Vapor Chamber Integration with Flexible Polymers in Wearable Tech

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vapor Chamber Technology Evolution and Integration Goals

Vapor chamber technology has evolved significantly over the past three decades, transitioning from rigid copper-based designs primarily used in stationary electronics to increasingly sophisticated thermal management solutions. The initial development in the 1990s focused on basic heat pipe principles adapted into planar structures for desktop computers and servers. By the early 2000s, vapor chambers began appearing in high-performance computing applications, characterized by their superior thermal spreading capabilities compared to traditional heat pipes.

The evolution accelerated in the 2010s with the miniaturization trend in consumer electronics, driving vapor chamber thickness reduction from several millimeters to sub-millimeter profiles. This period marked the first commercial implementations in premium smartphones and ultrabooks, though these solutions remained fundamentally rigid and relied on copper or aluminum construction with water as the working fluid.

Recent technological breakthroughs (2018-2023) have focused on addressing the inherent rigidity limitations of traditional vapor chambers. Innovations include ultra-thin vapor chambers (below 0.5mm), alternative working fluids with lower boiling points, and initial experiments with semi-flexible designs incorporating articulation points or segmented chambers connected by flexible conduits.

The integration goals for vapor chamber technology with flexible polymers represent a paradigm shift in thermal management for wearable technology. Primary objectives include developing vapor chambers with bending radii below 10mm without performance degradation, creating solutions that can withstand repeated flexing cycles (10,000+ without failure), and maintaining thermal performance comparable to rigid counterparts (thermal resistance below 0.1°C/W).

Additional integration goals focus on material compatibility between the working fluid and polymer substrates, preventing permeation and degradation over the product lifecycle. Weight reduction represents another critical objective, with targets of achieving at least 40% weight savings compared to metal-based solutions while maintaining structural integrity under various usage conditions.

Manufacturing scalability constitutes a significant integration goal, developing processes compatible with existing flexible electronics production lines. This includes low-temperature sealing methods, roll-to-roll compatible deposition techniques, and quality control protocols specific to flexible vapor chambers. The ultimate vision encompasses creating thermal management solutions that can conform to the human body's contours while efficiently dissipating heat from next-generation wearable processors, sensors, and batteries.

The evolution accelerated in the 2010s with the miniaturization trend in consumer electronics, driving vapor chamber thickness reduction from several millimeters to sub-millimeter profiles. This period marked the first commercial implementations in premium smartphones and ultrabooks, though these solutions remained fundamentally rigid and relied on copper or aluminum construction with water as the working fluid.

Recent technological breakthroughs (2018-2023) have focused on addressing the inherent rigidity limitations of traditional vapor chambers. Innovations include ultra-thin vapor chambers (below 0.5mm), alternative working fluids with lower boiling points, and initial experiments with semi-flexible designs incorporating articulation points or segmented chambers connected by flexible conduits.

The integration goals for vapor chamber technology with flexible polymers represent a paradigm shift in thermal management for wearable technology. Primary objectives include developing vapor chambers with bending radii below 10mm without performance degradation, creating solutions that can withstand repeated flexing cycles (10,000+ without failure), and maintaining thermal performance comparable to rigid counterparts (thermal resistance below 0.1°C/W).

Additional integration goals focus on material compatibility between the working fluid and polymer substrates, preventing permeation and degradation over the product lifecycle. Weight reduction represents another critical objective, with targets of achieving at least 40% weight savings compared to metal-based solutions while maintaining structural integrity under various usage conditions.

Manufacturing scalability constitutes a significant integration goal, developing processes compatible with existing flexible electronics production lines. This includes low-temperature sealing methods, roll-to-roll compatible deposition techniques, and quality control protocols specific to flexible vapor chambers. The ultimate vision encompasses creating thermal management solutions that can conform to the human body's contours while efficiently dissipating heat from next-generation wearable processors, sensors, and batteries.

Market Demand for Thermal Management in Wearable Devices

The wearable technology market has experienced exponential growth over the past decade, with global revenues reaching $116 billion in 2023 and projected to surpass $265 billion by 2028. Within this rapidly expanding sector, thermal management has emerged as a critical challenge that directly impacts device performance, user comfort, and overall product adoption rates.

