What Are the Innovations in Microinjection Molding for Nanotechnology?

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microinjection Molding Evolution and Objectives

Microinjection molding technology has evolved significantly since its inception in the late 1980s, emerging as a specialized adaptation of conventional injection molding to address the growing demand for miniaturized components. The initial development was primarily driven by the electronics and medical device industries, which required increasingly smaller and more precise plastic components. By the early 1990s, the first commercial microinjection molding machines were introduced, capable of producing parts with features in the sub-millimeter range.

The evolution accelerated in the early 2000s with the integration of advanced control systems and precision engineering, enabling the production of components with micro-features approaching the 10-micron scale. This period marked a critical transition from macro to micro manufacturing capabilities, establishing microinjection molding as a distinct manufacturing discipline rather than merely a scaled-down version of conventional processes.

A significant technological leap occurred between 2005 and 2010 with the development of specialized equipment designed specifically for micro-scale production. These systems incorporated innovations such as precise dosing units, advanced heating controls, and vacuum-assisted mold filling, addressing the unique challenges of polymer flow behavior at the micro scale. The introduction of variothermal process control during this period represented a breakthrough in overcoming the limitations of conventional molding for high-aspect-ratio microstructures.

The convergence with nanotechnology began to accelerate around 2010, as researchers and manufacturers sought to push the boundaries toward nano-scale features. This convergence has been characterized by the development of hybrid processes combining microinjection molding with techniques such as nanoimprint lithography and the incorporation of nanomaterials into polymer matrices to enhance functional properties.

The primary objective of current microinjection molding technology in nanotechnology applications is to bridge the gap between laboratory-scale fabrication techniques and industrial-scale manufacturing of nano-featured components. This includes achieving reliable replication of structures with dimensions below 100 nanometers while maintaining economically viable production rates. Additional objectives include expanding the range of processable materials to include high-performance polymers and nanocomposites, enhancing the precision of multi-material molding for complex functional devices, and developing in-line quality control methods capable of nano-scale metrology.

Looking forward, the field aims to establish microinjection molding as a cornerstone technology for mass-producing next-generation nanotechnology-enabled devices across sectors including healthcare, electronics, energy, and environmental applications. This evolution represents a critical pathway for translating nanoscience innovations into commercially viable products with widespread societal impact.

The evolution accelerated in the early 2000s with the integration of advanced control systems and precision engineering, enabling the production of components with micro-features approaching the 10-micron scale. This period marked a critical transition from macro to micro manufacturing capabilities, establishing microinjection molding as a distinct manufacturing discipline rather than merely a scaled-down version of conventional processes.

A significant technological leap occurred between 2005 and 2010 with the development of specialized equipment designed specifically for micro-scale production. These systems incorporated innovations such as precise dosing units, advanced heating controls, and vacuum-assisted mold filling, addressing the unique challenges of polymer flow behavior at the micro scale. The introduction of variothermal process control during this period represented a breakthrough in overcoming the limitations of conventional molding for high-aspect-ratio microstructures.

The convergence with nanotechnology began to accelerate around 2010, as researchers and manufacturers sought to push the boundaries toward nano-scale features. This convergence has been characterized by the development of hybrid processes combining microinjection molding with techniques such as nanoimprint lithography and the incorporation of nanomaterials into polymer matrices to enhance functional properties.

The primary objective of current microinjection molding technology in nanotechnology applications is to bridge the gap between laboratory-scale fabrication techniques and industrial-scale manufacturing of nano-featured components. This includes achieving reliable replication of structures with dimensions below 100 nanometers while maintaining economically viable production rates. Additional objectives include expanding the range of processable materials to include high-performance polymers and nanocomposites, enhancing the precision of multi-material molding for complex functional devices, and developing in-line quality control methods capable of nano-scale metrology.

Looking forward, the field aims to establish microinjection molding as a cornerstone technology for mass-producing next-generation nanotechnology-enabled devices across sectors including healthcare, electronics, energy, and environmental applications. This evolution represents a critical pathway for translating nanoscience innovations into commercially viable products with widespread societal impact.

