Debugging Common Issues in Buck Converter Circuits

JUN 27, 2025 |

Buck converters, also known as step-down converters, are essential components in many electronic circuits due to their ability to efficiently convert a higher input voltage to a lower output voltage. They are widely used in power supplies for a variety of applications, from computer motherboards to battery-powered devices. Despite their popularity, buck converters can present several challenges in both their design and operation. In this blog, we will explore some common issues faced in buck converter circuits and provide strategies for troubleshooting these problems.

Common Symptoms of Buck Converter Issues

Before delving into specific troubleshooting techniques, it is important to recognize the symptoms that indicate a buck converter is malfunctioning. Some of the most common issues include:

1. Output Voltage Instability: This occurs when the output voltage fluctuates instead of maintaining a steady level.

2. Excessive Heat: Overheating could indicate a problem with the converter or its components, leading to inefficiency or potential damage.

3. Noise and Electromagnetic Interference (EMI): Buck converters can generate noise that affects the performance of nearby circuits.

4. Inefficient Energy Conversion: If the converter is not operating efficiently, it can waste power and reduce the overall performance of the system.

Troubleshooting Output Voltage Instability

The instability of output voltage in buck converters can stem from several causes. Here are some steps to diagnose and resolve this issue:

- Check Component Ratings: Ensure that all components, such as capacitors and inductors, are rated appropriately for the operating conditions. Underrated components can lead to performance issues.

- Verify Feedback Loop Design: The feedback loop controls the output voltage. Incorrect feedback loop design can lead to oscillations. Ensure that the compensation network is correctly designed and implemented.

- Inspect PCB Layout: A poor layout can introduce parasitic inductance and capacitance, which can destabilize the converter. Use a ground plane and keep the path between components short and direct.

Addressing Overheating Issues

Overheating is a serious issue that can lead to component failure. Here are some steps to address this problem:

- Evaluate Load Conditions: Ensure that the converter is not overloaded. Excessive current draw can lead to overheating.

- Improve Heat Dissipation: Utilize heat sinks or thermal pads on components that generate significant heat. Ensure proper airflow around the converter circuit.

- Check Switching Frequency: High switching frequencies can lead to increased heat generation. Adjust the frequency to an optimal level that balances efficiency and heat generation.

Reducing Noise and EMI

Noise and electromagnetic interference can affect not only the buck converter but also other devices in the vicinity. Here's how to mitigate these issues:

- Use Shielding: Enclose the buck converter in a metal case or employ shielding materials to prevent electromagnetic emissions.

- Implement Filter Circuits: Use input and output filters to block high-frequency noise. Components like ferrite beads can be used to suppress EMI.

- Optimize Switching Transitions: Use snubber circuits to control the voltage and current transients during switching, which can help reduce noise.

Improving Energy Efficiency

Energy efficiency is crucial for extending the battery life in portable devices and reducing power consumption in general. Consider these steps to enhance efficiency:

- Select Appropriate Components: Use components with low equivalent series resistance (ESR) for capacitors and low resistance for inductors.

- Optimize Dead Time: Adjust the dead time in the switching cycle to minimize losses due to shoot-through currents.

- Use Synchronous Rectification: Replace diode-based rectification with synchronous rectification to reduce conduction losses.

Final Thoughts

Debugging buck converter circuits requires a systematic approach to identify and resolve issues effectively. By understanding the common problems and applying the troubleshooting techniques discussed, engineers and hobbyists alike can enhance the performance and reliability of their buck converter designs. While buck converters are inherently complex, a well-tuned converter can provide efficient power conversion, ensuring the success of the overall electronic system.

