China GB vs International IEC Standards: Converter Testing Differences

JUN 26, 2025 |

In the world of electrical engineering and power electronics, standards are essential in ensuring compatibility, safety, and efficiency across products and systems. Among the global standards, the International Electrotechnical Commission (IEC) standards are widely recognized and adopted. In contrast, China has its own set of national standards, known as the GB standards (Guobiao standards). While both aim to ensure quality and safety, there are inherent differences in their scope, requirements, and testing procedures, particularly when it comes to converter testing.

Scope and Intent

The IEC standards are developed through a consensus process involving multiple countries, which means they consider a broad range of needs and technologies. This makes them versatile and widely applicable across various international markets. China’s GB standards, however, are primarily designed to cater to the specific needs, conditions, and regulations within China. As such, they may emphasize different aspects in converter testing to address local priorities, such as specific environmental conditions or local grid compatibility.

Technical Differences in Converter Testing

One of the most significant differences between China GB and International IEC standards lies in the technical parameters for converter testing. IEC standards often provide a broad framework that manufacturers can adapt, focusing on general performance issues such as efficiency, power quality, and electromagnetic compatibility. They emphasize a comprehensive approach that can be applied universally, ensuring that converters perform reliably under typical operating conditions found internationally.

Conversely, GB standards might include specific requirements that are unique to China’s electric grid and environmental conditions. For instance, GB standards may demand more stringent testing in areas like harmonic distortion or thermal management, reflecting the unique challenges posed by local infrastructure and climate. This could mean additional testing cycles or different testing environments that manufacturers must adhere to if they are operating or selling products in China.

Test Environment and Conditions

The test environments prescribed by the IEC and GB standards can also differ. IEC standards often simulate a wide range of operating conditions to ensure global applicability, which means they must be adaptable to various climatic and geographical conditions. This can include testing temperature ranges, humidity levels, and other environmental factors that might affect converter performance.

In contrast, the GB standards might focus more specifically on conditions prevalent in China. For instance, converters might be tested for performance in high-humidity environments, given the prevalence of such conditions in many parts of China, or under specific voltage and frequency conditions that match the local power grid. These localized testing conditions ensure that products are not only safe but also optimized for performance in the Chinese market.

Compliance and Certification

Compliance with IEC standards often involves certification processes that are globally recognized, making it easier for products to be marketed internationally. This involves rigorous testing by certified laboratories and continuous quality audits. The certification process under IEC standards is generally well-structured, with clear guidelines on the requirements and the documentation needed to prove compliance.

On the other hand, obtaining certification under China’s GB standards may require navigation through different bureaucratic processes. Products may need to undergo additional testing in state-approved laboratories to ensure they meet the specific requirements set by the GB standards. This can sometimes be a more complex process, as it may involve negotiations with various government bodies and testing facilities specific to China.

Impact on Manufacturers and Consumers

For manufacturers, the existence of dual standards means that designing converters for both international and Chinese markets can be challenging. It necessitates a comprehensive understanding of both IEC and GB standards to ensure that products not only meet safety and performance criteria but also gain the necessary approvals for sale in different regions. This dual compliance can increase the cost of production and time-to-market, as additional testing and certification processes are required.

For consumers, however, these standards ensure that the converters available to them are safe, reliable, and suited to their specific needs. While the focus of IEC standards might appeal to a global audience with its inclusivity and broad applicability, the tailored approach of GB standards ensures that products are highly optimized for local conditions, potentially offering better performance and reliability in China.

Conclusion

In summary, while both the China GB and International IEC standards aim to ensure the safety and reliability of converters, their differences highlight the challenges and considerations in creating products for a global market. Understanding these differences is crucial for manufacturers looking to operate internationally, as well as for consumers who rely on these standards to inform their purchasing decisions. By recognizing the unique aspects of each set of standards, stakeholders can make informed choices that align with their needs and expectations, ensuring both compliance and satisfaction.

