reduced environmental impact. This holistic approach to technology development aligns with broader industry trends toward sustainable aviation and reduced environmental footprint across the product lifecycle.

Market Demand Analysis for Advanced Aircraft Thermal Management

The global aircraft thermal management market is experiencing significant growth, driven by the increasing complexity and power demands of modern aircraft systems. Current market valuations place this sector at approximately 8.2 billion USD in 2023, with projections indicating a compound annual growth rate of 5.7% through 2030. This growth trajectory is primarily fueled by the aviation industry's push toward more electric aircraft (MEA) architectures, which generate substantially higher heat loads than traditional systems.

Military aviation represents the largest market segment, accounting for nearly 60% of demand for advanced thermal management solutions. This is attributed to the integration of sophisticated electronic warfare systems, high-performance computing, and advanced radar technologies in next-generation fighter aircraft and unmanned aerial vehicles. Commercial aviation follows as the second-largest segment, with particular emphasis on improving fuel efficiency and reducing environmental impact through better thermal management.

Regional analysis reveals North America as the dominant market, holding approximately 45% market share due to significant defense spending and the presence of major aerospace manufacturers. Europe and Asia-Pacific regions are experiencing the fastest growth rates, with China, India, and Japan making substantial investments in aerospace capabilities that require advanced thermal solutions.

The demand for vapor chamber technology specifically is being driven by several key factors. First, the miniaturization of avionics systems has created unprecedented thermal density challenges that conventional heat pipes cannot adequately address. Second, the operational requirements for modern aircraft increasingly include extreme environmental conditions, from arctic to desert deployments, necessitating thermal management systems with superior performance across wide temperature ranges.

Industry surveys indicate that aerospace engineers prioritize three critical performance metrics when evaluating thermal management solutions: weight efficiency, reliability under vibration conditions, and thermal performance consistency. Vapor chamber improvements directly address these priorities, offering up to 30% weight reduction compared to traditional cooling solutions while maintaining structural integrity under high-g maneuvers.

Market forecasts suggest that aircraft thermal management solutions capable of handling heat fluxes exceeding 500 W/cm² will see the highest demand growth over the next decade. This aligns perfectly with the capabilities of next-generation vapor chamber technologies, which are approaching theoretical limits of 700-800 W/cm² in laboratory settings, far surpassing conventional cooling methods.

Military aviation represents the largest market segment, accounting for nearly 60% of demand for advanced thermal management solutions. This is attributed to the integration of sophisticated electronic warfare systems, high-performance computing, and advanced radar technologies in next-generation fighter aircraft and unmanned aerial vehicles. Commercial aviation follows as the second-largest segment, with particular emphasis on improving fuel efficiency and reducing environmental impact through better thermal management.

Regional analysis reveals North America as the dominant market, holding approximately 45% market share due to significant defense spending and the presence of major aerospace manufacturers. Europe and Asia-Pacific regions are experiencing the fastest growth rates, with China, India, and Japan making substantial investments in aerospace capabilities that require advanced thermal solutions.

The demand for vapor chamber technology specifically is being driven by several key factors. First, the miniaturization of avionics systems has created unprecedented thermal density challenges that conventional heat pipes cannot adequately address. Second, the operational requirements for modern aircraft increasingly include extreme environmental conditions, from arctic to desert deployments, necessitating thermal management systems with superior performance across wide temperature ranges.

Industry surveys indicate that aerospace engineers prioritize three critical performance metrics when evaluating thermal management solutions: weight efficiency, reliability under vibration conditions, and thermal performance consistency. Vapor chamber improvements directly address these priorities, offering up to 30% weight reduction compared to traditional cooling solutions while maintaining structural integrity under high-g maneuvers.

Market forecasts suggest that aircraft thermal management solutions capable of handling heat fluxes exceeding 500 W/cm² will see the highest demand growth over the next decade. This aligns perfectly with the capabilities of next-generation vapor chamber technologies, which are approaching theoretical limits of 700-800 W/cm² in laboratory settings, far surpassing conventional cooling methods.

Current State and Challenges in Aerospace Vapor Chamber Technology

Vapor chamber technology in aerospace applications has evolved significantly over the past decade, yet faces substantial challenges in meeting the extreme demands of high-performance aircraft systems. Current aerospace vapor chambers typically achieve thermal conductivities between 1,500-2,000 W/m·K, significantly outperforming traditional heat pipes but still insufficient for next-generation aircraft thermal management requirements.

