EMC Testing for Power Converters: IEC 61000-6 Series Guide

JUN 26, 2025 |

Understanding Electromagnetic Compatibility (EMC)

EMC is the ability of electrical equipment to function satisfactorily in its electromagnetic environment without introducing intolerable electromagnetic disturbances to anything in that environment. For power converters, achieving EMC compliance is crucial as they are often used in environments replete with potential sources of electromagnetic interference (EMI), such as industrial machines, communication devices, and other electronic equipment.

The Importance of EMC Testing for Power Converters

Power converters are integral to a wide range of applications, from industrial automation and renewable energy systems to consumer electronics. EMC testing ensures that these devices do not disrupt other equipment and are themselves immune to external electromagnetic influences. This not only protects the functionality and performance of the power converters but also safeguards other critical systems in their vicinity.

Overview of the IEC 61000-6 Series

The IEC 61000-6 series of standards specifically addresses EMC requirements for equipment used in various environments. The series is structured to cover both emission and immunity requirements, targeting specific operational environments to ensure comprehensive assessment and compliance.

IEC 61000-6-1: General Immunity for Residential, Commercial, and Light-Industrial Environments

This standard outlines the immunity requirements for equipment intended for use in residential, commercial, and light-industrial environments. It specifies the electromagnetic phenomena to which equipment must be immune, including electrostatic discharge, radiated and conducted electromagnetic disturbances, and power frequency magnetic fields. For power converters, compliance with IEC 61000-6-1 ensures they can withstand common electromagnetic disturbances found in these everyday settings.

IEC 61000-6-2: General Immunity for Industrial Environments

Power converters used in industrial environments face more severe electromagnetic challenges. IEC 61000-6-2 sets the immunity requirements for such environments, where stronger electromagnetic fields and transient disturbances are common. This standard is crucial for ensuring that power converters perform reliably in the robust electromagnetic environments typical of industrial settings.

IEC 61000-6-3: General Emission Standard for Residential, Commercial, and Light-Industrial Environments

While immunity deals with a device's ability to withstand interference, emission standards focus on the control of electromagnetic emissions produced by the device itself. IEC 61000-6-3 specifies limits for emissions to prevent interference with other equipment in residential, commercial, and light-industrial environments. This ensures that a power converter does not emit excessive electromagnetic energy that could disrupt nearby devices.

IEC 61000-6-4: General Emission Standard for Industrial Environments

This standard provides emission requirements for equipment used in industrial environments. Given the high density of electrical equipment in such settings, controlling emissions is essential to maintain a harmonious electromagnetic environment. By adhering to IEC 61000-6-4, power converters can operate without causing unwanted electromagnetic disturbances in industrial applications.

Implementing EMC Testing for Power Converters

EMC testing for power converters involves a series of tests to evaluate their compliance with the relevant IEC 61000-6 standards. These tests typically include:

1. **Radiated Emission Testing**: Measures the electromagnetic energy emitted by the converter and ensures it falls within acceptable limits.

2. **Conducted Emission Testing**: Assesses the electromagnetic energy conducted along power lines and other connections.

3. **Immunity Testing**: Evaluates the converter's resilience to electromagnetic disturbances, including electrostatic discharge, voltage dips, and electromagnetic fields.

4. **Harmonics and Flicker Testing**: Ensures that the power converter does not introduce unacceptable levels of harmonic distortion or voltage fluctuations into the power network.

Challenges and Best Practices

EMC testing can be complex, requiring specialized equipment and expertise. One of the challenges in testing power converters is managing the diverse operating conditions they may encounter. Best practices include:

- **Comprehensive Testing**: Conduct tests under various load conditions and environmental scenarios to ensure robust performance.

- **Early Integration**: Incorporate EMC considerations early in the design process to minimize costly redesigns and delays.

- **Iterative Testing**: Utilize iterative testing and design refinement to address any EMC issues detected during initial assessments.

Conclusion

The IEC 61000-6 series provides a structured approach for assessing the EMC performance of power converters. By adhering to these standards, manufacturers can ensure their products operate reliably and coexist peacefully with other electronic systems. EMC testing is not just a regulatory requirement; it is a commitment to quality and reliability that ultimately benefits both manufacturers and end-users.

