Calibrating ADCs: Offset and Gain Error Compensation

JUN 27, 2025 |

Analog-to-Digital Converters (ADCs) are pivotal in bridging the analog world with digital systems. However, ADCs are not flawless; they often exhibit errors that can affect the accuracy of digital representations of analog signals. Two primary errors that require compensation are offset error and gain error. Understanding and correcting these errors is crucial for precise measurements, especially in applications demanding high accuracy.

Offset Error in ADCs

Offset error refers to the difference between the actual output value and the expected value when the input is zero. Ideally, an ADC should output zero when there is no input signal. However, due to imperfections in the ADC's design or manufacturing, there might be a non-zero output even with a zero input signal. This deviation needs to be addressed to ensure the ADC's output accurately reflects the input signal.

The offset error can be attributed to various factors, including mismatches in the differential pair, leakage currents, or imperfections in reference voltages. To compensate for this error, calibration techniques are employed. One common method involves measuring the output when the input is grounded and adjusting the ADC's output algorithmically to subtract the offset error. This ensures that the ADC's zero level aligns with zero input signal conditions.

Gain Error in ADCs

Gain error occurs when the output span of the ADC does not match the expected range based on the input signal. It is essentially a scaling discrepancy between the input and output signals. For example, if an ADC is supposed to convert a 0-5V input signal to a specific digital range but fails to do so accurately, resulting in a compressed or expanded range, this is indicative of a gain error.

The root causes of gain error can include inaccuracies in the reference voltage, resistor mismatches, or variations in the ADC’s internal amplification circuit. To correct gain errors, it’s crucial to calibrate the ADC by comparing its output with known reference signals, and then adjusting its gain settings accordingly. This calibration process can involve mathematical adjustments in the conversion algorithm to ensure that the ADC outputs a value proportional to the input signal.

Methods of Calibration

Calibration of ADCs for offset and gain errors can be approached in several ways. Manual calibration involves physically adjusting components or settings within the ADC circuitry, which can be time-consuming and prone to human error. Automated calibration uses software algorithms to dynamically adjust the ADC's settings during operation. This method is typically more efficient and can adapt to changes in operating conditions more readily.

One popular technique is two-point calibration, where measurements are taken at two known input levels, often at zero and full-scale points. By analyzing the ADC's output at these levels, both offset and gain errors can be quantified and corrected. This method provides a straightforward approach to improving the accuracy of ADCs across their operational range.

Importance of ADC Calibration

The calibration of ADCs is crucial in ensuring that electronic systems function correctly and provide accurate data. In critical applications such as medical devices, aerospace systems, or precision instrumentation, even small errors can lead to significant consequences. Therefore, robust calibration procedures are essential to maintain the integrity and reliability of these systems.

Conclusion

Offset and gain errors are inherent challenges in the use of ADCs but can be effectively managed through calibration techniques. By understanding the nature of these errors and employing appropriate compensation methods, it is possible to enhance the performance and accuracy of ADCs. This ensures that the digital interpretation of analog signals is as precise as possible, fostering the development of reliable and efficient electronic systems.