Consumer surveys indicate that overheating ranks among the top three complaints for wearable device users, with 67% of smartwatch owners reporting discomfort during extended usage periods. This thermal discomfort not only affects user experience but also limits the computational capabilities manufacturers can integrate into their devices, creating a significant market gap for advanced thermal management solutions.

Healthcare wearables represent a particularly demanding segment, requiring continuous operation in direct contact with skin while maintaining strict temperature thresholds for both safety and sensor accuracy. Medical-grade wearables for continuous monitoring must maintain temperatures below 40°C to prevent skin irritation while ensuring consistent performance of temperature-sensitive components.

The fitness and athletic performance tracking segment demonstrates even more stringent requirements, with devices needing to function reliably under extreme physical exertion when body temperature and environmental factors combine to create challenging thermal conditions. Market research shows that 78% of athletes consider device overheating a significant factor in purchasing decisions.

Enterprise and industrial wearables face unique thermal challenges in environments where ambient temperatures may already be elevated. These applications often require extended battery life and higher processing capabilities, both of which generate additional heat that must be effectively managed.

Battery performance and longevity represent another critical market driver, as thermal management directly impacts charging efficiency and battery degradation rates. Studies demonstrate that maintaining optimal operating temperatures can extend battery lifespan by up to 40%, representing significant value for consumers and manufacturers alike.

The market demand for miniaturization continues to push the boundaries of thermal management, with consumers expecting increasingly powerful devices in smaller form factors. This trend has created substantial market pressure for innovative thermal solutions that can efficiently dissipate heat without adding significant weight or bulk to wearable products.

Emerging applications in augmented reality and virtual reality wearables present perhaps the most demanding thermal management challenges, with computational requirements approaching those of mobile computing devices while maintaining strict weight and comfort parameters necessary for head-mounted displays.

Consumer surveys indicate that overheating ranks among the top three complaints for wearable device users, with 67% of smartwatch owners reporting discomfort during extended usage periods. This thermal discomfort not only affects user experience but also limits the computational capabilities manufacturers can integrate into their devices, creating a significant market gap for advanced thermal management solutions.

Healthcare wearables represent a particularly demanding segment, requiring continuous operation in direct contact with skin while maintaining strict temperature thresholds for both safety and sensor accuracy. Medical-grade wearables for continuous monitoring must maintain temperatures below 40°C to prevent skin irritation while ensuring consistent performance of temperature-sensitive components.

The fitness and athletic performance tracking segment demonstrates even more stringent requirements, with devices needing to function reliably under extreme physical exertion when body temperature and environmental factors combine to create challenging thermal conditions. Market research shows that 78% of athletes consider device overheating a significant factor in purchasing decisions.

Enterprise and industrial wearables face unique thermal challenges in environments where ambient temperatures may already be elevated. These applications often require extended battery life and higher processing capabilities, both of which generate additional heat that must be effectively managed.

Battery performance and longevity represent another critical market driver, as thermal management directly impacts charging efficiency and battery degradation rates. Studies demonstrate that maintaining optimal operating temperatures can extend battery lifespan by up to 40%, representing significant value for consumers and manufacturers alike.

The market demand for miniaturization continues to push the boundaries of thermal management, with consumers expecting increasingly powerful devices in smaller form factors. This trend has created substantial market pressure for innovative thermal solutions that can efficiently dissipate heat without adding significant weight or bulk to wearable products.

Emerging applications in augmented reality and virtual reality wearables present perhaps the most demanding thermal management challenges, with computational requirements approaching those of mobile computing devices while maintaining strict weight and comfort parameters necessary for head-mounted displays.

Current Challenges in Flexible Vapor Chamber Technology

The integration of vapor chambers with flexible polymers in wearable technology faces several significant technical challenges that currently limit widespread adoption. Traditional vapor chambers, typically constructed from rigid metals like copper or aluminum, exhibit excellent thermal conductivity but lack the flexibility required for wearable applications. When attempting to create flexible versions, engineers encounter fundamental material compatibility issues between the metallic components and polymer substrates.

The hermetic sealing of flexible vapor chambers presents a particularly difficult challenge. As the device bends and flexes during normal wearable use, the integrity of seals is compromised, leading to working fluid leakage and rapid performance degradation. Current sealing technologies have not adequately addressed the dynamic stresses experienced at material interfaces during repeated flexing cycles.

