Vapor Chamber Integration for Improved Thermal Conductivity in Electronics

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vapor Chamber Technology Evolution and Objectives

Vapor chamber technology has evolved significantly since its inception in the 1960s as a specialized heat transfer solution. Initially developed for aerospace applications, these two-phase heat transfer devices have undergone substantial refinement to address the increasing thermal management challenges in electronics. The fundamental operating principle—utilizing phase change of a working fluid to efficiently transfer heat—has remained consistent, while manufacturing techniques, materials, and integration approaches have advanced dramatically.

The evolution trajectory shows three distinct phases: early development (1960s-1990s) focused on fundamental research and limited applications; mainstream adoption (1990s-2010s) characterized by standardization and cost reduction; and current advanced integration (2010s-present) featuring ultra-thin designs and complex three-dimensional structures tailored for modern electronics.

Material science breakthroughs have been pivotal in this evolution. The transition from traditional copper-water combinations to advanced composite wicks, sintered powder structures, and novel working fluids has enabled significant performance improvements. Manufacturing precision has similarly progressed from basic stamping and welding to advanced micro-etching, laser welding, and automated production lines capable of producing vapor chambers with thickness under 0.5mm.

The primary technical objective for vapor chamber integration is maximizing thermal conductivity while minimizing form factor impact. Modern electronics demand thermal solutions that can dissipate increasing power densities without compromising device dimensions. Specific performance targets include achieving effective thermal conductivity exceeding 1500 W/m·K, compared to copper's 400 W/m·K, while maintaining thickness below 0.3mm for mobile applications.

Secondary objectives include reliability enhancement to ensure consistent performance over 5+ year product lifecycles, cost optimization to enable broader market adoption, and manufacturing scalability to support high-volume production. Environmental considerations have also emerged as important objectives, with efforts to develop vapor chambers using non-toxic working fluids and recyclable materials.

The technology aims to address specific thermal challenges in next-generation electronics: managing transient thermal loads from increasingly dynamic processor workloads, cooling heterogeneous integrated circuits with varying heat generation profiles, and enabling sustained performance in thermally-constrained form factors like ultra-thin laptops, foldable devices, and wearable technology.

Future evolution targets include integration with active cooling systems, development of "smart" vapor chambers with embedded sensors for real-time thermal management, and exploration of novel form factors including flexible and stretchable variants to support emerging device categories.

The evolution trajectory shows three distinct phases: early development (1960s-1990s) focused on fundamental research and limited applications; mainstream adoption (1990s-2010s) characterized by standardization and cost reduction; and current advanced integration (2010s-present) featuring ultra-thin designs and complex three-dimensional structures tailored for modern electronics.

Material science breakthroughs have been pivotal in this evolution. The transition from traditional copper-water combinations to advanced composite wicks, sintered powder structures, and novel working fluids has enabled significant performance improvements. Manufacturing precision has similarly progressed from basic stamping and welding to advanced micro-etching, laser welding, and automated production lines capable of producing vapor chambers with thickness under 0.5mm.

The primary technical objective for vapor chamber integration is maximizing thermal conductivity while minimizing form factor impact. Modern electronics demand thermal solutions that can dissipate increasing power densities without compromising device dimensions. Specific performance targets include achieving effective thermal conductivity exceeding 1500 W/m·K, compared to copper's 400 W/m·K, while maintaining thickness below 0.3mm for mobile applications.

Secondary objectives include reliability enhancement to ensure consistent performance over 5+ year product lifecycles, cost optimization to enable broader market adoption, and manufacturing scalability to support high-volume production. Environmental considerations have also emerged as important objectives, with efforts to develop vapor chambers using non-toxic working fluids and recyclable materials.

The technology aims to address specific thermal challenges in next-generation electronics: managing transient thermal loads from increasingly dynamic processor workloads, cooling heterogeneous integrated circuits with varying heat generation profiles, and enabling sustained performance in thermally-constrained form factors like ultra-thin laptops, foldable devices, and wearable technology.

Future evolution targets include integration with active cooling systems, development of "smart" vapor chambers with embedded sensors for real-time thermal management, and exploration of novel form factors including flexible and stretchable variants to support emerging device categories.

