Vapor Chamber Potential in Augmenting Heat Spread in Compact Devices

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vapor Chamber Technology Evolution and Cooling Objectives

Vapor chamber technology has evolved significantly over the past three decades, transitioning from specialized aerospace applications to mainstream thermal management solutions. Initially developed in the 1990s as an advanced heat pipe variant, vapor chambers were primarily utilized in satellite thermal control systems where their superior heat spreading capabilities justified their high manufacturing costs. The fundamental operating principle—utilizing phase change of a working fluid to transport heat efficiently—has remained consistent, though manufacturing techniques and materials have undergone substantial refinement.

The evolution trajectory shows three distinct phases: the experimental period (1990-2005) characterized by proof-of-concept designs and limited commercial applications; the industrial adoption phase (2005-2015) marked by manufacturing standardization and cost reduction; and the current miniaturization era (2015-present) focused on ultra-thin designs and integration with complex electronic systems.

Cooling objectives for vapor chambers have become increasingly demanding as electronic devices continue to shrink while processing power increases. Modern compact devices generate heat fluxes exceeding 100 W/cm², creating thermal management challenges that conventional cooling solutions struggle to address. The primary cooling objectives now include achieving thermal resistance below 0.1°C/W, maintaining device skin temperatures below 40°C for user comfort, and ensuring uniform heat distribution to eliminate hotspots that can compromise component reliability.

A critical evolutionary trend has been the reduction in vapor chamber thickness, from early designs exceeding 5mm to current ultra-thin versions below 0.5mm, enabling integration into smartphones and other slim form factor devices. Simultaneously, working fluid chemistry has progressed from water to engineered fluids with optimized boiling points and surface tension properties, enhancing performance across wider operating temperature ranges.

Manufacturing techniques have similarly advanced, with traditional sintered copper wicks giving way to composite structures and novel fabrication methods like selective laser sintering. These innovations have addressed historical limitations in capillary performance and manufacturing scalability, while reducing production costs by approximately 70% over the past decade.

The cooling objectives for next-generation vapor chambers focus on three key areas: thermal performance enhancement through advanced wick structures capable of handling heat fluxes above 500 W/cm²; further thickness reduction to accommodate increasingly compact device designs; and cost optimization to enable broader market adoption across consumer electronics categories beyond premium segments.

The evolution trajectory shows three distinct phases: the experimental period (1990-2005) characterized by proof-of-concept designs and limited commercial applications; the industrial adoption phase (2005-2015) marked by manufacturing standardization and cost reduction; and the current miniaturization era (2015-present) focused on ultra-thin designs and integration with complex electronic systems.

Cooling objectives for vapor chambers have become increasingly demanding as electronic devices continue to shrink while processing power increases. Modern compact devices generate heat fluxes exceeding 100 W/cm², creating thermal management challenges that conventional cooling solutions struggle to address. The primary cooling objectives now include achieving thermal resistance below 0.1°C/W, maintaining device skin temperatures below 40°C for user comfort, and ensuring uniform heat distribution to eliminate hotspots that can compromise component reliability.

A critical evolutionary trend has been the reduction in vapor chamber thickness, from early designs exceeding 5mm to current ultra-thin versions below 0.5mm, enabling integration into smartphones and other slim form factor devices. Simultaneously, working fluid chemistry has progressed from water to engineered fluids with optimized boiling points and surface tension properties, enhancing performance across wider operating temperature ranges.

Manufacturing techniques have similarly advanced, with traditional sintered copper wicks giving way to composite structures and novel fabrication methods like selective laser sintering. These innovations have addressed historical limitations in capillary performance and manufacturing scalability, while reducing production costs by approximately 70% over the past decade.

The cooling objectives for next-generation vapor chambers focus on three key areas: thermal performance enhancement through advanced wick structures capable of handling heat fluxes above 500 W/cm²; further thickness reduction to accommodate increasingly compact device designs; and cost optimization to enable broader market adoption across consumer electronics categories beyond premium segments.

Market Demand Analysis for Advanced Thermal Solutions

The thermal management market is experiencing unprecedented growth driven by the miniaturization trend in electronic devices. As devices become smaller yet more powerful, the demand for advanced thermal solutions has intensified significantly. The global thermal management market is projected to reach $16.2 billion by 2026, growing at a CAGR of 8.2% from 2021. Within this market, vapor chamber technology is emerging as a critical component, particularly for compact high-performance devices.

