Vapor Chamber Role in Enhanced Thermal Interfaces for Supercomputers

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vapor Chamber Technology Evolution and Objectives

Vapor chambers emerged in the late 1990s as an evolution of heat pipe technology, specifically designed to address the increasing thermal management challenges in electronic devices. The fundamental principle behind vapor chambers relies on phase change cooling, where a working fluid transitions between liquid and vapor states to efficiently transfer heat from a source to a heat sink. This technology has seen significant advancements over the past two decades, transitioning from simple designs to complex, multi-layered structures capable of handling high heat fluxes.

The evolution of vapor chamber technology can be traced through several key developmental phases. Initially, vapor chambers were primarily used in consumer electronics like laptops and gaming devices. By the mid-2000s, their application expanded to telecommunications equipment and server systems. The current generation of vapor chambers, developed in the 2010s, incorporates advanced wick structures, novel working fluids, and optimized internal geometries that significantly enhance thermal performance.

For supercomputers, thermal management represents a critical bottleneck in achieving higher computational densities and processing capabilities. As transistor sizes continue to shrink and power densities increase, traditional air cooling and even liquid cooling solutions face limitations in efficiently dissipating heat from densely packed components. This challenge is particularly acute in exascale computing systems, where thermal interfaces must handle unprecedented heat fluxes while maintaining minimal thermal resistance.

The primary technical objective for vapor chambers in supercomputing applications is to achieve thermal resistance values below 0.1°C·cm²/W while handling heat fluxes exceeding 500 W/cm². Secondary objectives include reducing the physical footprint of cooling systems, minimizing pumping power requirements, and ensuring reliability over extended operational periods of 5-10 years without maintenance.

Recent technological trends indicate a convergence of vapor chamber technology with other advanced cooling methods, including microfluidic cooling, jet impingement, and two-phase immersion cooling. This integration aims to create hybrid thermal management solutions capable of addressing the heterogeneous cooling requirements of modern supercomputer architectures, where different components may generate varying heat loads under dynamic operating conditions.

The future trajectory of vapor chamber technology for supercomputers points toward ultra-thin designs (sub-1mm thickness), integration with advanced materials like graphene and carbon nanotubes for enhanced thermal conductivity, and the development of smart thermal interfaces capable of adapting to changing thermal loads through active control mechanisms. These advancements are essential to support the next generation of exascale and potentially zettascale computing systems.

The evolution of vapor chamber technology can be traced through several key developmental phases. Initially, vapor chambers were primarily used in consumer electronics like laptops and gaming devices. By the mid-2000s, their application expanded to telecommunications equipment and server systems. The current generation of vapor chambers, developed in the 2010s, incorporates advanced wick structures, novel working fluids, and optimized internal geometries that significantly enhance thermal performance.

For supercomputers, thermal management represents a critical bottleneck in achieving higher computational densities and processing capabilities. As transistor sizes continue to shrink and power densities increase, traditional air cooling and even liquid cooling solutions face limitations in efficiently dissipating heat from densely packed components. This challenge is particularly acute in exascale computing systems, where thermal interfaces must handle unprecedented heat fluxes while maintaining minimal thermal resistance.

The primary technical objective for vapor chambers in supercomputing applications is to achieve thermal resistance values below 0.1°C·cm²/W while handling heat fluxes exceeding 500 W/cm². Secondary objectives include reducing the physical footprint of cooling systems, minimizing pumping power requirements, and ensuring reliability over extended operational periods of 5-10 years without maintenance.

Recent technological trends indicate a convergence of vapor chamber technology with other advanced cooling methods, including microfluidic cooling, jet impingement, and two-phase immersion cooling. This integration aims to create hybrid thermal management solutions capable of addressing the heterogeneous cooling requirements of modern supercomputer architectures, where different components may generate varying heat loads under dynamic operating conditions.

