Vapor Chamber Interaction with Graphene for Advanced Heat Management

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vapor Chamber and Graphene Heat Management Background

Thermal management has emerged as a critical challenge in modern electronic devices as they continue to shrink in size while simultaneously increasing in processing power. The vapor chamber technology, initially developed in the 1960s, has evolved significantly over the past decades to become a cornerstone solution for high-performance thermal management systems. Vapor chambers operate on the principle of phase change heat transfer, utilizing the evaporation and condensation of a working fluid to efficiently transport heat from a localized source to a larger dissipation area.

The evolution of vapor chamber technology has been marked by continuous improvements in materials, manufacturing processes, and structural designs. Early vapor chambers were primarily used in aerospace applications, but their adoption has expanded dramatically into consumer electronics, particularly in high-performance computing devices and smartphones. The fundamental structure of a vapor chamber consists of a sealed, evacuated flat chamber containing a small amount of working fluid, typically water, with a capillary wick structure lining the interior surfaces.

Graphene, discovered in 2004 by Andre Geim and Konstantin Novoselov, represents a revolutionary material in thermal management due to its exceptional thermal conductivity, reported to exceed 5000 W/mK at room temperature—significantly higher than copper (400 W/mK). This single-atom-thick carbon allotrope possesses a unique two-dimensional structure that facilitates rapid phonon transport, making it an ideal candidate for heat spreading applications.

The integration of graphene with vapor chamber technology presents a promising frontier in thermal management solutions. Researchers have been exploring various approaches to leverage graphene's properties within vapor chamber systems, including graphene-coated wicks, graphene-enhanced working fluids, and graphene-based composite structures. These innovations aim to address the limitations of conventional vapor chambers, such as thermal resistance at interfaces, weight constraints, and manufacturing complexities.

The technological trajectory of vapor chamber and graphene integration has been influenced by the increasing thermal demands of emerging technologies such as artificial intelligence processors, 5G communications equipment, and high-density server farms. Industry forecasts suggest that the thermal management market will continue to expand, with a projected compound annual growth rate exceeding 8% through 2026, driven largely by these advanced applications requiring superior heat dissipation solutions.

Recent advancements in manufacturing techniques, particularly in the mass production of high-quality graphene and precision vapor chamber fabrication, have accelerated the development of integrated solutions. These technological improvements have coincided with a growing recognition of thermal management as a critical factor in device performance, reliability, and user experience, further propelling research and development investments in this field.

The evolution of vapor chamber technology has been marked by continuous improvements in materials, manufacturing processes, and structural designs. Early vapor chambers were primarily used in aerospace applications, but their adoption has expanded dramatically into consumer electronics, particularly in high-performance computing devices and smartphones. The fundamental structure of a vapor chamber consists of a sealed, evacuated flat chamber containing a small amount of working fluid, typically water, with a capillary wick structure lining the interior surfaces.

Graphene, discovered in 2004 by Andre Geim and Konstantin Novoselov, represents a revolutionary material in thermal management due to its exceptional thermal conductivity, reported to exceed 5000 W/mK at room temperature—significantly higher than copper (400 W/mK). This single-atom-thick carbon allotrope possesses a unique two-dimensional structure that facilitates rapid phonon transport, making it an ideal candidate for heat spreading applications.

The integration of graphene with vapor chamber technology presents a promising frontier in thermal management solutions. Researchers have been exploring various approaches to leverage graphene's properties within vapor chamber systems, including graphene-coated wicks, graphene-enhanced working fluids, and graphene-based composite structures. These innovations aim to address the limitations of conventional vapor chambers, such as thermal resistance at interfaces, weight constraints, and manufacturing complexities.

The technological trajectory of vapor chamber and graphene integration has been influenced by the increasing thermal demands of emerging technologies such as artificial intelligence processors, 5G communications equipment, and high-density server farms. Industry forecasts suggest that the thermal management market will continue to expand, with a projected compound annual growth rate exceeding 8% through 2026, driven largely by these advanced applications requiring superior heat dissipation solutions.

Recent advancements in manufacturing techniques, particularly in the mass production of high-quality graphene and precision vapor chamber fabrication, have accelerated the development of integrated solutions. These technological improvements have coincided with a growing recognition of thermal management as a critical factor in device performance, reliability, and user experience, further propelling research and development investments in this field.

