Busway vs Cable Tray: Power Distribution Cost Analysis

JUN 26, 2025 |

Installation Costs

The initial installation costs are a significant consideration when choosing between busways and cable trays. Busways often have a higher upfront cost due to the need for specialized components and the precision required for their installation. However, they offer the advantage of being modular and easier to install in complex environments. This modularity can lead to reduced labor costs and shorter installation times, particularly in configurations that require numerous turns or changes in direction.

On the other hand, cable trays are generally less expensive initially. They are a more traditional method of power distribution and require simpler materials. The installation process, however, can be more labor-intensive, especially in environments where the trays must be cut and adjusted to fit around obstacles or if they require extensive support systems. Therefore, while the material costs may be lower, the labor costs can add up, particularly in large or complex projects.

Flexibility and Scalability

When considering long-term costs, flexibility and scalability are critical. Busways offer superior flexibility in terms of modifications and expansions. Their plug-in units allow for quick and easy connections to new equipment without the need for rewiring. This adaptability can result in lower costs when future expansions or reconfigurations are needed, as less downtime and labor are generally required.

Cable trays, in contrast, are less flexible when it comes to modifications. Adding new cables often requires significant labor to thread them through existing trays, which can lead to increased downtime and labor costs. However, in environments where changes are infrequent, this may not be a significant concern.

Maintenance Costs

Maintenance is another crucial factor in the cost analysis of busways versus cable trays. Busways typically require less maintenance due to their enclosed design, which protects them from environmental factors such as dust and moisture. This can lead to a reduction in ongoing maintenance costs and increase the long-term reliability of the system.

Cable trays, being open systems, can accumulate dust and debris, requiring regular cleaning and inspection. Cables within the tray may also be more susceptible to wear and tear, potentially necessitating more frequent replacements or repairs. This can increase the overall maintenance costs over the lifespan of the system.

Safety and Reliability

Safety and reliability are paramount in any power distribution system. Busways are generally considered safer due to their enclosed and robust design, which minimizes the risk of electrical faults and exposure to live components. This can translate to lower insurance costs and reduced risk of costly downtime due to failures or accidents.

Cable trays, while generally safe, do expose cables to the environment, which can increase the risk of damage and faults. This exposure can lead to higher costs associated with repairs and potential safety incidents, particularly in harsh or demanding environments.

Conclusion

In conclusion, the choice between busways and cable trays for power distribution is largely influenced by the specific needs and conditions of the project at hand. Busways, with their higher initial costs, offer advantages in terms of flexibility, modularity, and reduced maintenance needs, which can lead to cost savings over time. Cable trays, while potentially less costly initially, may incur higher long-term expenses due to labor-intensive modifications and maintenance requirements.

Ultimately, the decision will depend on factors such as the complexity of the installation environment, the likelihood of future modifications, and the specific safety and reliability requirements of the application. By carefully considering these aspects, businesses can select the most cost-effective solution for their power distribution needs.