Consumer electronics represents the largest market segment demanding advanced thermal solutions, with smartphones, tablets, and ultrabooks leading adoption. The gaming industry follows closely, with high-performance laptops and consoles requiring efficient heat dissipation to maintain optimal performance during extended usage periods. Additionally, the telecommunications sector, particularly with the rollout of 5G infrastructure, has created substantial demand for thermal management solutions capable of handling increased power densities.

Enterprise computing systems, including data centers and server farms, constitute another significant market segment. With the exponential growth in cloud computing and AI applications, these facilities face critical thermal challenges that directly impact operational costs and system reliability. The automotive industry, especially with the rise of electric vehicles and autonomous driving systems, represents an emerging market with stringent thermal requirements for battery management systems and computing platforms.

Market research indicates that end-users are increasingly prioritizing thermal performance when making purchasing decisions. A recent industry survey revealed that 78% of smartphone users consider device overheating a significant concern, while 65% of gaming laptop purchasers rank thermal performance among their top three buying criteria. This consumer awareness has prompted manufacturers to emphasize thermal capabilities in their marketing strategies.

Regional analysis shows Asia Pacific dominating the thermal solutions market, accounting for approximately 42% of global demand, driven by the concentration of electronics manufacturing in countries like China, Taiwan, and South Korea. North America follows with 28% market share, with particular strength in high-performance computing applications. Europe represents about 22% of the market, with growing demand from automotive and industrial sectors.

The market demonstrates a clear willingness to pay premium prices for superior thermal performance. High-end consumer devices featuring advanced cooling solutions command price premiums of 15-20% compared to standard alternatives. This price elasticity indicates strong market recognition of the value proposition offered by technologies like vapor chambers in enhancing device performance, reliability, and user experience.

Consumer electronics represents the largest market segment demanding advanced thermal solutions, with smartphones, tablets, and ultrabooks leading adoption. The gaming industry follows closely, with high-performance laptops and consoles requiring efficient heat dissipation to maintain optimal performance during extended usage periods. Additionally, the telecommunications sector, particularly with the rollout of 5G infrastructure, has created substantial demand for thermal management solutions capable of handling increased power densities.

Enterprise computing systems, including data centers and server farms, constitute another significant market segment. With the exponential growth in cloud computing and AI applications, these facilities face critical thermal challenges that directly impact operational costs and system reliability. The automotive industry, especially with the rise of electric vehicles and autonomous driving systems, represents an emerging market with stringent thermal requirements for battery management systems and computing platforms.

Market research indicates that end-users are increasingly prioritizing thermal performance when making purchasing decisions. A recent industry survey revealed that 78% of smartphone users consider device overheating a significant concern, while 65% of gaming laptop purchasers rank thermal performance among their top three buying criteria. This consumer awareness has prompted manufacturers to emphasize thermal capabilities in their marketing strategies.

Regional analysis shows Asia Pacific dominating the thermal solutions market, accounting for approximately 42% of global demand, driven by the concentration of electronics manufacturing in countries like China, Taiwan, and South Korea. North America follows with 28% market share, with particular strength in high-performance computing applications. Europe represents about 22% of the market, with growing demand from automotive and industrial sectors.

The market demonstrates a clear willingness to pay premium prices for superior thermal performance. High-end consumer devices featuring advanced cooling solutions command price premiums of 15-20% compared to standard alternatives. This price elasticity indicates strong market recognition of the value proposition offered by technologies like vapor chambers in enhancing device performance, reliability, and user experience.

Current Vapor Chamber Implementation Challenges

Despite the promising thermal management capabilities of vapor chambers, their implementation in compact devices faces several significant challenges. The miniaturization of vapor chambers while maintaining their thermal performance presents a fundamental engineering obstacle. As devices become increasingly thinner, the internal space available for vapor chamber integration diminishes, limiting the volume for vapor formation and condensation processes essential to their operation.

Manufacturing complexity represents another major hurdle. The production of vapor chambers requires precise fabrication of internal wick structures, vacuum sealing, and working fluid charging processes. These manufacturing steps demand specialized equipment and stringent quality control measures, resulting in higher production costs compared to traditional thermal solutions like heat pipes or graphite sheets.

Material compatibility issues further complicate implementation. The working fluids used in vapor chambers must be chemically compatible with the chamber walls and wick structures to prevent corrosion or gas generation that could degrade performance over time. Additionally, the selection of appropriate working fluids becomes challenging when operating temperature ranges vary widely across different device usage scenarios.

