Vapor Chamber Material Innovations for Aerospace Applications

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aerospace Thermal Management Background and Objectives

Thermal management in aerospace applications has evolved significantly over the past decades, driven by the increasing power densities and miniaturization of electronic components in aircraft and spacecraft systems. Traditional cooling methods such as air cooling and liquid cooling have reached their limits in addressing the thermal challenges posed by modern aerospace electronics. The emergence of vapor chamber technology represents a paradigm shift in thermal management solutions, offering superior heat spreading capabilities and thermal efficiency.

The aerospace industry demands thermal management systems that can operate reliably under extreme conditions, including high-altitude environments, vacuum conditions, and significant temperature fluctuations. These systems must maintain optimal operating temperatures for critical electronic components while minimizing weight and volume constraints, which are paramount considerations in aerospace design.

Historically, thermal management in aerospace has progressed from simple heat sinks to more sophisticated solutions incorporating heat pipes and cold plates. The introduction of vapor chambers marks the latest advancement in this evolutionary trajectory, combining the principles of phase change heat transfer with innovative material science to create highly efficient thermal spreaders.

The primary objective of vapor chamber material innovations for aerospace applications is to develop thermal management solutions that can effectively dissipate heat from high-power electronic components while meeting the stringent requirements of aerospace environments. This includes achieving higher thermal conductivity, reduced weight, enhanced reliability, and improved resistance to extreme conditions.

Current research focuses on exploring novel materials and manufacturing techniques to enhance the performance of vapor chambers in aerospace settings. This encompasses investigations into advanced wick structures, working fluids with superior thermophysical properties, and envelope materials that offer improved strength-to-weight ratios and corrosion resistance.

The integration of vapor chamber technology into aerospace thermal management systems aims to address several critical challenges, including the thermal control of satellite electronics, cooling of aircraft avionics, and thermal regulation in space habitats. By enabling more efficient heat dissipation, these innovations contribute to extending the operational lifespan of aerospace systems and enhancing their overall reliability.

As aerospace systems continue to advance in complexity and capability, the demand for more effective thermal management solutions grows correspondingly. Vapor chamber material innovations represent a promising avenue for meeting these evolving requirements, potentially revolutionizing how thermal challenges are addressed in next-generation aerospace applications.

The aerospace industry demands thermal management systems that can operate reliably under extreme conditions, including high-altitude environments, vacuum conditions, and significant temperature fluctuations. These systems must maintain optimal operating temperatures for critical electronic components while minimizing weight and volume constraints, which are paramount considerations in aerospace design.

Historically, thermal management in aerospace has progressed from simple heat sinks to more sophisticated solutions incorporating heat pipes and cold plates. The introduction of vapor chambers marks the latest advancement in this evolutionary trajectory, combining the principles of phase change heat transfer with innovative material science to create highly efficient thermal spreaders.

The primary objective of vapor chamber material innovations for aerospace applications is to develop thermal management solutions that can effectively dissipate heat from high-power electronic components while meeting the stringent requirements of aerospace environments. This includes achieving higher thermal conductivity, reduced weight, enhanced reliability, and improved resistance to extreme conditions.

Current research focuses on exploring novel materials and manufacturing techniques to enhance the performance of vapor chambers in aerospace settings. This encompasses investigations into advanced wick structures, working fluids with superior thermophysical properties, and envelope materials that offer improved strength-to-weight ratios and corrosion resistance.

The integration of vapor chamber technology into aerospace thermal management systems aims to address several critical challenges, including the thermal control of satellite electronics, cooling of aircraft avionics, and thermal regulation in space habitats. By enabling more efficient heat dissipation, these innovations contribute to extending the operational lifespan of aerospace systems and enhancing their overall reliability.

As aerospace systems continue to advance in complexity and capability, the demand for more effective thermal management solutions grows correspondingly. Vapor chamber material innovations represent a promising avenue for meeting these evolving requirements, potentially revolutionizing how thermal challenges are addressed in next-generation aerospace applications.

Market Demand Analysis for Advanced Cooling Solutions in Aerospace

The aerospace industry is witnessing an unprecedented demand for advanced thermal management solutions, driven primarily by the increasing complexity and power density of avionics systems. Market research indicates that the global aerospace thermal management market is projected to reach $9.4 billion by 2028, with cooling solutions representing approximately 40% of this value. This growth trajectory is supported by the rapid evolution of satellite technology, hypersonic aircraft development, and the increasing electrification of aviation systems.

Within the commercial aviation sector, the push toward more electric aircraft (MEA) has created significant thermal challenges. Modern aircraft generate substantially more heat than their predecessors, with some next-generation commercial aircraft producing up to 1.5 MW of waste heat during operation. This has created a critical need for more efficient cooling technologies that can maintain optimal operating temperatures while minimizing weight penalties.

The defense aerospace segment presents even more demanding requirements, with high-performance military aircraft and space systems operating in extreme environments. Market analysis reveals that defense contractors are allocating approximately 15% of their R&D budgets to thermal management solutions, highlighting the strategic importance of this technology area.