Market Demand for Advanced Thermal Management Solutions

The global market for advanced thermal management solutions is experiencing unprecedented growth, driven primarily by the rapid evolution of electronic devices with higher power densities and miniaturization trends. Current market valuations indicate that the thermal management industry is projected to reach approximately 20 billion USD by 2026, with a compound annual growth rate exceeding 8%. This growth trajectory is particularly evident in sectors such as consumer electronics, telecommunications, automotive electronics, and high-performance computing.

Consumer electronics manufacturers are increasingly seeking more efficient thermal solutions as devices become thinner while processing capabilities continue to expand. Smartphones, tablets, and ultrabooks represent a significant market segment where traditional cooling methods are reaching their physical limitations. Industry surveys indicate that over 70% of electronics manufacturers consider thermal management as one of their top three design challenges, creating substantial demand for innovative solutions like vapor chamber technology.

The data center and server market presents another substantial growth opportunity for advanced thermal management. With the proliferation of cloud computing, artificial intelligence, and big data analytics, data centers are experiencing unprecedented thermal loads. Energy efficiency concerns further amplify the need for superior thermal solutions, as cooling can represent up to 40% of a data center's total energy consumption. This economic imperative is driving adoption of more efficient thermal technologies.

Automotive electronics represent an emerging high-growth segment for thermal management solutions. The transition toward electric vehicles and autonomous driving systems has dramatically increased the thermal management requirements in automotive applications. Electric vehicle battery systems, power electronics, and advanced driver-assistance systems all generate significant heat that must be efficiently dissipated to ensure performance, reliability, and safety.

Geographically, the Asia-Pacific region dominates the market demand, accounting for approximately 45% of global consumption, primarily due to the concentration of electronics manufacturing. North America and Europe follow with significant market shares, driven by their advanced technology sectors and automotive industries.

Customer requirements are increasingly focused on solutions that offer higher thermal conductivity, reduced thickness, uniform temperature distribution, and reliability under various operating conditions. Market research indicates that products offering a 30% improvement in thermal performance can command premium pricing, highlighting the value proposition of advanced solutions like vapor chamber technology. Additionally, environmental considerations are becoming increasingly important, with customers seeking solutions that reduce overall energy consumption and utilize environmentally friendly materials.

Consumer electronics manufacturers are increasingly seeking more efficient thermal solutions as devices become thinner while processing capabilities continue to expand. Smartphones, tablets, and ultrabooks represent a significant market segment where traditional cooling methods are reaching their physical limitations. Industry surveys indicate that over 70% of electronics manufacturers consider thermal management as one of their top three design challenges, creating substantial demand for innovative solutions like vapor chamber technology.

The data center and server market presents another substantial growth opportunity for advanced thermal management. With the proliferation of cloud computing, artificial intelligence, and big data analytics, data centers are experiencing unprecedented thermal loads. Energy efficiency concerns further amplify the need for superior thermal solutions, as cooling can represent up to 40% of a data center's total energy consumption. This economic imperative is driving adoption of more efficient thermal technologies.

Automotive electronics represent an emerging high-growth segment for thermal management solutions. The transition toward electric vehicles and autonomous driving systems has dramatically increased the thermal management requirements in automotive applications. Electric vehicle battery systems, power electronics, and advanced driver-assistance systems all generate significant heat that must be efficiently dissipated to ensure performance, reliability, and safety.

Geographically, the Asia-Pacific region dominates the market demand, accounting for approximately 45% of global consumption, primarily due to the concentration of electronics manufacturing. North America and Europe follow with significant market shares, driven by their advanced technology sectors and automotive industries.

Customer requirements are increasingly focused on solutions that offer higher thermal conductivity, reduced thickness, uniform temperature distribution, and reliability under various operating conditions. Market research indicates that products offering a 30% improvement in thermal performance can command premium pricing, highlighting the value proposition of advanced solutions like vapor chamber technology. Additionally, environmental considerations are becoming increasingly important, with customers seeking solutions that reduce overall energy consumption and utilize environmentally friendly materials.

Current State and Challenges in Electronics Cooling

The thermal management landscape in electronics has evolved significantly over the past decade, with traditional cooling methods increasingly struggling to meet the demands of modern high-performance devices. Air cooling systems, once the standard solution, have reached their practical limits as power densities in electronic components continue to rise exponentially. Even advanced heat sink designs with optimized fin structures and high-performance fans cannot effectively dissipate heat from the latest generation of processors and graphics cards.