Reliability concerns persist in vapor chamber technology, particularly regarding long-term performance stability. Potential issues include working fluid leakage, internal pressure changes due to non-condensable gas generation, and wick structure degradation over repeated thermal cycles. These reliability challenges are especially critical in consumer electronics where product lifespans of several years are expected without thermal performance degradation.

Cost considerations remain a significant barrier to widespread adoption. The complex manufacturing processes, specialized materials, and quality control requirements contribute to higher unit costs compared to conventional thermal solutions. This cost premium must be justified by performance advantages, creating a challenging value proposition for mass-market implementation.

Integration challenges with other device components also present difficulties. Vapor chambers must interface effectively with heat sources (processors, GPUs) and heat dissipation systems (fans, external surfaces) while accommodating various mounting constraints and avoiding interference with other components like batteries, circuit boards, and structural elements.

Performance consistency across different orientations and operating conditions represents another technical challenge. Unlike some simpler thermal solutions, vapor chamber performance can be affected by gravitational orientation, which becomes problematic in mobile devices used in various positions. Engineers must design vapor chambers that maintain consistent thermal performance regardless of device orientation.

These implementation challenges collectively explain why, despite their thermal advantages, vapor chambers have not yet achieved universal adoption in compact electronic devices, remaining primarily in premium or high-performance product segments where thermal demands justify their additional complexity and cost.

Manufacturing complexity represents another major hurdle. The production of vapor chambers requires precise fabrication of internal wick structures, vacuum sealing, and working fluid charging processes. These manufacturing steps demand specialized equipment and stringent quality control measures, resulting in higher production costs compared to traditional thermal solutions like heat pipes or graphite sheets.

Material compatibility issues further complicate implementation. The working fluids used in vapor chambers must be chemically compatible with the chamber walls and wick structures to prevent corrosion or gas generation that could degrade performance over time. Additionally, the selection of appropriate working fluids becomes challenging when operating temperature ranges vary widely across different device usage scenarios.

Reliability concerns persist in vapor chamber technology, particularly regarding long-term performance stability. Potential issues include working fluid leakage, internal pressure changes due to non-condensable gas generation, and wick structure degradation over repeated thermal cycles. These reliability challenges are especially critical in consumer electronics where product lifespans of several years are expected without thermal performance degradation.

Cost considerations remain a significant barrier to widespread adoption. The complex manufacturing processes, specialized materials, and quality control requirements contribute to higher unit costs compared to conventional thermal solutions. This cost premium must be justified by performance advantages, creating a challenging value proposition for mass-market implementation.

Integration challenges with other device components also present difficulties. Vapor chambers must interface effectively with heat sources (processors, GPUs) and heat dissipation systems (fans, external surfaces) while accommodating various mounting constraints and avoiding interference with other components like batteries, circuit boards, and structural elements.

Performance consistency across different orientations and operating conditions represents another technical challenge. Unlike some simpler thermal solutions, vapor chamber performance can be affected by gravitational orientation, which becomes problematic in mobile devices used in various positions. Engineers must design vapor chambers that maintain consistent thermal performance regardless of device orientation.

These implementation challenges collectively explain why, despite their thermal advantages, vapor chambers have not yet achieved universal adoption in compact electronic devices, remaining primarily in premium or high-performance product segments where thermal demands justify their additional complexity and cost.