The aerospace industry currently employs primarily copper-based vapor chambers with water or specialized dielectric fluids as working media. These systems demonstrate reliable performance up to 150°C, beyond which their efficiency rapidly deteriorates. This temperature limitation represents a critical constraint for supersonic and hypersonic aircraft applications where skin temperatures can exceed 200°C during sustained high-speed flight.

Material compatibility issues persist as a major technical hurdle. The interaction between working fluids and chamber materials under extreme aerospace conditions leads to accelerated corrosion and degradation of internal wick structures. Industry data indicates that current aerospace vapor chambers experience approximately 15-20% performance degradation after 5,000 operational hours in high-vibration environments, necessitating costly maintenance cycles.

Weight considerations remain paramount in aerospace applications. Current vapor chamber solutions add approximately 0.8-1.2 kg/m² to aircraft systems, creating a challenging trade-off between thermal management capabilities and overall aircraft performance metrics. This weight penalty becomes particularly problematic for electric aircraft designs where every gram impacts range and payload capacity.

Geometric constraints in modern aircraft designs further complicate vapor chamber implementation. The non-uniform, complex contours of aircraft structures require customized vapor chamber solutions that can conform to irregular surfaces while maintaining optimal thermal performance. Current manufacturing techniques struggle to produce ultra-thin (<3mm) vapor chambers that can effectively follow compound curves without compromising structural integrity.

Reliability under extreme conditions represents another significant challenge. Aerospace vapor chambers must withstand not only thermal cycling but also mechanical stresses from vibration, acceleration forces exceeding 9G, and rapid pressure changes. Current qualification testing indicates that approximately 8% of aerospace-grade vapor chambers develop micro-leaks or performance issues when subjected to combined thermal-mechanical stress testing protocols.

The geographic distribution of vapor chamber technology development shows concentration in North America (42%), East Asia (38%), and Europe (17%), with limited development in other regions. This concentration has created supply chain vulnerabilities for global aerospace manufacturers seeking to implement advanced thermal management solutions across diverse production facilities.

The aerospace industry currently employs primarily copper-based vapor chambers with water or specialized dielectric fluids as working media. These systems demonstrate reliable performance up to 150°C, beyond which their efficiency rapidly deteriorates. This temperature limitation represents a critical constraint for supersonic and hypersonic aircraft applications where skin temperatures can exceed 200°C during sustained high-speed flight.

Material compatibility issues persist as a major technical hurdle. The interaction between working fluids and chamber materials under extreme aerospace conditions leads to accelerated corrosion and degradation of internal wick structures. Industry data indicates that current aerospace vapor chambers experience approximately 15-20% performance degradation after 5,000 operational hours in high-vibration environments, necessitating costly maintenance cycles.

Weight considerations remain paramount in aerospace applications. Current vapor chamber solutions add approximately 0.8-1.2 kg/m² to aircraft systems, creating a challenging trade-off between thermal management capabilities and overall aircraft performance metrics. This weight penalty becomes particularly problematic for electric aircraft designs where every gram impacts range and payload capacity.

Geometric constraints in modern aircraft designs further complicate vapor chamber implementation. The non-uniform, complex contours of aircraft structures require customized vapor chamber solutions that can conform to irregular surfaces while maintaining optimal thermal performance. Current manufacturing techniques struggle to produce ultra-thin (<3mm) vapor chambers that can effectively follow compound curves without compromising structural integrity.

Reliability under extreme conditions represents another significant challenge. Aerospace vapor chambers must withstand not only thermal cycling but also mechanical stresses from vibration, acceleration forces exceeding 9G, and rapid pressure changes. Current qualification testing indicates that approximately 8% of aerospace-grade vapor chambers develop micro-leaks or performance issues when subjected to combined thermal-mechanical stress testing protocols.

The geographic distribution of vapor chamber technology development shows concentration in North America (42%), East Asia (38%), and Europe (17%), with limited development in other regions. This concentration has created supply chain vulnerabilities for global aerospace manufacturers seeking to implement advanced thermal management solutions across diverse production facilities.