Manufacturing scalability remains another significant obstacle. Existing production methods for flexible vapor chambers are largely experimental and laboratory-based, utilizing techniques that are difficult to scale to mass production. The precision required for proper wick structures and internal chamber geometry is challenging to maintain when transitioning to flexible substrates and high-volume manufacturing processes.

Thermal performance degradation during bending represents a critical technical limitation. Studies have shown that vapor chamber thermal conductivity can decrease by 30-50% when bent to conformable angles needed for wearable applications. This performance reduction stems from changes in the internal fluid dynamics and potential formation of dry spots in the wick structure during deformation.

Material thickness constraints further complicate development efforts. Wearable devices demand ultra-thin thermal solutions, typically under 1mm, but reducing vapor chamber thickness while maintaining adequate vapor space and wick structures compromises thermal performance. Current flexible vapor chamber prototypes struggle to achieve the necessary thinness while delivering acceptable thermal management.

Long-term reliability under repeated mechanical stress remains largely unproven. Wearable devices may undergo thousands of flexing cycles during their operational lifetime, and current flexible vapor chamber designs show significant performance deterioration after relatively few cycles. The fatigue behavior of internal components, particularly at material interfaces and wick structures, requires substantial improvement.

Cost-effectiveness presents another barrier, as current manufacturing approaches for flexible vapor chambers involve complex multi-step processes and expensive materials. The production economics have not yet reached the point where integration into consumer wearable products is commercially viable at scale.

The hermetic sealing of flexible vapor chambers presents a particularly difficult challenge. As the device bends and flexes during normal wearable use, the integrity of seals is compromised, leading to working fluid leakage and rapid performance degradation. Current sealing technologies have not adequately addressed the dynamic stresses experienced at material interfaces during repeated flexing cycles.

Manufacturing scalability remains another significant obstacle. Existing production methods for flexible vapor chambers are largely experimental and laboratory-based, utilizing techniques that are difficult to scale to mass production. The precision required for proper wick structures and internal chamber geometry is challenging to maintain when transitioning to flexible substrates and high-volume manufacturing processes.

Thermal performance degradation during bending represents a critical technical limitation. Studies have shown that vapor chamber thermal conductivity can decrease by 30-50% when bent to conformable angles needed for wearable applications. This performance reduction stems from changes in the internal fluid dynamics and potential formation of dry spots in the wick structure during deformation.

Material thickness constraints further complicate development efforts. Wearable devices demand ultra-thin thermal solutions, typically under 1mm, but reducing vapor chamber thickness while maintaining adequate vapor space and wick structures compromises thermal performance. Current flexible vapor chamber prototypes struggle to achieve the necessary thinness while delivering acceptable thermal management.

Long-term reliability under repeated mechanical stress remains largely unproven. Wearable devices may undergo thousands of flexing cycles during their operational lifetime, and current flexible vapor chamber designs show significant performance deterioration after relatively few cycles. The fatigue behavior of internal components, particularly at material interfaces and wick structures, requires substantial improvement.

Cost-effectiveness presents another barrier, as current manufacturing approaches for flexible vapor chambers involve complex multi-step processes and expensive materials. The production economics have not yet reached the point where integration into consumer wearable products is commercially viable at scale.

Current Vapor Chamber-Polymer Integration Approaches

01 Flexible vapor chamber designs for electronic devices

Vapor chambers can be designed with flexible structures to accommodate the curved or bendable surfaces of modern electronic devices. These flexible designs often incorporate malleable materials or segmented structures that can bend without compromising the thermal performance. The flexibility allows for better integration with slim, curved devices while maintaining efficient heat dissipation capabilities.- Flexible vapor chamber designs for electronic devices: Vapor chambers can be designed with flexible structures to accommodate the curved or bendable surfaces of modern electronic devices. These designs incorporate materials and construction methods that allow the vapor chamber to flex without compromising its thermal performance. The flexibility enables better integration with slim, non-planar device designs while maintaining efficient heat dissipation capabilities.

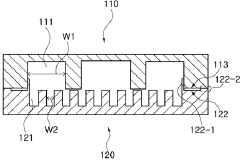

- Materials selection for flexible vapor chambers: The choice of materials significantly impacts the flexibility of vapor chambers. Advanced materials such as thin copper foils, flexible polymers, or composite materials can be used for the chamber walls. The working fluid and wick structure materials are also selected to maintain proper operation when the chamber is flexed. These material combinations enable the vapor chamber to bend while maintaining its structural integrity and heat transfer efficiency.