Contemporary Vapor Chamber Design Approaches

01 Vapor chamber structure and design

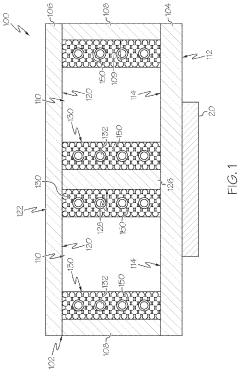

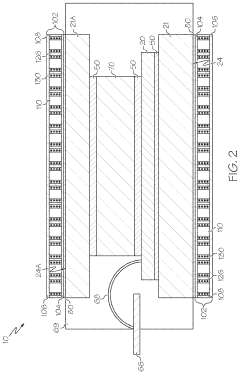

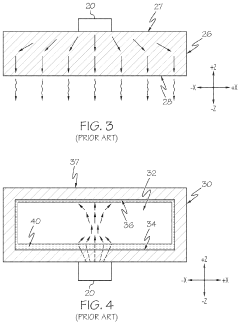

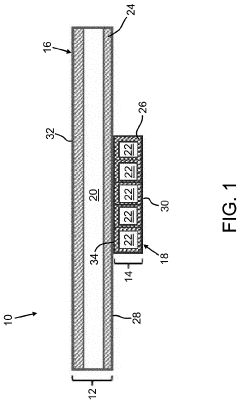

Vapor chambers are designed with specific structural elements to optimize heat spreading. These designs include internal wick structures, vapor spaces, and condensation surfaces that facilitate the phase-change heat transfer process. The chambers are typically flat and thin with sealed enclosures containing working fluid that evaporates at hot spots and condenses at cooler areas, effectively spreading heat across larger surface areas.- Vapor chamber structure and design: Vapor chambers are designed with specific structural elements to optimize heat spreading. These designs include internal wick structures, vapor spaces, and condensation surfaces that work together to efficiently transfer heat from a source to a larger area. The chambers may incorporate multiple layers, specialized wall structures, and optimized internal geometries to enhance thermal conductivity and heat distribution across electronic devices.

- Integration with electronic devices: Vapor chambers are integrated into various electronic devices to manage thermal issues. They are commonly used in smartphones, computers, and other high-performance electronics where heat dissipation is critical. The chambers can be designed to fit specific form factors, including thin devices, and can be combined with other cooling solutions like heat sinks and fans to create comprehensive thermal management systems.

- Advanced materials for vapor chambers: The performance of vapor chambers is significantly influenced by the materials used in their construction. Advanced materials such as copper, aluminum alloys, and specialized composites are employed to enhance thermal conductivity. Working fluids inside the chambers are carefully selected for their phase-change properties, and wick structures may incorporate novel materials like sintered metal powders or micro-grooved surfaces to improve capillary action and heat transfer efficiency.

- Vapor chamber manufacturing techniques: Manufacturing processes for vapor chambers include precision stamping, diffusion bonding, and vacuum sealing techniques. Advanced fabrication methods allow for the creation of ultra-thin vapor chambers with complex internal structures. The manufacturing process must ensure proper evacuation of air, filling with working fluid, and hermetic sealing to maintain long-term performance. Quality control measures are implemented to verify the structural integrity and thermal performance of the finished vapor chambers.

- Thermal performance optimization: Optimization of vapor chamber performance involves careful design of heat input and output interfaces, working fluid selection, and internal flow dynamics. Computational fluid dynamics and thermal modeling are used to predict and enhance performance. Various techniques are employed to improve heat spreading efficiency, including the use of multiple evaporator regions, optimized condensation surfaces, and strategic placement within thermal management systems. Performance metrics include thermal resistance, response time, and uniformity of temperature distribution.

02 Working fluid selection and optimization

The selection of appropriate working fluids is crucial for vapor chamber performance. Different fluids offer varying thermal properties, evaporation rates, and compatibility with chamber materials. Optimized working fluids can significantly enhance heat transfer efficiency, operating temperature ranges, and overall thermal performance of vapor chamber systems. Advanced formulations may include additives to improve wetting characteristics and reduce fluid degradation over time.Expand Specific Solutions03 Integration with electronic devices

Vapor chambers are increasingly integrated into electronic devices for thermal management. These heat spreading solutions are particularly valuable in compact electronic devices where traditional heat sinks are insufficient. The integration involves specific mounting techniques, interface materials, and design considerations to ensure optimal thermal contact with heat-generating components while maintaining the slim profile of modern electronics.Expand Specific Solutions04 Manufacturing techniques and materials

Advanced manufacturing techniques are employed to produce efficient vapor chambers. These include precision stamping, diffusion bonding, sintering of wick structures, and specialized sealing methods. Material selection is critical, with copper, aluminum, and their alloys being common choices for the chamber shell due to their high thermal conductivity. The internal wick structures may use sintered metal powders, mesh screens, or microgrooved surfaces to enhance capillary action.Expand Specific Solutions05 Performance enhancement methods