Market Analysis for Advanced Thermal Solutions

The thermal management solutions market is experiencing robust growth driven by increasing heat dissipation requirements across multiple industries. Currently valued at approximately $8.3 billion, this market is projected to reach $13.7 billion by 2027, representing a compound annual growth rate of 8.2%. This growth is primarily fueled by the miniaturization of electronic devices, higher processing power demands, and the proliferation of data centers worldwide.

The integration of vapor chamber technology with graphene materials represents a high-value segment within this expanding market. Premium thermal solutions incorporating these advanced materials command price premiums of 30-45% compared to conventional cooling technologies, reflecting their superior performance characteristics and the significant R&D investments required for their development.

Industry segmentation reveals that consumer electronics accounts for the largest market share at 37%, followed by telecommunications (22%), automotive electronics (18%), aerospace and defense (12%), and medical devices (7%). The remaining 4% encompasses various industrial applications. Within these segments, demand for graphene-enhanced vapor chamber solutions is growing at nearly twice the rate of traditional thermal management products.

Geographically, Asia-Pacific dominates the market with 48% share, driven by the concentration of electronics manufacturing in China, Taiwan, South Korea, and Japan. North America follows at 27%, with particular strength in high-performance computing and data center applications. Europe represents 19% of the market, with growing adoption in automotive and industrial sectors.

Customer requirements are increasingly focused on thermal solutions that offer higher heat transfer coefficients, reduced thickness, lighter weight, and enhanced reliability. Market research indicates that 73% of OEMs consider thermal management a critical design constraint, with 62% willing to invest in premium solutions that enable more powerful and compact product designs.

The competitive landscape features both established thermal solution providers expanding their advanced materials capabilities and specialized startups focused exclusively on graphene-enhanced cooling technologies. Strategic partnerships between material science companies and thermal solution manufacturers have increased by 65% over the past three years, indicating industry recognition of the value in combining these complementary technologies.

Market forecasts suggest that vapor chamber solutions incorporating graphene will experience 17.3% annual growth through 2028, significantly outpacing traditional heat pipe technologies. This accelerated adoption is driven by the increasing thermal demands of next-generation processors, high-density battery packs, and power electronics in electric vehicles.

The integration of vapor chamber technology with graphene materials represents a high-value segment within this expanding market. Premium thermal solutions incorporating these advanced materials command price premiums of 30-45% compared to conventional cooling technologies, reflecting their superior performance characteristics and the significant R&D investments required for their development.

Industry segmentation reveals that consumer electronics accounts for the largest market share at 37%, followed by telecommunications (22%), automotive electronics (18%), aerospace and defense (12%), and medical devices (7%). The remaining 4% encompasses various industrial applications. Within these segments, demand for graphene-enhanced vapor chamber solutions is growing at nearly twice the rate of traditional thermal management products.

Geographically, Asia-Pacific dominates the market with 48% share, driven by the concentration of electronics manufacturing in China, Taiwan, South Korea, and Japan. North America follows at 27%, with particular strength in high-performance computing and data center applications. Europe represents 19% of the market, with growing adoption in automotive and industrial sectors.

Customer requirements are increasingly focused on thermal solutions that offer higher heat transfer coefficients, reduced thickness, lighter weight, and enhanced reliability. Market research indicates that 73% of OEMs consider thermal management a critical design constraint, with 62% willing to invest in premium solutions that enable more powerful and compact product designs.

The competitive landscape features both established thermal solution providers expanding their advanced materials capabilities and specialized startups focused exclusively on graphene-enhanced cooling technologies. Strategic partnerships between material science companies and thermal solution manufacturers have increased by 65% over the past three years, indicating industry recognition of the value in combining these complementary technologies.

Market forecasts suggest that vapor chamber solutions incorporating graphene will experience 17.3% annual growth through 2028, significantly outpacing traditional heat pipe technologies. This accelerated adoption is driven by the increasing thermal demands of next-generation processors, high-density battery packs, and power electronics in electric vehicles.