Liquid cooling technologies have gained prominence as an alternative, offering superior thermal conductivity compared to air-based systems. However, these solutions introduce complexity, maintenance requirements, and reliability concerns due to the risk of leakage. The integration challenges of liquid cooling systems also present significant barriers to widespread adoption in consumer electronics and compact devices.

Heat pipes, which utilize phase change principles to transfer heat efficiently, represent a middle ground between air and liquid cooling. While effective for moderate thermal loads, traditional heat pipe designs face limitations in their ability to spread heat uniformly across larger surface areas, creating hotspots that can compromise device performance and longevity.

The miniaturization trend in electronics has further exacerbated cooling challenges. As devices become thinner and more compact, the available space for thermal management solutions decreases dramatically. This spatial constraint forces engineers to seek more efficient cooling technologies that can operate within increasingly restricted form factors while handling growing thermal loads.

Power density in electronic components has reached critical levels, with some high-performance computing chips exceeding 500 W/cm². This extreme concentration of heat generation creates significant challenges for even the most advanced cooling technologies currently available. The thermal interface between heat-generating components and cooling solutions remains a persistent bottleneck, with thermal interface materials struggling to efficiently transfer heat across these critical junctions.

Environmental and regulatory pressures add another dimension to the cooling challenge. Energy efficiency requirements and restrictions on certain refrigerants and materials have limited design options. Additionally, noise constraints in consumer and office environments restrict the use of high-speed fans and other active cooling solutions that generate significant acoustic output.

The reliability requirements for modern electronics further complicate thermal management. Cooling solutions must maintain performance over extended operational lifetimes while withstanding thermal cycling, vibration, and other environmental stresses. This is particularly challenging for mobile devices and automotive electronics that operate in variable and sometimes harsh conditions.

Liquid cooling technologies have gained prominence as an alternative, offering superior thermal conductivity compared to air-based systems. However, these solutions introduce complexity, maintenance requirements, and reliability concerns due to the risk of leakage. The integration challenges of liquid cooling systems also present significant barriers to widespread adoption in consumer electronics and compact devices.

Heat pipes, which utilize phase change principles to transfer heat efficiently, represent a middle ground between air and liquid cooling. While effective for moderate thermal loads, traditional heat pipe designs face limitations in their ability to spread heat uniformly across larger surface areas, creating hotspots that can compromise device performance and longevity.

The miniaturization trend in electronics has further exacerbated cooling challenges. As devices become thinner and more compact, the available space for thermal management solutions decreases dramatically. This spatial constraint forces engineers to seek more efficient cooling technologies that can operate within increasingly restricted form factors while handling growing thermal loads.

Power density in electronic components has reached critical levels, with some high-performance computing chips exceeding 500 W/cm². This extreme concentration of heat generation creates significant challenges for even the most advanced cooling technologies currently available. The thermal interface between heat-generating components and cooling solutions remains a persistent bottleneck, with thermal interface materials struggling to efficiently transfer heat across these critical junctions.

Environmental and regulatory pressures add another dimension to the cooling challenge. Energy efficiency requirements and restrictions on certain refrigerants and materials have limited design options. Additionally, noise constraints in consumer and office environments restrict the use of high-speed fans and other active cooling solutions that generate significant acoustic output.

The reliability requirements for modern electronics further complicate thermal management. Cooling solutions must maintain performance over extended operational lifetimes while withstanding thermal cycling, vibration, and other environmental stresses. This is particularly challenging for mobile devices and automotive electronics that operate in variable and sometimes harsh conditions.

