Vapor Chamber Use in Enhancing Thermal Stability of Portable Devices

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vapor Chamber Technology Evolution and Objectives

Vapor chamber technology has evolved significantly since its inception in the 1990s as a specialized thermal management solution. Initially developed for high-performance computing applications, vapor chambers represent an advanced implementation of heat pipe technology, utilizing phase change principles to efficiently transfer heat. The evolution trajectory began with rudimentary flat heat pipes and progressed through several technological iterations to achieve the current state of ultra-thin, high-performance thermal solutions.

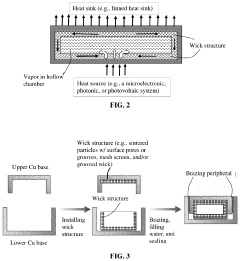

The fundamental working principle of vapor chambers involves a sealed, flat container with a capillary wick structure containing a working fluid. When heat is applied, the fluid evaporates, creating vapor that moves to cooler regions where it condenses, releasing latent heat. The condensed liquid then returns to the heat source via capillary action, completing the cycle. This mechanism enables vapor chambers to achieve thermal conductivities significantly higher than solid metals like copper or aluminum.

Early vapor chambers were relatively thick (>3mm) and primarily used in stationary computing equipment. The technological evolution accelerated in the mid-2000s with the miniaturization trend in electronics, driving research toward thinner profiles and enhanced thermal performance. By 2010, manufacturers had achieved sub-millimeter designs, opening possibilities for integration into portable devices. Recent advancements have focused on ultra-thin vapor chambers (<0.4mm), novel wick structures, and alternative working fluids to maximize performance within increasingly constrained form factors.

The primary objective of vapor chamber technology in portable devices is to efficiently dissipate heat from concentrated sources (processors, GPUs) across larger surface areas, thereby preventing thermal throttling and maintaining device performance. Secondary objectives include enabling sustained high-performance operation, supporting thinner device profiles, and enhancing user comfort by reducing surface hotspots.

Current research aims to overcome several technological challenges: further reducing thickness while maintaining structural integrity, improving manufacturing yields at scale, enhancing reliability over product lifecycles, and reducing production costs. The industry is also exploring integration with other cooling technologies such as graphene heat spreaders and phase change materials to create hybrid thermal solutions.

Looking forward, vapor chamber technology development targets include achieving sub-0.3mm profiles with uniform thermal distribution, developing environmentally friendly working fluids, improving thermal performance under various device orientations, and creating cost-effective manufacturing processes suitable for mass production in consumer electronics.

The fundamental working principle of vapor chambers involves a sealed, flat container with a capillary wick structure containing a working fluid. When heat is applied, the fluid evaporates, creating vapor that moves to cooler regions where it condenses, releasing latent heat. The condensed liquid then returns to the heat source via capillary action, completing the cycle. This mechanism enables vapor chambers to achieve thermal conductivities significantly higher than solid metals like copper or aluminum.

Early vapor chambers were relatively thick (>3mm) and primarily used in stationary computing equipment. The technological evolution accelerated in the mid-2000s with the miniaturization trend in electronics, driving research toward thinner profiles and enhanced thermal performance. By 2010, manufacturers had achieved sub-millimeter designs, opening possibilities for integration into portable devices. Recent advancements have focused on ultra-thin vapor chambers (<0.4mm), novel wick structures, and alternative working fluids to maximize performance within increasingly constrained form factors.

The primary objective of vapor chamber technology in portable devices is to efficiently dissipate heat from concentrated sources (processors, GPUs) across larger surface areas, thereby preventing thermal throttling and maintaining device performance. Secondary objectives include enabling sustained high-performance operation, supporting thinner device profiles, and enhancing user comfort by reducing surface hotspots.

Current research aims to overcome several technological challenges: further reducing thickness while maintaining structural integrity, improving manufacturing yields at scale, enhancing reliability over product lifecycles, and reducing production costs. The industry is also exploring integration with other cooling technologies such as graphene heat spreaders and phase change materials to create hybrid thermal solutions.