Space applications represent the fastest-growing segment for advanced cooling solutions, expanding at an annual rate of 12.3%. The miniaturization of satellites, particularly in the burgeoning small satellite market, has intensified cooling challenges due to the limited surface area available for heat rejection. Additionally, the increasing deployment of high-power instruments and communication systems in space platforms has created demand for cooling solutions that can operate reliably in the vacuum of space.

Regional market analysis shows North America leading with 38% market share, followed by Europe (27%) and Asia-Pacific (24%). However, the Asia-Pacific region is experiencing the highest growth rate at 14.2% annually, driven by expanding aerospace industries in China and India.

Customer requirements are increasingly focused on solutions that offer high thermal performance while minimizing mass, volume, and power consumption. Survey data from aerospace system integrators indicates that 78% consider thermal management a critical design constraint, with 65% specifically seeking advanced two-phase cooling technologies like vapor chambers.

Market forecasts suggest that vapor chamber technologies specifically engineered for aerospace applications will experience compound annual growth of 16.8% through 2030, outpacing the broader thermal management market. This accelerated growth is attributed to the superior performance characteristics of vapor chambers compared to traditional cooling methods, particularly in applications where weight and space constraints are paramount.

Within the commercial aviation sector, the push toward more electric aircraft (MEA) has created significant thermal challenges. Modern aircraft generate substantially more heat than their predecessors, with some next-generation commercial aircraft producing up to 1.5 MW of waste heat during operation. This has created a critical need for more efficient cooling technologies that can maintain optimal operating temperatures while minimizing weight penalties.

The defense aerospace segment presents even more demanding requirements, with high-performance military aircraft and space systems operating in extreme environments. Market analysis reveals that defense contractors are allocating approximately 15% of their R&D budgets to thermal management solutions, highlighting the strategic importance of this technology area.

Space applications represent the fastest-growing segment for advanced cooling solutions, expanding at an annual rate of 12.3%. The miniaturization of satellites, particularly in the burgeoning small satellite market, has intensified cooling challenges due to the limited surface area available for heat rejection. Additionally, the increasing deployment of high-power instruments and communication systems in space platforms has created demand for cooling solutions that can operate reliably in the vacuum of space.

Regional market analysis shows North America leading with 38% market share, followed by Europe (27%) and Asia-Pacific (24%). However, the Asia-Pacific region is experiencing the highest growth rate at 14.2% annually, driven by expanding aerospace industries in China and India.

Customer requirements are increasingly focused on solutions that offer high thermal performance while minimizing mass, volume, and power consumption. Survey data from aerospace system integrators indicates that 78% consider thermal management a critical design constraint, with 65% specifically seeking advanced two-phase cooling technologies like vapor chambers.

Market forecasts suggest that vapor chamber technologies specifically engineered for aerospace applications will experience compound annual growth of 16.8% through 2030, outpacing the broader thermal management market. This accelerated growth is attributed to the superior performance characteristics of vapor chambers compared to traditional cooling methods, particularly in applications where weight and space constraints are paramount.

Current State and Challenges of Vapor Chamber Technology

Vapor chamber technology has evolved significantly over the past decade, establishing itself as a critical thermal management solution in aerospace applications. Current vapor chambers utilize primarily copper as the base material due to its excellent thermal conductivity and compatibility with working fluids. However, the aerospace sector demands increasingly lightweight solutions without compromising thermal performance, creating a fundamental materials challenge.

The state-of-the-art vapor chambers face several critical limitations when applied to aerospace environments. Weight constraints represent the foremost challenge, as traditional copper-based systems contribute significantly to overall system mass. This becomes particularly problematic in satellite systems and aircraft where every gram impacts fuel efficiency and payload capacity. Additionally, the extreme temperature fluctuations encountered in aerospace applications (-65°C to +150°C) stress conventional materials beyond their optimal operating ranges.

Corrosion resistance presents another significant hurdle, especially with exposure to various working fluids and external environmental factors. Current vapor chamber materials often exhibit degradation over extended mission lifetimes, compromising long-term reliability. This is compounded by the need for materials that can withstand the vibration and mechanical stress profiles unique to aerospace launch and operation conditions.

Manufacturing complexity further constrains innovation, as advanced geometries and miniaturization requirements demand increasingly sophisticated production techniques. The industry currently struggles with cost-effective methods to produce ultra-thin vapor chambers with complex internal wick structures at scale. This manufacturing bottleneck limits widespread adoption despite the clear thermal management benefits.

Geographically, vapor chamber technology development shows distinct regional characteristics. North American research focuses primarily on aerospace-grade aluminum alloys and composite integration, while Asian manufacturers lead in copper-based mass production techniques. European research centers have made significant advances in titanium-based systems and advanced manufacturing methods, though commercialization remains limited.

Recent material innovations have begun exploring aluminum-graphene composites and ceramic-metal hybrid structures, though these remain largely experimental. The integration of additive manufacturing techniques has enabled more complex internal geometries but has introduced new challenges in material porosity control and long-term reliability verification.