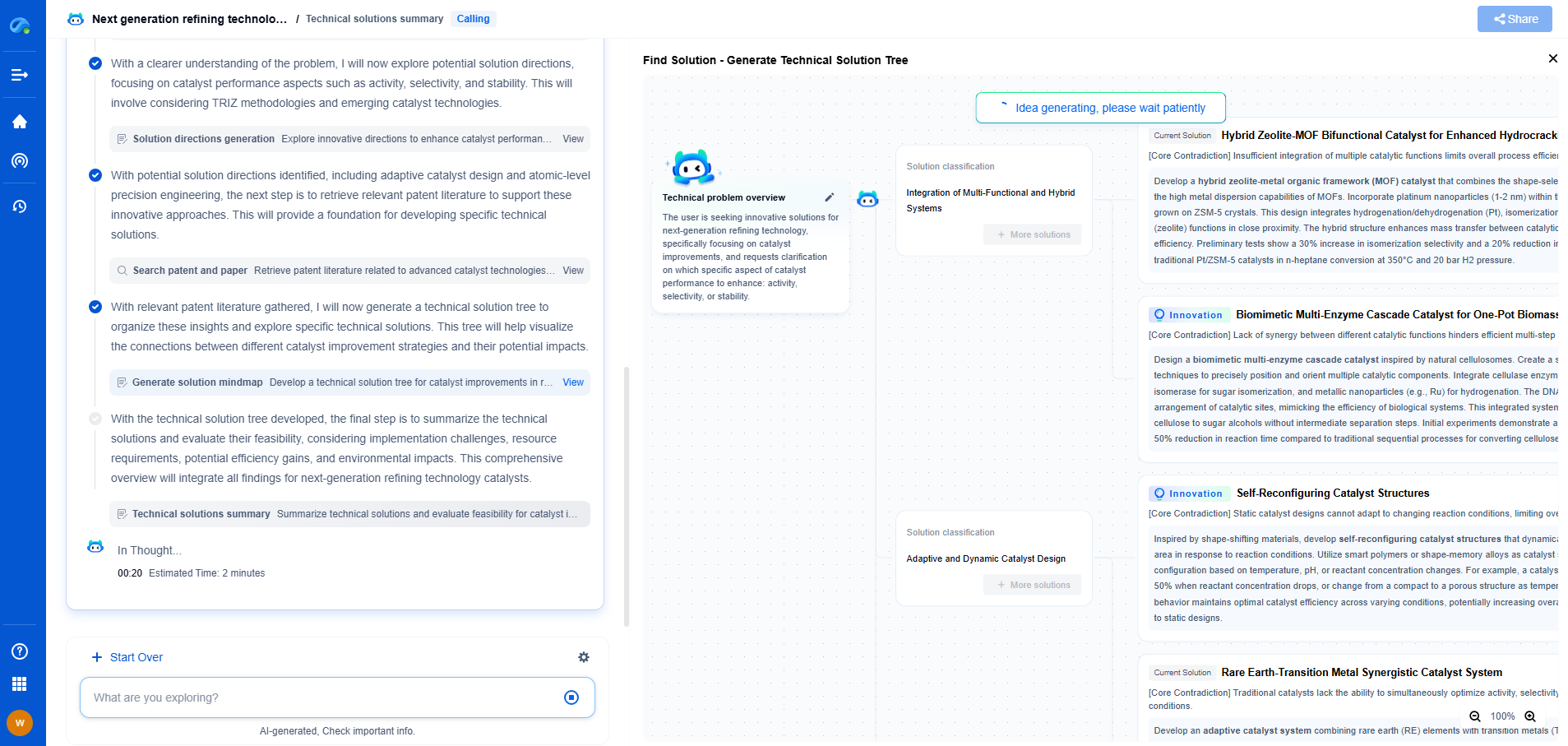

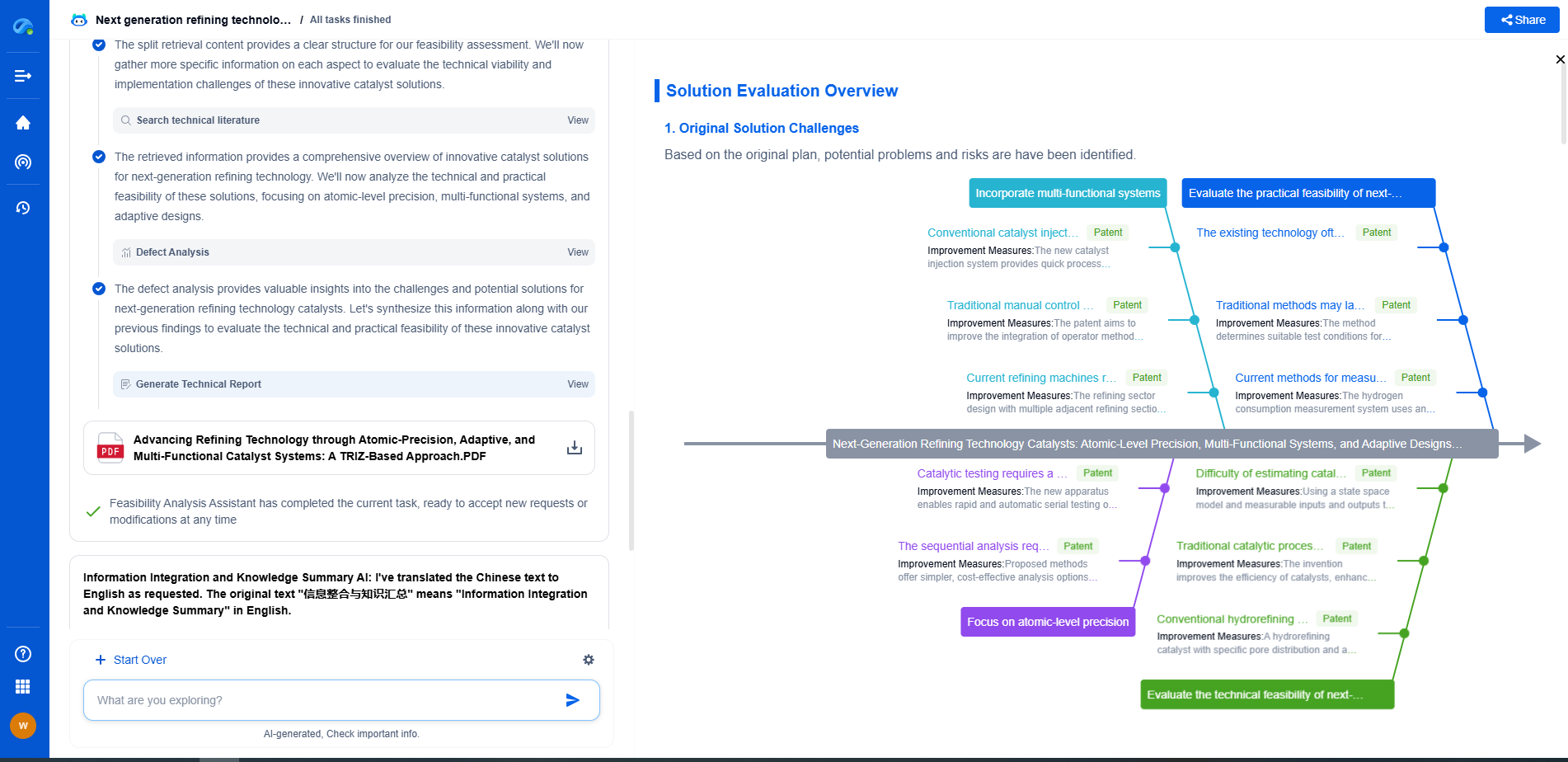

Accelerate Electronic Circuit Innovation with AI-Powered Insights from Patsnap Eureka

The world of electronic circuits is evolving faster than ever—from high-speed analog signal processing to digital modulation systems, PLLs, oscillators, and cutting-edge power management ICs. For R&D engineers, IP professionals, and strategic decision-makers in this space, staying ahead of the curve means navigating a massive and rapidly growing landscape of patents, technical literature, and competitor moves.

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

🚀 Experience the next level of innovation intelligence. Try Patsnap Eureka today and discover how AI can power your breakthroughs in electronic circuit design and strategy. Book a free trial or schedule a personalized demo now.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com