Various methods are employed to enhance vapor chamber performance. These include multi-layer wick structures, hybrid designs combining vapor chambers with heat pipes, surface treatments to improve wettability, and optimization of chamber geometry. Advanced vapor chambers may incorporate nanostructured materials or composite wicks to improve capillary pressure and reduce thermal resistance, resulting in more efficient heat spreading across larger areas.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The vapor chamber technology market for compact device thermal management is in a growth phase, with increasing adoption driven by miniaturization trends. The market is expanding rapidly as thermal challenges become critical in electronics design, projected to reach significant scale in the next five years. Leading players demonstrate varying levels of technological maturity: Samsung Electronics, LG Electronics, and Intel have established advanced vapor chamber implementations, while Cooler Master and Asia Vital Components offer specialized cooling solutions. Emerging competitors include Xiaomi, Huawei, and Honor, who are actively integrating this technology into mobile devices. Research institutions like Purdue Research Foundation and South China University of Technology are advancing fundamental innovations, creating a competitive landscape balanced between established manufacturers and emerging technology developers.

Cooler Master Co. Ltd.

Technical Solution: Cooler Master has developed advanced Vapor Chamber technology specifically designed for compact devices like smartphones, gaming handhelds, and ultra-thin laptops. Their solution utilizes a flattened heat pipe design with a vacuum-sealed chamber containing a small amount of working fluid. When heat is applied, the liquid vaporizes and moves to cooler areas where it condenses back to liquid form, creating an efficient heat transfer cycle. Cooler Master's implementation features a proprietary sintered copper powder wick structure that enhances capillary action and fluid circulation, allowing for more efficient heat distribution across the entire surface area. Their latest designs incorporate ultra-thin vapor chambers (less than 0.3mm thick) with optimized internal structures that can be custom-shaped to fit complex device geometries while maintaining thermal performance. The company has also developed hybrid solutions that combine vapor chambers with traditional heat pipes for multi-directional heat dissipation in devices with multiple heat sources.

Strengths: Superior thermal spreading efficiency compared to traditional copper heat spreaders, with up to 60% better heat distribution. Highly customizable form factors allow integration into increasingly thin devices. Weaknesses: Higher manufacturing costs compared to traditional cooling solutions, and potential reliability concerns with ultra-thin designs that may be more susceptible to damage during assembly or device drops.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has pioneered an advanced multi-layered Vapor Chamber cooling system for their flagship smartphones and other compact devices. Their technology utilizes a sophisticated stainless steel chamber design with optimized internal structure featuring micro-channels and custom wick patterns that maximize surface contact with heat sources. Samsung's vapor chambers incorporate a proprietary working fluid mixture that offers improved phase-change efficiency across a wider temperature range than conventional solutions. The company has developed manufacturing techniques that allow for vapor chambers as thin as 0.25mm while maintaining structural integrity and thermal performance. Samsung's latest implementations feature 3D contoured vapor chambers that conform to the internal device architecture, allowing cooling components to wrap around batteries and other components for maximum contact with heat-generating elements. Their vapor chambers achieve thermal conductivity values exceeding 1500 W/m·K, significantly outperforming solid copper heat spreaders (400 W/m·K). Samsung has also integrated their vapor chamber technology with graphite sheets and thermal interface materials to create comprehensive thermal management systems for their most thermally demanding devices.

Strengths: Industry-leading thinness while maintaining excellent thermal performance, enabling implementation in ultra-slim smartphones. Extensive manufacturing capabilities allow for mass production with consistent quality. Weaknesses: Proprietary nature of their technology limits broader industry adoption, and the complex manufacturing process results in higher component costs compared to traditional cooling solutions.

Key Patents and Innovations in Vapor Chamber Technology

Vapor chamber heat spreaders having improved transient thermal response and methods of making the same

PatentActiveUS10948241B2

Innovation

- A vapor chamber heat spreader with a thermal compensation layer incorporating core-shell phase change particles embedded in a porous metal wick structure, which enhances heat capacity and transient thermal response by absorbing heat without increasing temperature during phase change.