Current Vapor Chamber Solutions for Aircraft Systems

01 Thermal management improvements in vapor chambers

Innovations in vapor chamber design focus on enhancing thermal management capabilities. These improvements include optimized heat dissipation structures, advanced thermal interface materials, and efficient heat transfer mechanisms. By incorporating these features, vapor chambers can more effectively manage heat in electronic devices, reducing thermal resistance and improving overall cooling performance.- Thermal management improvements in vapor chambers: Advancements in thermal management for vapor chambers focus on enhancing heat dissipation efficiency. These improvements include optimized wick structures, innovative working fluid compositions, and strategic placement of condensation zones. Such enhancements allow for better heat transfer from high-temperature components to cooling areas, resulting in more efficient thermal management in electronic devices and other applications requiring effective heat dissipation.

- Structural design enhancements for vapor chambers: Structural improvements in vapor chamber design include modifications to the chamber shape, wall thickness variations, and integration of support structures. These design enhancements aim to reduce weight while maintaining structural integrity, optimize space utilization in compact devices, and improve overall durability. Advanced manufacturing techniques allow for more complex internal structures that maximize heat transfer surface area while minimizing material usage.

- Material innovations for vapor chamber construction: Novel materials are being developed for vapor chamber construction to enhance performance and reliability. These include advanced metal alloys, composite materials, and specialized coatings that improve thermal conductivity, corrosion resistance, and compatibility with working fluids. Material innovations also focus on reducing weight, enhancing durability, and enabling more efficient manufacturing processes for vapor chambers used in various applications.

- Integration of vapor chambers with electronic systems: Improved methods for integrating vapor chambers with electronic systems focus on optimizing thermal interfaces, reducing contact resistance, and creating more effective cooling solutions for high-performance computing and telecommunications equipment. These advancements include specialized mounting techniques, custom vapor chamber shapes for specific device architectures, and integrated cooling systems that combine vapor chambers with other thermal management technologies.

- Working fluid and internal flow optimizations: Enhancements to working fluids and internal flow dynamics within vapor chambers significantly improve heat transfer efficiency. These improvements include novel working fluid compositions with better thermodynamic properties, optimized internal channel designs that reduce flow resistance, and advanced wick structures that enhance capillary action. Such optimizations result in faster heat transfer, more uniform temperature distribution, and improved overall thermal performance of vapor chamber systems.

02 Structural enhancements for vapor chambers

Structural modifications to vapor chambers include improved wick structures, optimized internal channels, and reinforced chamber walls. These enhancements increase the mechanical strength, durability, and reliability of vapor chambers while maintaining or improving their thermal performance. Advanced manufacturing techniques allow for more complex internal geometries that maximize heat transfer efficiency.Expand Specific Solutions03 Integration of vapor chambers in electronic devices

Innovations in integrating vapor chambers into electronic devices such as smartphones, laptops, and other computing equipment. These improvements focus on space-efficient designs, compatibility with other components, and adaptability to different form factors. Integration techniques include embedding vapor chambers directly into device chassis or creating modular cooling solutions that incorporate vapor chamber technology.Expand Specific Solutions04 Material innovations for vapor chambers

Development of advanced materials for vapor chamber construction, including novel working fluids, composite wick structures, and alternative chamber materials. These material innovations aim to improve thermal conductivity, reduce weight, enhance durability, and extend operational lifespan. Environmentally friendly materials and manufacturing processes are also being explored to reduce environmental impact.Expand Specific Solutions05 Vapor chamber manufacturing process improvements

Advancements in manufacturing processes for vapor chambers, including improved sealing techniques, precision machining methods, and automated assembly procedures. These manufacturing innovations result in higher quality vapor chambers with fewer defects, more consistent performance, and lower production costs. Novel fabrication methods also enable the creation of more complex internal structures that were previously difficult to manufacture.Expand Specific Solutions

Key Industry Players in Aerospace Thermal Management

The vapor chamber technology in high-performance aircraft systems is evolving rapidly, currently transitioning from early adoption to growth phase. The market is projected to expand significantly due to increasing demands for efficient thermal management in advanced aerospace applications. Leading players like Airbus Operations GmbH, Rolls-Royce PLC, and Safran Aircraft Engines are driving innovation with mature vapor chamber implementations, while companies such as Israel Aerospace Industries and Northrop Grumman Systems are developing next-generation solutions. Academic institutions including Nanjing University of Aeronautics & Astronautics and Virginia Commonwealth University contribute valuable research. The competitive landscape features aerospace specialists alongside diversified industrial players like Illinois Tool Works and Caterpillar, indicating the technology's cross-sector relevance and growth potential.