Current Vapor Chamber Integration Methodologies

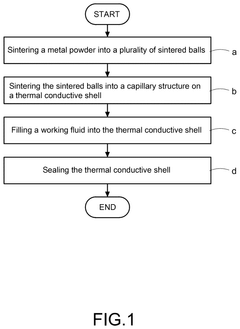

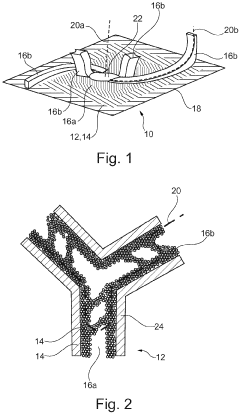

01 Vapor chamber structure for enhanced thermal conductivity

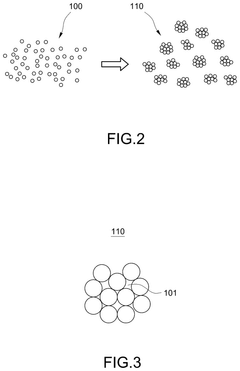

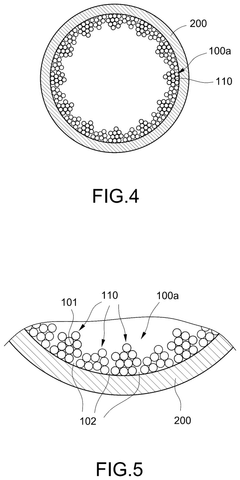

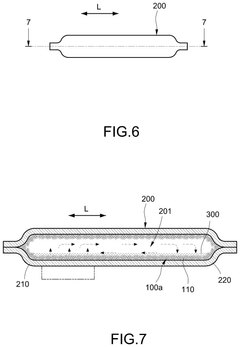

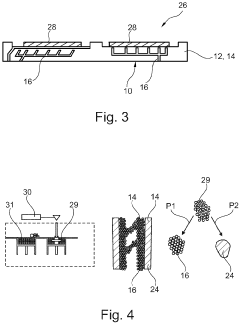

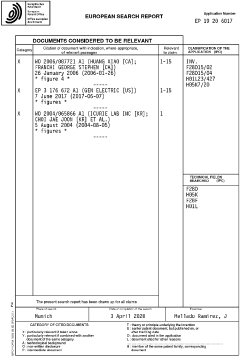

Vapor chambers can be designed with specific structural features to enhance thermal conductivity. These designs include optimized internal structures, specialized wick arrangements, and innovative chamber geometries that facilitate efficient heat transfer. The internal structure affects vapor flow patterns and condensation rates, directly impacting the overall thermal conductivity of the vapor chamber system.- Vapor chamber structure for enhanced thermal conductivity: Vapor chambers can be designed with specific structural features to enhance thermal conductivity. These designs include optimized internal structures, wick arrangements, and vapor flow paths that facilitate efficient heat transfer. The structure may incorporate multiple chambers, specialized wall configurations, or integrated heat pipes to maximize thermal performance and ensure rapid heat dissipation from hot spots to cooler regions.

- Working fluid selection and composition for vapor chambers: The selection and composition of working fluids significantly impact the thermal conductivity of vapor chambers. Different fluids offer varying thermodynamic properties that affect phase change efficiency and heat transfer capabilities. Engineered fluid mixtures, additives, or nanofluid suspensions can be incorporated to enhance thermal conductivity, reduce operating temperatures, and improve overall heat transfer performance across different operating conditions.

- Measurement and testing methods for vapor chamber thermal conductivity: Various methods and apparatus have been developed to accurately measure and test the thermal conductivity of vapor chambers. These include specialized thermal testing equipment, conductivity measurement devices, and performance evaluation systems. Testing protocols may involve temperature gradient analysis, heat flux measurement, or transient testing to characterize thermal performance under different operating conditions and validate design improvements.

- Wick structure optimization for improved thermal performance: The wick structure within vapor chambers plays a crucial role in determining thermal conductivity. Advanced wick designs incorporate varying porosity, multi-layer structures, or composite materials to optimize capillary action and fluid return. Specialized wick patterns, sintered metal powders, or engineered microstructures can enhance liquid distribution, minimize dry-out conditions, and improve overall heat transfer efficiency across the vapor chamber.

- Interface materials and thermal coupling techniques: The thermal conductivity of vapor chamber systems is significantly affected by interface materials and coupling techniques used to connect the chamber to heat sources and heat sinks. Specialized thermal interface materials, bonding methods, and contact surface preparations can minimize thermal resistance at junctions. Advanced integration techniques ensure efficient heat transfer into and out of the vapor chamber, reducing overall thermal resistance in the cooling system.