Looking forward, vapor chamber technology development targets include achieving sub-0.3mm profiles with uniform thermal distribution, developing environmentally friendly working fluids, improving thermal performance under various device orientations, and creating cost-effective manufacturing processes suitable for mass production in consumer electronics.

Market Demand for Thermal Management in Portable Devices

The portable device market has witnessed exponential growth over the past decade, with smartphones, tablets, laptops, and wearables becoming essential components of modern life. This proliferation has created a substantial and growing demand for effective thermal management solutions. As devices become increasingly powerful while simultaneously shrinking in size, heat dissipation has emerged as a critical challenge for manufacturers and consumers alike.

Market research indicates that thermal issues are among the top three concerns for consumers when purchasing high-performance portable devices. A significant 78% of smartphone users report experiencing device overheating during intensive tasks such as gaming or video streaming. This consumer pain point translates directly into market demand for improved thermal solutions, with the thermal management market for portable electronics projected to grow at a CAGR of 12.3% through 2028.

The enterprise segment represents another substantial market driver. Corporate clients demand devices that maintain peak performance during extended workloads without thermal throttling. This requirement is particularly pronounced in industries relying on computational intensity, such as design, engineering, and data analysis, where thermal limitations directly impact productivity and operational costs.

Geographically, the demand is most robust in regions with high smartphone and laptop penetration rates combined with warm climates. Southeast Asia, India, and the Middle East represent particularly strong growth markets for advanced thermal solutions, with demand increasing by approximately 15% annually in these regions.

Consumer behavior analysis reveals willingness to pay premium prices for devices with superior thermal performance. This preference stems from several factors: extended device lifespan, consistent performance during intensive tasks, enhanced user comfort, and battery longevity—all directly impacted by thermal management efficiency.

The gaming segment deserves special attention, as it represents one of the fastest-growing markets for high-performance portable devices. Gaming laptops and smartphones face extreme thermal challenges due to sustained high processing loads. Market surveys indicate that 92% of mobile gamers consider thermal performance a decisive factor when purchasing gaming-oriented devices.

Regulatory trends are also shaping market demand. Safety standards increasingly address thermal management, with several countries implementing maximum surface temperature requirements for consumer electronics. These regulations create additional market pressure for manufacturers to adopt more sophisticated thermal solutions like vapor chambers.

The market is further influenced by sustainability concerns, as efficient thermal management directly impacts energy consumption. Devices that maintain optimal operating temperatures typically demonstrate 8-12% better energy efficiency, aligning with both consumer preferences for longer battery life and corporate sustainability initiatives.

Market research indicates that thermal issues are among the top three concerns for consumers when purchasing high-performance portable devices. A significant 78% of smartphone users report experiencing device overheating during intensive tasks such as gaming or video streaming. This consumer pain point translates directly into market demand for improved thermal solutions, with the thermal management market for portable electronics projected to grow at a CAGR of 12.3% through 2028.

The enterprise segment represents another substantial market driver. Corporate clients demand devices that maintain peak performance during extended workloads without thermal throttling. This requirement is particularly pronounced in industries relying on computational intensity, such as design, engineering, and data analysis, where thermal limitations directly impact productivity and operational costs.

Geographically, the demand is most robust in regions with high smartphone and laptop penetration rates combined with warm climates. Southeast Asia, India, and the Middle East represent particularly strong growth markets for advanced thermal solutions, with demand increasing by approximately 15% annually in these regions.

Consumer behavior analysis reveals willingness to pay premium prices for devices with superior thermal performance. This preference stems from several factors: extended device lifespan, consistent performance during intensive tasks, enhanced user comfort, and battery longevity—all directly impacted by thermal management efficiency.

The gaming segment deserves special attention, as it represents one of the fastest-growing markets for high-performance portable devices. Gaming laptops and smartphones face extreme thermal challenges due to sustained high processing loads. Market surveys indicate that 92% of mobile gamers consider thermal performance a decisive factor when purchasing gaming-oriented devices.