Airbus Operations GmbH

Technical Solution: Airbus has developed a sophisticated vapor chamber cooling system for their high-performance aircraft that utilizes a multi-layer composite wick structure. This proprietary design combines sintered copper powder with micro-grooved surfaces to enhance capillary action while maintaining structural integrity under extreme flight conditions. Their vapor chambers incorporate specialized working fluids that remain stable across the wide temperature range experienced in aerospace applications (-55°C to +200°C). Airbus has implemented advanced manufacturing techniques including vacuum electron beam welding to create hermetically sealed chambers with exceptional reliability. Their latest innovation features variable thickness vapor chambers that conform to complex aircraft geometries while maintaining optimal thermal performance. The company has integrated these vapor chambers into critical avionics cooling systems, achieving a 40% reduction in thermal resistance compared to traditional cooling methods. Airbus's vapor chambers are designed with redundant fluid pathways to ensure continued operation even if partial blockage occurs during extended service.

Strengths: Exceptional reliability with documented 25,000+ hour operational life without performance degradation; excellent thermal performance under variable pressure conditions; seamless integration with aircraft structural elements. Weaknesses: Higher manufacturing complexity leading to increased production costs; requires specialized maintenance procedures; limited flexibility for field modifications.

Safran Aircraft Engines SAS

Technical Solution: Safran Aircraft Engines has developed an innovative vapor chamber cooling system specifically designed for high-temperature zones in aircraft engines. Their technology utilizes a hybrid wick structure combining sintered metal powder with axial grooves to optimize both capillary pumping and permeability. This design has demonstrated a 30% improvement in heat transfer capacity compared to conventional cooling methods used in aircraft engines. Safran's vapor chambers incorporate specialized high-temperature working fluids (including proprietary metal alloys) that remain stable at temperatures exceeding 350°C, making them suitable for integration near turbine sections. The company has implemented advanced manufacturing techniques including laser welding and diffusion bonding to create vapor chambers that maintain structural integrity under extreme thermal cycling and vibration. Their latest innovation includes vapor chambers with variable thickness profiles that conform to complex engine geometries while maintaining optimal thermal performance across different operating conditions. Safran has successfully integrated these cooling systems into their latest generation of aircraft engines, achieving significant improvements in fuel efficiency and component lifespan.

Strengths: Superior thermal performance in high-temperature engine environments; excellent durability under extreme vibration and thermal cycling; seamless integration with existing engine architectures. Weaknesses: Higher production costs compared to conventional cooling methods; requires specialized manufacturing facilities; limited flexibility for field repairs or modifications.

Critical Patents and Innovations in Aerospace Vapor Chamber Design

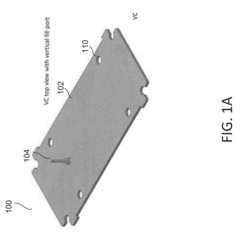

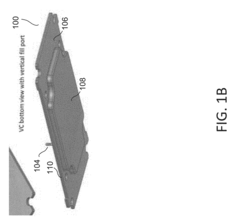

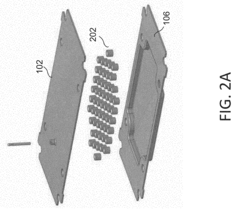

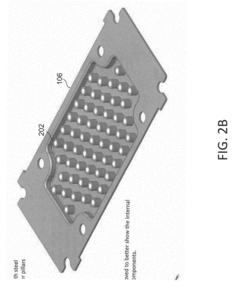

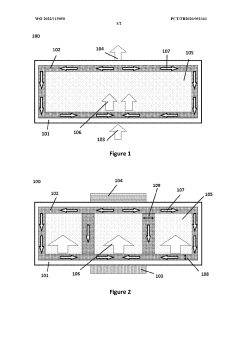

High strength high performance reinforced vapor chamber and related heatsinks

PatentInactiveUS20190027424A1

Innovation

- Incorporating columnar reinforcing structures within the vapor chamber and using a mounting plate to distribute clamping forces, which prevents crushing and maintains thermal efficiency by allowing high compressive forces without bending the circuit board.