02 Working fluid selection and composition for vapor chambers

The selection and composition of working fluids significantly impact the thermal conductivity of vapor chambers. Different fluids have varying thermophysical properties that affect heat transfer efficiency. Engineered fluid mixtures can be formulated to optimize phase change characteristics, wetting properties, and operating temperature ranges, resulting in enhanced thermal conductivity performance across different operating conditions.Expand Specific Solutions03 Measurement and testing methods for vapor chamber thermal conductivity

Various methods and apparatus have been developed to accurately measure and test the thermal conductivity of vapor chambers. These include specialized testing equipment, thermal imaging techniques, and computational models that can evaluate performance under different conditions. Standardized testing protocols help in comparing different vapor chamber designs and validating their thermal performance characteristics.Expand Specific Solutions04 Interface materials and surface treatments for improved thermal conductivity

The thermal conductivity of vapor chambers can be enhanced through specialized interface materials and surface treatments. These include nano-coatings, sintered metal surfaces, and composite materials that improve wetting characteristics and heat transfer at critical interfaces. Surface modifications can reduce thermal resistance at contact points and enhance the overall efficiency of the vapor chamber system.Expand Specific Solutions05 Integration of vapor chambers in electronic cooling systems

Vapor chambers can be effectively integrated into electronic cooling systems to maximize thermal conductivity benefits. Design considerations include optimal placement relative to heat sources, integration with heat sinks, and compatibility with other cooling components. Advanced integration approaches address challenges such as space constraints, orientation effects, and thermal expansion issues while maintaining high thermal conductivity performance.Expand Specific Solutions

Key Industry Players in Vapor Chamber Manufacturing

The vapor chamber thermal management market is currently in a growth phase, with increasing demand driven by the miniaturization and higher power densities in modern electronics. The global market size is estimated to reach $3-4 billion by 2025, growing at a CAGR of approximately 15%. Technologically, the field is maturing rapidly with key players at different development stages. Delta Electronics, Cooler Master, and Taiwan Microloops lead with advanced vapor chamber solutions for consumer electronics, while Intel, Samsung, and Qualcomm are integrating these technologies into their semiconductor products. Traditional thermal management companies like 3M and LG Electronics are expanding their portfolios through R&D investments. Emerging players such as NAWATechnologies are introducing innovative carbon-based solutions, indicating the industry's evolution toward more efficient thermal management systems for next-generation electronics.

Cooler Master Co. Ltd.

Technical Solution: Cooler Master has pioneered innovative vapor chamber cooling solutions specifically designed for gaming and high-performance computing applications. Their technology features vapor chambers with optimized internal geometries that maximize surface area for heat absorption and dissipation. Cooler Master's vapor chambers utilize sintered copper powder wicks with controlled porosity gradients that enhance fluid circulation efficiency[5]. The company has developed specialized manufacturing techniques that allow for complex three-dimensional vapor chamber shapes, enabling better integration with irregular heat sources. Their vapor chamber solutions incorporate proprietary working fluids that remain stable at operating temperatures ranging from -40°C to +120°C, ensuring consistent performance across diverse environmental conditions. Cooler Master has also implemented hybrid cooling systems that combine vapor chambers with traditional heat pipes and fin arrays, achieving thermal resistance values as low as 0.05°C/W in their premium cooling products[7]. Their manufacturing process includes rigorous quality control measures with 100% performance testing before product release.

Strengths: Excellent thermal performance in high-heat-flux applications; versatile form factors adaptable to various device configurations; strong integration with existing cooling system components. Weaknesses: Premium pricing compared to conventional cooling solutions; limited standardization across product lines; potential for performance degradation in sub-optimal mounting conditions.

Taiwan Microloops Corp.

Technical Solution: Taiwan Microloops has developed specialized vapor chamber technology focused on ultra-thin form factors for mobile and compact electronic devices. Their proprietary vapor chamber designs feature micro-structured wick patterns with optimized capillary structures that enhance fluid circulation in extremely confined spaces. Taiwan Microloops' vapor chambers utilize advanced manufacturing techniques that enable thickness profiles as thin as 0.25mm while maintaining thermal conductivity values exceeding 1200 W/m·K[6]. The company has pioneered vapor chamber designs with asymmetric internal structures that can be customized to address specific hotspot patterns in complex electronic devices. Their vapor chambers incorporate specialized working fluids with low latent heat of vaporization, enabling rapid thermal response to sudden power spikes. Taiwan Microloops has also developed automated manufacturing processes that ensure consistent quality while reducing production costs by approximately 30% compared to traditional manufacturing methods[8]. Their vapor chamber solutions feature proprietary corner structures that minimize dead zones and enhance overall thermal performance in rectangular form factors common in modern electronics.