Nanotechnology Market Demand Analysis

The nanotechnology market has been experiencing significant growth, with the global market value projected to reach $125 billion by 2024, growing at a CAGR of approximately 13.3%. This expansion is largely driven by increasing applications across multiple industries including healthcare, electronics, energy, and materials science. Microinjection molding technologies specifically address critical manufacturing needs within this expanding market.

Healthcare and medical devices represent the largest segment demanding microinjection molding capabilities for nanotechnology applications. The need for minimally invasive surgical tools, drug delivery systems, implantable devices, and diagnostic equipment is creating substantial market pull. Precision components with nanoscale features are essential for next-generation medical devices, with particular growth in microfluidic devices for point-of-care diagnostics and lab-on-a-chip applications.

Electronics manufacturers constitute another major market segment, with demand for smaller, more efficient components driving innovation in microinjection molding. The miniaturization trend in consumer electronics, coupled with the emergence of wearable technology, has created significant demand for nano-featured plastic components. Industry analysts predict this segment will grow at 15.2% annually through 2026, outpacing the overall market.

Regional analysis reveals Asia-Pacific as the fastest-growing market for nanotechnology applications utilizing microinjection molding, with China, Japan, and South Korea leading development. North America maintains the largest market share due to extensive research infrastructure and established medical device manufacturing. European demand is primarily driven by automotive and precision engineering applications.

End-user surveys indicate increasing requirements for tighter tolerances, complex geometries, and multi-material capabilities in nano-molded components. Manufacturers report challenges meeting specifications below 10 microns while maintaining cost-effectiveness at production scale. This gap between technical capabilities and market needs represents a significant opportunity for innovation.

Material science advancements are creating new market opportunities, with high-performance polymers and polymer-nanoparticle composites enabling novel applications. Biodegradable and biocompatible materials are experiencing particularly strong demand growth for medical applications, with market research indicating a 17.8% annual growth rate for these specialized materials.

Cost considerations remain a critical market factor, with industry stakeholders seeking solutions that balance nanoscale precision with economic viability. Current market analysis suggests a price sensitivity threshold approximately 2.5 times that of conventional micro-molding, beyond which adoption rates decline significantly despite technical advantages.

Healthcare and medical devices represent the largest segment demanding microinjection molding capabilities for nanotechnology applications. The need for minimally invasive surgical tools, drug delivery systems, implantable devices, and diagnostic equipment is creating substantial market pull. Precision components with nanoscale features are essential for next-generation medical devices, with particular growth in microfluidic devices for point-of-care diagnostics and lab-on-a-chip applications.

Electronics manufacturers constitute another major market segment, with demand for smaller, more efficient components driving innovation in microinjection molding. The miniaturization trend in consumer electronics, coupled with the emergence of wearable technology, has created significant demand for nano-featured plastic components. Industry analysts predict this segment will grow at 15.2% annually through 2026, outpacing the overall market.

Regional analysis reveals Asia-Pacific as the fastest-growing market for nanotechnology applications utilizing microinjection molding, with China, Japan, and South Korea leading development. North America maintains the largest market share due to extensive research infrastructure and established medical device manufacturing. European demand is primarily driven by automotive and precision engineering applications.

End-user surveys indicate increasing requirements for tighter tolerances, complex geometries, and multi-material capabilities in nano-molded components. Manufacturers report challenges meeting specifications below 10 microns while maintaining cost-effectiveness at production scale. This gap between technical capabilities and market needs represents a significant opportunity for innovation.

Material science advancements are creating new market opportunities, with high-performance polymers and polymer-nanoparticle composites enabling novel applications. Biodegradable and biocompatible materials are experiencing particularly strong demand growth for medical applications, with market research indicating a 17.8% annual growth rate for these specialized materials.

Cost considerations remain a critical market factor, with industry stakeholders seeking solutions that balance nanoscale precision with economic viability. Current market analysis suggests a price sensitivity threshold approximately 2.5 times that of conventional micro-molding, beyond which adoption rates decline significantly despite technical advantages.