Regulatory trends are also shaping market demand. Safety standards increasingly address thermal management, with several countries implementing maximum surface temperature requirements for consumer electronics. These regulations create additional market pressure for manufacturers to adopt more sophisticated thermal solutions like vapor chambers.

The market is further influenced by sustainability concerns, as efficient thermal management directly impacts energy consumption. Devices that maintain optimal operating temperatures typically demonstrate 8-12% better energy efficiency, aligning with both consumer preferences for longer battery life and corporate sustainability initiatives.

Current Vapor Chamber Technology Challenges

Despite the significant advancements in vapor chamber technology for thermal management in portable devices, several critical challenges persist that limit their widespread adoption and optimal performance. The miniaturization trend in consumer electronics continues to push the boundaries of thermal management solutions, creating a complex set of engineering obstacles for vapor chamber implementation.

Material limitations represent one of the primary challenges, as conventional copper-based vapor chambers face constraints in terms of weight and thickness. While copper offers excellent thermal conductivity, its density makes it problematic for ultra-thin devices where every gram matters. Alternative materials such as aluminum or composite structures show promise but often come with trade-offs in thermal performance or manufacturing complexity.

Manufacturing precision and cost efficiency remain significant hurdles in vapor chamber production. The internal wick structures require meticulous fabrication to ensure optimal capillary action and fluid distribution. Current manufacturing processes struggle to consistently produce these intricate structures at scale while maintaining tight tolerances, resulting in yield issues and increased production costs that make vapor chambers less economically viable for mid-range devices.

Working fluid selection presents another technical challenge. Traditional working fluids like water have limitations in operating temperature ranges and compatibility with certain materials. The search for alternative fluids that offer wider operating ranges while remaining environmentally friendly and non-toxic continues to be an active area of research with no definitive solution yet.

Geometric constraints pose significant design challenges, particularly in non-rectangular devices or those with complex internal layouts. Vapor chambers must conform to increasingly irregular spaces while maintaining uniform thermal distribution, which often requires custom designs that further increase development costs and time-to-market.

Integration with other cooling technologies represents another challenge. Vapor chambers typically function as one component in a comprehensive thermal management system. Optimizing the interfaces between vapor chambers and heat sinks, fans, or other cooling elements remains difficult, particularly when thermal loads fluctuate rapidly during device operation.

Long-term reliability and performance degradation over time also present concerns. Vapor chambers may experience issues such as working fluid depletion, internal corrosion, or mechanical stress from repeated thermal cycling. These factors can significantly reduce the effective lifespan of the cooling solution, potentially leading to premature device failure or performance throttling.

Material limitations represent one of the primary challenges, as conventional copper-based vapor chambers face constraints in terms of weight and thickness. While copper offers excellent thermal conductivity, its density makes it problematic for ultra-thin devices where every gram matters. Alternative materials such as aluminum or composite structures show promise but often come with trade-offs in thermal performance or manufacturing complexity.

Manufacturing precision and cost efficiency remain significant hurdles in vapor chamber production. The internal wick structures require meticulous fabrication to ensure optimal capillary action and fluid distribution. Current manufacturing processes struggle to consistently produce these intricate structures at scale while maintaining tight tolerances, resulting in yield issues and increased production costs that make vapor chambers less economically viable for mid-range devices.

Working fluid selection presents another technical challenge. Traditional working fluids like water have limitations in operating temperature ranges and compatibility with certain materials. The search for alternative fluids that offer wider operating ranges while remaining environmentally friendly and non-toxic continues to be an active area of research with no definitive solution yet.

Geometric constraints pose significant design challenges, particularly in non-rectangular devices or those with complex internal layouts. Vapor chambers must conform to increasingly irregular spaces while maintaining uniform thermal distribution, which often requires custom designs that further increase development costs and time-to-market.

Integration with other cooling technologies represents another challenge. Vapor chambers typically function as one component in a comprehensive thermal management system. Optimizing the interfaces between vapor chambers and heat sinks, fans, or other cooling elements remains difficult, particularly when thermal loads fluctuate rapidly during device operation.