Strengths: Industry-leading thin profile capabilities; excellent thermal performance in space-constrained applications; customizable designs for specific device thermal profiles. Weaknesses: Limited production capacity compared to larger manufacturers; higher unit costs for low-volume specialized designs; potential durability concerns with ultra-thin implementations.

Critical Patents and Innovations in Vapor Chamber Design

Heat transfer device and a manufacturing method thereof

PatentPendingUS20250129994A1

Innovation

- A phase change heat transfer device with a capillary structure made by secondary sintering, featuring sintered balls with first pores and larger second pores between them, which improves permeability and breathability, allowing for better fluid flow and retention.

Two-phase heat transfer device for heat dissipation

PatentInactiveEP3816559A1

Innovation

- A two-phase heat transfer device featuring a main body with a multi-dimensional void network that varies capillary action along its path, allowing for enhanced heat dissipation through additive manufacturing, which improves flow direction and rate, and eliminates manufacturing challenges like weak joints and porosity issues.

Materials Science Advancements for Vapor Chamber Efficiency

Recent advancements in materials science have significantly enhanced vapor chamber efficiency, revolutionizing thermal management in electronics. Traditional copper-based vapor chambers are increasingly being supplemented or replaced with novel materials that offer superior thermal conductivity properties. Graphene, with its exceptional thermal conductivity of approximately 5000 W/mK, represents a breakthrough material that outperforms conventional copper (400 W/mK) by an order of magnitude. When incorporated into vapor chamber structures, graphene-enhanced wicks and condensers demonstrate up to 60% improvement in heat transfer capability.

Nano-engineered porous materials have emerged as another critical advancement, offering optimized capillary action within vapor chambers. These materials feature precisely controlled pore size distributions, typically ranging from 10-500nm, creating ideal conditions for working fluid circulation. Studies indicate that these nano-engineered structures can improve effective thermal conductivity by 30-45% compared to conventional sintered powder wicks.

Composite materials combining metallic substrates with ceramic or carbon-based enhancements represent a hybrid approach gaining traction in high-performance applications. These composites leverage the structural integrity of metals while incorporating the thermal advantages of advanced materials. For instance, aluminum-graphite composites demonstrate thermal conductivity improvements of 25-35% while maintaining mechanical robustness necessary for integration into electronic devices.

Surface treatment technologies have evolved to address the critical interface between vapor and liquid phases. Hydrophilic-hydrophobic patterned surfaces, created through advanced deposition and etching techniques, optimize the condensation and evaporation cycles within vapor chambers. These biomimetic surfaces, inspired by natural phenomena like lotus leaves, can enhance heat transfer coefficients by up to 40% at the phase-change interfaces.

Working fluid innovations complement these material advancements, with engineered nanofluids containing suspended nanoparticles demonstrating enhanced thermal properties. These fluids, typically incorporating metal oxide or carbon nanoparticles at concentrations of 0.01-5% by volume, show thermal conductivity improvements of 15-40% compared to conventional working fluids like water or methanol.

Manufacturing processes have similarly evolved, with techniques like selective laser sintering and atomic layer deposition enabling previously impossible microstructures. These processes allow for the creation of vapor chamber components with feature sizes down to several nanometers, optimizing fluid channels and wick structures for maximum thermal performance while minimizing material usage and overall device weight.

Nano-engineered porous materials have emerged as another critical advancement, offering optimized capillary action within vapor chambers. These materials feature precisely controlled pore size distributions, typically ranging from 10-500nm, creating ideal conditions for working fluid circulation. Studies indicate that these nano-engineered structures can improve effective thermal conductivity by 30-45% compared to conventional sintered powder wicks.

Composite materials combining metallic substrates with ceramic or carbon-based enhancements represent a hybrid approach gaining traction in high-performance applications. These composites leverage the structural integrity of metals while incorporating the thermal advantages of advanced materials. For instance, aluminum-graphite composites demonstrate thermal conductivity improvements of 25-35% while maintaining mechanical robustness necessary for integration into electronic devices.

Surface treatment technologies have evolved to address the critical interface between vapor and liquid phases. Hydrophilic-hydrophobic patterned surfaces, created through advanced deposition and etching techniques, optimize the condensation and evaporation cycles within vapor chambers. These biomimetic surfaces, inspired by natural phenomena like lotus leaves, can enhance heat transfer coefficients by up to 40% at the phase-change interfaces.

