Automated Test Systems for Power Supply Production

JUN 27, 2025 |

In today's rapidly advancing technological landscape, the demand for reliable and efficient power supplies has never been higher. As industries and consumers increasingly rely on electronic devices, the pressure on manufacturers to produce high-quality power supplies intensifies. Automated test systems have emerged as a vital solution to meet these demands, ensuring production efficiency while maintaining the highest standards of quality and reliability.

Benefits of Automation in Power Supply Testing

Automated test systems offer numerous advantages over traditional manual testing methods. One of the most significant benefits is the reduction in human error. Manual testing is prone to inconsistencies and mistakes, whereas automated systems provide precise and repeatable results. This consistency is crucial in maintaining the reliability of power supplies, preventing costly errors and potential recalls.

Another advantage is the increased efficiency of production processes. Automated systems can conduct tests at a much faster rate than human testers, significantly speeding up the production line. This efficiency not only reduces production costs but also enables manufacturers to meet the growing demand for power supplies without compromising on quality.

Key Components of Automated Test Systems

Automated test systems in power supply production typically consist of several key components. Firstly, advanced software platforms are used to program and control the testing process. These platforms enable manufacturers to customize test parameters and procedures to suit specific product requirements. The software's flexibility allows for adjustments as new products are developed and specifications change.

Hardware components, such as test benches and measurement instruments, are equally important. These tools are integrated with the software to perform various tests on power supplies, including voltage, current, and frequency measurements. The hardware must be robust and accurate to ensure the reliability of the test results.

Data management is another critical component. Automated test systems generate vast amounts of data during the testing process. Efficient data storage and analysis tools help manufacturers track performance metrics, identify trends, and make informed decisions about production improvements.

Challenges in Implementing Automated Test Systems

Despite their benefits, implementing automated test systems in power supply production is not without challenges. One of the primary obstacles is the initial cost of investment. The technology and infrastructure required for automation can be expensive, posing a significant barrier for smaller companies. However, the long-term savings and quality improvements often justify the initial expenditure.

Another challenge is the complexity of integration. Automated systems must seamlessly integrate with existing production processes and equipment, which can require significant planning and coordination. Manufacturers may need to invest time and resources into training staff to effectively operate and maintain these systems.

Emerging Trends and Future Outlook

The future of automated test systems in power supply production looks promising. As technology continues to evolve, we can expect further advancements in testing capabilities and efficiencies. One emerging trend is the use of artificial intelligence and machine learning in test systems. These technologies have the potential to further reduce human oversight, optimize test procedures, and predict potential issues before they arise.

Additionally, the rise of the Internet of Things (IoT) is influencing power supply testing. Connected devices can provide real-time data to test systems, allowing for more dynamic and responsive testing processes. This connectivity could lead to more proactive maintenance and higher-quality power supplies.

Conclusion

Automated test systems are transforming power supply production, offering manufacturers a way to enhance quality, efficiency, and reliability. While challenges remain, the benefits of automation far outweigh the drawbacks. As technology continues to progress, automated test systems will undoubtedly play an increasingly crucial role in meeting the ever-growing demands of the power supply industry. Manufacturers who invest in these systems today will be well-positioned to lead the market tomorrow.