- Manufacturing techniques for flexible vapor chambers: Specialized manufacturing techniques are employed to create flexible vapor chambers. These include advanced bonding methods, precision stamping of thin materials, and innovative sealing technologies that maintain hermeticity while allowing flexibility. Some approaches involve segmented designs with flexible joints between rigid sections, while others use inherently flexible materials throughout the entire structure.

- Integration of flexible vapor chambers in mobile devices: Flexible vapor chambers are particularly valuable in mobile devices like smartphones and tablets where space is limited and form factors are increasingly non-planar. The integration requires careful consideration of attachment methods, thermal interface materials, and mechanical stress management. These vapor chambers can conform to the internal contours of devices, enabling more efficient cooling of components like processors and batteries without adding significant thickness.

- Performance optimization of flexible vapor chambers: Various design optimizations can enhance the performance of flexible vapor chambers. These include specialized wick structures that maintain capillary action when bent, variable thickness designs that concentrate flexibility in specific regions, and hybrid cooling solutions that combine vapor chambers with other thermal management technologies. Advanced testing methods are used to verify that thermal performance is maintained across different bending states and over the lifetime of the device.

02 Materials enhancing vapor chamber flexibility

Specific materials can be incorporated into vapor chamber construction to enhance flexibility while maintaining thermal conductivity. These may include flexible metal alloys, polymer composites, or specialized wick structures that can deform without failure. The selection of appropriate materials is crucial for creating vapor chambers that can withstand repeated bending or flexing while continuing to function effectively as heat transfer devices.Expand Specific Solutions03 Articulated vapor chamber systems

Articulated or segmented vapor chamber designs feature multiple connected chambers that can move relative to each other, providing flexibility to the overall system. These designs incorporate hinges, joints, or flexible connectors between rigid chamber sections, allowing the thermal solution to adapt to changing device configurations or to conform to non-planar surfaces while maintaining thermal performance across the entire system.Expand Specific Solutions04 Flexible wick structures for vapor chambers

Innovative wick structures within vapor chambers can be designed to maintain capillary action even when flexed or bent. These specialized wicks may use mesh materials, sintered powders with elastic binders, or microstructured surfaces that can deform while continuing to transport working fluid. The flexibility of the wick is essential for ensuring that the vapor chamber continues to function efficiently when subjected to bending or flexing forces.Expand Specific Solutions05 Manufacturing methods for flexible vapor chambers

Specialized manufacturing techniques have been developed to produce flexible vapor chambers. These methods may include selective bonding processes, advanced welding techniques for thin materials, or additive manufacturing approaches that create structures with inherent flexibility. The manufacturing process must ensure that the chamber remains hermetically sealed despite flexing, with particular attention to the integrity of seams and joints that might be subjected to repeated stress.Expand Specific Solutions

Key Industry Players in Flexible Thermal Management

The integration of vapor chambers with flexible polymers in wearable technology is currently in an early growth phase, with the market expected to expand significantly as demand for advanced thermal management in compact wearable devices increases. The global market for this technology is projected to reach approximately $2-3 billion by 2025, driven by consumer electronics and health monitoring applications. From a technical maturity perspective, the field is still evolving, with companies at different development stages. W.L. Gore & Associates leads with established expertise in breathable membranes, while Align Technology and Boston Scientific are advancing medical-grade flexible polymer applications. Newer entrants like Verdex Technology are pioneering nanofiber integration, and research partnerships with institutions like Carnegie Mellon University are accelerating innovation in polymer-based thermal solutions for next-generation wearables.

BOE Technology Group Co., Ltd.

Technical Solution: BOE Technology has developed a comprehensive vapor chamber solution for flexible display applications in wearable technology. Their approach utilizes ultra-thin copper-polymer composite vapor chambers with thickness ranging from 0.15mm to 0.4mm that can be integrated directly into flexible OLED substrates. BOE's technology incorporates a specialized sintered powder wick structure that maintains capillary action even during repeated flexing cycles, with demonstrated reliability for over 200,000 flex cycles. The company has created a proprietary interface layer that addresses the thermal expansion mismatch between metal vapor chambers and polymer substrates, preventing delamination during thermal cycling. Their manufacturing process utilizes roll-to-roll techniques that enable mass production while maintaining tight tolerances for the vapor chamber's internal structures. BOE has successfully implemented this technology in prototype flexible smartwatches and AR glasses, demonstrating temperature reductions of up to 15°C compared to conventional cooling solutions while maintaining the flexibility required for wearable applications.