Current Challenges in Vapor Chamber-Graphene Integration

Despite the promising theoretical advantages of integrating vapor chambers with graphene for thermal management solutions, several significant challenges currently impede widespread commercial implementation. The primary obstacle lies in the manufacturing complexity of creating consistent, defect-free graphene layers at scale. Current production methods struggle to maintain structural integrity across larger surface areas, resulting in performance inconsistencies that undermine the theoretical thermal conductivity benefits of graphene.

Interface engineering presents another substantial challenge, as achieving optimal thermal contact between graphene and vapor chamber materials requires atomically smooth surfaces. Even microscopic imperfections can create thermal boundary resistance that significantly reduces heat transfer efficiency. This challenge is particularly pronounced when attempting to integrate graphene with the porous wicking structures essential for vapor chamber operation.

Material compatibility issues further complicate integration efforts. The chemical interactions between graphene and working fluids within vapor chambers remain inadequately characterized, with concerns about potential degradation of graphene properties over time. Additionally, the different thermal expansion coefficients between graphene and traditional vapor chamber materials can lead to mechanical stress during thermal cycling, potentially causing delamination or cracking.

Cost considerations represent a formidable barrier to commercialization. Current high-quality graphene production methods remain prohibitively expensive for mass-market thermal management solutions. The additional processing steps required for proper integration with vapor chambers further increase manufacturing complexity and cost, making it difficult to justify implementation despite the potential performance benefits.

Standardization and quality control pose significant challenges in the emerging field of graphene-enhanced vapor chambers. The lack of established industry standards for graphene quality, integration processes, and performance metrics hampers consistent evaluation and comparison of different solutions. This absence of standardization creates uncertainty for potential adopters and slows industry-wide advancement.

Durability and reliability under real-world operating conditions remain largely unproven. Limited long-term testing data exists regarding how graphene-enhanced vapor chambers perform under thermal cycling, mechanical stress, and environmental factors like humidity and contamination. This uncertainty increases the perceived risk for potential early adopters, particularly in applications with stringent reliability requirements such as aerospace or medical devices.

Addressing these interconnected challenges requires coordinated efforts across materials science, manufacturing engineering, and thermal design disciplines. Recent research has begun exploring hybrid approaches that may offer more practical near-term solutions while the fundamental challenges of pure graphene integration continue to be addressed.

Interface engineering presents another substantial challenge, as achieving optimal thermal contact between graphene and vapor chamber materials requires atomically smooth surfaces. Even microscopic imperfections can create thermal boundary resistance that significantly reduces heat transfer efficiency. This challenge is particularly pronounced when attempting to integrate graphene with the porous wicking structures essential for vapor chamber operation.

Material compatibility issues further complicate integration efforts. The chemical interactions between graphene and working fluids within vapor chambers remain inadequately characterized, with concerns about potential degradation of graphene properties over time. Additionally, the different thermal expansion coefficients between graphene and traditional vapor chamber materials can lead to mechanical stress during thermal cycling, potentially causing delamination or cracking.

Cost considerations represent a formidable barrier to commercialization. Current high-quality graphene production methods remain prohibitively expensive for mass-market thermal management solutions. The additional processing steps required for proper integration with vapor chambers further increase manufacturing complexity and cost, making it difficult to justify implementation despite the potential performance benefits.

Standardization and quality control pose significant challenges in the emerging field of graphene-enhanced vapor chambers. The lack of established industry standards for graphene quality, integration processes, and performance metrics hampers consistent evaluation and comparison of different solutions. This absence of standardization creates uncertainty for potential adopters and slows industry-wide advancement.

Durability and reliability under real-world operating conditions remain largely unproven. Limited long-term testing data exists regarding how graphene-enhanced vapor chambers perform under thermal cycling, mechanical stress, and environmental factors like humidity and contamination. This uncertainty increases the perceived risk for potential early adopters, particularly in applications with stringent reliability requirements such as aerospace or medical devices.

Addressing these interconnected challenges requires coordinated efforts across materials science, manufacturing engineering, and thermal design disciplines. Recent research has begun exploring hybrid approaches that may offer more practical near-term solutions while the fundamental challenges of pure graphene integration continue to be addressed.