Current Capabilities and Barriers in Micro-Molding

Microinjection molding technology has evolved significantly over the past decade, enabling the production of increasingly smaller components with higher precision. Current capabilities in micro-molding for nanotechnology applications include the ability to produce parts with features in the sub-micron range, with some advanced systems achieving dimensional tolerances of ±1-2 μm. Modern equipment can process a wide range of thermoplastics, including high-performance polymers like PEEK, LCP, and PLA, which are essential for biomedical and electronic applications.

The latest micro-molding machines incorporate sophisticated control systems that allow for precise regulation of injection parameters, including pressure profiles, velocity, and temperature distribution. These advancements have enabled cycle times as low as 4-6 seconds for simple micro-components, significantly improving production efficiency. Additionally, in-mold sensors and real-time monitoring systems have enhanced process stability and part quality consistency, reducing defect rates to below 50 parts per million in optimized production environments.

Despite these impressive capabilities, several significant barriers continue to challenge the advancement of micro-molding for nanotechnology applications. Material flow behavior at the micro and nano scales remains difficult to predict accurately, as conventional polymer flow models become less reliable at these dimensions. The rheological properties of polymers change dramatically when forced through micro-channels, leading to unexpected flow patterns and solidification behaviors that complicate mold design and process optimization.

Tool fabrication represents another major barrier, as creating mold cavities with nano-scale features requires specialized techniques beyond traditional machining. While micro-EDM, laser ablation, and LIGA processes have improved micro-feature creation, achieving consistent surface finishes below 50 nm roughness remains challenging and expensive. The wear characteristics of these precision molds also present concerns, as even minimal degradation can significantly impact part quality at the nano scale.

Demolding challenges are particularly pronounced in micro-molding, as surface forces become increasingly dominant at smaller scales. The high surface-to-volume ratio of micro-parts leads to stronger adhesion to mold surfaces, requiring specialized coatings or surface treatments to facilitate reliable part ejection without damage. These treatments must maintain effectiveness over thousands of molding cycles while withstanding high temperatures and pressures.

Process monitoring and quality control present additional barriers, as conventional inspection methods lack the resolution needed for nano-featured components. Advanced techniques like confocal microscopy and white light interferometry offer potential solutions but are difficult to implement in-line for high-volume production. The development of cost-effective, high-speed inspection systems capable of detecting defects at the nano scale remains a significant challenge for the industry.

The latest micro-molding machines incorporate sophisticated control systems that allow for precise regulation of injection parameters, including pressure profiles, velocity, and temperature distribution. These advancements have enabled cycle times as low as 4-6 seconds for simple micro-components, significantly improving production efficiency. Additionally, in-mold sensors and real-time monitoring systems have enhanced process stability and part quality consistency, reducing defect rates to below 50 parts per million in optimized production environments.

Despite these impressive capabilities, several significant barriers continue to challenge the advancement of micro-molding for nanotechnology applications. Material flow behavior at the micro and nano scales remains difficult to predict accurately, as conventional polymer flow models become less reliable at these dimensions. The rheological properties of polymers change dramatically when forced through micro-channels, leading to unexpected flow patterns and solidification behaviors that complicate mold design and process optimization.

Tool fabrication represents another major barrier, as creating mold cavities with nano-scale features requires specialized techniques beyond traditional machining. While micro-EDM, laser ablation, and LIGA processes have improved micro-feature creation, achieving consistent surface finishes below 50 nm roughness remains challenging and expensive. The wear characteristics of these precision molds also present concerns, as even minimal degradation can significantly impact part quality at the nano scale.

Demolding challenges are particularly pronounced in micro-molding, as surface forces become increasingly dominant at smaller scales. The high surface-to-volume ratio of micro-parts leads to stronger adhesion to mold surfaces, requiring specialized coatings or surface treatments to facilitate reliable part ejection without damage. These treatments must maintain effectiveness over thousands of molding cycles while withstanding high temperatures and pressures.

Process monitoring and quality control present additional barriers, as conventional inspection methods lack the resolution needed for nano-featured components. Advanced techniques like confocal microscopy and white light interferometry offer potential solutions but are difficult to implement in-line for high-volume production. The development of cost-effective, high-speed inspection systems capable of detecting defects at the nano scale remains a significant challenge for the industry.