Strengths: Highly optimized for flexible display applications; established mass production capabilities; excellent thermal performance in ultra-thin form factors. Weaknesses: Currently optimized primarily for display applications rather than broader wearable thermal management; higher cost compared to conventional cooling solutions; requires specialized integration processes.

W. L. Gore & Associates, Inc.

Technical Solution: W. L. Gore has developed advanced vapor chamber integration systems utilizing their proprietary ePTFE (expanded polytetrafluoroethylene) technology for wearable applications. Their approach combines microporous ePTFE membranes with vapor chamber thermal management to create ultra-thin, flexible cooling solutions. The company's technology enables vapor chambers as thin as 0.3mm that can be integrated into flexible polymer substrates while maintaining thermal conductivity up to 1500 W/m·K. Gore's solution incorporates a specialized working fluid compatible with polymer interfaces and utilizes a hybrid wick structure that maintains capillary action even during flexing. Their manufacturing process involves laser-welding techniques that create hermetic seals between the vapor chamber and polymer substrates without compromising flexibility or introducing thermal resistance at interfaces.

Strengths: Exceptional flexibility while maintaining thermal performance; proprietary ePTFE technology provides superior moisture management and durability; established manufacturing capabilities for mass production. Weaknesses: Higher cost compared to conventional cooling solutions; limited to applications where premium pricing is acceptable; requires specialized integration processes that may limit adoption by smaller manufacturers.

Critical Patents in Flexible Vapor Chamber Technology

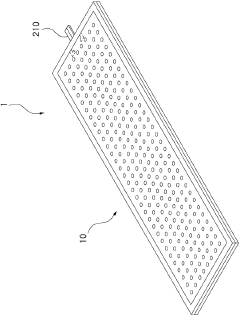

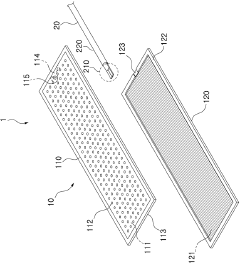

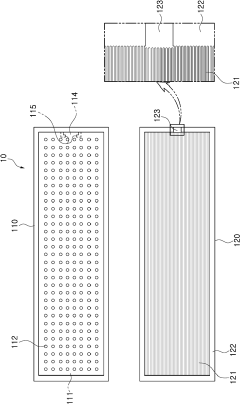

Flexible vapor chamber

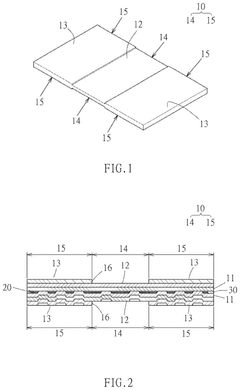

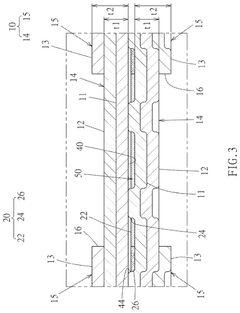

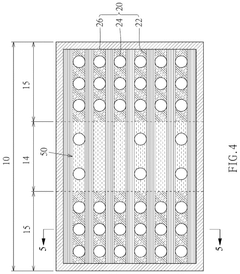

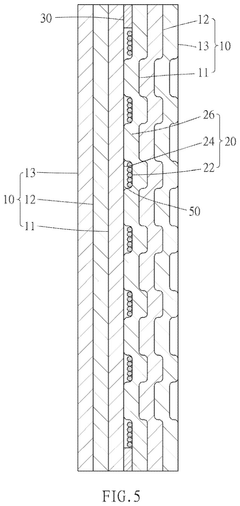

PatentActiveUS20250146761A1

Innovation

- A flexible vapor chamber is developed, comprising two flexible enclosures with a wick structure, each made of a layered structure including a first metal film, a flexible polymer film, and two second metal films, allowing for flexible bending and accommodating the folding of electronic devices.

Vapor chamber and manufacturing method thereof

PatentPendingKR1020240076976A

Innovation

- The vapor chamber is designed with a non-metallic upper and lower housing, featuring capillary force generators with specific groove widths and materials, and a manufacturing process that includes vacuum formation and laser bonding to reduce radio interference while maintaining cooling performance.