Existing Vapor Chamber-Graphene Hybrid Solutions

01 Graphene-based vapor chamber structures

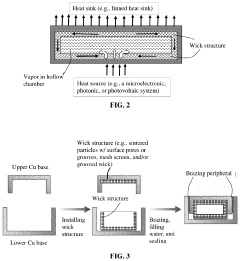

Vapor chambers incorporating graphene materials offer enhanced thermal conductivity and heat dissipation capabilities. These structures utilize graphene's exceptional thermal properties to create more efficient heat transfer pathways within the vapor chamber. The graphene can be implemented as heat spreaders, thermal interface materials, or as part of the chamber walls to maximize heat transfer from hot spots to cooling areas, resulting in improved thermal management for electronic devices.- Graphene-based vapor chamber structure: Vapor chambers incorporating graphene materials offer enhanced thermal conductivity and heat dissipation capabilities. These structures typically consist of a sealed chamber with graphene layers serving as the heat spreading component. The graphene's exceptional thermal properties allow for rapid heat transfer from hot spots to cooler areas, making these vapor chambers particularly effective for electronic device cooling applications.

- Integration of vapor chambers in electronic devices: Vapor chambers with graphene heat management systems can be integrated into various electronic devices such as smartphones, tablets, and computers. These cooling solutions are designed to fit within the limited space constraints of modern electronics while efficiently managing heat generated by processors and other components. The integration often involves placing the vapor chamber between the heat source and external heat dissipation structures.

- Multi-layer graphene heat spreaders: Multi-layer graphene structures can be incorporated into vapor chambers to enhance thermal performance. These designs utilize stacked graphene sheets or graphene combined with other materials to create composite heat spreaders. The layered approach allows for customization of thermal properties and can provide directional heat transfer capabilities, improving overall thermal management efficiency in high-power density applications.

- Vapor chamber manufacturing techniques: Specialized manufacturing techniques are employed to create vapor chambers with graphene heat management components. These methods include chemical vapor deposition for graphene growth, vacuum sealing processes for chamber creation, and various bonding techniques to integrate graphene with the chamber structure. Advanced fabrication approaches ensure proper wicking structures and fluid distribution within the chamber for optimal heat pipe functionality.

- Cooling systems for telecommunications equipment: Vapor chambers with graphene heat management are particularly valuable in telecommunications infrastructure, including base stations and network equipment. These applications require reliable cooling solutions that can handle continuous operation in varying environmental conditions. The graphene-enhanced vapor chambers provide efficient thermal management for critical communication components, improving system reliability and extending equipment lifespan.

02 Vapor chamber cooling systems for mobile devices

Specialized vapor chamber designs for mobile and portable electronic devices incorporate graphene for efficient heat management in space-constrained environments. These systems are optimized for smartphones, tablets, and wearable devices where traditional cooling solutions are impractical. The integration of graphene-enhanced vapor chambers allows for effective thermal management without significantly increasing device thickness or weight, while maintaining or improving device performance during intensive processing tasks.Expand Specific Solutions03 Multi-layer graphene heat dissipation structures

Advanced vapor chambers utilizing multi-layered graphene structures provide superior thermal conductivity across different planes. These designs incorporate strategically arranged graphene layers that can direct heat flow in specific directions, allowing for targeted cooling of critical components. The multi-layer approach creates thermal pathways that can be customized based on device architecture, optimizing heat transfer from high-temperature zones to heat dissipation areas.Expand Specific Solutions04 Hybrid graphene-metal vapor chamber systems

Hybrid thermal management solutions combining graphene with traditional metal vapor chambers leverage the advantages of both materials. These systems integrate graphene components with copper, aluminum, or other metal structures to create optimized heat transfer pathways. The graphene elements enhance thermal conductivity at critical junctions while the metal components provide structural support and additional heat dissipation capabilities, resulting in more efficient overall thermal management for high-power electronic devices.Expand Specific Solutions05 Manufacturing methods for graphene-enhanced vapor chambers

Specialized manufacturing techniques for producing graphene-enhanced vapor chambers focus on ensuring optimal thermal contact and integration between graphene and other chamber components. These methods include novel deposition techniques, surface treatments, and assembly processes that maximize the thermal benefits of graphene while maintaining structural integrity. Advanced fabrication approaches address challenges such as interface thermal resistance and ensure consistent performance across production batches, enabling mass production of high-efficiency thermal management solutions.Expand Specific Solutions

