Automating RF Tests with LabVIEW and PXI Systems

JUN 27, 2025 |

In the rapidly evolving world of wireless communication, Radio Frequency (RF) testing has become increasingly crucial. RF testing ensures that devices meet regulatory standards and function optimally within designated frequency bands. Traditionally, RF testing has been a manual, time-consuming process that requires significant expertise. However, with technological advancements, automation has become viable and beneficial. LabVIEW and PXI systems offer a robust solution for automating RF tests, improving efficiency, accuracy, and repeatability.

Understanding RF Testing

RF testing involves measuring various parameters such as power levels, frequency response, modulation accuracy, and signal integrity. These tests are critical for devices like smartphones, Wi-Fi routers, and other wireless communication equipment. As the demand for high-performance wireless devices grows, ensuring the quality and reliability of RF components becomes paramount.

The Role of LabVIEW and PXI Systems

LabVIEW, developed by National Instruments, is a leading graphical programming platform designed for data acquisition, instrument control, and automation. It's particularly beneficial for RF testing due to its intuitive interface and extensive libraries.

PXI (PCI eXtensions for Instrumentation) systems provide a modular platform that integrates hardware and software for automated testing applications. PXI combines PCI electrical-bus features with the rugged mechanical packaging of CompactPCI, offering high-speed data processing capabilities essential for RF testing.

Advantages of Automating RF Tests

1. Enhanced Efficiency: Automation significantly reduces the time required for testing. Automated systems can perform numerous tests simultaneously, allowing engineers to focus on analysis rather than repetitive manual tasks.

2. Improved Accuracy: Automated testing minimizes human error, ensuring consistent and precise measurements. This is crucial for RF testing, where even minor inaccuracies can lead to significant issues in device performance.

3. Scalability: As the complexity of RF devices increases, automated systems can be easily scaled to accommodate new test requirements. LabVIEW and PXI platforms are adaptable, allowing for seamless integration of additional modules and software updates.

Implementing Automation with LabVIEW and PXI

To automate RF testing using LabVIEW and PXI systems, one must first configure the hardware setup. PXI chassis are equipped with various modules tailored for RF testing, including signal analyzers, generators, and switches. LabVIEW interfaces with these modules to create customized test sequences.

1. Designing Test Sequences: LabVIEW's graphical programming allows users to design test sequences without extensive coding knowledge. Engineers can drag and drop functions to create complex test routines, integrating control logic, signal processing, and data analysis.

2. Data Acquisition and Analysis: LabVIEW facilitates real-time data acquisition and analysis, enabling engineers to monitor results instantly. This capability is essential for detecting anomalies or deviations early in the testing process.

3. Reporting and Documentation: Automated systems can generate detailed reports, documenting test results and compliance status. This feature streamlines the documentation process, ensuring traceability and accountability.

Challenges and Considerations

While automation offers numerous benefits, several challenges must be addressed. Ensuring compatibility between different hardware modules and software components can be complex. Additionally, initial setup and calibration require expertise to optimize system performance.

Moreover, understanding the specific requirements of RF testing standards is crucial. Engineers must stay updated with industry regulations to ensure that automated systems comply with the latest guidelines.

Conclusion

Automating RF tests with LabVIEW and PXI systems revolutionizes the testing process, offering unparalleled efficiency, accuracy, and scalability. As wireless technologies continue to evolve, automated solutions will play an increasingly vital role in ensuring the quality and reliability of RF devices. By leveraging the strengths of LabVIEW and PXI, engineers can streamline their testing workflows, allowing for faster innovation and improved product performance. With careful implementation and ongoing optimization, automated RF testing can significantly enhance the capabilities of any testing facility.