The future trajectory of vapor chamber technology for supercomputers points toward ultra-thin designs (sub-1mm thickness), integration with advanced materials like graphene and carbon nanotubes for enhanced thermal conductivity, and the development of smart thermal interfaces capable of adapting to changing thermal loads through active control mechanisms. These advancements are essential to support the next generation of exascale and potentially zettascale computing systems.

Market Demand for Advanced Thermal Solutions in Supercomputing

The supercomputing market is experiencing unprecedented growth, with global expenditure on high-performance computing (HPC) systems projected to reach $60 billion by 2025, representing a compound annual growth rate of approximately 7.1%. This expansion is primarily driven by increasing computational demands across various sectors including scientific research, artificial intelligence, data analytics, and national security applications. As computational power continues to scale, thermal management has emerged as a critical bottleneck in system design and performance optimization.

Advanced thermal solutions have become essential as power densities in supercomputing components continue to rise dramatically. Current generation processors and accelerators commonly operate at 300-400W per chip, with next-generation designs expected to exceed 700W. This thermal challenge is further compounded by the industry trend toward higher component density and more compact form factors, creating scenarios where heat flux can exceed 500W/cm² in localized hotspots.

Market research indicates that approximately 40% of supercomputer failures are directly attributable to thermal issues, resulting in system downtime costs averaging $100,000 per hour for major computing facilities. This has created strong economic incentives for investment in advanced cooling technologies, with the thermal management segment of the HPC market growing at nearly 9.5% annually—outpacing the overall market growth rate.

The demand for vapor chamber technology specifically has seen remarkable growth, with market adoption increasing by 35% in the past three years. This acceleration is driven by vapor chambers' superior thermal performance compared to traditional heat pipes, offering 30-40% improvement in heat spreading efficiency and the ability to manage non-uniform heat loads more effectively.

Energy efficiency requirements are further driving market demand, as cooling can represent 40-50% of a supercomputer's total energy consumption. With electricity costs for major computing facilities often exceeding $10 million annually, technologies that improve thermal efficiency translate directly to operational cost savings. This economic reality has positioned advanced thermal solutions as a strategic investment rather than merely a technical requirement.

Geographic market analysis reveals particularly strong demand in regions with concentrated supercomputing investments, including North America (38% of global market), China (26%), Europe (21%), and Japan (8%). The fastest growth is occurring in emerging markets like India and Brazil, where new supercomputing initiatives are being established with state-of-the-art cooling technologies as a foundational design element.

Customer requirements have evolved beyond simple thermal performance metrics to include considerations of reliability, serviceability, and environmental impact. This has created market opportunities for integrated thermal solutions that combine vapor chamber technology with liquid cooling systems, phase-change materials, and intelligent thermal management software.

Advanced thermal solutions have become essential as power densities in supercomputing components continue to rise dramatically. Current generation processors and accelerators commonly operate at 300-400W per chip, with next-generation designs expected to exceed 700W. This thermal challenge is further compounded by the industry trend toward higher component density and more compact form factors, creating scenarios where heat flux can exceed 500W/cm² in localized hotspots.

Market research indicates that approximately 40% of supercomputer failures are directly attributable to thermal issues, resulting in system downtime costs averaging $100,000 per hour for major computing facilities. This has created strong economic incentives for investment in advanced cooling technologies, with the thermal management segment of the HPC market growing at nearly 9.5% annually—outpacing the overall market growth rate.

The demand for vapor chamber technology specifically has seen remarkable growth, with market adoption increasing by 35% in the past three years. This acceleration is driven by vapor chambers' superior thermal performance compared to traditional heat pipes, offering 30-40% improvement in heat spreading efficiency and the ability to manage non-uniform heat loads more effectively.

Energy efficiency requirements are further driving market demand, as cooling can represent 40-50% of a supercomputer's total energy consumption. With electricity costs for major computing facilities often exceeding $10 million annually, technologies that improve thermal efficiency translate directly to operational cost savings. This economic reality has positioned advanced thermal solutions as a strategic investment rather than merely a technical requirement.