Stay Ahead in Power Systems Innovation

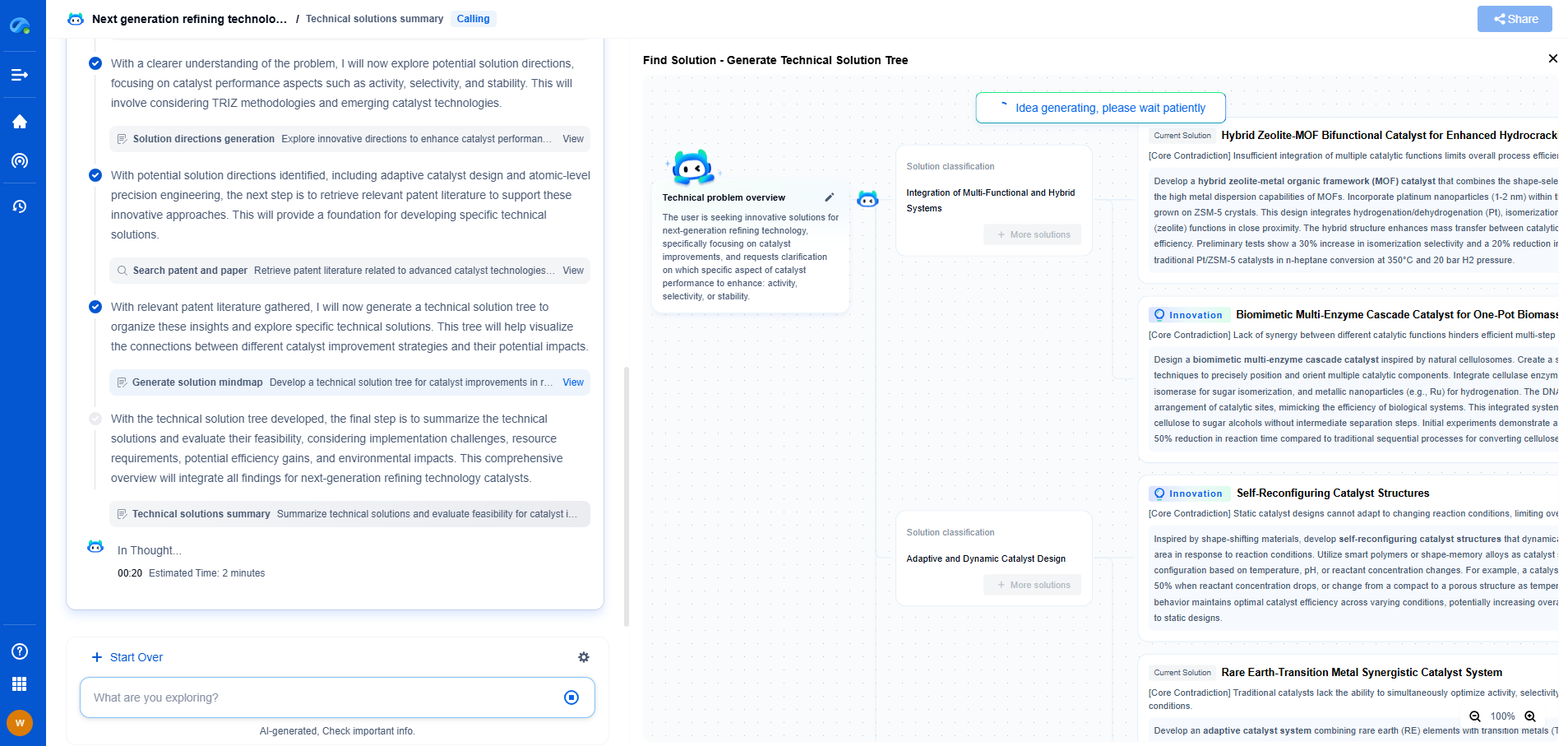

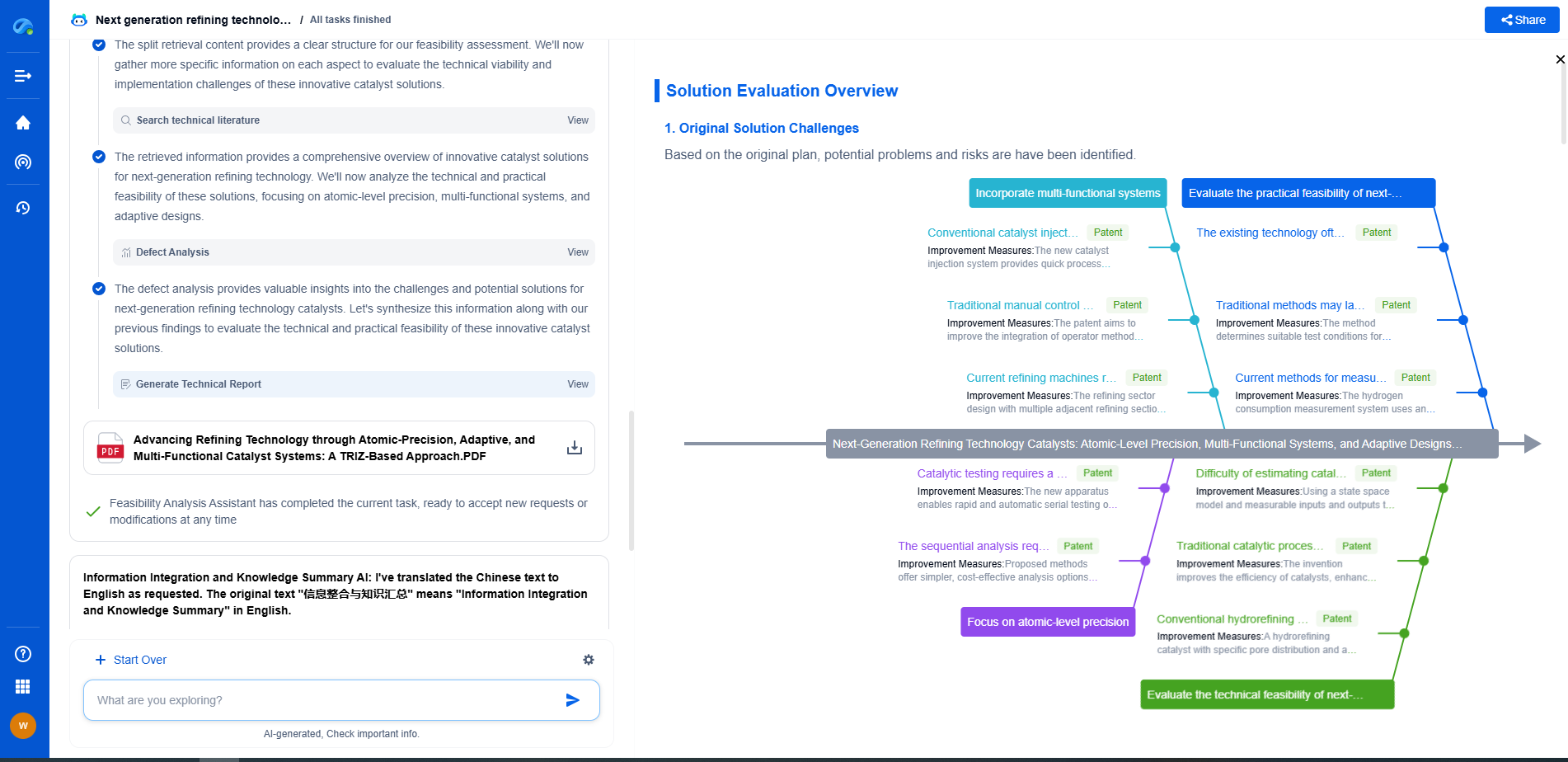

From intelligent microgrids and energy storage integration to dynamic load balancing and DC-DC converter optimization, the power supply systems domain is rapidly evolving to meet the demands of electrification, decarbonization, and energy resilience.

In such a high-stakes environment, how can your R&D and patent strategy keep up?

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

👉 Experience how Patsnap Eureka can supercharge your workflow in power systems R&D and IP analysis. Request a live demo or start your trial today.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com