Working fluid innovations complement these material advancements, with engineered nanofluids containing suspended nanoparticles demonstrating enhanced thermal properties. These fluids, typically incorporating metal oxide or carbon nanoparticles at concentrations of 0.01-5% by volume, show thermal conductivity improvements of 15-40% compared to conventional working fluids like water or methanol.

Manufacturing processes have similarly evolved, with techniques like selective laser sintering and atomic layer deposition enabling previously impossible microstructures. These processes allow for the creation of vapor chamber components with feature sizes down to several nanometers, optimizing fluid channels and wick structures for maximum thermal performance while minimizing material usage and overall device weight.

Environmental Impact and Sustainability Considerations

The integration of Vapor Chamber technology in electronics presents significant environmental and sustainability implications that warrant careful consideration. The manufacturing process of vapor chambers typically involves metals like copper, aluminum, and stainless steel, which require substantial energy for extraction and processing. This energy-intensive production contributes to carbon emissions and resource depletion, particularly concerning for copper, which faces increasing scarcity concerns.

However, vapor chambers offer notable environmental benefits through their operational efficiency. By enhancing thermal conductivity and heat dissipation in electronic devices, they enable more efficient energy usage and potentially extend product lifespans. This improved thermal management allows for the development of more compact devices that utilize fewer materials while maintaining performance, thereby reducing electronic waste generation.

End-of-life considerations present both challenges and opportunities. While vapor chambers contain valuable metals that can be reclaimed through recycling processes, their complex, sealed construction can complicate disassembly and material separation. The industry is increasingly exploring design-for-disassembly approaches to address these recycling challenges, with some manufacturers implementing take-back programs specifically for thermal management components.

The environmental footprint of vapor chamber technology extends to working fluid selection. Traditional heat pipes often utilize water as the working fluid, but some vapor chamber designs incorporate specialized fluids with varying environmental impacts. The industry trend is moving toward non-toxic, non-flammable alternatives with minimal global warming potential, reflecting growing environmental consciousness in thermal solution engineering.

From a lifecycle assessment perspective, vapor chambers demonstrate a favorable environmental profile when their manufacturing impacts are balanced against operational benefits. Studies indicate that the energy savings achieved through improved thermal efficiency typically offset the initial production energy investment within 1-3 years of device operation, depending on application intensity and usage patterns.

Regulatory frameworks are increasingly influencing vapor chamber development, with initiatives like the European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations driving manufacturers toward more environmentally benign materials and processes. These regulatory pressures, combined with corporate sustainability commitments, are accelerating innovation in green manufacturing techniques for vapor chamber production.

However, vapor chambers offer notable environmental benefits through their operational efficiency. By enhancing thermal conductivity and heat dissipation in electronic devices, they enable more efficient energy usage and potentially extend product lifespans. This improved thermal management allows for the development of more compact devices that utilize fewer materials while maintaining performance, thereby reducing electronic waste generation.

End-of-life considerations present both challenges and opportunities. While vapor chambers contain valuable metals that can be reclaimed through recycling processes, their complex, sealed construction can complicate disassembly and material separation. The industry is increasingly exploring design-for-disassembly approaches to address these recycling challenges, with some manufacturers implementing take-back programs specifically for thermal management components.

The environmental footprint of vapor chamber technology extends to working fluid selection. Traditional heat pipes often utilize water as the working fluid, but some vapor chamber designs incorporate specialized fluids with varying environmental impacts. The industry trend is moving toward non-toxic, non-flammable alternatives with minimal global warming potential, reflecting growing environmental consciousness in thermal solution engineering.

From a lifecycle assessment perspective, vapor chambers demonstrate a favorable environmental profile when their manufacturing impacts are balanced against operational benefits. Studies indicate that the energy savings achieved through improved thermal efficiency typically offset the initial production energy investment within 1-3 years of device operation, depending on application intensity and usage patterns.

Regulatory frameworks are increasingly influencing vapor chamber development, with initiatives like the European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations driving manufacturers toward more environmentally benign materials and processes. These regulatory pressures, combined with corporate sustainability commitments, are accelerating innovation in green manufacturing techniques for vapor chamber production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!