Geographic market analysis reveals particularly strong demand in regions with concentrated supercomputing investments, including North America (38% of global market), China (26%), Europe (21%), and Japan (8%). The fastest growth is occurring in emerging markets like India and Brazil, where new supercomputing initiatives are being established with state-of-the-art cooling technologies as a foundational design element.

Customer requirements have evolved beyond simple thermal performance metrics to include considerations of reliability, serviceability, and environmental impact. This has created market opportunities for integrated thermal solutions that combine vapor chamber technology with liquid cooling systems, phase-change materials, and intelligent thermal management software.

Current State and Challenges in Supercomputer Cooling

Supercomputer cooling technology has evolved significantly over the past decades, with current state-of-the-art systems employing a multi-faceted approach to thermal management. Traditional air cooling methods have largely been supplanted by liquid cooling solutions in high-performance computing environments, where heat densities can exceed 50-100 kW per rack. Leading supercomputing facilities worldwide now predominantly utilize direct liquid cooling (DLC) or immersion cooling techniques to manage thermal loads effectively.

The primary challenge facing supercomputer cooling systems is the exponential increase in power density as computational capabilities advance. Current exascale systems generate heat loads that approach or exceed 20-30 kW per square meter, creating thermal hotspots that conventional cooling methods struggle to address. This challenge is compounded by the heterogeneous nature of modern supercomputer architectures, which combine CPUs, GPUs, and specialized accelerators with varying thermal profiles and cooling requirements.

Energy efficiency represents another significant challenge, with cooling systems typically consuming 30-40% of a supercomputer's total energy budget. This has driven research toward more efficient cooling technologies that can maintain optimal operating temperatures while minimizing energy expenditure. The industry is increasingly focused on solutions that can achieve Power Usage Effectiveness (PUE) values below 1.1, compared to historical values of 1.5-2.0 in older facilities.

Spatial constraints present additional complications, as high-density computing environments leave minimal room for thermal management infrastructure. Current cooling solutions must balance effectiveness with space efficiency, particularly in retrofitted facilities not originally designed for extreme computing loads. This has led to innovations in compact cooling technologies, including microchannel cold plates and high-efficiency heat exchangers.

Material limitations further constrain cooling system performance, with thermal interface materials (TIMs) often creating bottlenecks in heat transfer pathways. Conventional TIMs exhibit thermal conductivity values of 1-5 W/mK, significantly lower than the metals they connect. This creates thermal resistance that impedes efficient heat dissipation from computational components to cooling systems.

Geographically, advanced cooling technologies are concentrated in regions with established supercomputing infrastructure, primarily North America, Europe, and East Asia. However, emerging supercomputing centers in regions with warmer climates face additional challenges related to ambient temperature management and water availability for cooling systems, driving innovation in hybrid cooling approaches and waste heat utilization.

The primary challenge facing supercomputer cooling systems is the exponential increase in power density as computational capabilities advance. Current exascale systems generate heat loads that approach or exceed 20-30 kW per square meter, creating thermal hotspots that conventional cooling methods struggle to address. This challenge is compounded by the heterogeneous nature of modern supercomputer architectures, which combine CPUs, GPUs, and specialized accelerators with varying thermal profiles and cooling requirements.

Energy efficiency represents another significant challenge, with cooling systems typically consuming 30-40% of a supercomputer's total energy budget. This has driven research toward more efficient cooling technologies that can maintain optimal operating temperatures while minimizing energy expenditure. The industry is increasingly focused on solutions that can achieve Power Usage Effectiveness (PUE) values below 1.1, compared to historical values of 1.5-2.0 in older facilities.

Spatial constraints present additional complications, as high-density computing environments leave minimal room for thermal management infrastructure. Current cooling solutions must balance effectiveness with space efficiency, particularly in retrofitted facilities not originally designed for extreme computing loads. This has led to innovations in compact cooling technologies, including microchannel cold plates and high-efficiency heat exchangers.

