3D Printed Antennas: Custom RF Designs for IoT

JUL 14, 2025 |

The advent of 3D printing technology has revolutionized various industries, from healthcare to aerospace. In recent years, this transformative technology has made significant inroads into the world of radio frequency (RF) engineering, particularly in designing antennas for the Internet of Things (IoT). Custom 3D printed antennas offer a unique blend of flexibility, innovation, and efficiency, promising to change the way we think about IoT connectivity.

The Need for Custom RF Designs in IoT

IoT devices are becoming increasingly prevalent in our daily lives, with applications ranging from smart homes and healthcare to industrial automation and environmental monitoring. Each IoT application has unique requirements in terms of range, frequency, and power consumption. Traditional antenna manufacturing methods often struggle to meet these diverse demands due to their limitations in terms of design complexity and production cost. This is where 3D printing steps in, providing a versatile solution that allows for the rapid prototyping and production of custom antennas tailored to specific IoT applications.

Advantages of 3D Printed Antennas

1. **Design Flexibility:** One of the most significant advantages of 3D printing is its ability to produce complex geometries that are often impossible with traditional manufacturing techniques. This flexibility enables engineers to explore innovative antenna designs that can improve performance, reduce size, and enhance integration with IoT devices.

2. **Cost-Effectiveness:** Traditional antenna manufacturing requires expensive molds and tooling, leading to high production costs, especially for small batches. In contrast, 3D printing eliminates the need for such tooling, making it an economical choice for producing small quantities or even unique, customized antennas.

3. **Rapid Prototyping:** 3D printing allows for quick iterations of antenna designs, enabling engineers to test and refine prototypes rapidly. This capability is crucial in the fast-paced IoT industry, where time-to-market can be a critical factor in a product's success.

4. **Material Versatility:** The range of materials compatible with 3D printing continues to expand, including conductive materials suitable for RF applications. This versatility opens up new possibilities for integrating antennas directly into the structure of IoT devices, potentially reducing weight and improving durability.

Applications of 3D Printed Antennas in IoT

The applications of 3D printed antennas in IoT are vast and varied. For instance, in the domain of wearable technology, custom antennas can be integrated seamlessly into fabrics or flexible materials, enhancing user comfort without compromising performance. In smart agriculture, 3D printed antennas can be tailored to specific environmental conditions, ensuring reliable connectivity even in remote locations. Additionally, in urban environments, where IoT devices are densely packed, custom antennas can help mitigate interference and improve communication efficiency.

Challenges and Future Prospects

While the benefits of 3D printed antennas for IoT are compelling, several challenges remain. The precision and reliability of 3D printed components can sometimes fall short of those produced by traditional methods, particularly for high-frequency applications. Moreover, the range of materials available for 3D printing in RF applications is still limited, though it is expanding rapidly.

Despite these challenges, the future of 3D printed antennas in IoT looks promising. Ongoing advancements in 3D printing technology, materials science, and RF engineering are expected to overcome current limitations, paving the way for even more innovative and efficient designs. As these technologies mature, we can anticipate a proliferation of IoT devices with custom-tailored antennas, each optimized for its unique application, ultimately leading to more reliable and efficient IoT networks.

Conclusion

In conclusion, 3D printed antennas represent a significant leap forward in the design and manufacture of RF components for IoT applications. With their unparalleled design flexibility, cost-effectiveness, and rapid prototyping capabilities, 3D printing offers a powerful tool for creating customized antenna solutions that meet the diverse needs of the ever-expanding IoT landscape. As this technology continues to evolve, it holds the potential to unlock new possibilities and drive the next wave of innovation in IoT connectivity.

From 5G NR to SDN and quantum-safe encryption, the digital communication landscape is evolving faster than ever. For R&D teams and IP professionals, tracking protocol shifts, understanding standards like 3GPP and IEEE 802, and monitoring the global patent race are now mission-critical.