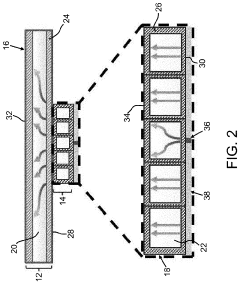

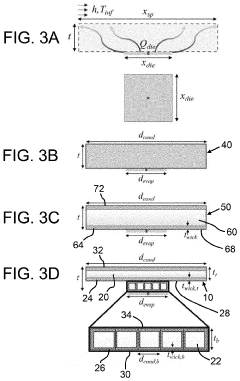

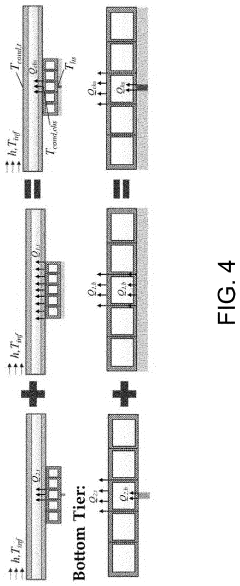

Vapor chamber devices and methods of dissipating heat therewith

PatentActiveUS20210372709A1

Innovation

- A cascaded multi-core vapor chamber device with a top-tier subunit for bulk heat spreading and a bottom-tier subunit with multiple vapor cores to attenuate high heat flux hotspots, decoupling the spreading of total background power from individual hotspots and reducing conduction resistance.

Material Science Advancements for Enhanced Thermal Performance

Recent advancements in material science have significantly contributed to enhancing the thermal performance of vapor chambers in compact electronic devices. The development of novel porous wick structures using copper, aluminum, and nickel-based materials has revolutionized capillary action efficiency, enabling faster and more uniform liquid transport within vapor chambers. These advanced materials exhibit superior thermal conductivity while maintaining structural integrity under high-temperature operating conditions.

Nano-engineered surfaces represent another breakthrough in vapor chamber technology. By manipulating surface properties at the nanoscale, researchers have created specialized coatings that enhance phase-change heat transfer at the evaporator and condenser interfaces. These surfaces feature optimized wettability characteristics and increased effective surface area, resulting in reduced thermal resistance and improved heat dissipation capabilities by up to 30% compared to conventional designs.

Composite materials combining metals with graphene, carbon nanotubes, and ceramic particles have emerged as promising candidates for next-generation vapor chamber construction. These hybrid materials offer exceptional thermal conductivity while addressing traditional limitations such as weight constraints and manufacturing complexity. For instance, graphene-enhanced copper composites demonstrate thermal conductivity improvements of 15-25% while maintaining comparable mechanical properties to pure copper.

The integration of phase-change materials (PCMs) within vapor chamber structures represents an innovative approach to thermal management. These materials absorb excess heat during peak operation through phase transition processes and release it during lower power states, effectively dampening temperature fluctuations. Advanced microencapsulation techniques have overcome previous limitations related to PCM containment and cycling stability, making them viable for long-term deployment in consumer electronics.

Manufacturing innovations have enabled the production of ultra-thin vapor chambers with wall thicknesses below 0.3mm while maintaining structural integrity. This has been achieved through precision metallurgy techniques and advanced sintering processes that create optimized porous structures. Additionally, the development of environmentally friendly working fluids with enhanced thermophysical properties has addressed concerns regarding traditional refrigerants, offering improved performance while meeting stringent environmental regulations.

Computational materials science has accelerated the discovery and optimization of vapor chamber materials through high-throughput screening and machine learning algorithms. These approaches have identified promising material combinations and structural configurations that would have been impractical to discover through conventional experimental methods, significantly reducing development cycles and enabling rapid iteration of design concepts.

Nano-engineered surfaces represent another breakthrough in vapor chamber technology. By manipulating surface properties at the nanoscale, researchers have created specialized coatings that enhance phase-change heat transfer at the evaporator and condenser interfaces. These surfaces feature optimized wettability characteristics and increased effective surface area, resulting in reduced thermal resistance and improved heat dissipation capabilities by up to 30% compared to conventional designs.

Composite materials combining metals with graphene, carbon nanotubes, and ceramic particles have emerged as promising candidates for next-generation vapor chamber construction. These hybrid materials offer exceptional thermal conductivity while addressing traditional limitations such as weight constraints and manufacturing complexity. For instance, graphene-enhanced copper composites demonstrate thermal conductivity improvements of 15-25% while maintaining comparable mechanical properties to pure copper.

The integration of phase-change materials (PCMs) within vapor chamber structures represents an innovative approach to thermal management. These materials absorb excess heat during peak operation through phase transition processes and release it during lower power states, effectively dampening temperature fluctuations. Advanced microencapsulation techniques have overcome previous limitations related to PCM containment and cycling stability, making them viable for long-term deployment in consumer electronics.

Manufacturing innovations have enabled the production of ultra-thin vapor chambers with wall thicknesses below 0.3mm while maintaining structural integrity. This has been achieved through precision metallurgy techniques and advanced sintering processes that create optimized porous structures. Additionally, the development of environmentally friendly working fluids with enhanced thermophysical properties has addressed concerns regarding traditional refrigerants, offering improved performance while meeting stringent environmental regulations.