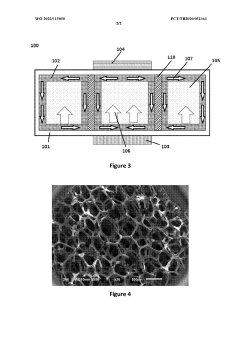

Performance enhancement in thermal system with porous surfaces

PatentWO2022115050A1

Innovation

- The use of optimized 3-D graphene structures in the form of aerogel, foam, or sponge as a porous wick medium within vapor chambers, providing high thermal conductivity and mechanical stability without compromising the base metallic surface structure, with pore sizes ranging from 1 pm to 1000 pm, to enhance thermal performance.

Material Science Advancements for Next-Generation Vapor Chambers

Recent advancements in material science have opened new frontiers for vapor chamber technology in high-performance aircraft systems. Nanomaterials, particularly carbon nanotubes and graphene, demonstrate exceptional thermal conductivity properties that significantly outperform traditional copper-based structures. These materials offer thermal conductivity values exceeding 3000 W/m·K compared to copper's 400 W/m·K, while simultaneously reducing weight by up to 60% - a critical factor in aerospace applications.

Composite materials combining metallic matrices with ceramic reinforcements present another promising direction. These composites maintain structural integrity under extreme temperature fluctuations (from -65°C to +150°C) commonly experienced in aerospace environments while offering enhanced resistance to the corrosive effects of working fluids within vapor chambers.

Phase-change materials (PCMs) integrated into vapor chamber designs represent a significant innovation for thermal management. These materials absorb excess heat during peak operational demands and release it during lower-demand periods, effectively smoothing thermal profiles across flight envelopes. Advanced PCMs with melting points specifically engineered for aircraft operational temperatures (80-120°C range) show particular promise.

Surface treatment technologies have evolved to create optimized wicking structures within vapor chambers. Plasma etching and laser surface texturing now enable the creation of multi-scale hierarchical structures that enhance capillary action by up to 300% compared to conventional sintered powder wicks, dramatically improving fluid circulation efficiency within the chamber.

Additive manufacturing breakthroughs allow for previously impossible vapor chamber geometries. 3D printing technologies utilizing direct metal laser sintering (DMLS) can now produce complex internal structures with feature sizes below 100 microns, enabling vapor chambers that conform precisely to irregular mounting surfaces in aircraft systems while incorporating optimized flow channels.

Corrosion-resistant alloys specifically developed for aerospace applications address the longevity concerns of vapor chambers. These specialized materials maintain performance characteristics over extended operational lifetimes (10,000+ hours) while withstanding the aggressive working fluids necessary for high-temperature heat transfer applications.

Self-healing materials represent the cutting edge of vapor chamber technology. These innovative materials incorporate microcapsules containing healing agents that automatically release when microcracks form, preventing catastrophic failure and extending operational lifetimes. Early laboratory tests demonstrate up to 85% recovery of thermal performance after damage events, potentially revolutionizing maintenance requirements for aircraft thermal management systems.

Composite materials combining metallic matrices with ceramic reinforcements present another promising direction. These composites maintain structural integrity under extreme temperature fluctuations (from -65°C to +150°C) commonly experienced in aerospace environments while offering enhanced resistance to the corrosive effects of working fluids within vapor chambers.

Phase-change materials (PCMs) integrated into vapor chamber designs represent a significant innovation for thermal management. These materials absorb excess heat during peak operational demands and release it during lower-demand periods, effectively smoothing thermal profiles across flight envelopes. Advanced PCMs with melting points specifically engineered for aircraft operational temperatures (80-120°C range) show particular promise.

Surface treatment technologies have evolved to create optimized wicking structures within vapor chambers. Plasma etching and laser surface texturing now enable the creation of multi-scale hierarchical structures that enhance capillary action by up to 300% compared to conventional sintered powder wicks, dramatically improving fluid circulation efficiency within the chamber.

Additive manufacturing breakthroughs allow for previously impossible vapor chamber geometries. 3D printing technologies utilizing direct metal laser sintering (DMLS) can now produce complex internal structures with feature sizes below 100 microns, enabling vapor chambers that conform precisely to irregular mounting surfaces in aircraft systems while incorporating optimized flow channels.

Corrosion-resistant alloys specifically developed for aerospace applications address the longevity concerns of vapor chambers. These specialized materials maintain performance characteristics over extended operational lifetimes (10,000+ hours) while withstanding the aggressive working fluids necessary for high-temperature heat transfer applications.