The regulatory landscape adds another layer of complexity, with aerospace certification requirements imposing stringent reliability and safety standards that many novel material solutions struggle to satisfy. This regulatory hurdle often extends development timelines and increases costs, further constraining innovation in this critical technology area.

The state-of-the-art vapor chambers face several critical limitations when applied to aerospace environments. Weight constraints represent the foremost challenge, as traditional copper-based systems contribute significantly to overall system mass. This becomes particularly problematic in satellite systems and aircraft where every gram impacts fuel efficiency and payload capacity. Additionally, the extreme temperature fluctuations encountered in aerospace applications (-65°C to +150°C) stress conventional materials beyond their optimal operating ranges.

Corrosion resistance presents another significant hurdle, especially with exposure to various working fluids and external environmental factors. Current vapor chamber materials often exhibit degradation over extended mission lifetimes, compromising long-term reliability. This is compounded by the need for materials that can withstand the vibration and mechanical stress profiles unique to aerospace launch and operation conditions.

Manufacturing complexity further constrains innovation, as advanced geometries and miniaturization requirements demand increasingly sophisticated production techniques. The industry currently struggles with cost-effective methods to produce ultra-thin vapor chambers with complex internal wick structures at scale. This manufacturing bottleneck limits widespread adoption despite the clear thermal management benefits.

Geographically, vapor chamber technology development shows distinct regional characteristics. North American research focuses primarily on aerospace-grade aluminum alloys and composite integration, while Asian manufacturers lead in copper-based mass production techniques. European research centers have made significant advances in titanium-based systems and advanced manufacturing methods, though commercialization remains limited.

Recent material innovations have begun exploring aluminum-graphene composites and ceramic-metal hybrid structures, though these remain largely experimental. The integration of additive manufacturing techniques has enabled more complex internal geometries but has introduced new challenges in material porosity control and long-term reliability verification.

The regulatory landscape adds another layer of complexity, with aerospace certification requirements imposing stringent reliability and safety standards that many novel material solutions struggle to satisfy. This regulatory hurdle often extends development timelines and increases costs, further constraining innovation in this critical technology area.

