Automotive IC Design: Meeting AEC-Q100 with Robust Methods

JUN 27, 2025 |

In the realm of automotive electronics, Integrated Circuits (ICs) play a pivotal role in ensuring the safety, reliability, and efficiency of vehicles. Automotive IC design is a specialized field that demands rigorous standards and methodologies. One such crucial standard is the AEC-Q100, which provides guidelines for the qualification of ICs used in automotive applications. This blog delves into the intricacies of automotive IC design and how robust methods can help meet the AEC-Q100 standards.

Understanding AEC-Q100 Standards

AEC-Q100 is a stress test qualification for ICs used in automotive applications. It is a globally recognized standard set by the Automotive Electronics Council (AEC) to ensure that electronic components can withstand the harsh environments and rigorous conditions they encounter in vehicles. AEC-Q100 outlines a series of tests for various stress factors, such as temperature, humidity, vibration, and electrical parameters. Meeting these standards is crucial for manufacturers to guarantee that their products are reliable and durable under real-world automotive conditions.

The Importance of Robust IC Design

The automotive environment is not forgiving. It demands components that can operate reliably over a wide temperature range, withstand physical shocks, and continue to function during electrical surges and drops. Robust IC design is essential to meet AEC-Q100 standards because it ensures that the ICs are not only functional but also resilient. This involves adopting design practices that prioritize reliability from the earliest stages of development.

Design Strategies for AEC-Q100 Compliance

1. **Temperature Management**: Automotive ICs need to operate across a broad temperature range, often between -40°C to 150°C. Design strategies such as using materials with high thermal conductivity, implementing effective heat dissipation techniques, and conducting thorough thermal simulations can help manage temperature-induced stress.

2. **Electrical Stress Handling**: Voltage fluctuations and power surges are common in automotive environments. Designing ICs with robust power management circuits, incorporating surge protection, and ensuring proper grounding and shielding are critical to handling electrical stress.

3. **Vibration and Mechanical Shock Resistance**: Vehicles are subject to constant motion and vibration. IC design should include the use of shock-absorbing materials, mechanical reinforcement of sensitive components, and comprehensive testing for vibration resistance.

4. **Humidity and Environmental Conditions**: Moisture and contaminants can compromise IC performance. Designing with protective coatings, sealed packaging, and choosing materials resistant to corrosion can enhance the durability of ICs against environmental factors.

Testing and Validation

Meeting AEC-Q100 standards requires rigorous testing and validation processes. This involves subjecting ICs to a battery of tests that mimic real-world conditions. Stress tests must be conducted to identify potential failure points and verify that the design can withstand them. Comprehensive simulation tools and accelerated life testing are employed to predict long-term reliability. Validation is not a one-time process but a continuous effort throughout the IC development cycle.

Collaboration and Continuous Improvement

Achieving AEC-Q100 compliance is not a solitary effort. It involves collaboration between design teams, material scientists, testing engineers, and quality assurance professionals. The automotive industry is rapidly evolving, and so are the standards and expectations. Continuous improvement in design methodologies and staying abreast of technological advancements are crucial for maintaining compliance and ensuring competitiveness in the market.

Conclusion

Automotive IC design is a challenging yet rewarding field that demands adherence to stringent standards such as AEC-Q100. By employing robust design methods and strategies, manufacturers can produce ICs that are not only compliant but also excel in performance and reliability. As the automotive industry continues to evolve, the importance of meeting these standards will only grow, making robust IC design an indispensable part of the development process.