State-of-the-Art Microinjection Molding Techniques

01 Advanced mold design for microinjection molding

Innovations in mold design specifically for microinjection molding processes have significantly improved the production of micro-scale components. These advancements include precision mold cavities, improved cooling channels, and specialized ejection systems that enable the production of complex microstructures with high accuracy. The enhanced mold designs allow for better control of material flow, reduced cycle times, and improved part quality in micro-scale applications.- Advanced micro-mold design and fabrication techniques: Innovations in micro-mold design and fabrication techniques have significantly improved microinjection molding processes. These advancements include precision engineering of mold cavities, development of multi-cavity molds, and implementation of novel surface treatments to enhance mold performance. These techniques allow for the production of complex microstructures with high accuracy and repeatability, which is essential for applications in medical devices, electronics, and other high-precision industries.

- Novel materials for microinjection molding: The development of specialized materials for microinjection molding has expanded the capabilities of this manufacturing process. These materials include high-flow polymers, biocompatible compounds, and nanocomposites that offer improved mechanical properties, enhanced flow characteristics, and better surface finish. The use of these advanced materials enables the production of micro-components with superior performance characteristics, making them suitable for demanding applications in medical, automotive, and consumer electronics sectors.

- Process optimization and control systems: Innovations in process optimization and control systems have revolutionized microinjection molding. These advancements include real-time monitoring technologies, adaptive control algorithms, and simulation-based optimization approaches that ensure consistent quality and reduce cycle times. By precisely controlling parameters such as injection pressure, temperature, and cooling rates, manufacturers can achieve higher precision, better repeatability, and improved efficiency in microinjection molding operations.

- Microinjection molding for biomedical applications: The application of microinjection molding in the biomedical field has seen significant innovations. These developments include the production of microfluidic devices, drug delivery systems, and implantable medical components. The ability to mold microscale features with biocompatible materials has enabled advancements in point-of-care diagnostics, lab-on-a-chip devices, and personalized medicine. These innovations have contributed to more effective healthcare solutions and improved patient outcomes.

- Integration of microinjection molding with other technologies: The integration of microinjection molding with complementary technologies has created new manufacturing paradigms. These integrations include combinations with 3D printing, automated assembly systems, and in-mold decoration techniques. By merging microinjection molding with these technologies, manufacturers can achieve greater design freedom, functional integration, and production efficiency. This convergence of technologies enables the creation of complex micro-components with embedded functionalities and reduced assembly requirements.

02 Novel materials for microinjection molding

Development of specialized materials tailored for microinjection molding processes has expanded the capabilities of this manufacturing technique. These materials offer improved flow properties at micro-scale, better surface finish, enhanced mechanical properties, and compatibility with various post-processing treatments. The formulations are specifically designed to maintain stability during the high-pressure, high-shear conditions of microinjection molding while enabling the production of increasingly smaller and more complex components.Expand Specific Solutions03 Microinjection molding for biomedical applications

Microinjection molding has been adapted for various biomedical applications, including the production of microfluidic devices, drug delivery systems, and medical diagnostic tools. These innovations involve specialized processing techniques to ensure biocompatibility, sterility, and precision in medical components. The technology enables the mass production of complex biomedical devices with micro-features that would be difficult or impossible to achieve with conventional manufacturing methods.Expand Specific Solutions04 Automation and process control in microinjection molding

Advanced automation and process control systems have been developed specifically for microinjection molding operations. These systems incorporate real-time monitoring, artificial intelligence, and precise control algorithms to optimize the molding process. The innovations include sensor integration for quality control, adaptive processing parameters, and automated handling systems designed for micro-components, resulting in improved consistency, reduced defects, and enhanced production efficiency.Expand Specific Solutions05 Multi-material and hybrid microinjection molding techniques