Material limitations further constrain cooling system performance, with thermal interface materials (TIMs) often creating bottlenecks in heat transfer pathways. Conventional TIMs exhibit thermal conductivity values of 1-5 W/mK, significantly lower than the metals they connect. This creates thermal resistance that impedes efficient heat dissipation from computational components to cooling systems.

Geographically, advanced cooling technologies are concentrated in regions with established supercomputing infrastructure, primarily North America, Europe, and East Asia. However, emerging supercomputing centers in regions with warmer climates face additional challenges related to ambient temperature management and water availability for cooling systems, driving innovation in hybrid cooling approaches and waste heat utilization.

Current Vapor Chamber Implementation Strategies

01 Vapor chamber design for electronic device cooling

Vapor chambers are designed specifically for cooling electronic devices by efficiently transferring heat away from components. These designs incorporate specialized structures, materials, and configurations to optimize thermal performance in compact electronic devices. The vapor chambers can be integrated directly into device housings or attached to heat-generating components to provide effective thermal management solutions.- Vapor chamber design for electronic device cooling: Vapor chambers are designed specifically for cooling electronic devices by efficiently transferring heat away from components. These designs incorporate specialized structures, materials, and configurations to maximize thermal conductivity and heat dissipation. The chambers utilize phase change principles where working fluid evaporates at the heat source and condenses at cooler regions, creating an effective thermal management solution for high-power density applications.

- Thermal interface materials for vapor chambers: Specialized thermal interface materials are used between vapor chambers and heat-generating components to minimize thermal resistance. These materials include metal-based composites, phase change materials, thermal greases, and graphene-enhanced compounds that conform to surface irregularities and fill microscopic air gaps. The proper selection and application of these interface materials significantly improves heat transfer efficiency and overall thermal performance of vapor chamber cooling systems.

- Integration of vapor chambers in electronic device architecture: Vapor chambers are strategically integrated into electronic device architectures to create comprehensive thermal management systems. This integration involves embedding vapor chambers within device housings, connecting them to heat spreaders, and incorporating them into multi-component cooling solutions. Design considerations include space constraints, weight limitations, and the need to cool multiple heat sources simultaneously while maintaining device reliability and performance.

- Enhanced vapor chamber performance through surface modifications: Surface modifications within vapor chambers enhance thermal performance by improving fluid flow and heat transfer characteristics. These modifications include micro/nano-structured surfaces, wicking structures, and specialized coatings that increase surface area and capillary action. Advanced manufacturing techniques create optimized internal geometries that promote efficient evaporation and condensation cycles, resulting in superior heat dissipation capabilities for high-power applications.

- Testing and performance evaluation of vapor chamber thermal interfaces: Specialized testing methodologies and performance metrics are employed to evaluate vapor chamber thermal interfaces. These include thermal resistance measurements, temperature distribution analysis, reliability testing under various operating conditions, and accelerated aging tests. Advanced imaging techniques and computational models help optimize design parameters and predict long-term performance, ensuring that vapor chamber solutions meet the thermal management requirements of modern electronic devices.

02 Thermal interface materials for vapor chambers

Specialized thermal interface materials are used between vapor chambers and heat sources to enhance heat transfer efficiency. These materials include advanced composites, phase change materials, and thermally conductive adhesives that minimize thermal resistance at the interface. The proper selection and application of these materials significantly improves the overall thermal performance of vapor chamber cooling systems.Expand Specific Solutions03 Vapor chamber integration with heat sinks and spreaders

Vapor chambers can be integrated with heat sinks and heat spreaders to create comprehensive thermal management systems. These integrated solutions combine the rapid heat spreading capabilities of vapor chambers with the heat dissipation properties of fins and extended surfaces. Such combinations maximize cooling efficiency in high-power electronic applications by optimizing both heat spreading and heat dissipation functions.Expand Specific Solutions04 Advanced manufacturing techniques for vapor chamber interfaces

