Edge AI in Manufacturing: Predictive Maintenance with 5G MEC

JUL 14, 2025 |

In recent years, the manufacturing sector has seen a surge in technological advancements. One of the most transformative concepts is Edge AI, which refers to the deployment of artificial intelligence (AI) applications at the edge of the network, closer to where data is generated. This approach reduces latency, improves response times, and enhances data processing efficiency. When combined with 5G Mobile Edge Computing (MEC), Edge AI is revolutionizing predictive maintenance, offering manufacturers new avenues to optimize operations and reduce downtime.

The Role of Predictive Maintenance in Manufacturing

Predictive maintenance is a strategy that involves monitoring equipment conditions in real-time to predict when maintenance should be performed. This approach contrasts with reactive maintenance (fixing equipment after it breaks) and preventive maintenance (regularly scheduled maintenance regardless of equipment condition). Predictive maintenance aims to reduce maintenance costs and downtime by addressing issues before they lead to equipment failure.

The Impact of 5G on Edge AI

5G technology plays a crucial role in the integration of Edge AI within manufacturing facilities. With its high-speed data transfer capabilities, ultra-reliable low-latency communication, and the ability to connect a vast number of devices simultaneously, 5G enhances the performance of Edge AI applications. It allows for seamless data exchange between sensors, machines, and AI models, facilitating rapid decision-making and precise analytics.

Benefits of Edge AI and 5G MEC in Predictive Maintenance

1. **Real-Time Data Processing**: Edge AI processes data locally, significantly reducing the time it takes to analyze data and make decisions. This real-time analysis is crucial for predictive maintenance, where delays could mean the difference between minor repairs and significant equipment failures.

2. **Reduced Latency and Downtime**: The combination of 5G MEC and Edge AI minimizes latency by processing data close to its source. This improvement leads to faster detection of potential issues and quicker implementation of corrective measures, thus reducing equipment downtime.

3. **Improved Efficiency and Cost Savings**: By predicting maintenance needs accurately, manufacturers can avoid unnecessary maintenance activities and allocate resources more efficiently. This optimization results in substantial cost savings and enhances overall operational efficiency.

4. **Scalability and Flexibility**: The modular nature of Edge AI systems and the expansive capabilities of 5G allow manufacturing setups to scale easily. Companies can adapt to changing production demands and integrate new technologies without significant disruptions.

Challenges and Considerations

While the benefits are significant, adopting Edge AI and 5G MEC for predictive maintenance is not without challenges. Manufacturers must consider the initial investment costs in infrastructure, the complexity of integrating with existing systems, and potential cybersecurity risks. Furthermore, there is a need for skilled personnel who can manage and maintain these advanced systems.

Future Outlook

The future of Edge AI in manufacturing, bolstered by 5G MEC, looks promising. As technology continues to evolve, we can expect even more sophisticated predictive maintenance solutions that will further streamline manufacturing processes. The integration of AI with IoT devices will enable more comprehensive data collection and analysis, leading to smarter, more autonomous manufacturing environments.

Conclusion

Edge AI combined with 5G MEC is set to redefine predictive maintenance in manufacturing. By harnessing the power of real-time data processing and enhanced connectivity, manufacturers can achieve unprecedented levels of efficiency and reliability. As the industry continues to embrace these innovations, the potential for increased productivity and reduced operational costs becomes a tangible reality. The journey towards smarter manufacturing has begun, and those who adapt will lead the charge into a new era of industrial excellence.

From 5G NR to SDN and quantum-safe encryption, the digital communication landscape is evolving faster than ever. For R&D teams and IP professionals, tracking protocol shifts, understanding standards like 3GPP and IEEE 802, and monitoring the global patent race are now mission-critical.