Self-healing materials represent the cutting edge of vapor chamber technology. These innovative materials incorporate microcapsules containing healing agents that automatically release when microcracks form, preventing catastrophic failure and extending operational lifetimes. Early laboratory tests demonstrate up to 85% recovery of thermal performance after damage events, potentially revolutionizing maintenance requirements for aircraft thermal management systems.

Environmental Impact and Sustainability Considerations

The environmental impact of vapor chamber technology in high-performance aircraft systems represents a critical consideration as aerospace manufacturers increasingly prioritize sustainability. Traditional thermal management systems often rely on materials and refrigerants with significant environmental footprints, whereas vapor chamber technology offers several sustainability advantages. The reduced weight of advanced vapor chamber designs directly translates to fuel efficiency improvements, with estimates suggesting that each kilogram of weight reduction can save approximately 25-30 gallons of fuel annually per aircraft in commercial aviation applications.

Material selection for vapor chamber manufacturing has evolved significantly toward environmental responsibility. The transition from copper-based chambers to aluminum and composite materials not only enhances performance but also reduces the environmental impact of resource extraction. Copper mining and processing are associated with substantial water consumption, habitat disruption, and energy expenditure, while aluminum recycling requires only 5% of the energy needed for primary production. Additionally, newer vapor chamber designs incorporate biodegradable working fluids instead of traditional refrigerants with high global warming potential (GWP).

Life cycle assessment (LCA) studies indicate that vapor chamber cooling systems demonstrate 15-20% lower carbon footprint compared to conventional active cooling systems when evaluated across their entire operational lifespan. This advantage stems primarily from operational efficiency rather than manufacturing processes, highlighting the importance of considering full product lifecycles in environmental impact evaluations. The extended service life of modern vapor chambers—typically 20-25 years with minimal maintenance—further enhances their sustainability profile by reducing replacement frequency and associated resource consumption.

Regulatory frameworks increasingly influence vapor chamber development in aerospace applications. The International Civil Aviation Organization's Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA) and the European Union's more stringent emissions standards have accelerated adoption of more efficient thermal management technologies. Manufacturers implementing advanced vapor chamber solutions can achieve compliance advantages while simultaneously reducing operational costs.

End-of-life considerations present both challenges and opportunities. While vapor chambers contain valuable metals that can be reclaimed through recycling processes, the composite nature of advanced designs can complicate material separation. Industry leaders are addressing this through design-for-disassembly approaches and establishing specialized recycling partnerships. Some manufacturers have implemented take-back programs that recover over 85% of materials from decommissioned thermal management systems, creating a circular economy model that significantly reduces waste.

Material selection for vapor chamber manufacturing has evolved significantly toward environmental responsibility. The transition from copper-based chambers to aluminum and composite materials not only enhances performance but also reduces the environmental impact of resource extraction. Copper mining and processing are associated with substantial water consumption, habitat disruption, and energy expenditure, while aluminum recycling requires only 5% of the energy needed for primary production. Additionally, newer vapor chamber designs incorporate biodegradable working fluids instead of traditional refrigerants with high global warming potential (GWP).

Life cycle assessment (LCA) studies indicate that vapor chamber cooling systems demonstrate 15-20% lower carbon footprint compared to conventional active cooling systems when evaluated across their entire operational lifespan. This advantage stems primarily from operational efficiency rather than manufacturing processes, highlighting the importance of considering full product lifecycles in environmental impact evaluations. The extended service life of modern vapor chambers—typically 20-25 years with minimal maintenance—further enhances their sustainability profile by reducing replacement frequency and associated resource consumption.

Regulatory frameworks increasingly influence vapor chamber development in aerospace applications. The International Civil Aviation Organization's Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA) and the European Union's more stringent emissions standards have accelerated adoption of more efficient thermal management technologies. Manufacturers implementing advanced vapor chamber solutions can achieve compliance advantages while simultaneously reducing operational costs.

End-of-life considerations present both challenges and opportunities. While vapor chambers contain valuable metals that can be reclaimed through recycling processes, the composite nature of advanced designs can complicate material separation. Industry leaders are addressing this through design-for-disassembly approaches and establishing specialized recycling partnerships. Some manufacturers have implemented take-back programs that recover over 85% of materials from decommissioned thermal management systems, creating a circular economy model that significantly reduces waste.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!