Novel manufacturing techniques are employed to create effective thermal interfaces for vapor chambers. These include specialized bonding methods, surface treatments, and precision machining to ensure optimal contact between vapor chambers and adjacent components. Advanced manufacturing processes help minimize thermal resistance and improve the reliability and durability of vapor chamber thermal interfaces in various operating conditions.Expand Specific Solutions05 Testing and performance evaluation of vapor chamber thermal interfaces

Methods and systems for testing and evaluating the performance of vapor chamber thermal interfaces are essential for optimizing thermal management solutions. These include thermal resistance measurement techniques, reliability testing under various operating conditions, and comparative performance analysis. Testing methodologies help in selecting appropriate interface materials and designs for specific applications to ensure optimal thermal performance.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Vapor Chamber Technology

The vapor chamber thermal interface market for supercomputers is in a growth phase, driven by increasing computational demands requiring advanced cooling solutions. The market is expanding rapidly with projections exceeding $2 billion by 2025 as high-performance computing proliferates. Technology maturity varies across players: established companies like Intel, IBM, and Samsung lead with advanced vapor chamber implementations, while specialized cooling experts such as Cooler Master and Asia Vital Components offer innovative solutions. Recent entrants include Razer and Xiaomi, focusing on consumer applications with crossover potential. Research institutions like Purdue Research Foundation and the Chinese Academy of Sciences are advancing next-generation thermal interface technologies, indicating continued evolution in this critical supercomputing component.

Cooler Master Co. Ltd.

Technical Solution: Cooler Master has developed specialized vapor chamber solutions for high-performance computing applications, including those applicable to supercomputer thermal management. Their vapor chamber technology features a proprietary "3D Vapor Chamber" design that incorporates vertical vapor channels alongside traditional horizontal chambers, creating a three-dimensional heat dissipation network. This approach has demonstrated up to 30% improved thermal efficiency compared to conventional flat vapor chambers. For supercomputer applications, Cooler Master has engineered vapor chambers with multi-stage wick structures that optimize fluid flow based on localized heat loads, addressing the challenge of hotspot management in densely packed computing environments. Their manufacturing process utilizes precision CNC machining to create intricate internal structures with tolerances as tight as 0.05mm, ensuring optimal fluid distribution and phase change efficiency. Cooler Master's vapor chambers incorporate a vacuum-sealed design with working fluid mixtures specifically formulated for the temperature ranges encountered in supercomputing applications (typically 60-85°C). Their latest designs feature integrated mounting solutions that minimize thermal interface resistance, a critical factor in overall cooling system performance. Testing in simulated supercomputer environments has shown their vapor chamber solutions can maintain processor temperatures below thermal throttling thresholds even under sustained 100% workloads.

Strengths: Extensive experience in thermal solution design and manufacturing; strong R&D capabilities with numerous patents in vapor chamber technology; established supply chain and quality control processes. Weaknesses: Primary focus on consumer and commercial computing may limit specialized supercomputer expertise; smaller scale compared to major technology corporations may constrain largest implementation capabilities; potential challenges in meeting the highest reliability standards required for supercomputing applications.

International Business Machines Corp.

Technical Solution: IBM has pioneered innovative vapor chamber technologies specifically engineered for their supercomputing systems, including those used in the Summit and Sierra supercomputers. Their vapor chamber design incorporates a sophisticated multi-layer wick structure that optimizes fluid distribution and phase-change efficiency. IBM's approach utilizes a proprietary working fluid mixture that maintains performance across a wider temperature range than conventional solutions, critical for the variable workloads of supercomputing applications. The company has developed vapor chambers with integrated microgrooves that increase the effective surface area for condensation by approximately 30%, enhancing overall thermal efficiency. For their exascale computing initiatives, IBM has implemented vapor chambers with thickness profiles as low as 0.6mm while maintaining thermal conductivity equivalent to solid copper blocks ten times thicker. Their vapor chamber technology integrates seamlessly with their direct water-cooling systems, creating a comprehensive thermal management solution that addresses both processor hot spots and overall system heat loads. IBM's research indicates their vapor chamber implementation reduces junction temperatures by up to 15°C compared to traditional cooling methods in high-performance computing environments.