Material Science Advancements for Wearable Cooling

Recent advancements in material science have revolutionized the wearable cooling technology landscape, particularly in the integration of vapor chambers with flexible polymers. The evolution of thermally conductive polymers has been instrumental in this development, with new composite materials exhibiting thermal conductivity values approaching 20 W/m·K, a significant improvement from the 0.2-0.5 W/m·K range of traditional polymers.

Graphene-enhanced polymer composites represent a breakthrough in this field, offering exceptional thermal conductivity while maintaining the flexibility required for wearable applications. These materials incorporate graphene nanoplatelets or reduced graphene oxide within polymer matrices, creating pathways for efficient heat dissipation without compromising mechanical properties.

Phase-change materials (PCMs) embedded in polymer structures have emerged as another innovative approach. These materials can absorb and release thermal energy during phase transitions, providing temperature regulation capabilities critical for wearable cooling systems. Recent developments have focused on microencapsulation techniques that prevent leakage while maintaining thermal performance over thousands of cycles.

Vapor-permeable yet waterproof membranes constitute another significant advancement. These materials allow water vapor to escape while preventing liquid water penetration, addressing the moisture management challenges in wearable cooling technologies. The latest generation of these membranes incorporates nanoporous structures with precisely controlled pore sizes, optimizing both breathability and waterproofing properties.

Stretchable thermal interface materials (TIMs) have been developed specifically for the wearable technology sector. These materials maintain thermal conductivity even when subjected to repeated stretching and compression, ensuring consistent performance during body movement. Silicone-based TIMs infused with boron nitride nanotubes have shown particular promise, retaining over 90% of their thermal conductivity after 1000 stretch cycles.

Bio-based polymers derived from renewable resources are gaining traction as sustainable alternatives to petroleum-based materials. These polymers offer comparable thermal properties while reducing environmental impact. Cellulose nanofiber reinforced composites, for instance, demonstrate thermal conductivity values competitive with synthetic alternatives while being biodegradable.

Self-healing polymer systems represent the cutting edge of material science for wearable cooling. These materials can repair microdamage through various mechanisms, including encapsulated healing agents or dynamic chemical bonds, extending the operational lifespan of wearable devices. Recent research has demonstrated self-healing polymers capable of restoring up to 85% of their original thermal conductivity after mechanical damage.

Graphene-enhanced polymer composites represent a breakthrough in this field, offering exceptional thermal conductivity while maintaining the flexibility required for wearable applications. These materials incorporate graphene nanoplatelets or reduced graphene oxide within polymer matrices, creating pathways for efficient heat dissipation without compromising mechanical properties.

Phase-change materials (PCMs) embedded in polymer structures have emerged as another innovative approach. These materials can absorb and release thermal energy during phase transitions, providing temperature regulation capabilities critical for wearable cooling systems. Recent developments have focused on microencapsulation techniques that prevent leakage while maintaining thermal performance over thousands of cycles.

Vapor-permeable yet waterproof membranes constitute another significant advancement. These materials allow water vapor to escape while preventing liquid water penetration, addressing the moisture management challenges in wearable cooling technologies. The latest generation of these membranes incorporates nanoporous structures with precisely controlled pore sizes, optimizing both breathability and waterproofing properties.

Stretchable thermal interface materials (TIMs) have been developed specifically for the wearable technology sector. These materials maintain thermal conductivity even when subjected to repeated stretching and compression, ensuring consistent performance during body movement. Silicone-based TIMs infused with boron nitride nanotubes have shown particular promise, retaining over 90% of their thermal conductivity after 1000 stretch cycles.

Bio-based polymers derived from renewable resources are gaining traction as sustainable alternatives to petroleum-based materials. These polymers offer comparable thermal properties while reducing environmental impact. Cellulose nanofiber reinforced composites, for instance, demonstrate thermal conductivity values competitive with synthetic alternatives while being biodegradable.

Self-healing polymer systems represent the cutting edge of material science for wearable cooling. These materials can repair microdamage through various mechanisms, including encapsulated healing agents or dynamic chemical bonds, extending the operational lifespan of wearable devices. Recent research has demonstrated self-healing polymers capable of restoring up to 85% of their original thermal conductivity after mechanical damage.

