Design for Testability (DFT): Why It Matters in IC Development

JUN 27, 2025 |

Design for Testability (DFT) is an essential aspect of integrated circuit (IC) development that ensures the functionality and performance of a chip can be efficiently validated. In the competitive landscape of semiconductor manufacturing, the ability to test chips quickly and accurately is crucial for maintaining quality, minimizing costs, and accelerating time-to-market. By incorporating DFT principles into IC design, manufacturers can significantly enhance the testability of their products, leading to improved reliability and customer satisfaction.

The Importance of DFT in IC Development

DFT plays a critical role in IC development for several reasons. First and foremost, it helps identify potential defects or faults in the manufacturing process. As ICs become more complex, with billions of transistors on a single chip, the likelihood of errors increases. DFT techniques, such as scan chains and built-in self-test (BIST), allow engineers to detect and diagnose faults quickly, preventing defective products from reaching the market.

Additionally, DFT reduces testing time and costs. Traditional testing methods can be time-consuming and expensive, especially for complex IC designs. Incorporating DFT strategies enables more efficient testing procedures, reducing the need for costly equipment and lengthy testing processes. This efficiency translates to lower production costs and faster turnaround times, giving manufacturers a competitive edge.

Key DFT Techniques

Several techniques are commonly used in DFT to enhance the testability of ICs. One of the most widely used methods is the implementation of scan chains. Scan chains connect flip-flops within a circuit in a linear sequence, allowing for systematic testing of digital logic components. By shifting test patterns through the scan chain, engineers can detect faults within the circuit efficiently.

Another important DFT technique is Built-In Self-Test (BIST). BIST involves embedding test circuitry within the IC itself, enabling the chip to test its own functionality autonomously. This approach not only reduces the need for external testing equipment but also allows for continuous monitoring and testing during the chip’s operation, identifying faults that may occur post-manufacture.

Boundary scan is yet another technique that is particularly useful for testing interconnects between chips. By incorporating boundary scan cells along the input and output paths of a chip, engineers can test the connections between multiple ICs in a system, ensuring signal integrity and functionality.

Challenges in Implementing DFT

Despite its advantages, implementing DFT can present challenges to designers. One major challenge is the potential increase in design complexity and chip area. DFT features, like scan chains and BIST, require additional circuitry, which can lead to increased silicon area and power consumption. Designers must balance the benefits of DFT with the practical limitations of the IC design, finding ways to optimize the integration of testability features without compromising performance.

Moreover, DFT integration requires careful planning and design expertise. Ensuring that DFT components do not interfere with the chip's primary functionalities is crucial. Designers must have a deep understanding of both the IC’s architecture and the implications of DFT techniques to effectively implement testability without adversely affecting the overall design.

The Future of DFT in IC Development

As semiconductor technology continues to evolve, the role of DFT in IC development is likely to become even more critical. With the advent of advanced technologies such as 3D ICs and heterogeneous integration, ensuring testability will be paramount. DFT techniques will need to adapt to address new challenges presented by these emerging technologies, requiring ongoing innovation and refinement.

Moreover, the increasing complexity and miniaturization of ICs demand more sophisticated DFT solutions. Automation and machine learning may play a significant role in the future of DFT, offering dynamic and adaptive testing capabilities to meet the needs of next-generation chips.

Conclusion

Design for Testability is a vital component of modern IC development, providing the means to ensure quality, reliability, and cost-efficiency in manufacturing. By understanding and applying DFT principles, designers and manufacturers can improve product performance, reduce time-to-market, and gain a competitive advantage in the semiconductor industry. As technology advances, the importance of DFT will continue to grow, driving innovation and excellence in IC design and development.