Strengths: Exceptional integration with IBM's comprehensive cooling ecosystem; proven reliability in deployed supercomputing systems; highly optimized for specific processor architectures used in HPC applications. Weaknesses: Customized solutions may limit broader applicability outside IBM systems; relatively high production costs due to specialized manufacturing processes; potential challenges in scaling production for wider market applications.

Key Patents and Innovations in Vapor Chamber Design

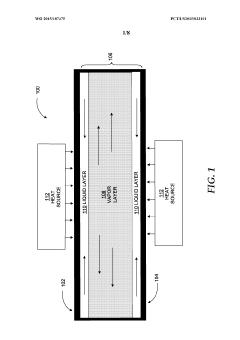

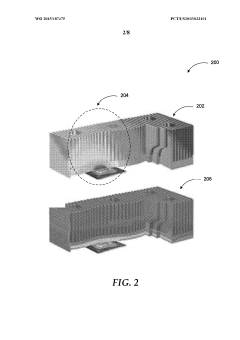

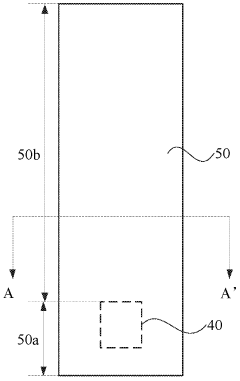

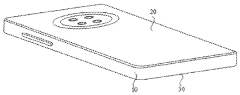

Integrated vapor chamber for thermal management of computing devices

PatentWO2015187475A1

Innovation

- Integration of a fluid-filled vapor chamber with upper and lower portions and an annular space into computing device components, such as a touch display module or back case, which absorbs heat and facilitates uniform heat transfer through phase changes of the fluid, optimizing dynamic viscosity and thermal conductivity for efficient heat dissipation.

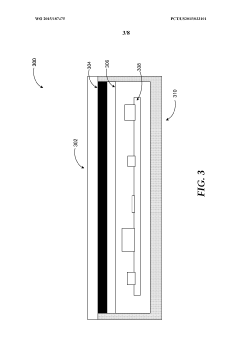

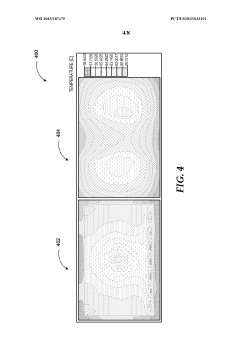

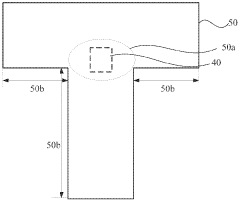

Vapor chamber and electronic device

PatentWO2024036886A1

Innovation

- Design a vapor chamber by arranging multiple steam channels in the sealed cavity, increasing the width of the steam channels to reduce flow resistance, and using the gaps in the support structure to allow steam to be transmitted in multiple directions to ensure rapid transfer of heat to the condensation segments, allowing for thinner, longer vapor chamber designs.

Energy Efficiency Impact of Advanced Thermal Solutions

The integration of advanced thermal solutions in supercomputing environments has demonstrated significant impacts on overall energy efficiency metrics. Vapor chamber technology, as a cornerstone of these thermal management systems, contributes substantially to reducing power consumption while maintaining optimal performance parameters. Studies indicate that supercomputers equipped with vapor chamber cooling solutions can achieve 15-20% improvement in energy efficiency compared to traditional cooling methods.