Durability and Reliability Testing Methodologies

The integration of vapor chambers with flexible polymers in wearable technology necessitates comprehensive durability and reliability testing methodologies to ensure product longevity and performance under real-world conditions. These testing protocols must address the unique challenges posed by the combination of rigid thermal management components with flexible substrates in dynamic wearable environments.

Accelerated life testing represents a cornerstone methodology, subjecting integrated vapor chamber-polymer assemblies to intensified stress conditions that simulate extended use periods within compressed timeframes. This approach typically involves thermal cycling between extreme temperatures (-20°C to 60°C) to evaluate thermal expansion compatibility between vapor chambers and polymer matrices, with 500-1000 cycles generally considered sufficient for wearable applications.

Mechanical flexibility testing employs standardized bend radius assessments, where samples undergo repeated flexing at predetermined angles (typically 5,000-10,000 cycles at 45°-180° bends) to evaluate potential delamination, crack formation, or thermal performance degradation. Advanced testing platforms incorporate multi-axis movement patterns that replicate actual body movements during various activities.

Environmental resistance testing exposes prototypes to controlled humidity (85% RH), salt spray, UV radiation, and chemical exposure scenarios common in wearable applications. These tests evaluate potential polymer degradation, vapor chamber seal integrity, and overall system resilience against environmental factors that could compromise thermal performance or structural integrity.

Drop and impact testing follows modified ASTM standards adapted specifically for wearable technology, with test parameters calibrated to represent realistic usage scenarios. Samples typically undergo multiple impact events from various angles and heights (0.5-1.5 meters) to assess structural integrity and post-impact thermal performance.

Wear simulation testing employs specialized equipment that replicates friction, pressure, and abrasion conditions experienced during daily wear. These tests evaluate surface degradation, interface integrity between vapor chambers and polymer substrates, and potential changes in thermal conductivity pathways after extended wear periods.

Non-destructive evaluation techniques, including infrared thermography, acoustic microscopy, and micro-CT scanning, provide critical data on internal structural changes without compromising sample integrity. These methods enable researchers to track progressive degradation mechanisms and identify failure precursors before catastrophic failure occurs.

Statistical reliability modeling complements physical testing by establishing mathematical frameworks for predicting long-term performance based on accelerated test data. Weibull distribution analysis and Monte Carlo simulations help quantify reliability metrics and establish confidence intervals for product lifetime predictions under various usage scenarios.

Accelerated life testing represents a cornerstone methodology, subjecting integrated vapor chamber-polymer assemblies to intensified stress conditions that simulate extended use periods within compressed timeframes. This approach typically involves thermal cycling between extreme temperatures (-20°C to 60°C) to evaluate thermal expansion compatibility between vapor chambers and polymer matrices, with 500-1000 cycles generally considered sufficient for wearable applications.

Mechanical flexibility testing employs standardized bend radius assessments, where samples undergo repeated flexing at predetermined angles (typically 5,000-10,000 cycles at 45°-180° bends) to evaluate potential delamination, crack formation, or thermal performance degradation. Advanced testing platforms incorporate multi-axis movement patterns that replicate actual body movements during various activities.

Environmental resistance testing exposes prototypes to controlled humidity (85% RH), salt spray, UV radiation, and chemical exposure scenarios common in wearable applications. These tests evaluate potential polymer degradation, vapor chamber seal integrity, and overall system resilience against environmental factors that could compromise thermal performance or structural integrity.

Drop and impact testing follows modified ASTM standards adapted specifically for wearable technology, with test parameters calibrated to represent realistic usage scenarios. Samples typically undergo multiple impact events from various angles and heights (0.5-1.5 meters) to assess structural integrity and post-impact thermal performance.

Wear simulation testing employs specialized equipment that replicates friction, pressure, and abrasion conditions experienced during daily wear. These tests evaluate surface degradation, interface integrity between vapor chambers and polymer substrates, and potential changes in thermal conductivity pathways after extended wear periods.

Non-destructive evaluation techniques, including infrared thermography, acoustic microscopy, and micro-CT scanning, provide critical data on internal structural changes without compromising sample integrity. These methods enable researchers to track progressive degradation mechanisms and identify failure precursors before catastrophic failure occurs.

Statistical reliability modeling complements physical testing by establishing mathematical frameworks for predicting long-term performance based on accelerated test data. Weibull distribution analysis and Monte Carlo simulations help quantify reliability metrics and establish confidence intervals for product lifetime predictions under various usage scenarios.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!