Stay Ahead in Power Systems Innovation

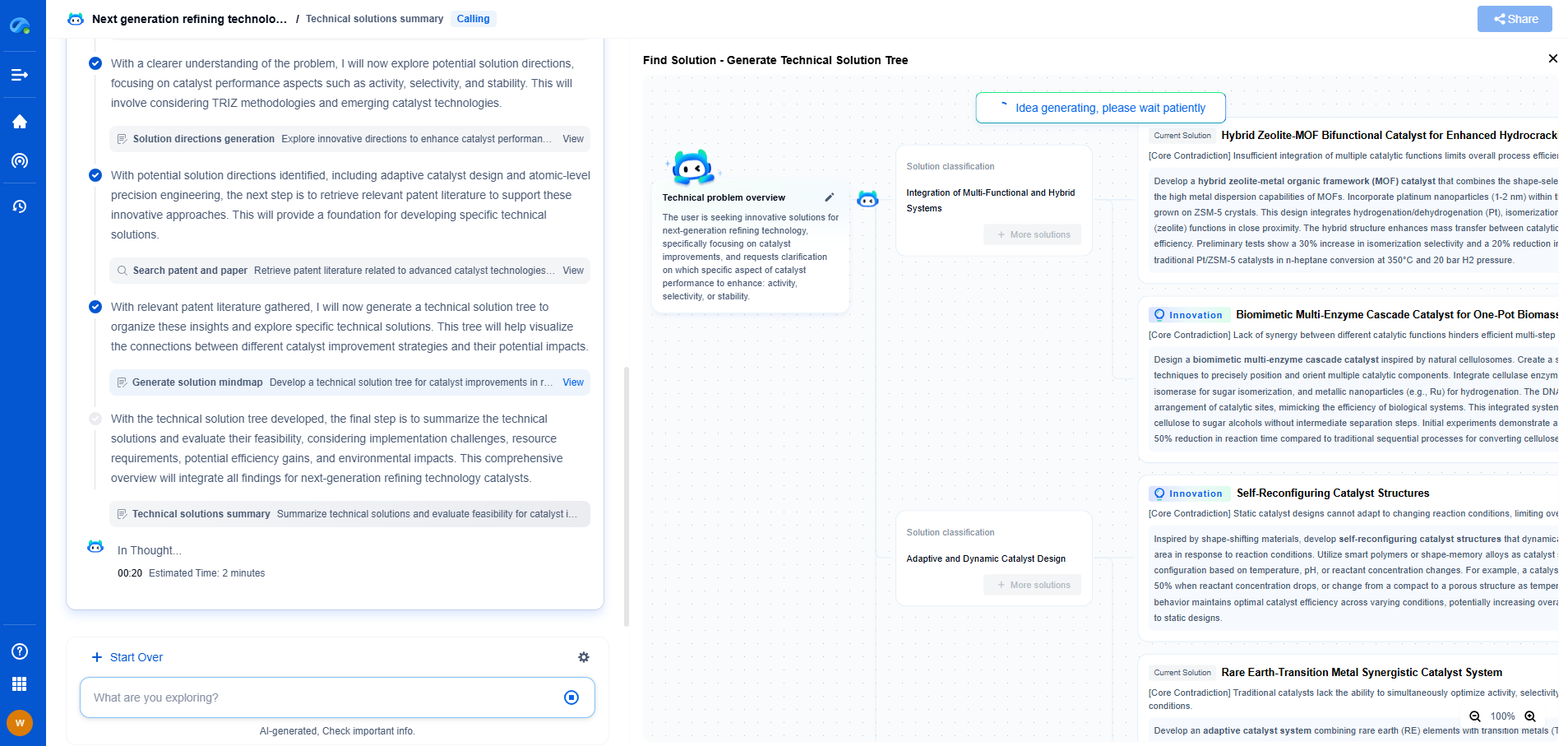

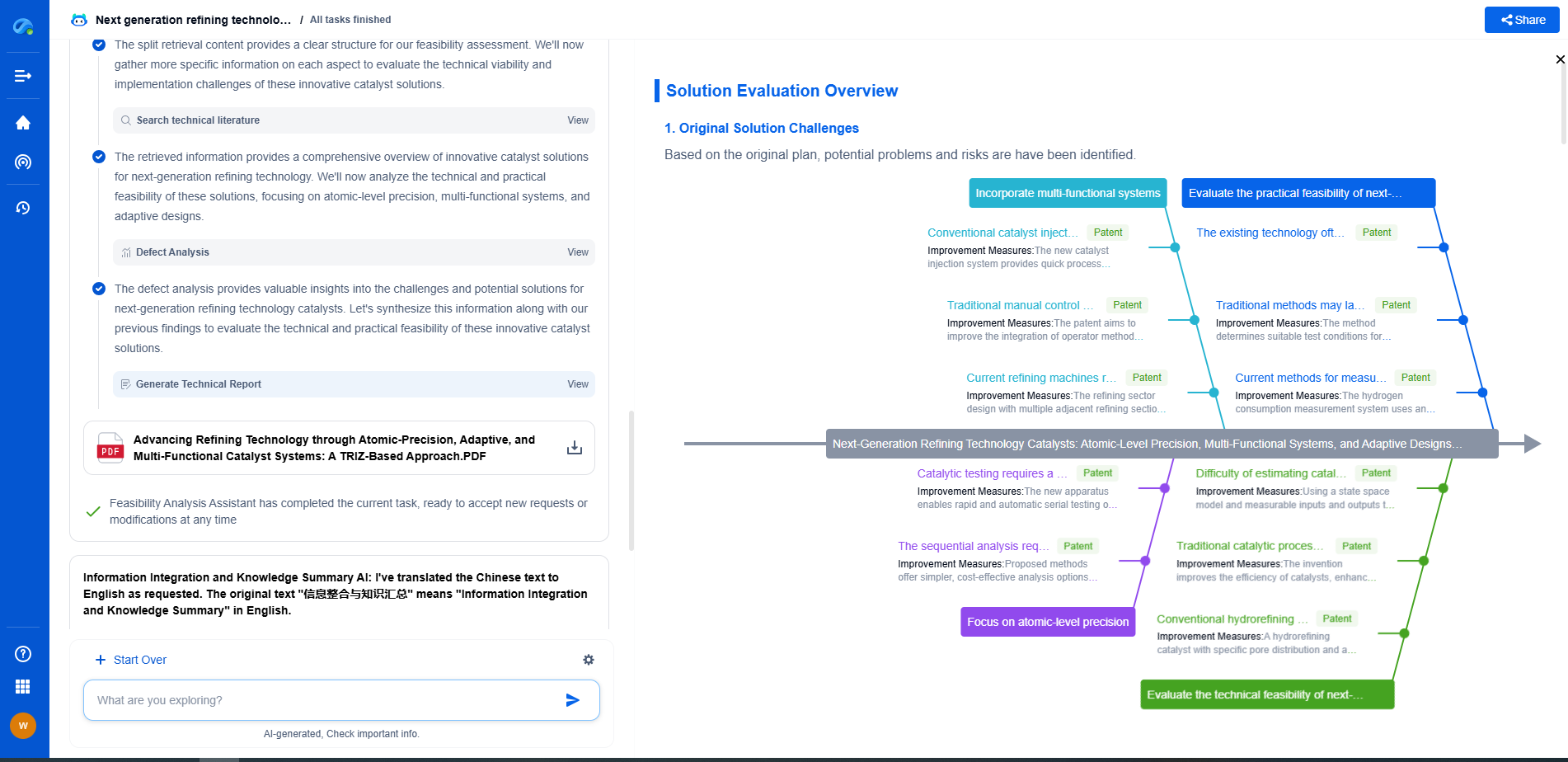

From intelligent microgrids and energy storage integration to dynamic load balancing and DC-DC converter optimization, the power supply systems domain is rapidly evolving to meet the demands of electrification, decarbonization, and energy resilience.

In such a high-stakes environment, how can your R&D and patent strategy keep up?

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

👉 Experience how Patsnap Eureka can supercharge your workflow in power systems R&D and IP analysis. Request a live demo or start your trial today.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com