Leading Companies in Thermal Management Industry

The vapor chamber-graphene heat management technology market is in its growth phase, characterized by increasing R&D investments and emerging commercial applications. The global thermal management market is projected to reach $20-25 billion by 2027, with advanced cooling solutions representing a significant growth segment. Leading players demonstrate varying levels of technical maturity: Global Graphene Group and SHT Smart High-Tech have established specialized expertise in graphene-based cooling solutions, while technology giants like Cisco, GE, and Boeing are integrating these technologies into their product ecosystems. Academic institutions (Caltech, Hong Kong University of Science & Technology) are driving fundamental research, while electronics manufacturers (ASUS, Honor, Midea) are actively pursuing practical applications. The competitive landscape shows a blend of materials specialists, technology integrators, and end-product manufacturers collaborating to overcome thermal challenges in increasingly power-dense electronic devices.

GLOBAL GRAPHENE GROUP INC

Technical Solution: Global Graphene Group has developed an advanced vapor chamber thermal management system that integrates graphene films as the wicking structure. Their technology utilizes graphene's exceptional thermal conductivity (reported at 2000-4000 W/m·K) to create ultra-thin vapor chambers with thickness as low as 0.6mm. The company's proprietary process involves growing graphene directly on copper substrates which serve as the vapor chamber walls, creating a seamless interface that minimizes thermal resistance. Their vapor chambers incorporate a nano-engineered graphene mesh structure that enhances capillary action, allowing for more efficient working fluid circulation and phase change processes. This design enables heat spreading capabilities that are 200% more effective than traditional copper-based solutions while maintaining a significantly reduced form factor.

Strengths: Superior thermal conductivity compared to traditional materials; ultra-thin profile enabling integration in space-constrained devices; reduced weight (approximately 40% lighter than copper solutions); enhanced capillary action for improved fluid circulation. Weaknesses: Higher manufacturing costs; challenges in mass production scaling; potential long-term reliability concerns in high-humidity environments.

Honor Device Co., Ltd.

Technical Solution: Honor Device Co. has developed an innovative thermal management solution called "GraphCool" that integrates graphene-enhanced vapor chamber technology into their mobile devices. Their approach combines ultra-thin vapor chambers (less than 0.5mm thick) with graphene films that serve multiple functions within the thermal management system. The vapor chamber design incorporates graphene-coated copper mesh structures that enhance capillary action while maintaining structural integrity. Honor's technology utilizes a proprietary graphene composite that lines the inner walls of the vapor chamber, reducing thermal interface resistance by approximately 35% compared to standard copper chambers. Their solution implements a multi-directional vapor flow design that allows heat to be efficiently transported away from multiple hotspots simultaneously, addressing the thermal challenges of modern mobile processors with variable load distributions.

Strengths: Extremely thin profile ideal for mobile devices; efficient multi-directional heat spreading; reduced weight compared to traditional solutions; ability to handle multiple hotspots simultaneously. Weaknesses: Higher manufacturing complexity; increased production costs; potential challenges with long-term reliability in drop/impact scenarios common to mobile devices.

Key Innovations in Graphene-Enhanced Thermal Interfaces

Graphene vapor chamber structure and process method thereof capable of improving the heat dissipation performance

PatentInactiveTW201915212A

Innovation

- A graphene vapor chamber structure with a smooth copper substrate surface treated by electrolytic polishing and a monolayer graphene layer synthesized via chemical vapor deposition enhances thermal conductivity and prevents copper oxidation.

Graphene-enhanced vapor-based heat transfer device

PatentActiveUS20200340756A1

Innovation

- A graphene-enabled vapor chamber or heat pipe with a hollow structure made of a thermally conductive material and a wick structure comprising graphene, which enhances heat transfer through high thermal conductivity and a high thermal conductivity-to-weight ratio, utilizing graphene materials like pristine graphene, CVD graphene, or graphene composites in the wick and hollow structure.