Current Vapor Chamber Material Solutions for Aerospace

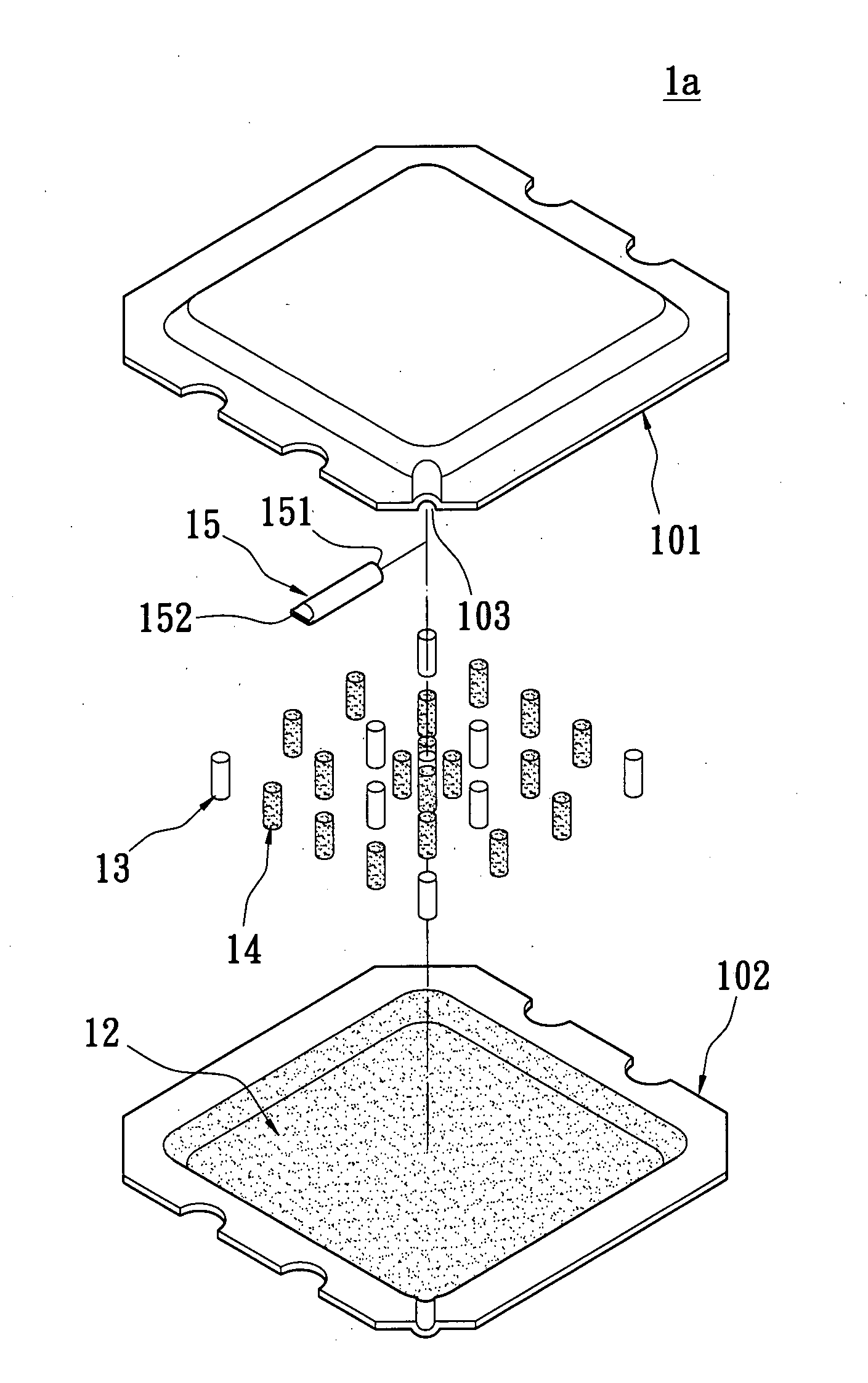

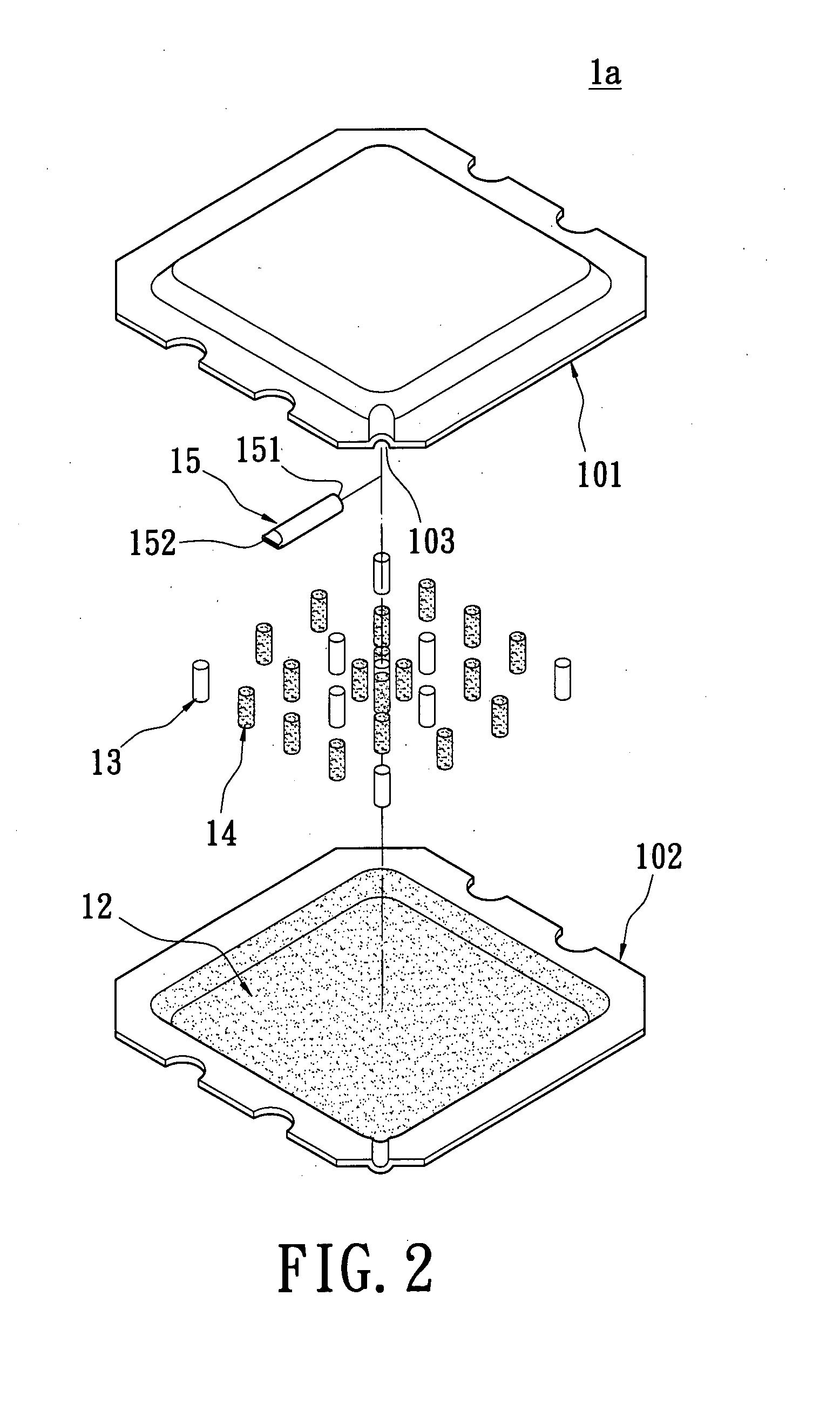

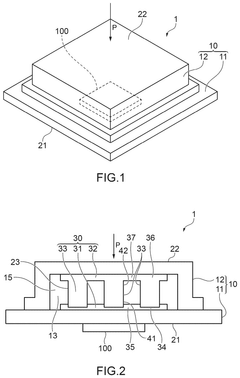

01 Vapor chamber design for electronic devices

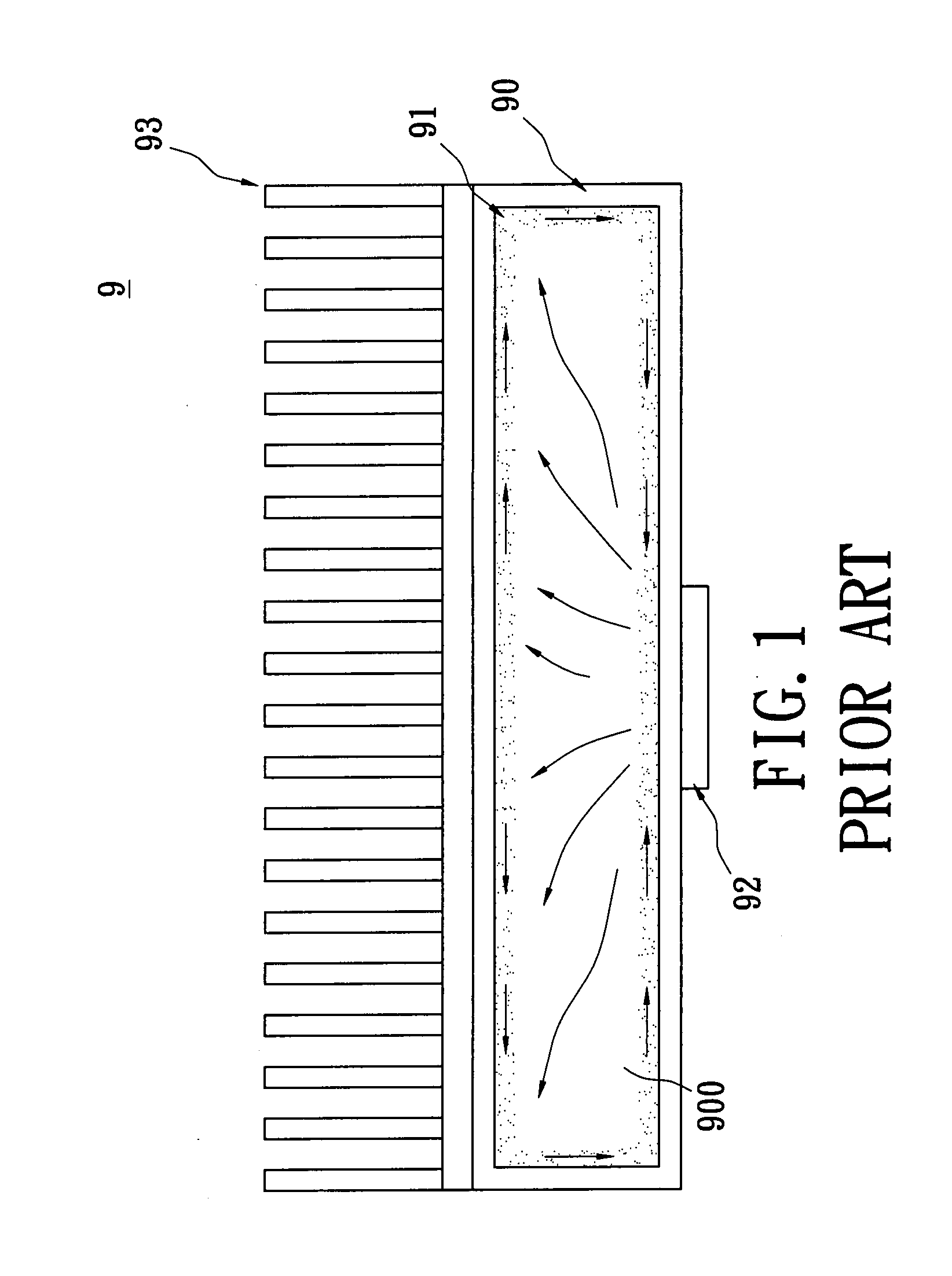

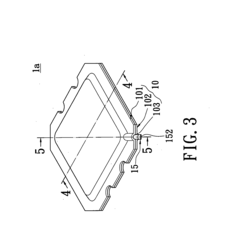

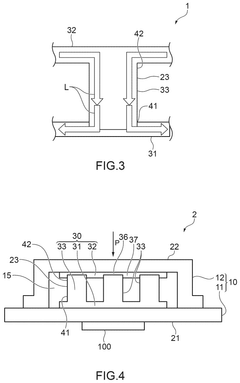

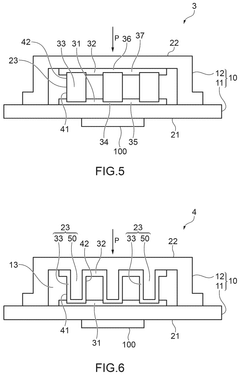

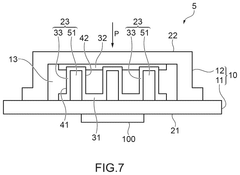

Vapor chambers are used in electronic devices for efficient heat dissipation. These chambers typically consist of a sealed container with a working fluid that evaporates at the heat source and condenses at cooler areas, effectively transferring heat away from critical components. The design may include various structural elements such as wicks, support structures, and specialized coatings to enhance thermal performance and reliability in compact electronic devices.- Vapor chamber structure and design: Vapor chambers are designed with specific structural elements to enhance heat dissipation. These designs include various internal configurations, wick structures, and vapor flow channels that optimize thermal performance. The chambers typically consist of a sealed container with a working fluid that evaporates at the heat source and condenses at cooler regions, effectively transferring heat across the device.