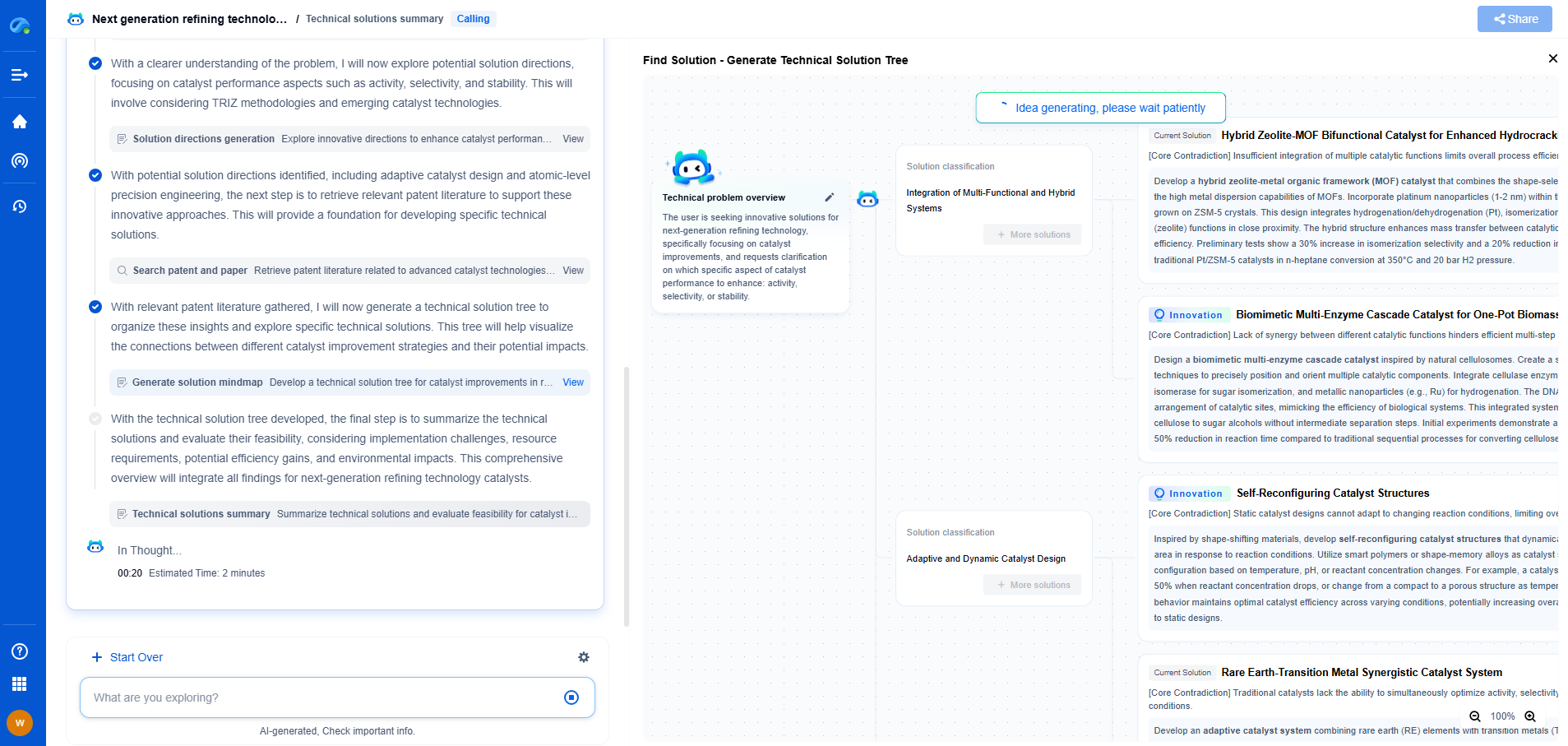

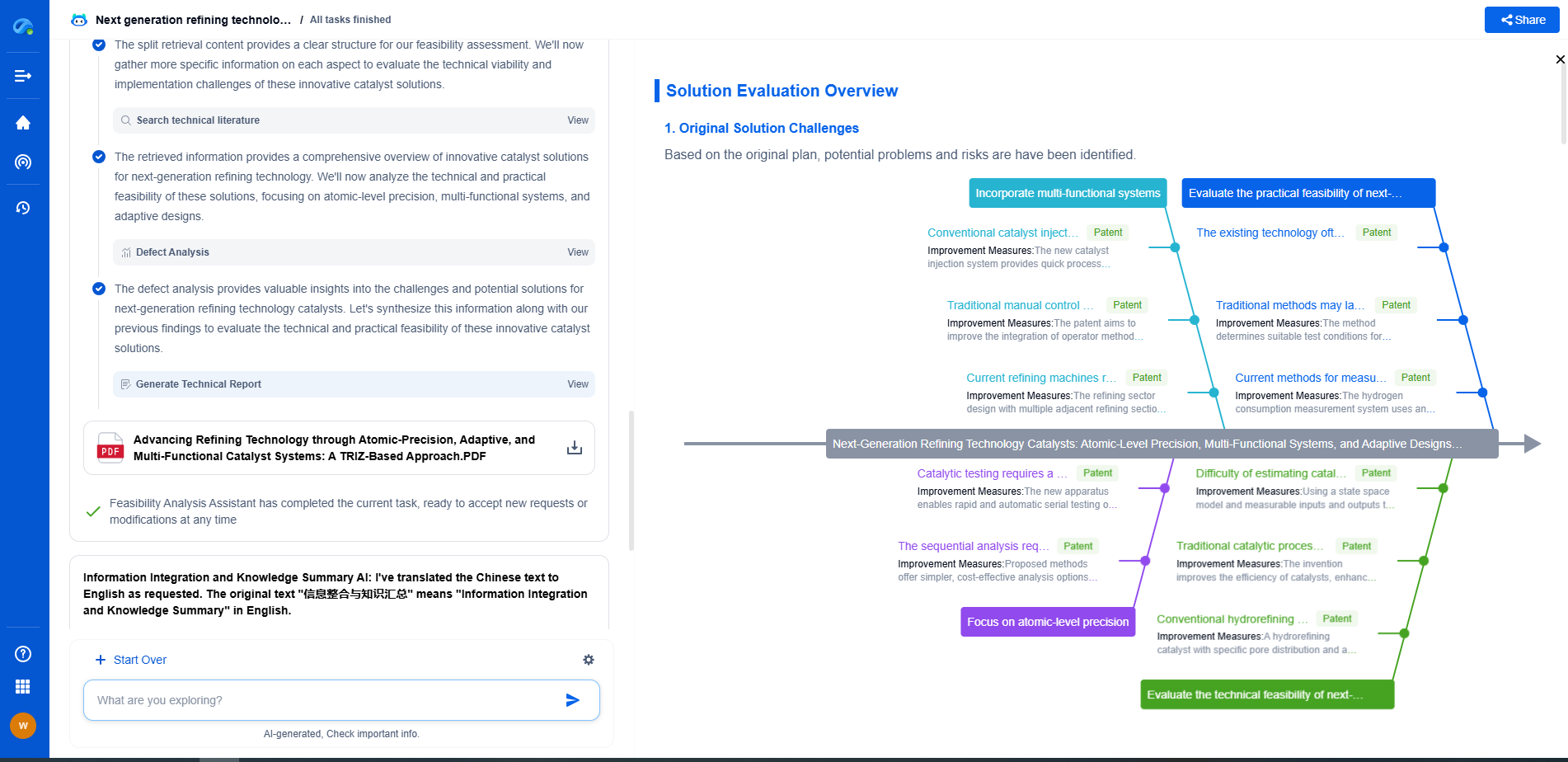

Accelerate Electronic Circuit Innovation with AI-Powered Insights from Patsnap Eureka

The world of electronic circuits is evolving faster than ever—from high-speed analog signal processing to digital modulation systems, PLLs, oscillators, and cutting-edge power management ICs. For R&D engineers, IP professionals, and strategic decision-makers in this space, staying ahead of the curve means navigating a massive and rapidly growing landscape of patents, technical literature, and competitor moves.

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

🚀 Experience the next level of innovation intelligence. Try Patsnap Eureka today and discover how AI can power your breakthroughs in electronic circuit design and strategy. Book a free trial or schedule a personalized demo now.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com