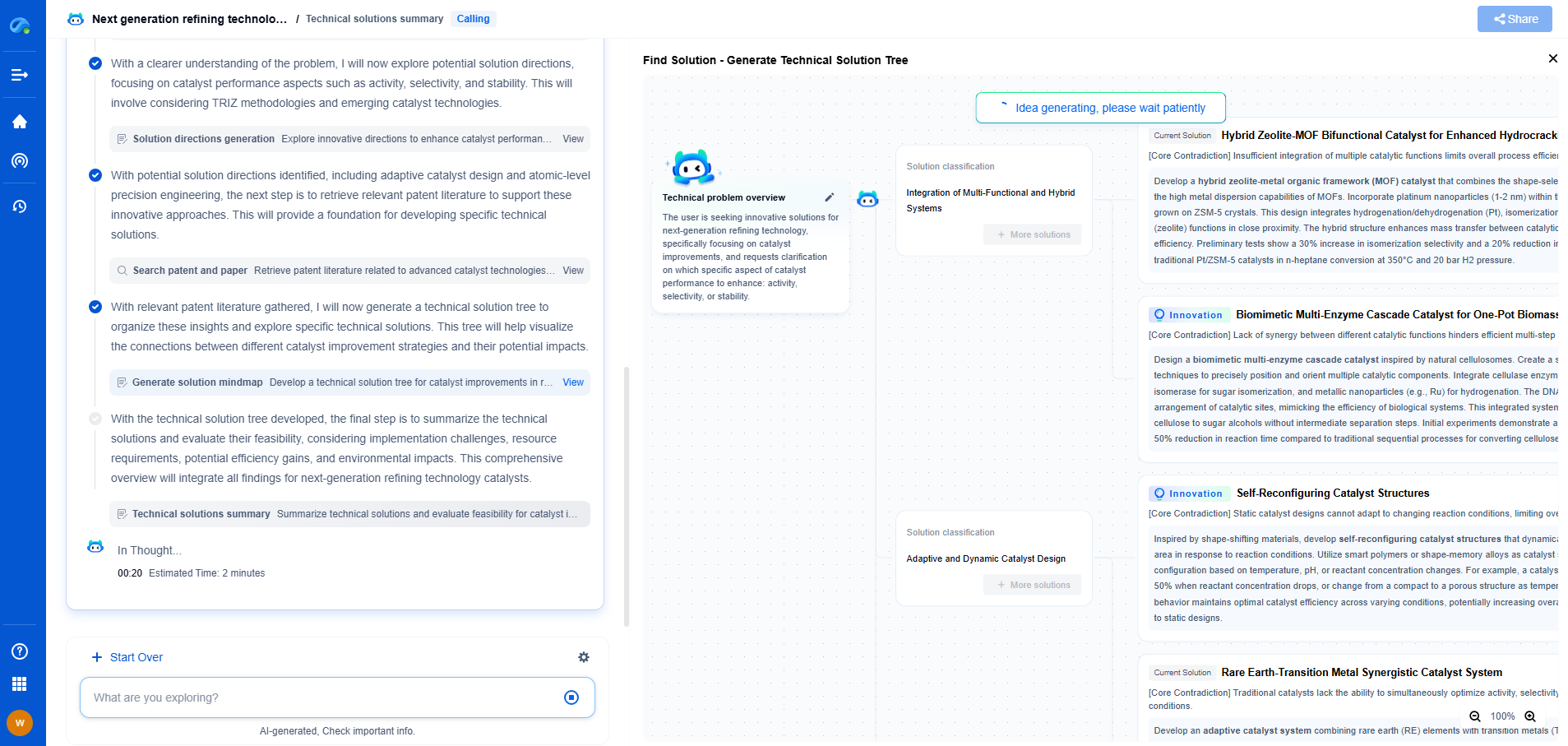

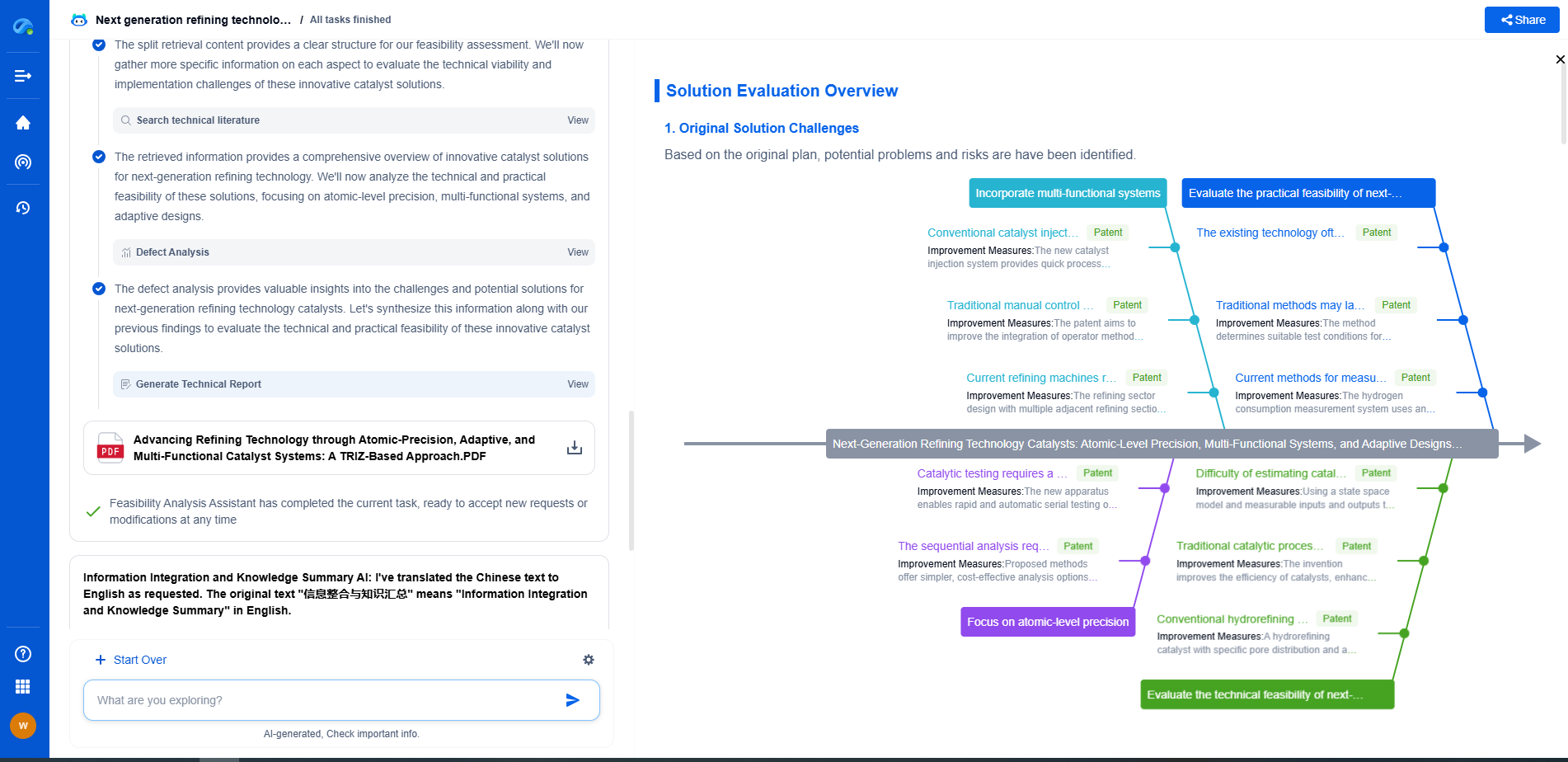

Accelerate Electronic Circuit Innovation with AI-Powered Insights from Patsnap Eureka

The world of electronic circuits is evolving faster than ever—from high-speed analog signal processing to digital modulation systems, PLLs, oscillators, and cutting-edge power management ICs. For R&D engineers, IP professionals, and strategic decision-makers in this space, staying ahead of the curve means navigating a massive and rapidly growing landscape of patents, technical literature, and competitor moves.

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

🚀 Experience the next level of innovation intelligence. Try Patsnap Eureka today and discover how AI can power your breakthroughs in electronic circuit design and strategy. Book a free trial or schedule a personalized demo now.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com