- Vapor chamber applications in electronic devices: Vapor chambers are widely implemented in electronic devices for thermal management. They are particularly valuable in compact devices like smartphones, tablets, and laptops where space is limited but heat dissipation is critical. These thermal solutions help maintain optimal operating temperatures for processors and other heat-generating components, improving device performance and longevity.

- Advanced materials for vapor chamber efficiency: The efficiency of vapor chambers is significantly influenced by the materials used in their construction. Advanced materials with high thermal conductivity are employed for the chamber walls, while specialized wicking materials enhance the capillary action of the working fluid. Innovations in material science have led to thinner, lighter, and more effective vapor chamber designs with improved heat transfer capabilities.

- Integration of vapor chambers in cooling systems: Vapor chambers are often integrated into larger cooling systems that may include heat sinks, fans, or liquid cooling components. This integration creates comprehensive thermal management solutions for complex electronic systems. The vapor chamber serves as an efficient heat spreader, distributing heat evenly across the cooling system and enhancing overall thermal performance.

- Innovative vapor chamber manufacturing techniques: Manufacturing techniques for vapor chambers have evolved to improve performance and reduce costs. These innovations include advanced sealing methods, precision machining of internal structures, and automated assembly processes. Novel fabrication approaches allow for customized vapor chamber designs tailored to specific thermal management requirements, enabling their application in diverse industries and products.

02 Wireless communication systems with thermal management

Vapor chambers are integrated into wireless communication systems to manage thermal issues in high-performance network equipment. These thermal solutions help maintain optimal operating temperatures for communication hardware such as base stations, routers, and network servers. The vapor chamber designs are specifically adapted to address the unique cooling requirements of wireless communication infrastructure while maintaining signal integrity and system reliability.Expand Specific Solutions03 Medical device applications of vapor chambers

Vapor chamber technology is utilized in medical devices for temperature control and thermal management. These applications include cooling systems for diagnostic equipment, therapeutic devices, and implantable medical technologies. The vapor chambers are designed to meet strict medical safety standards while providing efficient heat transfer in sensitive healthcare applications, ensuring patient safety and device reliability.Expand Specific Solutions04 Portable electronic device cooling solutions

Specialized vapor chamber designs for portable electronic devices such as smartphones, tablets, and laptops provide enhanced cooling in ultra-thin form factors. These solutions incorporate advanced materials and manufacturing techniques to create extremely thin yet effective heat dissipation systems. The vapor chambers are customized to address the unique thermal challenges of portable devices while maintaining their slim profiles and lightweight characteristics.Expand Specific Solutions05 Industrial and automotive vapor chamber applications

Vapor chambers are employed in industrial equipment and automotive systems for managing high heat loads in demanding environments. These applications include cooling for power electronics, industrial machinery, vehicle powertrains, and battery thermal management systems. The vapor chambers are designed to withstand harsh operating conditions while providing reliable and efficient thermal management for critical industrial and automotive components.Expand Specific Solutions

Key Industry Players in Aerospace Thermal Solutions

The aerospace vapor chamber material innovation landscape is currently in a growth phase, with an estimated market size of $1.5-2 billion and expanding at 8-10% annually. The competitive field features established aerospace players like Rolls-Royce and United Technologies alongside thermal management specialists such as Furukawa Electric, Asia Vital Components, and Taiwan Microloops. Technology maturity varies significantly across applications, with companies at different development stages. Furukawa Electric and Shin-Etsu Chemical lead in advanced material formulations, while aerospace giants Rolls-Royce and Kawasaki Heavy Industries focus on integration and performance optimization. Academic-industry partnerships with institutions like Sichuan University are accelerating innovation in lightweight composite materials and nano-enhanced thermal solutions for next-generation aerospace thermal management systems.

ROLLS ROYCE PLC

Technical Solution: Rolls-Royce has developed advanced vapor chamber cooling systems utilizing composite materials specifically engineered for aerospace applications. Their technology incorporates sintered copper wicks with nano-coatings that enhance thermal conductivity while reducing weight. The company's aerospace vapor chambers feature multi-layer composite structures with titanium outer shells for structural integrity and corrosion resistance, while maintaining internal copper structures for optimal heat transfer. These systems are designed to operate under extreme aerospace conditions, including high-altitude pressure differentials and vibration environments. Rolls-Royce has integrated these vapor chambers into their latest generation of aircraft engines, where they effectively manage heat loads in fuel systems and electronic control units, enabling higher power densities while maintaining critical temperature limits.