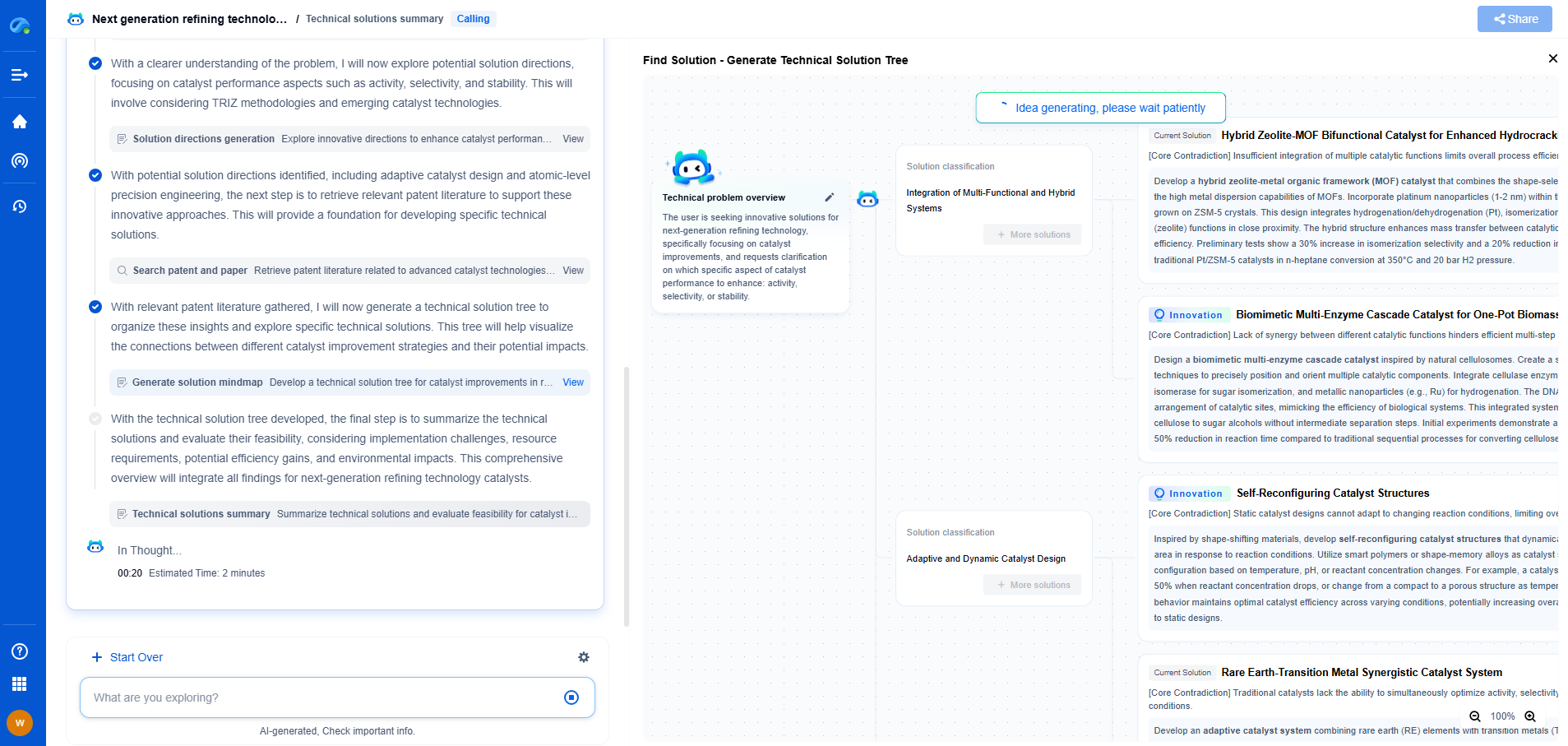

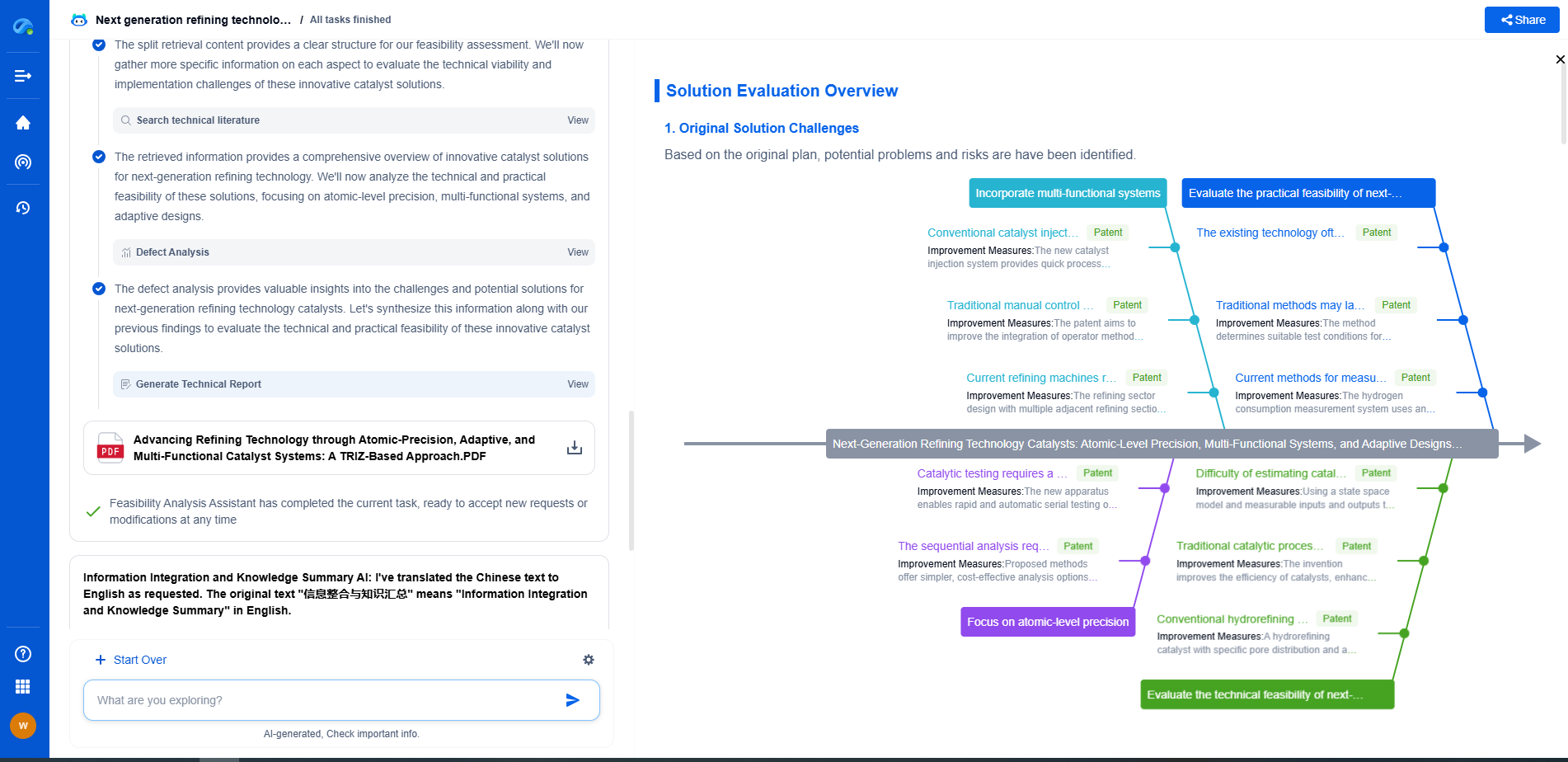

Accelerate Electronic Circuit Innovation with AI-Powered Insights from Patsnap Eureka

The world of electronic circuits is evolving faster than ever—from high-speed analog signal processing to digital modulation systems, PLLs, oscillators, and cutting-edge power management ICs. For R&D engineers, IP professionals, and strategic decision-makers in this space, staying ahead of the curve means navigating a massive and rapidly growing landscape of patents, technical literature, and competitor moves.

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

🚀 Experience the next level of innovation intelligence. Try Patsnap Eureka today and discover how AI can power your breakthroughs in electronic circuit design and strategy. Book a free trial or schedule a personalized demo now.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com