Innovative approaches combining microinjection molding with other manufacturing processes or enabling the molding of multiple materials in a single operation have expanded the capabilities of micro-manufacturing. These techniques include overmolding, insert molding at the micro-scale, and integration with additive manufacturing processes. The hybrid approaches allow for the creation of complex micro-components with varying material properties, embedded electronics, or functional gradients that cannot be achieved through conventional single-material molding.Expand Specific Solutions

Leading Companies in Nano-Scale Molding Industry

Microinjection molding for nanotechnology is currently in a growth phase, with the market expanding due to increasing applications in medical devices, consumer electronics, and automotive components. The global market size is estimated to reach significant value as industries adopt miniaturization trends. Technologically, the field is advancing rapidly but remains specialized, with varying maturity levels across applications. Leading players include Husky Injection Molding Systems, which dominates in equipment manufacturing; NIL Technology and EV Group focusing on nanopatterning solutions; and Sony, Sharp, and LG Electronics driving consumer applications. Academic institutions like Technical University of Denmark, Zhejiang University, and Georgia Tech contribute significant research advancements, while collaborations between industry leaders and research institutions accelerate innovation in precision molding techniques for nano-scale components.

Husky Injection Molding Systems Ltd.

Technical Solution: Husky has developed advanced micro-molding systems specifically designed for nanotechnology applications, featuring their patented Ultra Packaging technology. Their innovation focuses on high-precision micro-featured molds with tolerances down to 1-2 microns and specialized hot runner systems that prevent material degradation during processing. Husky's HyPET HPP5 platform incorporates advanced servo-electric drives and pressure sensors that enable real-time adjustments during the injection process, critical for nano-scale feature replication. Their systems utilize specialized vacuum-assisted mold filling technology to ensure complete filling of nano-scale cavities and prevent air entrapment [1]. Additionally, Husky has pioneered specialized cooling channel designs using conformal cooling technology that maintains optimal temperature distribution across micro-mold surfaces, significantly reducing cycle times while improving part quality and consistency.

Strengths: Superior precision with industry-leading tolerances down to 1-2 microns; integrated quality control systems with real-time monitoring capabilities; advanced material handling systems that minimize degradation. Weaknesses: Higher initial investment costs compared to conventional systems; requires specialized operator training; limited compatibility with certain advanced nano-composite materials.

NIL Technology ApS

Technical Solution: NIL Technology has developed specialized nano-imprint lithography solutions specifically optimized for microinjection molding applications. Their proprietary NILT platform integrates seamlessly with existing injection molding infrastructure while enabling feature sizes down to 20nm [3]. The company's innovation centers around their master origination technology, which utilizes electron beam lithography to create ultra-precise master templates that can be replicated through microinjection molding processes. NIL Technology has pioneered hybrid mold inserts that combine traditional steel mold bases with nano-patterned nickel shims, allowing conventional injection molding machines to produce parts with nano-features. Their process incorporates specialized surface treatments that enhance demolding of high-aspect-ratio nano-structures without damage. Additionally, they've developed proprietary anti-sticking coatings that significantly extend mold life while maintaining feature fidelity. Recent innovations include their multi-level patterning technology that enables hierarchical structures combining micro and nano features in a single molding step.

Strengths: Seamless integration with existing injection molding equipment; specialized expertise in master origination techniques; cost-effective approach for high-volume nano-manufacturing. Weaknesses: Limited to certain geometries and aspect ratios; requires specialized mold inserts that need periodic replacement; more suitable for surface nano-features than full 3D nano-structures.

Breakthrough Patents in Nano-Molding Technologies

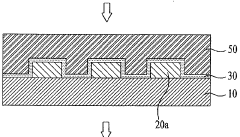

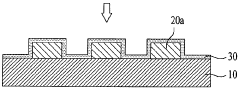

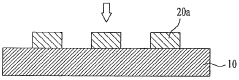

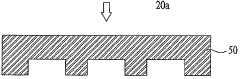

Method for manufacturing a master mold which is used to form a micropatterned film applied to an exterior of a household appliance and manufacturing apparatus and method of the film using the master mold

PatentWO2011028060A2

Innovation

- A method involving the use of a stainless steel substrate with photoresist application, UV irradiation, and wet etching to create a master mold, which can then replicate micropatterns onto synthetic resin substrates, allowing for the production of micropatterned films that can be applied to household appliances with varying sizes and designs at a lower cost.