Strengths: Superior weight-to-performance ratio optimized for aerospace applications; exceptional reliability under extreme operating conditions; integrated systems approach that considers the entire thermal management ecosystem. Weaknesses: Higher manufacturing costs compared to conventional cooling solutions; requires specialized production facilities; more complex maintenance procedures.

Shaanxi Sirui Advanced Materials Co., Ltd.

Technical Solution: Shaanxi Sirui has developed specialized vapor chamber materials utilizing graphene-enhanced copper composites that deliver superior thermal conductivity while reducing weight for aerospace applications. Their proprietary manufacturing process creates ultra-thin vapor chambers (as thin as 0.6mm) with internal sintered powder structures optimized for capillary action in microgravity environments. The company has pioneered the use of nano-coatings that enhance the wettability of internal surfaces, improving fluid circulation and heat transfer efficiency by approximately 30% compared to conventional designs. Their aerospace vapor chambers incorporate specialized working fluids with wide operating temperature ranges (-70°C to +180°C) and low vapor pressures to maintain performance in the vacuum of space. These systems have been successfully deployed in satellite thermal management applications, where they've demonstrated exceptional reliability during thermal cycling tests simulating orbital conditions.

Strengths: Industry-leading thermal performance-to-weight ratio; extensive experience with aerospace qualification testing; ability to manufacture custom shapes for complex integration requirements. Weaknesses: Limited production capacity for large aerospace programs; relatively new entrant to international aerospace supply chains; higher cost compared to conventional thermal solutions.

Critical Patents and Innovations in Aerospace-Grade Vapor Chambers

Vapor chamber structure and method for manufacturing the same

PatentInactiveUS20090040726A1

Innovation

- Incorporating structure strengthening bodies and backflow accelerating bodies within the vapor chamber to support the casing and enhance the sealing effect, while forming a wick layer on the internal surface to facilitate efficient heat transfer and fluid circulation.

Vapor chamber

PatentPendingUS20240401885A1

Innovation

- A vapor chamber design featuring a container with integrated wick portions and a support portion that connects the first and second surfaces, where the porosity of the wick portions differs to enhance integration and prevent expansion, utilizing sintered bodies of metal powder for improved capillary forces and reflux characteristics.

Environmental Impact and Sustainability Considerations

The aerospace industry's growing focus on environmental sustainability has placed significant pressure on vapor chamber material development to align with global ecological goals. Traditional vapor chamber materials often contain heavy metals and toxic substances that pose environmental risks during manufacturing, operation, and end-of-life disposal. Recent innovations are increasingly prioritizing environmentally friendly alternatives that maintain or exceed performance specifications while reducing ecological footprints.

Material selection for aerospace vapor chambers now incorporates comprehensive life cycle assessments (LCA) to evaluate environmental impacts from raw material extraction through manufacturing, use, and eventual disposal. Research indicates that replacing conventional copper with aluminum-based alloys can reduce the carbon footprint by approximately 35% while maintaining 90% of thermal performance in specific applications. Similarly, working fluids are transitioning from harmful refrigerants to water-based solutions supplemented with nanomaterials for enhanced performance.

Manufacturing processes for next-generation vapor chambers are evolving to minimize waste and energy consumption. Advanced sintering techniques reduce energy requirements by up to 40% compared to traditional methods, while precision manufacturing has decreased material waste by nearly 25% in leading aerospace facilities. These improvements directly contribute to reduced greenhouse gas emissions associated with vapor chamber production.

Recyclability and circular economy principles are becoming central to aerospace thermal management design philosophy. Modular vapor chamber designs that facilitate disassembly and material recovery are gaining traction, with some manufacturers achieving 80% material reclamation rates. Innovative joining techniques allow for non-destructive separation of components at end-of-life, preserving material integrity for subsequent reuse cycles.

Regulatory compliance is driving further sustainability innovations in vapor chamber materials. The aerospace industry's adaptation to regulations such as REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) has accelerated the development of non-toxic alternatives to traditional working fluids and structural materials. These regulatory frameworks have effectively catalyzed research into bio-based polymers and naturally derived components that can withstand the extreme conditions of aerospace applications.

Energy efficiency improvements in vapor chamber performance directly contribute to reduced fuel consumption in aircraft and lower power requirements in satellite thermal management systems. Studies demonstrate that advanced vapor chamber materials can improve overall system efficiency by 3-7%, translating to significant lifetime emissions reductions for aerospace vehicles. This efficiency-sustainability connection represents a critical value proposition for next-generation material development in the industry.

Material selection for aerospace vapor chambers now incorporates comprehensive life cycle assessments (LCA) to evaluate environmental impacts from raw material extraction through manufacturing, use, and eventual disposal. Research indicates that replacing conventional copper with aluminum-based alloys can reduce the carbon footprint by approximately 35% while maintaining 90% of thermal performance in specific applications. Similarly, working fluids are transitioning from harmful refrigerants to water-based solutions supplemented with nanomaterials for enhanced performance.

Manufacturing processes for next-generation vapor chambers are evolving to minimize waste and energy consumption. Advanced sintering techniques reduce energy requirements by up to 40% compared to traditional methods, while precision manufacturing has decreased material waste by nearly 25% in leading aerospace facilities. These improvements directly contribute to reduced greenhouse gas emissions associated with vapor chamber production.