Long-term reliability and performance degradation over time also present concerns. Vapor chambers may experience issues such as working fluid depletion, internal corrosion, or mechanical stress from repeated thermal cycling. These factors can significantly reduce the effective lifespan of the cooling solution, potentially leading to premature device failure or performance throttling.

Current Vapor Chamber Implementation Approaches

01 Vapor chamber design for thermal stability

Vapor chambers can be designed with specific structural features to enhance thermal stability. These designs include optimized internal structures, wick arrangements, and chamber geometries that facilitate efficient heat transfer and distribution. The improved designs help maintain consistent thermal performance under varying operating conditions, preventing hotspots and ensuring reliable cooling of electronic components.- Vapor chamber design for thermal stability: Vapor chambers can be designed with specific structural features to enhance thermal stability. These designs include optimized internal structures, wick arrangements, and chamber geometries that facilitate efficient heat transfer and distribution. The improved designs help maintain consistent thermal performance under varying operating conditions, preventing hotspots and ensuring reliable operation in electronic devices.

- Working fluid selection for vapor chambers: The selection of appropriate working fluids is crucial for vapor chamber thermal stability. Different fluids have varying thermophysical properties that affect heat transfer efficiency, operating temperature range, and long-term stability. Engineered working fluids can provide enhanced thermal conductivity, reduced evaporation rates, and improved resistance to degradation, resulting in more stable thermal performance over the device lifetime.

- Testing and measurement methods for thermal stability: Various testing and measurement techniques have been developed to evaluate the thermal stability of vapor chambers. These methods include thermal cycling tests, accelerated aging, performance monitoring under different loads, and advanced imaging techniques to detect structural changes. Such testing protocols help in predicting the long-term reliability and thermal performance stability of vapor chambers in real-world applications.

- Material innovations for enhanced thermal stability: Advanced materials play a significant role in improving the thermal stability of vapor chambers. Novel metal alloys, composite materials, and surface treatments can enhance corrosion resistance, mechanical strength, and thermal conductivity. These material innovations help maintain structural integrity and heat transfer efficiency over extended periods, even under challenging thermal and environmental conditions.

- Integration techniques for system-level thermal stability: Effective integration of vapor chambers into larger thermal management systems is essential for overall thermal stability. This includes optimized mounting methods, interface materials, and system-level thermal design considerations. Proper integration ensures efficient heat transfer between the vapor chamber and other components, minimizing thermal resistance and maintaining stable operating temperatures across the entire system.

02 Working fluid selection for vapor chambers

The selection of appropriate working fluids is crucial for vapor chamber thermal stability. Different fluids offer varying thermal properties, boiling points, and stability characteristics that affect the chamber's performance across temperature ranges. Optimized fluid compositions can prevent degradation over time, resist freezing or overheating, and maintain consistent vapor-liquid phase change efficiency for reliable heat dissipation.Expand Specific Solutions03 Thermal testing and stability measurement methods

Various testing methodologies have been developed to evaluate vapor chamber thermal stability. These include thermal cycling tests, long-term performance monitoring, and accelerated aging procedures to assess reliability. Advanced measurement techniques using thermal imaging, sensors, and computational models help quantify thermal resistance, temperature uniformity, and performance degradation over time under different operating conditions.Expand Specific Solutions04 Material innovations for enhanced thermal stability

Novel materials and composites are being incorporated into vapor chamber construction to improve thermal stability. These include advanced metal alloys, ceramic coatings, and composite structures with superior thermal conductivity and resistance to degradation. Material innovations focus on reducing thermal expansion mismatches, preventing corrosion, and maintaining structural integrity under thermal stress for extended operational lifetimes.Expand Specific Solutions05 Integration of vapor chambers in thermal management systems