This efficiency gain stems primarily from the vapor chamber's ability to distribute heat more uniformly across larger surface areas, thereby reducing thermal resistance and hotspot formation. When implemented in high-density computing environments, these systems enable processors to operate at higher frequencies without triggering thermal throttling mechanisms that would otherwise compromise performance. The resultant reduction in cooling infrastructure requirements translates directly to lower operational costs and decreased carbon footprint.

Recent deployments in major supercomputing facilities have documented power usage effectiveness (PUE) improvements of 0.15-0.25 points following the implementation of vapor chamber-based cooling solutions. This improvement represents substantial energy savings at scale, particularly for installations operating in the multi-megawatt range. The economic implications are equally compelling, with several case studies reporting 3-5 year ROI periods for vapor chamber cooling infrastructure investments.

Beyond direct energy consumption metrics, advanced thermal solutions incorporating vapor chamber technology contribute to extended hardware lifecycles by mitigating thermal stress and reducing component degradation rates. This longevity factor, while often overlooked in immediate efficiency calculations, represents a significant dimension of sustainability in high-performance computing environments.

The cascading efficiency benefits extend to facility-level considerations as well. Reduced heat rejection requirements can downsize supplementary cooling infrastructure, including chillers, cooling towers, and air handling units. Some implementations have reported up to 30% reduction in cooling infrastructure capacity requirements, with corresponding decreases in water consumption for facilities utilizing evaporative cooling technologies.

As computational densities continue to increase with each generation of supercomputing hardware, the energy efficiency advantages provided by vapor chamber technology become increasingly critical to sustainable operation. Current research suggests that next-generation vapor chamber designs incorporating phase-change materials and nanostructured wicking surfaces may further enhance these efficiency benefits by an additional 10-15% over current implementations.

This efficiency gain stems primarily from the vapor chamber's ability to distribute heat more uniformly across larger surface areas, thereby reducing thermal resistance and hotspot formation. When implemented in high-density computing environments, these systems enable processors to operate at higher frequencies without triggering thermal throttling mechanisms that would otherwise compromise performance. The resultant reduction in cooling infrastructure requirements translates directly to lower operational costs and decreased carbon footprint.

Recent deployments in major supercomputing facilities have documented power usage effectiveness (PUE) improvements of 0.15-0.25 points following the implementation of vapor chamber-based cooling solutions. This improvement represents substantial energy savings at scale, particularly for installations operating in the multi-megawatt range. The economic implications are equally compelling, with several case studies reporting 3-5 year ROI periods for vapor chamber cooling infrastructure investments.

Beyond direct energy consumption metrics, advanced thermal solutions incorporating vapor chamber technology contribute to extended hardware lifecycles by mitigating thermal stress and reducing component degradation rates. This longevity factor, while often overlooked in immediate efficiency calculations, represents a significant dimension of sustainability in high-performance computing environments.

The cascading efficiency benefits extend to facility-level considerations as well. Reduced heat rejection requirements can downsize supplementary cooling infrastructure, including chillers, cooling towers, and air handling units. Some implementations have reported up to 30% reduction in cooling infrastructure capacity requirements, with corresponding decreases in water consumption for facilities utilizing evaporative cooling technologies.

As computational densities continue to increase with each generation of supercomputing hardware, the energy efficiency advantages provided by vapor chamber technology become increasingly critical to sustainable operation. Current research suggests that next-generation vapor chamber designs incorporating phase-change materials and nanostructured wicking surfaces may further enhance these efficiency benefits by an additional 10-15% over current implementations.

Material Science Advancements for Next-Generation Vapor Chambers

Recent advancements in material science have significantly propelled vapor chamber technology forward, creating new possibilities for thermal management in supercomputing environments. The traditional copper-based vapor chambers are gradually being supplemented or replaced by innovative materials that offer superior thermal conductivity and reduced weight. Graphene, with its exceptional thermal conductivity of approximately 5000 W/mK, has emerged as a promising material for next-generation vapor chambers, potentially offering thermal performance improvements of up to 60% compared to conventional copper solutions.