Recyclability and circular economy principles are becoming central to aerospace thermal management design philosophy. Modular vapor chamber designs that facilitate disassembly and material recovery are gaining traction, with some manufacturers achieving 80% material reclamation rates. Innovative joining techniques allow for non-destructive separation of components at end-of-life, preserving material integrity for subsequent reuse cycles.

Regulatory compliance is driving further sustainability innovations in vapor chamber materials. The aerospace industry's adaptation to regulations such as REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) has accelerated the development of non-toxic alternatives to traditional working fluids and structural materials. These regulatory frameworks have effectively catalyzed research into bio-based polymers and naturally derived components that can withstand the extreme conditions of aerospace applications.

Energy efficiency improvements in vapor chamber performance directly contribute to reduced fuel consumption in aircraft and lower power requirements in satellite thermal management systems. Studies demonstrate that advanced vapor chamber materials can improve overall system efficiency by 3-7%, translating to significant lifetime emissions reductions for aerospace vehicles. This efficiency-sustainability connection represents a critical value proposition for next-generation material development in the industry.

Certification and Safety Standards for Aerospace Thermal Components

The aerospace industry imposes stringent certification and safety standards on all components, with thermal management systems being particularly critical due to their role in preventing catastrophic failures. For Vapor Chamber technology to be viable in aerospace applications, it must comply with multiple regulatory frameworks established by organizations such as the Federal Aviation Administration (FAA), European Union Aviation Safety Agency (EASA), and the Department of Defense (DoD).

Material certification for aerospace thermal components follows a rigorous multi-stage process. Initially, materials must undergo extensive testing for thermal conductivity stability under extreme temperature cycling conditions (-65°C to +150°C) typical in aerospace environments. These tests must demonstrate less than 5% performance degradation over the expected service life, which often exceeds 20,000 flight hours.

Flammability requirements present another significant hurdle, with materials needing to meet FAR 25.853 standards for flame resistance and smoke emission. Vapor Chamber materials must achieve V-0 rating under UL 94 testing protocols, with self-extinguishing properties within 10 seconds of flame removal.

Outgassing certification is particularly relevant for space applications, where materials must comply with ASTM E595 standards, requiring Total Mass Loss (TML) below 1.0% and Collected Volatile Condensable Materials (CVCM) under 0.1%. These stringent requirements significantly limit material selection for aerospace Vapor Chambers compared to consumer electronics applications.

Mechanical integrity standards require thermal components to withstand vibration profiles defined in MIL-STD-810H, including random vibration testing between 20-2000 Hz at up to 7.7g RMS for fixed-wing aircraft applications. Additionally, shock resistance certification requires survival of 20g acceleration pulses without performance degradation.

Quality assurance protocols mandate 100% non-destructive testing for aerospace-grade Vapor Chambers, typically employing techniques such as X-ray inspection, ultrasonic scanning, and thermal performance validation. Each unit must be individually traceable through its entire manufacturing process, with comprehensive documentation maintained for a minimum of 10 years.

The certification timeline for new thermal management materials in aerospace applications typically spans 3-5 years, representing a significant barrier to rapid innovation. This extended timeline necessitates early engagement with certification authorities when developing novel Vapor Chamber materials for aerospace thermal management solutions.

Material certification for aerospace thermal components follows a rigorous multi-stage process. Initially, materials must undergo extensive testing for thermal conductivity stability under extreme temperature cycling conditions (-65°C to +150°C) typical in aerospace environments. These tests must demonstrate less than 5% performance degradation over the expected service life, which often exceeds 20,000 flight hours.

Flammability requirements present another significant hurdle, with materials needing to meet FAR 25.853 standards for flame resistance and smoke emission. Vapor Chamber materials must achieve V-0 rating under UL 94 testing protocols, with self-extinguishing properties within 10 seconds of flame removal.

Outgassing certification is particularly relevant for space applications, where materials must comply with ASTM E595 standards, requiring Total Mass Loss (TML) below 1.0% and Collected Volatile Condensable Materials (CVCM) under 0.1%. These stringent requirements significantly limit material selection for aerospace Vapor Chambers compared to consumer electronics applications.

Mechanical integrity standards require thermal components to withstand vibration profiles defined in MIL-STD-810H, including random vibration testing between 20-2000 Hz at up to 7.7g RMS for fixed-wing aircraft applications. Additionally, shock resistance certification requires survival of 20g acceleration pulses without performance degradation.

Quality assurance protocols mandate 100% non-destructive testing for aerospace-grade Vapor Chambers, typically employing techniques such as X-ray inspection, ultrasonic scanning, and thermal performance validation. Each unit must be individually traceable through its entire manufacturing process, with comprehensive documentation maintained for a minimum of 10 years.

The certification timeline for new thermal management materials in aerospace applications typically spans 3-5 years, representing a significant barrier to rapid innovation. This extended timeline necessitates early engagement with certification authorities when developing novel Vapor Chamber materials for aerospace thermal management solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!