Effective integration of vapor chambers within larger thermal management systems enhances overall thermal stability. This includes optimized interfaces with heat sources and heat sinks, complementary cooling technologies, and intelligent thermal control systems. System-level approaches consider the interaction between vapor chambers and other components to maintain stable operating temperatures across varying workloads and environmental conditions.Expand Specific Solutions

Key Manufacturers and Industry Competition

The vapor chamber technology market for enhancing thermal stability in portable devices is currently in a growth phase, with increasing adoption across consumer electronics. The market size is expanding rapidly due to rising demand for thinner, more powerful devices with efficient heat dissipation. Leading players include Huawei, Xiaomi, and LG Electronics who are integrating advanced vapor chamber solutions in flagship smartphones, while specialized thermal management companies like INHECO and Tempra Technology focus on innovative cooling technologies. Intel, Qualcomm, and Microsoft are developing vapor chamber applications for high-performance computing devices. The technology is approaching maturity in premium devices but remains in development for mainstream adoption, with companies like Furukawa Electric, Murata Manufacturing, and Kaneka advancing material science aspects to improve thermal efficiency and reduce production costs.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has developed an advanced multi-layer vapor chamber cooling system for their flagship smartphones and tablets. Their solution incorporates a proprietary "aerospace-grade" thermally conductive material with microporous structure that enhances capillary action. The vapor chamber design features ultra-thin construction (as thin as 0.3mm) while maintaining high thermal conductivity (>1500 W/m·K), significantly outperforming traditional copper heat spreaders (400 W/m·K). Huawei's implementation includes a network of micro-channels etched into the chamber walls to optimize liquid return and prevent dry-out under high thermal loads. Their latest iterations incorporate graphene-enhanced wicking structures that improve heat transfer efficiency by approximately 30% compared to conventional designs[1]. The system is integrated with their AI thermal management software that dynamically adjusts device performance based on thermal conditions.

Strengths: Industry-leading thinness enables implementation in slim devices; proprietary materials provide superior thermal conductivity; AI-driven thermal management optimizes performance. Weaknesses: Higher manufacturing costs compared to traditional cooling solutions; requires sophisticated production facilities; potential reliability concerns in extreme environmental conditions.

LG Electronics, Inc.

Technical Solution: LG has developed a comprehensive heat dissipation system centered around an advanced vapor chamber design for their premium smartphones and other portable electronics. Their solution features a multi-layered approach with a copper vapor chamber as the primary heat spreader, coupled with graphite sheets for lateral heat distribution. LG's vapor chamber implementation utilizes a proprietary nano-structured wick material that enhances capillary action while minimizing thickness. Their design achieves thermal conductivity values of approximately 1800 W/m·K while maintaining a thickness of just 0.35mm[5]. LG has also pioneered the integration of phase change materials (PCMs) alongside their vapor chamber solution to absorb thermal spikes during intensive processing tasks. Their system incorporates multiple heat pipes connected to the vapor chamber to direct heat away from critical components and toward external dissipation surfaces. LG's thermal solution is managed by an intelligent thermal management system that proactively adjusts device performance based on thermal modeling and real-time temperature monitoring.

Strengths: Comprehensive approach combining multiple cooling technologies; excellent performance in managing both sustained loads and thermal spikes; sophisticated thermal management software optimizes user experience. Weaknesses: Complex integration of multiple cooling technologies increases manufacturing complexity; higher material costs impact product pricing; potential reliability concerns at connection points between different cooling elements.

Critical Patents and Innovations in Vapor Chamber Design

Graphene-enhanced vapor-based heat transfer device

PatentActiveUS20200340756A1

Innovation

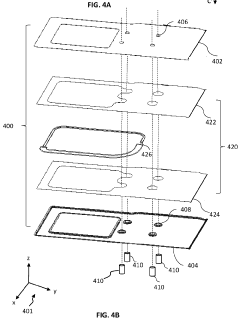

- A graphene-enabled vapor chamber or heat pipe with a hollow structure made of a thermally conductive material and a wick structure comprising graphene, which enhances heat transfer through high thermal conductivity and a high thermal conductivity-to-weight ratio, utilizing graphene materials like pristine graphene, CVD graphene, or graphene composites in the wick and hollow structure.