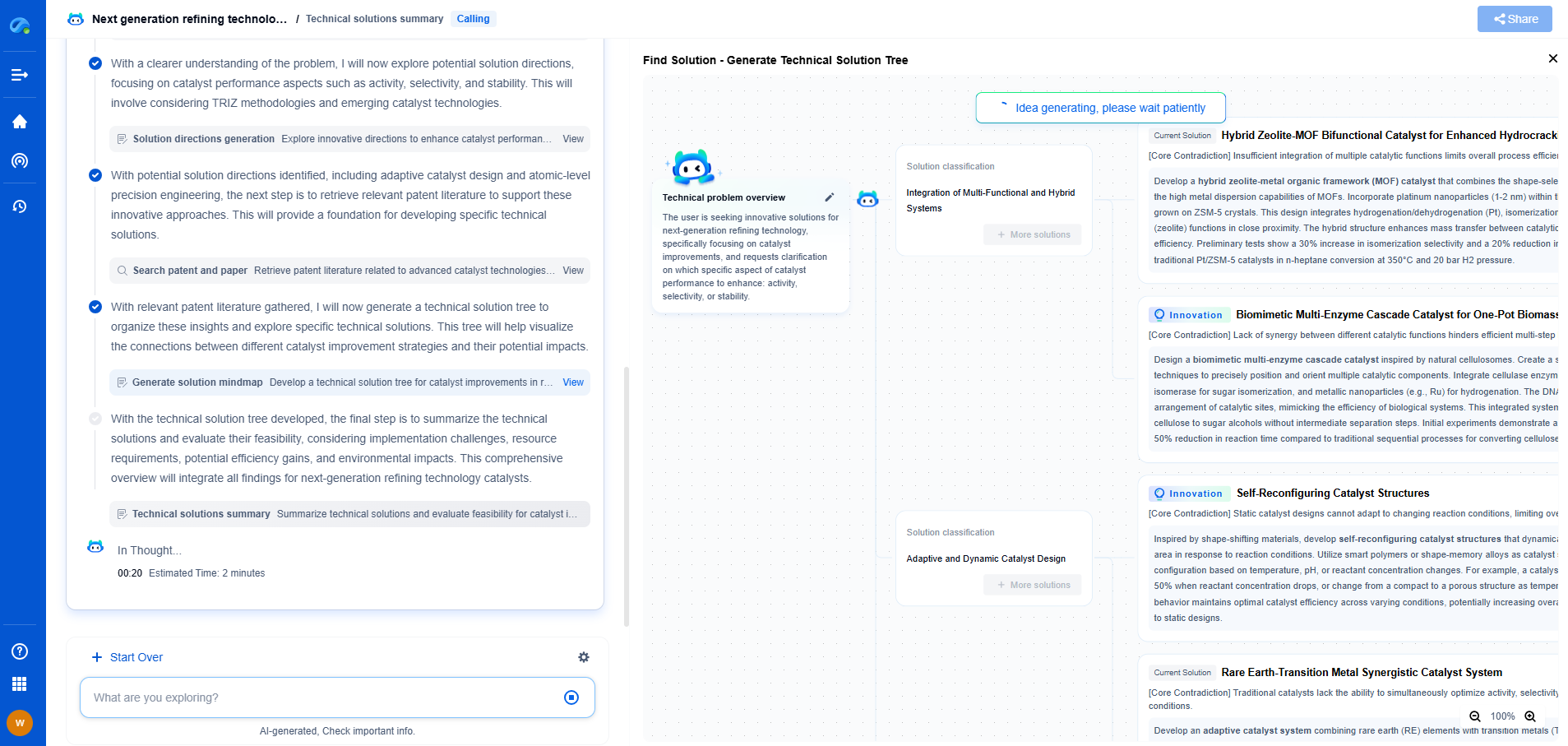

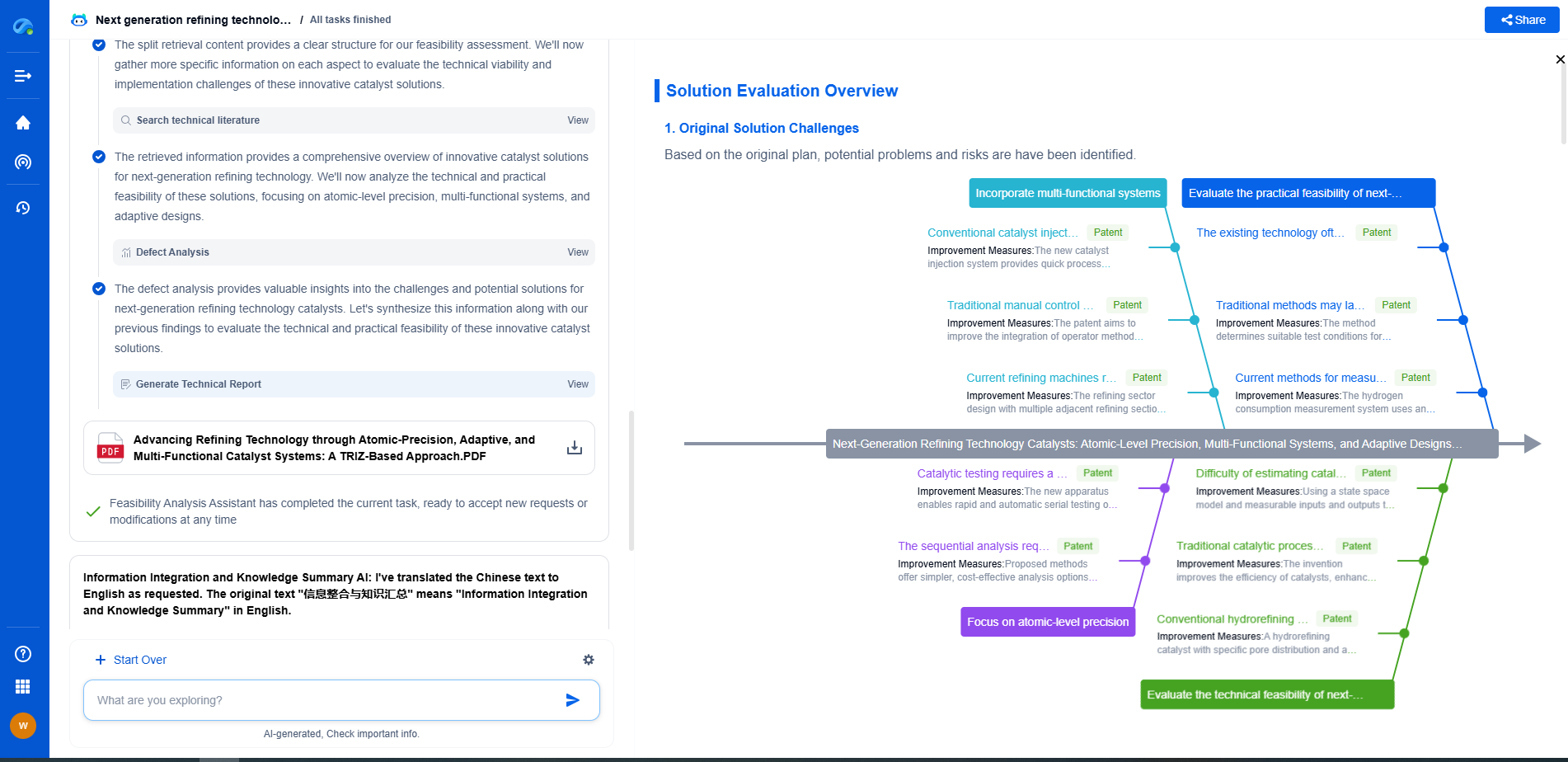

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

📡 Experience Patsnap Eureka today and unlock next-gen insights into digital communication infrastructure, before your competitors do.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com