Material Advancements for Nano-Molding Applications

The evolution of materials for microinjection molding in nanotechnology represents a critical frontier in advanced manufacturing. Traditional polymers used in conventional injection molding often fail to meet the stringent requirements of nano-scale applications, necessitating the development of specialized materials with enhanced properties.

Polymer nanocomposites have emerged as revolutionary materials for nano-molding applications, combining conventional thermoplastics with nanoscale fillers such as carbon nanotubes, graphene, and metal nanoparticles. These composites exhibit significantly improved mechanical strength, thermal stability, and electrical conductivity while maintaining the processability required for microinjection molding. The incorporation of just 2-5% nanofillers can enhance tensile strength by up to 40% compared to neat polymers.

Bioresorbable and biocompatible polymers represent another significant advancement, particularly for medical nanotechnology applications. Materials such as polylactic acid (PLA), polyglycolic acid (PGA), and their copolymers offer controlled degradation profiles while maintaining sufficient mechanical properties for nano-molding processes. These materials enable the production of biodegradable nano-featured implants and drug delivery systems with precise release kinetics.

High-performance engineering thermoplastics including polyetheretherketone (PEEK), polyimide (PI), and liquid crystal polymers (LCPs) have been reformulated specifically for nano-molding applications. These materials offer exceptional dimensional stability, chemical resistance, and the ability to withstand extreme processing conditions required for replicating nanoscale features with high fidelity.

Metal and ceramic injection molding (MIM and CIM) materials have also been adapted for nano-applications through the development of ultrafine powders with particle sizes below 100nm. These advanced feedstocks enable the production of complex metal and ceramic components with nanoscale features, opening new possibilities in electronics, sensors, and catalytic applications.

Smart and responsive materials represent the cutting edge of nano-molding innovation. Shape memory polymers, stimuli-responsive hydrogels, and materials with self-healing properties can be processed via microinjection molding to create dynamic nanostructures that respond to environmental changes such as temperature, pH, or electrical stimulation.

Surface modification techniques have been developed to enhance the interfacial properties of molded nanostructures. Plasma treatments, chemical functionalization, and nanoscale coatings can be applied to improve adhesion, wettability, and biocompatibility without compromising the dimensional accuracy of molded features as small as 50 nanometers.

Polymer nanocomposites have emerged as revolutionary materials for nano-molding applications, combining conventional thermoplastics with nanoscale fillers such as carbon nanotubes, graphene, and metal nanoparticles. These composites exhibit significantly improved mechanical strength, thermal stability, and electrical conductivity while maintaining the processability required for microinjection molding. The incorporation of just 2-5% nanofillers can enhance tensile strength by up to 40% compared to neat polymers.

Bioresorbable and biocompatible polymers represent another significant advancement, particularly for medical nanotechnology applications. Materials such as polylactic acid (PLA), polyglycolic acid (PGA), and their copolymers offer controlled degradation profiles while maintaining sufficient mechanical properties for nano-molding processes. These materials enable the production of biodegradable nano-featured implants and drug delivery systems with precise release kinetics.

High-performance engineering thermoplastics including polyetheretherketone (PEEK), polyimide (PI), and liquid crystal polymers (LCPs) have been reformulated specifically for nano-molding applications. These materials offer exceptional dimensional stability, chemical resistance, and the ability to withstand extreme processing conditions required for replicating nanoscale features with high fidelity.

Metal and ceramic injection molding (MIM and CIM) materials have also been adapted for nano-applications through the development of ultrafine powders with particle sizes below 100nm. These advanced feedstocks enable the production of complex metal and ceramic components with nanoscale features, opening new possibilities in electronics, sensors, and catalytic applications.

Smart and responsive materials represent the cutting edge of nano-molding innovation. Shape memory polymers, stimuli-responsive hydrogels, and materials with self-healing properties can be processed via microinjection molding to create dynamic nanostructures that respond to environmental changes such as temperature, pH, or electrical stimulation.