Computational materials science has accelerated the discovery and optimization of vapor chamber materials through high-throughput screening and machine learning algorithms. These approaches have identified promising material combinations and structural configurations that would have been impractical to discover through conventional experimental methods, significantly reducing development cycles and enabling rapid iteration of design concepts.

Environmental Impact and Sustainability Considerations

The environmental impact of vapor chamber technology in compact devices extends beyond mere performance considerations, encompassing significant sustainability implications. Vapor chambers utilize minimal quantities of working fluid, typically water or other environmentally benign substances, which presents a marked advantage over traditional cooling solutions that may employ harmful refrigerants or require substantial material resources.

Manufacturing processes for vapor chambers have evolved to reduce environmental footprints through optimized material selection and production techniques. The primary materials—copper, aluminum, and stainless steel—are highly recyclable, contributing to circular economy principles. However, the etching processes used to create internal wick structures often involve chemicals that require careful handling and disposal to prevent environmental contamination.

Energy efficiency represents a paramount environmental benefit of vapor chamber implementation. By enhancing thermal management in compact devices, vapor chambers enable more efficient operation at optimal temperatures, potentially reducing overall power consumption by 5-15% compared to conventional cooling solutions. This efficiency translates directly to reduced carbon emissions throughout the device lifecycle.

Lifecycle assessment studies indicate that vapor chambers can extend device longevity by preventing thermal degradation of components. Each additional year of device operation represents significant embodied energy and resource savings that would otherwise be expended in manufacturing replacement products. Research suggests that effective thermal management can extend smartphone and tablet lifespans by up to 30%.

The miniaturization potential of vapor chambers supports broader sustainability goals by enabling more compact device designs without thermal compromises. This reduction in material usage across millions of consumer electronics represents substantial resource conservation at scale. Additionally, the passive operation of vapor chambers eliminates the energy consumption and failure points associated with active cooling components like fans.

End-of-life considerations for vapor chambers present both challenges and opportunities. While the metallic components are readily recyclable, the hermetic sealing and internal structures can complicate disassembly processes. Industry initiatives are emerging to address these challenges through design-for-disassembly approaches and specialized recycling protocols for vapor chamber-equipped devices.

Future sustainability improvements in vapor chamber technology are focusing on bio-derived working fluids, reduced-impact manufacturing processes, and designs that facilitate easier separation of components at end-of-life. These innovations promise to further enhance the environmental credentials of vapor chamber cooling solutions in next-generation compact devices.

Manufacturing processes for vapor chambers have evolved to reduce environmental footprints through optimized material selection and production techniques. The primary materials—copper, aluminum, and stainless steel—are highly recyclable, contributing to circular economy principles. However, the etching processes used to create internal wick structures often involve chemicals that require careful handling and disposal to prevent environmental contamination.

Energy efficiency represents a paramount environmental benefit of vapor chamber implementation. By enhancing thermal management in compact devices, vapor chambers enable more efficient operation at optimal temperatures, potentially reducing overall power consumption by 5-15% compared to conventional cooling solutions. This efficiency translates directly to reduced carbon emissions throughout the device lifecycle.

Lifecycle assessment studies indicate that vapor chambers can extend device longevity by preventing thermal degradation of components. Each additional year of device operation represents significant embodied energy and resource savings that would otherwise be expended in manufacturing replacement products. Research suggests that effective thermal management can extend smartphone and tablet lifespans by up to 30%.

The miniaturization potential of vapor chambers supports broader sustainability goals by enabling more compact device designs without thermal compromises. This reduction in material usage across millions of consumer electronics represents substantial resource conservation at scale. Additionally, the passive operation of vapor chambers eliminates the energy consumption and failure points associated with active cooling components like fans.

End-of-life considerations for vapor chambers present both challenges and opportunities. While the metallic components are readily recyclable, the hermetic sealing and internal structures can complicate disassembly processes. Industry initiatives are emerging to address these challenges through design-for-disassembly approaches and specialized recycling protocols for vapor chamber-equipped devices.

Future sustainability improvements in vapor chamber technology are focusing on bio-derived working fluids, reduced-impact manufacturing processes, and designs that facilitate easier separation of components at end-of-life. These innovations promise to further enhance the environmental credentials of vapor chamber cooling solutions in next-generation compact devices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!