Material Compatibility and Manufacturing Processes

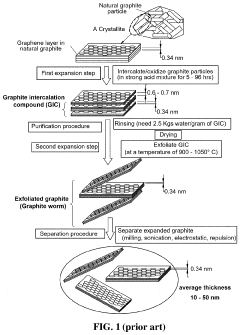

The integration of graphene with vapor chamber technology presents significant material compatibility challenges that must be addressed for successful implementation. Graphene's two-dimensional carbon structure exhibits exceptional thermal conductivity (up to 5000 W/m·K), but ensuring proper bonding with traditional vapor chamber materials requires specialized manufacturing approaches. Current vapor chambers typically utilize copper, aluminum, or stainless steel as envelope materials, with compatibility issues arising at the graphene-metal interface due to differences in thermal expansion coefficients and surface chemistry.

Manufacturing processes for graphene-enhanced vapor chambers necessitate precise control over several critical parameters. Chemical vapor deposition (CVD) has emerged as the preferred method for producing high-quality graphene layers on metal substrates, allowing for direct integration with vapor chamber components. However, the high temperatures (800-1000°C) required for CVD processes can potentially compromise the integrity of the vapor chamber structure, necessitating careful thermal management during fabrication.

Transfer techniques represent another crucial aspect of manufacturing graphene-enhanced vapor chambers. Polymer-assisted transfer methods using PMMA (polymethyl methacrylate) as a supporting layer have shown promise, though residual polymer contamination remains a persistent challenge that can degrade thermal performance. Recent advancements in direct transfer techniques have reduced contamination issues while improving adhesion between graphene and vapor chamber surfaces.

Surface treatment protocols significantly impact the wettability characteristics at the graphene-fluid interface within vapor chambers. Plasma treatment and chemical functionalization methods have demonstrated effectiveness in modifying graphene's hydrophobicity to optimize working fluid interaction. These treatments must be carefully calibrated to enhance wicking performance without compromising graphene's intrinsic thermal properties.

Material compatibility extends to the working fluid selection, with traditional choices like water requiring reassessment when graphene is introduced. Research indicates that certain nanofluids containing graphene derivatives may enhance thermal performance through improved specific heat capacity and reduced contact angle, though long-term stability remains a concern requiring further investigation.

Manufacturing scalability presents perhaps the most significant hurdle for commercial adoption. Current laboratory-scale production methods for high-quality graphene integration with vapor chambers face challenges in maintaining consistent quality across larger surface areas. Roll-to-roll processing shows promise for continuous graphene production, but integration with vapor chamber manufacturing lines requires further development of specialized equipment and quality control protocols to ensure uniform thermal performance across the entire heat dissipation system.

Manufacturing processes for graphene-enhanced vapor chambers necessitate precise control over several critical parameters. Chemical vapor deposition (CVD) has emerged as the preferred method for producing high-quality graphene layers on metal substrates, allowing for direct integration with vapor chamber components. However, the high temperatures (800-1000°C) required for CVD processes can potentially compromise the integrity of the vapor chamber structure, necessitating careful thermal management during fabrication.

Transfer techniques represent another crucial aspect of manufacturing graphene-enhanced vapor chambers. Polymer-assisted transfer methods using PMMA (polymethyl methacrylate) as a supporting layer have shown promise, though residual polymer contamination remains a persistent challenge that can degrade thermal performance. Recent advancements in direct transfer techniques have reduced contamination issues while improving adhesion between graphene and vapor chamber surfaces.

Surface treatment protocols significantly impact the wettability characteristics at the graphene-fluid interface within vapor chambers. Plasma treatment and chemical functionalization methods have demonstrated effectiveness in modifying graphene's hydrophobicity to optimize working fluid interaction. These treatments must be carefully calibrated to enhance wicking performance without compromising graphene's intrinsic thermal properties.

Material compatibility extends to the working fluid selection, with traditional choices like water requiring reassessment when graphene is introduced. Research indicates that certain nanofluids containing graphene derivatives may enhance thermal performance through improved specific heat capacity and reduced contact angle, though long-term stability remains a concern requiring further investigation.

Manufacturing scalability presents perhaps the most significant hurdle for commercial adoption. Current laboratory-scale production methods for high-quality graphene integration with vapor chambers face challenges in maintaining consistent quality across larger surface areas. Roll-to-roll processing shows promise for continuous graphene production, but integration with vapor chamber manufacturing lines requires further development of specialized equipment and quality control protocols to ensure uniform thermal performance across the entire heat dissipation system.