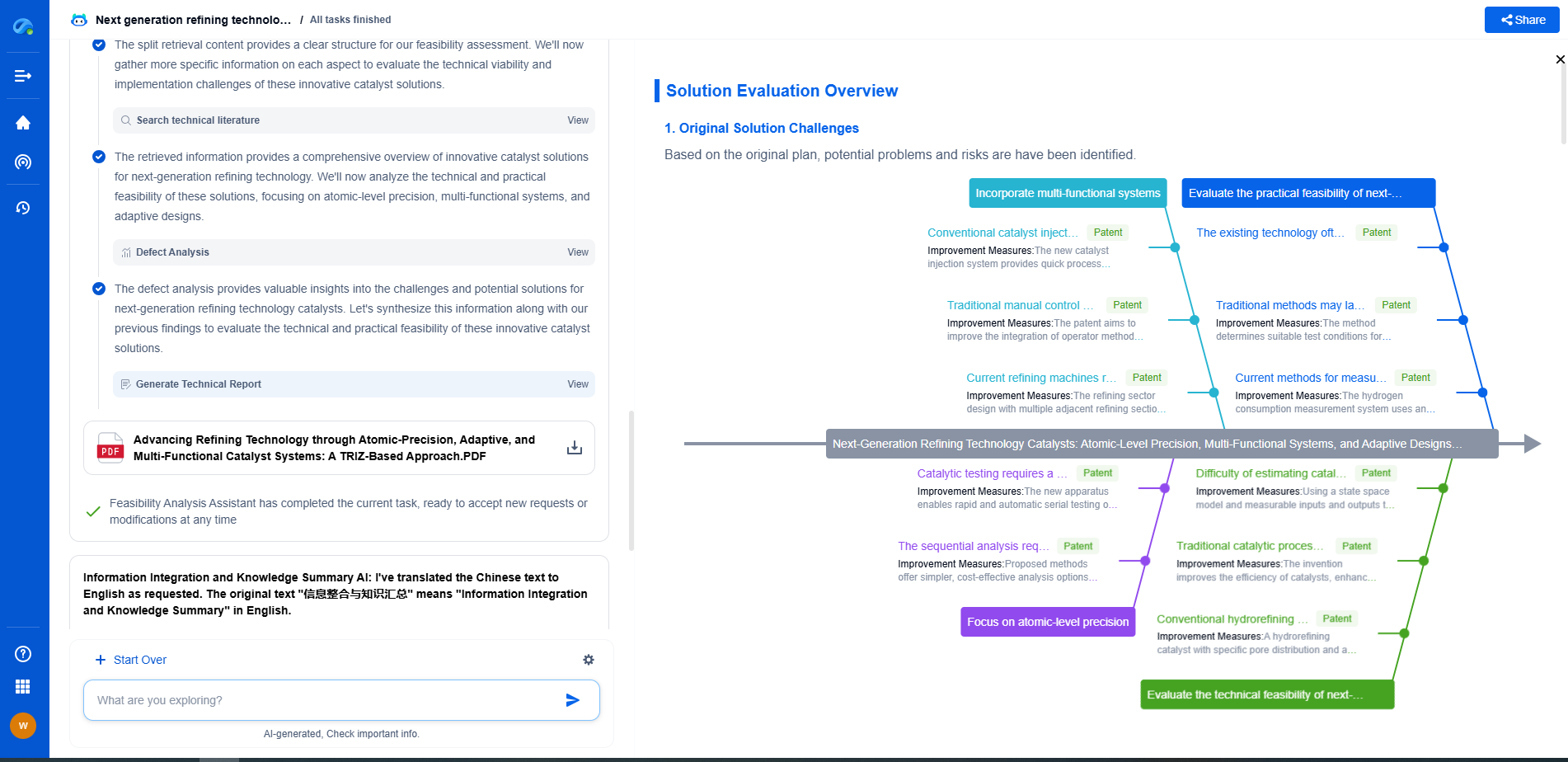

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

📡 Experience Patsnap Eureka today and unlock next-gen insights into digital communication infrastructure, before your competitors do.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com