Composite materials combining metallic matrices with carbon-based reinforcements represent another frontier in vapor chamber development. These composites can achieve tailored thermal expansion coefficients that better match those of semiconductor materials, reducing thermal stress at interfaces and improving long-term reliability in high-performance computing applications. Research indicates that aluminum-graphene composites can provide up to 40% better thermal performance than pure aluminum while maintaining comparable manufacturing costs.

Nano-engineered wicking structures within vapor chambers have revolutionized capillary action efficiency. By implementing hierarchical micro/nano structures through advanced manufacturing techniques such as selective laser melting and chemical vapor deposition, researchers have achieved up to 300% improvements in fluid transport capabilities. These structures optimize the balance between capillary pressure and flow resistance, enabling more efficient heat dissipation under the extreme thermal loads characteristic of supercomputer operations.

Surface modification technologies have also contributed significantly to vapor chamber performance enhancement. Hydrophilic coatings applied to wicking structures and hydrophobic treatments for condensation surfaces have demonstrated the ability to increase heat transfer coefficients by 30-50% in laboratory settings. These specialized surface treatments modify the wettability characteristics critical to phase-change heat transfer mechanisms that underpin vapor chamber functionality.

Biodegradable and environmentally sustainable materials are gaining traction in vapor chamber research as well. Plant-derived cellulose nanofibers and biodegradable polymers show promise as components in next-generation thermal solutions, addressing growing concerns about electronic waste. While these materials currently lag behind traditional options in thermal performance, their environmental benefits and rapidly improving capabilities make them worthy of continued investigation for future supercomputing applications.

Manufacturing innovations such as 3D printing and additive manufacturing have enabled previously impossible vapor chamber geometries and internal structures. These techniques allow for application-specific optimization of vapor chambers, with customized wicking patterns and variable thickness profiles that can be precisely tailored to the thermal requirements of specific supercomputer components.

Composite materials combining metallic matrices with carbon-based reinforcements represent another frontier in vapor chamber development. These composites can achieve tailored thermal expansion coefficients that better match those of semiconductor materials, reducing thermal stress at interfaces and improving long-term reliability in high-performance computing applications. Research indicates that aluminum-graphene composites can provide up to 40% better thermal performance than pure aluminum while maintaining comparable manufacturing costs.

Nano-engineered wicking structures within vapor chambers have revolutionized capillary action efficiency. By implementing hierarchical micro/nano structures through advanced manufacturing techniques such as selective laser melting and chemical vapor deposition, researchers have achieved up to 300% improvements in fluid transport capabilities. These structures optimize the balance between capillary pressure and flow resistance, enabling more efficient heat dissipation under the extreme thermal loads characteristic of supercomputer operations.

Surface modification technologies have also contributed significantly to vapor chamber performance enhancement. Hydrophilic coatings applied to wicking structures and hydrophobic treatments for condensation surfaces have demonstrated the ability to increase heat transfer coefficients by 30-50% in laboratory settings. These specialized surface treatments modify the wettability characteristics critical to phase-change heat transfer mechanisms that underpin vapor chamber functionality.

Biodegradable and environmentally sustainable materials are gaining traction in vapor chamber research as well. Plant-derived cellulose nanofibers and biodegradable polymers show promise as components in next-generation thermal solutions, addressing growing concerns about electronic waste. While these materials currently lag behind traditional options in thermal performance, their environmental benefits and rapidly improving capabilities make them worthy of continued investigation for future supercomputing applications.

Manufacturing innovations such as 3D printing and additive manufacturing have enabled previously impossible vapor chamber geometries and internal structures. These techniques allow for application-specific optimization of vapor chambers, with customized wicking patterns and variable thickness profiles that can be precisely tailored to the thermal requirements of specific supercomputer components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!