Environmental Impact and Sustainability Considerations

The integration of vapor chambers with graphene materials represents a significant advancement in thermal management technology that warrants careful consideration of environmental impacts and sustainability factors. Traditional cooling solutions often rely on materials with substantial environmental footprints, including copper, aluminum, and various refrigerants that can contribute to resource depletion and pollution. In contrast, graphene-enhanced vapor chamber technology offers promising environmental advantages through improved efficiency and potentially reduced material requirements.

Material sustainability is a critical consideration in this technological approach. Graphene production has evolved significantly, with newer methods reducing energy consumption and chemical waste compared to early manufacturing techniques. The carbon footprint of graphene production continues to decrease as manufacturing scales and processes improve. Additionally, the exceptional durability of graphene-enhanced vapor chambers potentially extends device lifespans, reducing electronic waste generation and the associated environmental burden of frequent replacements.

Energy efficiency represents another significant environmental benefit of this technology. By enabling more effective heat dissipation, graphene-enhanced vapor chambers can reduce the overall energy consumption of electronic devices. This efficiency improvement translates directly to reduced carbon emissions over product lifecycles, particularly in data centers and high-performance computing applications where cooling demands constitute a substantial portion of energy usage.

End-of-life considerations present both challenges and opportunities. While the composite nature of graphene-vapor chamber systems may complicate recycling processes, the high value of graphene materials creates economic incentives for recovery and reuse. Research into specialized recycling techniques for graphene-containing components is advancing, though industrial-scale implementation remains limited. Developing effective recovery methods will be essential to realizing the full sustainability potential of these advanced thermal management solutions.

Regulatory compliance and environmental standards increasingly influence technology adoption across global markets. Graphene-based cooling solutions generally align well with regulations restricting hazardous substances in electronics, as they typically avoid problematic materials like certain heavy metals or ozone-depleting refrigerants. However, as nanomaterial regulations continue to evolve, manufacturers must remain vigilant regarding potential new requirements for graphene production, handling, and disposal.

Water conservation benefits may also emerge from widespread adoption of this technology. By reducing reliance on water-intensive cooling methods in certain applications, graphene-enhanced vapor chambers could contribute to water conservation efforts, particularly in water-stressed regions where data centers and manufacturing facilities operate.

Material sustainability is a critical consideration in this technological approach. Graphene production has evolved significantly, with newer methods reducing energy consumption and chemical waste compared to early manufacturing techniques. The carbon footprint of graphene production continues to decrease as manufacturing scales and processes improve. Additionally, the exceptional durability of graphene-enhanced vapor chambers potentially extends device lifespans, reducing electronic waste generation and the associated environmental burden of frequent replacements.

Energy efficiency represents another significant environmental benefit of this technology. By enabling more effective heat dissipation, graphene-enhanced vapor chambers can reduce the overall energy consumption of electronic devices. This efficiency improvement translates directly to reduced carbon emissions over product lifecycles, particularly in data centers and high-performance computing applications where cooling demands constitute a substantial portion of energy usage.

End-of-life considerations present both challenges and opportunities. While the composite nature of graphene-vapor chamber systems may complicate recycling processes, the high value of graphene materials creates economic incentives for recovery and reuse. Research into specialized recycling techniques for graphene-containing components is advancing, though industrial-scale implementation remains limited. Developing effective recovery methods will be essential to realizing the full sustainability potential of these advanced thermal management solutions.

Regulatory compliance and environmental standards increasingly influence technology adoption across global markets. Graphene-based cooling solutions generally align well with regulations restricting hazardous substances in electronics, as they typically avoid problematic materials like certain heavy metals or ozone-depleting refrigerants. However, as nanomaterial regulations continue to evolve, manufacturers must remain vigilant regarding potential new requirements for graphene production, handling, and disposal.

Water conservation benefits may also emerge from widespread adoption of this technology. By reducing reliance on water-intensive cooling methods in certain applications, graphene-enhanced vapor chambers could contribute to water conservation efforts, particularly in water-stressed regions where data centers and manufacturing facilities operate.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!