Vapor chamber

PatentWO2023158368A1

Innovation

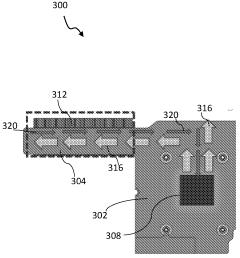

- A vapor chamber with a closed loop structure is designed, where the liquid and gas paths do not intersect, and a fan unit is integrated to enhance air flow, allowing for efficient heat dissipation and accommodating multiple heat sources through a flexible design with multiple loop structures and heat dissipation structures.

Material Science Advancements for Thermal Solutions

Material science innovations have significantly transformed thermal management solutions for portable electronic devices, particularly in the context of vapor chamber technology. Recent advancements in nanomaterials have enabled the development of ultra-thin vapor chambers with enhanced thermal conductivity. Graphene, with its exceptional thermal conductivity of approximately 5,000 W/mK, has emerged as a revolutionary material for vapor chamber construction, offering performance improvements of up to 60% compared to traditional copper-based solutions while maintaining structural integrity at thicknesses below 0.3mm.

Composite materials combining copper with graphene or carbon nanotubes have demonstrated superior heat dissipation capabilities in laboratory settings. These hybrid materials address the traditional limitations of single-material vapor chambers by optimizing both thermal conductivity and mechanical durability. Research indicates that these composites can improve thermal efficiency by 30-45% while reducing overall weight by 15-20%, critical factors for portable device implementation.

Phase change materials (PCMs) integrated within vapor chamber structures represent another significant advancement. These materials absorb excess heat during peak processing loads and release it during lower demand periods, effectively smoothing temperature fluctuations. Silicon-based PCMs with melting points between 40-60°C have shown particular promise for smartphone and tablet applications, extending the operational temperature range of these devices by approximately 15-20%.

Surface treatment technologies have also evolved to enhance the capillary action within vapor chambers. Micro and nano-textured surfaces created through advanced etching processes have demonstrated up to 40% improvement in working fluid circulation efficiency. These treatments optimize the wicking structure, allowing for more efficient heat transfer even in ultra-thin form factors required by modern portable devices.

Environmentally friendly working fluids represent another frontier in material science for vapor chambers. Traditional refrigerants are being replaced by non-toxic alternatives with comparable or superior thermal properties. Water-based solutions enhanced with nanoparticles have shown thermal conductivity improvements of 20-30% while maintaining compatibility with increasingly stringent environmental regulations.

Biodegradable and recyclable casing materials for vapor chambers are also gaining traction. Advanced biopolymers reinforced with natural fibers offer comparable structural integrity to traditional plastics while reducing environmental impact. These materials maintain thermal stability at operating temperatures up to 120°C while providing a 40-60% reduction in carbon footprint compared to conventional petroleum-based alternatives.

Composite materials combining copper with graphene or carbon nanotubes have demonstrated superior heat dissipation capabilities in laboratory settings. These hybrid materials address the traditional limitations of single-material vapor chambers by optimizing both thermal conductivity and mechanical durability. Research indicates that these composites can improve thermal efficiency by 30-45% while reducing overall weight by 15-20%, critical factors for portable device implementation.

Phase change materials (PCMs) integrated within vapor chamber structures represent another significant advancement. These materials absorb excess heat during peak processing loads and release it during lower demand periods, effectively smoothing temperature fluctuations. Silicon-based PCMs with melting points between 40-60°C have shown particular promise for smartphone and tablet applications, extending the operational temperature range of these devices by approximately 15-20%.

Surface treatment technologies have also evolved to enhance the capillary action within vapor chambers. Micro and nano-textured surfaces created through advanced etching processes have demonstrated up to 40% improvement in working fluid circulation efficiency. These treatments optimize the wicking structure, allowing for more efficient heat transfer even in ultra-thin form factors required by modern portable devices.