Stay Ahead in Power Systems Innovation

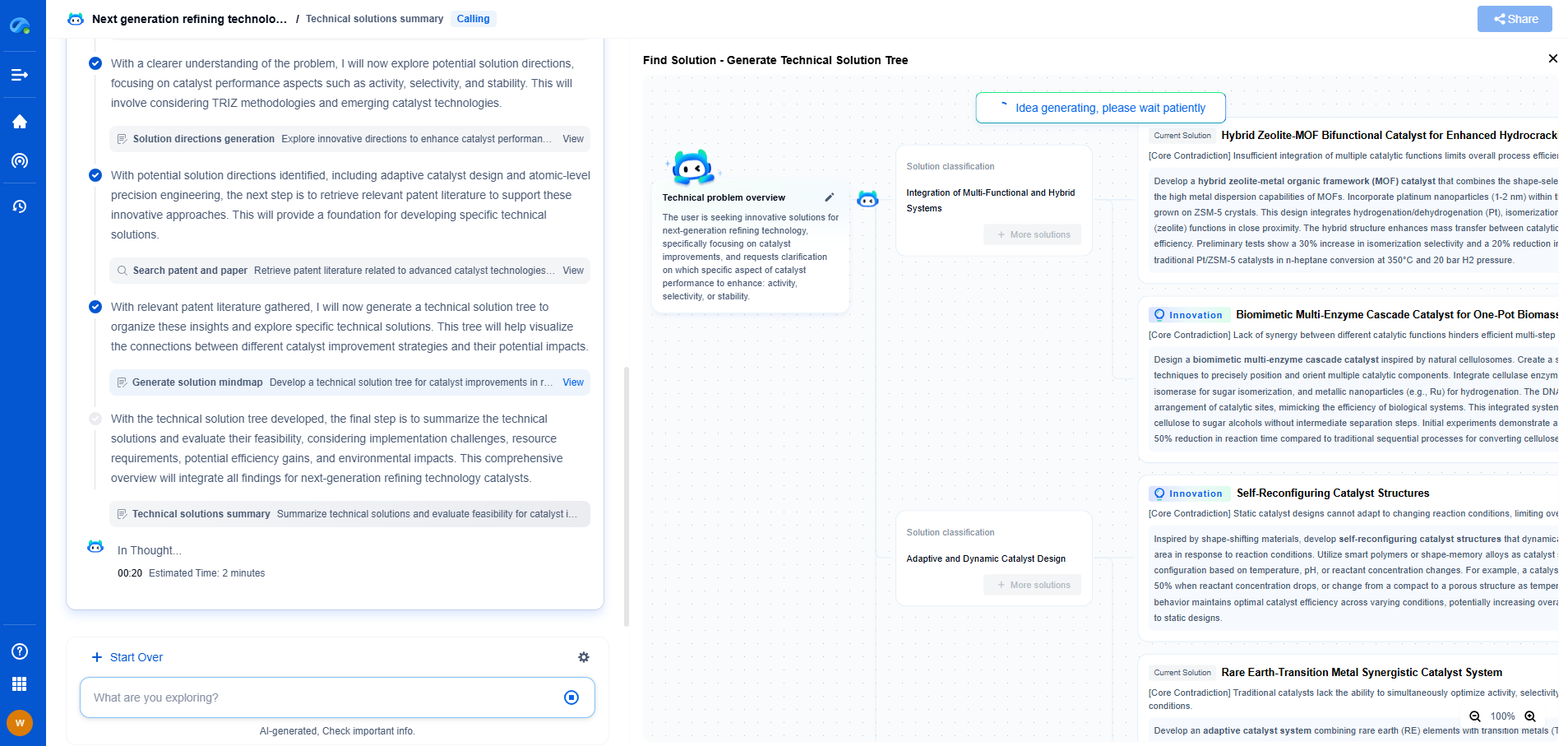

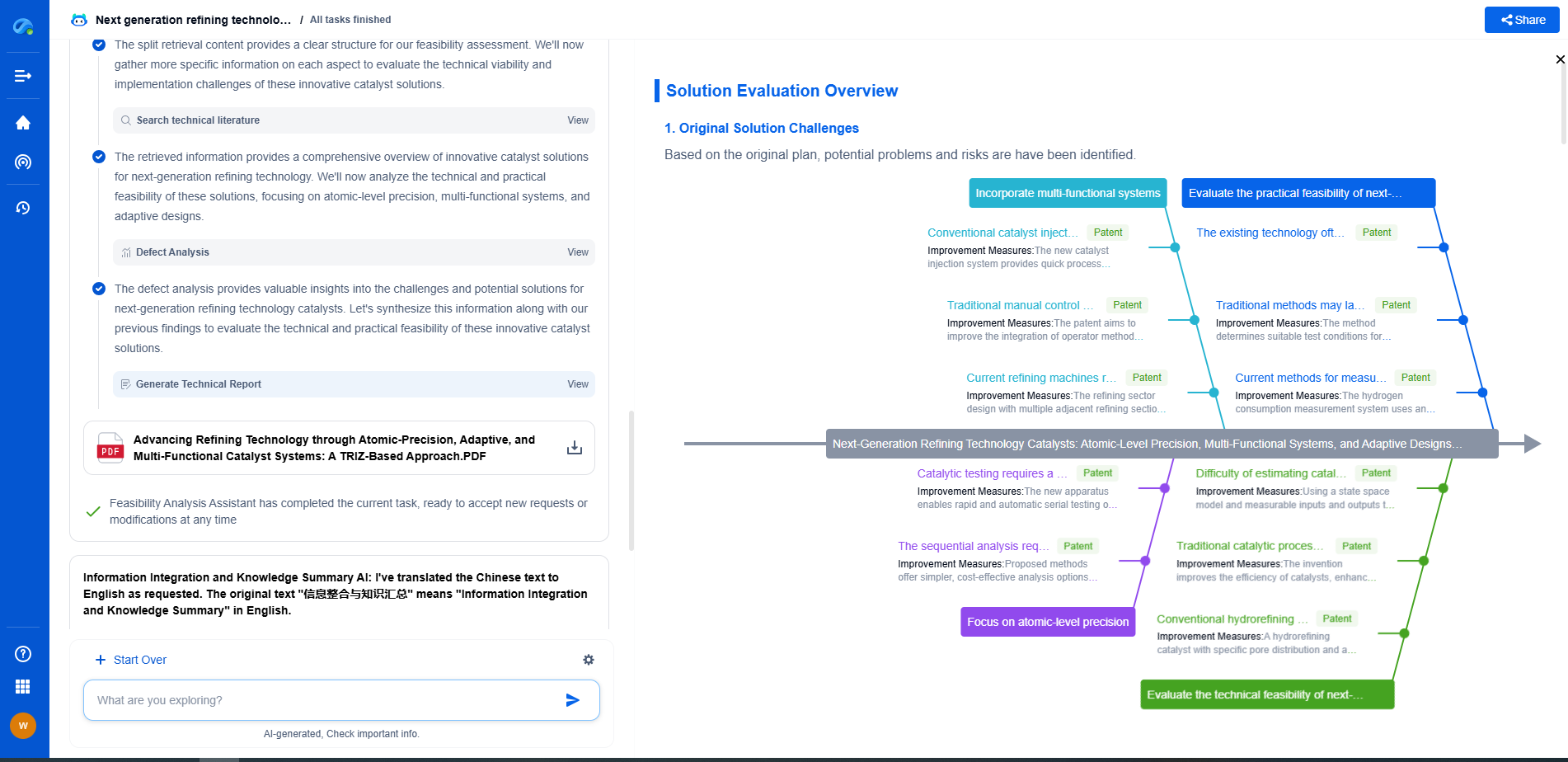

From intelligent microgrids and energy storage integration to dynamic load balancing and DC-DC converter optimization, the power supply systems domain is rapidly evolving to meet the demands of electrification, decarbonization, and energy resilience.

In such a high-stakes environment, how can your R&D and patent strategy keep up?

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

👉 Experience how Patsnap Eureka can supercharge your workflow in power systems R&D and IP analysis. Request a live demo or start your trial today.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com