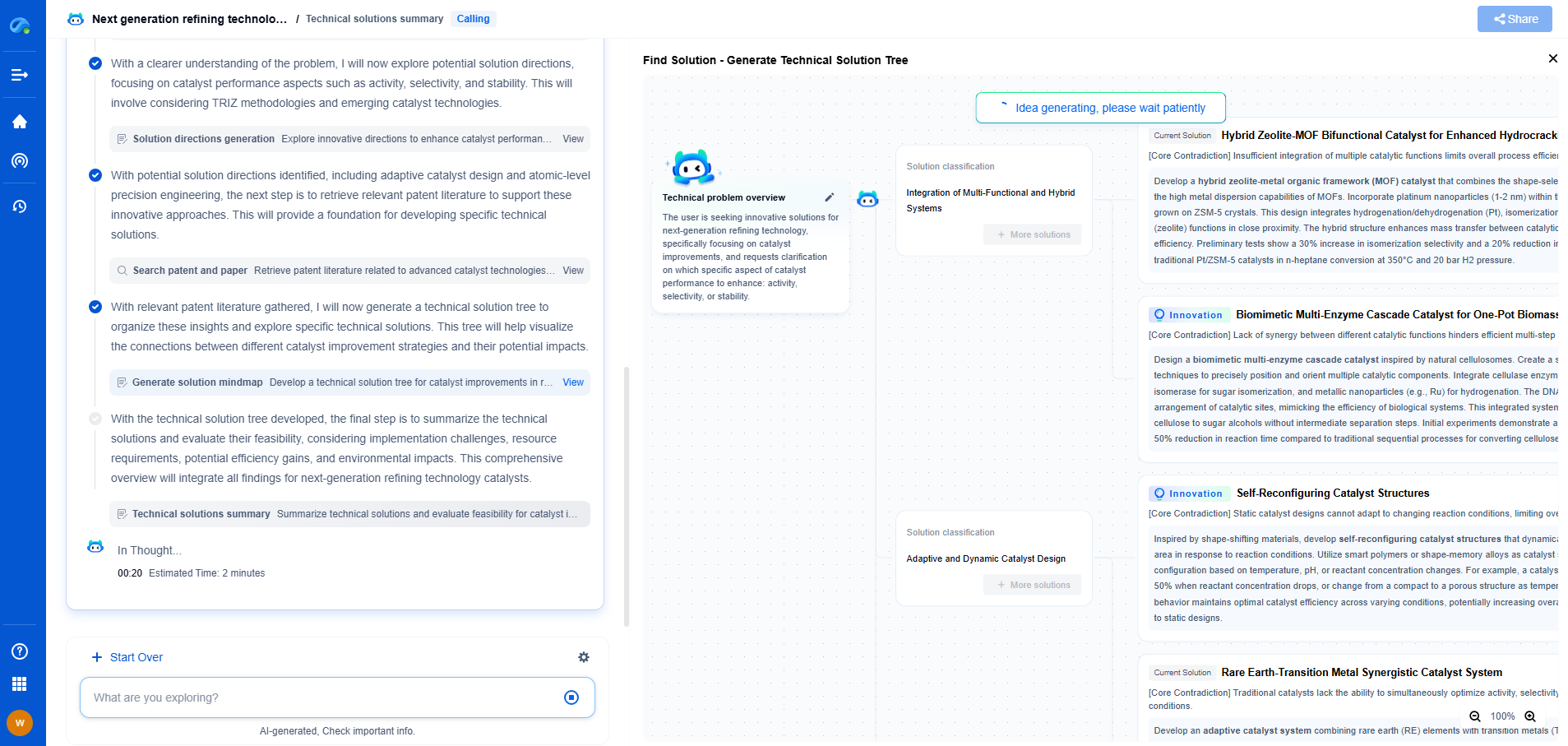

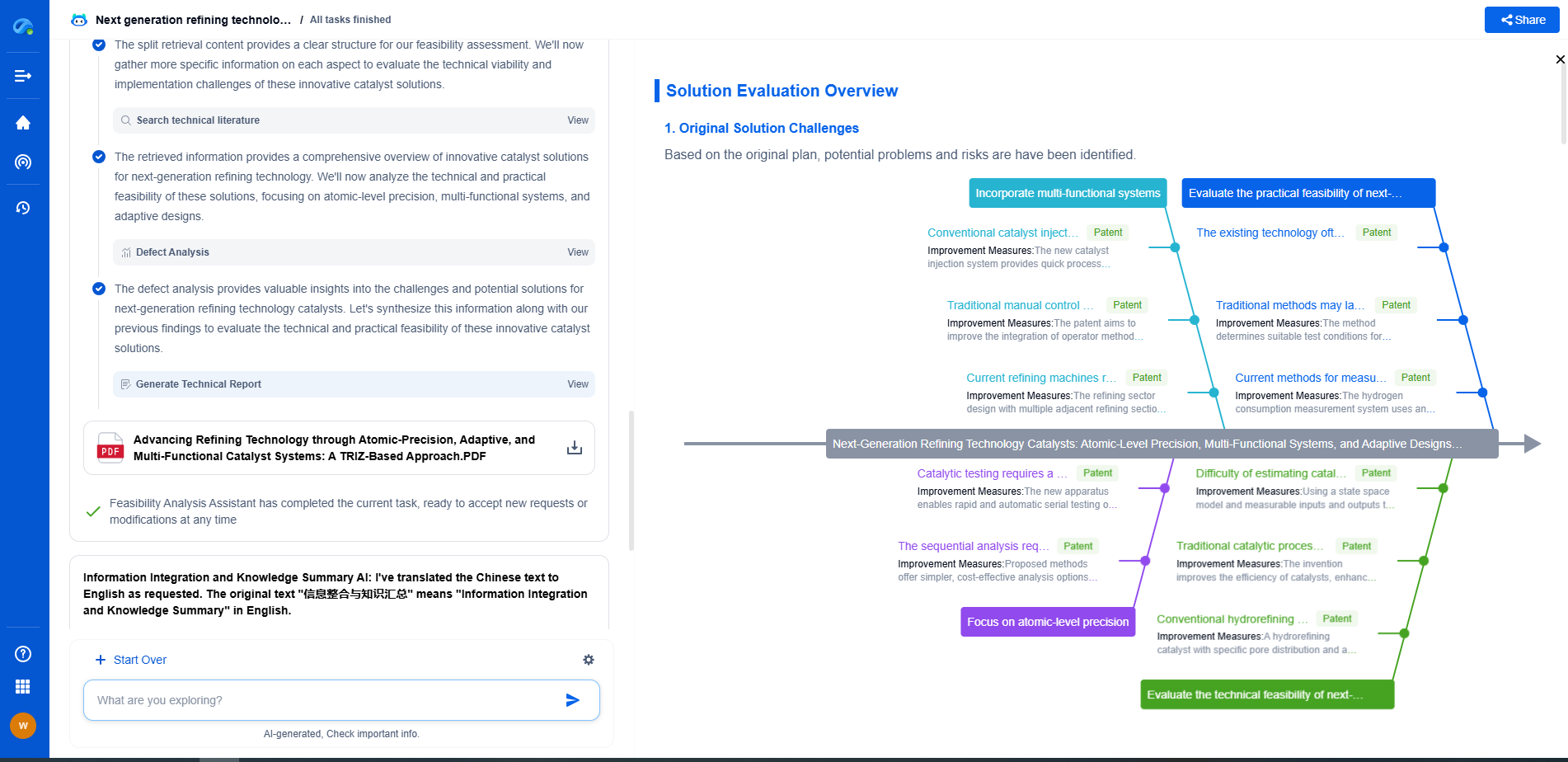

Accelerate Electronic Circuit Innovation with AI-Powered Insights from Patsnap Eureka

The world of electronic circuits is evolving faster than ever—from high-speed analog signal processing to digital modulation systems, PLLs, oscillators, and cutting-edge power management ICs. For R&D engineers, IP professionals, and strategic decision-makers in this space, staying ahead of the curve means navigating a massive and rapidly growing landscape of patents, technical literature, and competitor moves.

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

🚀 Experience the next level of innovation intelligence. Try Patsnap Eureka today and discover how AI can power your breakthroughs in electronic circuit design and strategy. Book a free trial or schedule a personalized demo now.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com