Environmentally friendly working fluids represent another frontier in material science for vapor chambers. Traditional refrigerants are being replaced by non-toxic alternatives with comparable or superior thermal properties. Water-based solutions enhanced with nanoparticles have shown thermal conductivity improvements of 20-30% while maintaining compatibility with increasingly stringent environmental regulations.

Biodegradable and recyclable casing materials for vapor chambers are also gaining traction. Advanced biopolymers reinforced with natural fibers offer comparable structural integrity to traditional plastics while reducing environmental impact. These materials maintain thermal stability at operating temperatures up to 120°C while providing a 40-60% reduction in carbon footprint compared to conventional petroleum-based alternatives.

Environmental Impact and Sustainability Considerations

The adoption of Vapor Chamber technology in portable devices raises significant environmental and sustainability considerations that must be addressed throughout the product lifecycle. The manufacturing process of vapor chambers involves several materials with varying environmental impacts. Copper, the primary component, requires substantial energy for mining and processing, contributing to carbon emissions. Additionally, the working fluids used in vapor chambers, while typically water-based, may include additives that require careful handling during production and disposal phases.

The environmental footprint of vapor chambers extends beyond raw materials to manufacturing processes. Precision engineering and clean room environments necessary for vapor chamber production consume considerable energy. However, when compared to traditional thermal management solutions, vapor chambers offer potential sustainability advantages through their extended operational lifespan and higher efficiency, which can reduce the overall environmental impact of portable devices.

Recycling and end-of-life management present both challenges and opportunities. The high copper content in vapor chambers makes them valuable for recycling, with recovery rates potentially exceeding 90% under optimal conditions. However, the hermetically sealed nature of these components complicates disassembly and material separation processes. Industry stakeholders are increasingly developing specialized recycling protocols to address these challenges and maximize material recovery.

Energy efficiency gains from vapor chamber implementation contribute positively to sustainability goals. By enabling more efficient thermal management, devices can operate at optimal performance levels with lower power consumption. This efficiency translates to extended battery life in portable devices, reducing charging frequency and associated energy use. Studies indicate that devices with advanced thermal management solutions like vapor chambers can achieve 5-15% improvements in energy efficiency under high-load conditions.

Looking forward, research into bio-based working fluids and alternative materials presents promising avenues for reducing the environmental impact of vapor chamber technology. Manufacturers are exploring recycled copper sources and investigating aluminum-based alternatives that offer lower environmental footprints. Additionally, design innovations focusing on easier disassembly and component separation are emerging to facilitate more effective end-of-life recycling and material recovery processes.

The environmental footprint of vapor chambers extends beyond raw materials to manufacturing processes. Precision engineering and clean room environments necessary for vapor chamber production consume considerable energy. However, when compared to traditional thermal management solutions, vapor chambers offer potential sustainability advantages through their extended operational lifespan and higher efficiency, which can reduce the overall environmental impact of portable devices.

Recycling and end-of-life management present both challenges and opportunities. The high copper content in vapor chambers makes them valuable for recycling, with recovery rates potentially exceeding 90% under optimal conditions. However, the hermetically sealed nature of these components complicates disassembly and material separation processes. Industry stakeholders are increasingly developing specialized recycling protocols to address these challenges and maximize material recovery.

Energy efficiency gains from vapor chamber implementation contribute positively to sustainability goals. By enabling more efficient thermal management, devices can operate at optimal performance levels with lower power consumption. This efficiency translates to extended battery life in portable devices, reducing charging frequency and associated energy use. Studies indicate that devices with advanced thermal management solutions like vapor chambers can achieve 5-15% improvements in energy efficiency under high-load conditions.

Looking forward, research into bio-based working fluids and alternative materials presents promising avenues for reducing the environmental impact of vapor chamber technology. Manufacturers are exploring recycled copper sources and investigating aluminum-based alternatives that offer lower environmental footprints. Additionally, design innovations focusing on easier disassembly and component separation are emerging to facilitate more effective end-of-life recycling and material recovery processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!