Surface modification techniques have been developed to enhance the interfacial properties of molded nanostructures. Plasma treatments, chemical functionalization, and nanoscale coatings can be applied to improve adhesion, wettability, and biocompatibility without compromising the dimensional accuracy of molded features as small as 50 nanometers.

Quality Control Systems for Nano-Scale Production

Quality control systems for nano-scale production in microinjection molding represent a critical frontier in nanotechnology manufacturing. Traditional quality control methods prove inadequate when dealing with components featuring sub-micron features, necessitating innovative approaches that combine advanced metrology with real-time monitoring capabilities.

Optical measurement systems have evolved significantly to address nano-scale quality requirements. Confocal microscopy, white light interferometry, and digital holographic microscopy now offer non-contact measurement capabilities with resolution down to nanometer levels. These systems can detect surface defects and dimensional variations that would be impossible to identify with conventional inspection methods.

In-mold sensing technologies have emerged as a breakthrough innovation for real-time quality monitoring. Piezoelectric sensors embedded within mold cavities can detect pressure variations during the injection process with extraordinary sensitivity, allowing manufacturers to identify inconsistencies in material flow that might lead to nano-scale defects. Similarly, ultrasonic sensors can monitor material solidification patterns at the molecular level.

Machine learning algorithms have been integrated into quality control systems to analyze the massive datasets generated during nano-scale production. These AI-powered systems can identify subtle patterns and correlations between process parameters and product quality that human operators might miss. Predictive maintenance capabilities further enhance production stability by anticipating equipment issues before they impact product quality.

Computed tomography (CT) scanning has been adapted for non-destructive testing of micro-molded components, enabling complete volumetric inspection of internal features without damaging the product. With resolutions approaching 100 nanometers, modern industrial CT systems can verify internal structures and detect voids or inclusions that might compromise product performance.

Statistical process control methodologies have been refined specifically for nano-scale production environments. These systems employ specialized sampling techniques and tolerance models that account for the unique challenges of working at the nanometer scale, where even minor variations can have significant functional impacts.

Traceability systems have also evolved to meet the demands of nano-scale production. Advanced part marking technologies, including laser-encoded identifiers and embedded RFID tags, enable comprehensive tracking of components throughout their lifecycle. This capability is particularly valuable in regulated industries like medical devices and aerospace, where component history documentation is mandatory.

Optical measurement systems have evolved significantly to address nano-scale quality requirements. Confocal microscopy, white light interferometry, and digital holographic microscopy now offer non-contact measurement capabilities with resolution down to nanometer levels. These systems can detect surface defects and dimensional variations that would be impossible to identify with conventional inspection methods.

In-mold sensing technologies have emerged as a breakthrough innovation for real-time quality monitoring. Piezoelectric sensors embedded within mold cavities can detect pressure variations during the injection process with extraordinary sensitivity, allowing manufacturers to identify inconsistencies in material flow that might lead to nano-scale defects. Similarly, ultrasonic sensors can monitor material solidification patterns at the molecular level.

Machine learning algorithms have been integrated into quality control systems to analyze the massive datasets generated during nano-scale production. These AI-powered systems can identify subtle patterns and correlations between process parameters and product quality that human operators might miss. Predictive maintenance capabilities further enhance production stability by anticipating equipment issues before they impact product quality.

Computed tomography (CT) scanning has been adapted for non-destructive testing of micro-molded components, enabling complete volumetric inspection of internal features without damaging the product. With resolutions approaching 100 nanometers, modern industrial CT systems can verify internal structures and detect voids or inclusions that might compromise product performance.

Statistical process control methodologies have been refined specifically for nano-scale production environments. These systems employ specialized sampling techniques and tolerance models that account for the unique challenges of working at the nanometer scale, where even minor variations can have significant functional impacts.

Traceability systems have also evolved to meet the demands of nano-scale production. Advanced part marking technologies, including laser-encoded identifiers and embedded RFID tags, enable comprehensive tracking of components throughout their lifecycle. This capability is particularly valuable in regulated industries like medical devices and aerospace, where component history documentation is mandatory.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!