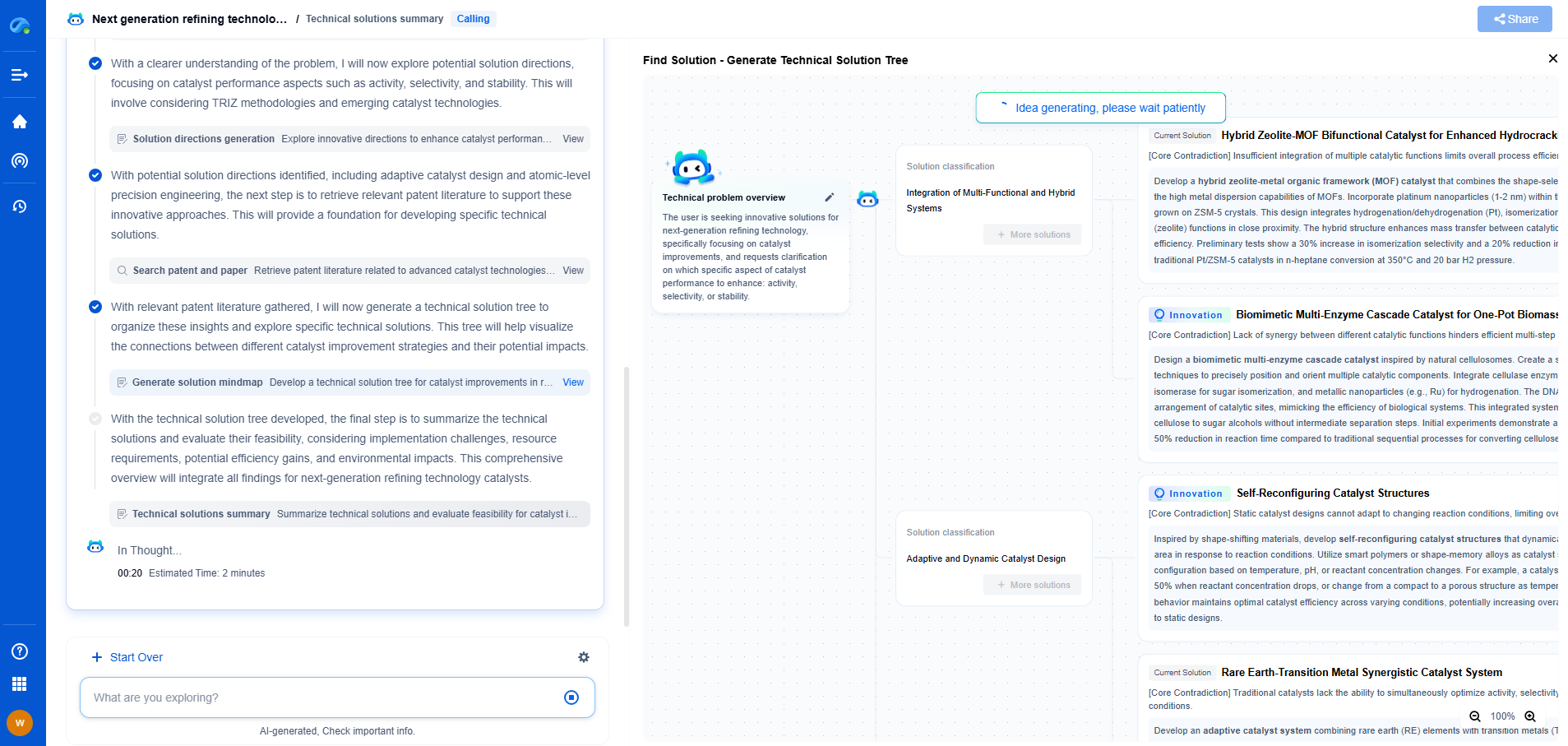

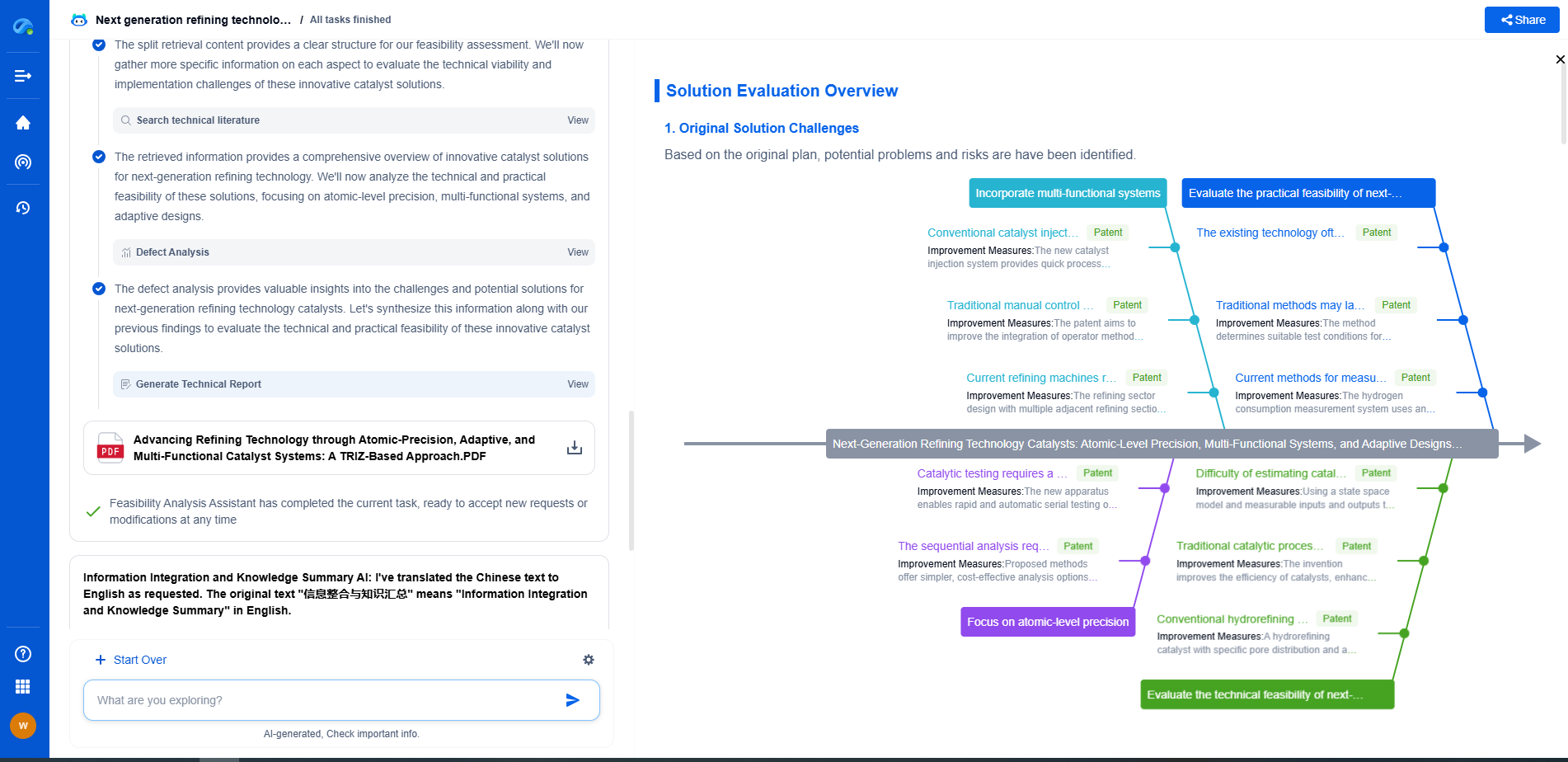

Accelerate Electronic Circuit Innovation with AI-Powered Insights from Patsnap Eureka

The world of electronic circuits is evolving faster than ever—from high-speed analog signal processing to digital modulation systems, PLLs, oscillators, and cutting-edge power management ICs. For R&D engineers, IP professionals, and strategic decision-makers in this space, staying ahead of the curve means navigating a massive and rapidly growing landscape of patents, technical literature, and competitor moves.

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

🚀 Experience the next level of innovation intelligence. Try Patsnap Eureka today and discover how AI can power your breakthroughs in electronic circuit design and strategy. Book a free trial or schedule a personalized demo now.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com