Flywheel vs Compressed Air Energy Storage: Response Time & Efficiency Compared

JUN 26, 2025 |

As the world pivots towards renewable energy sources, efficient and responsive energy storage systems have become critical in ensuring grid stability and reliability. Among the myriad of energy storage solutions, Flywheel Energy Storage (FES) and Compressed Air Energy Storage (CAES) have gained attention for their unique characteristics and applications. This article delves into the response time and efficiency of these two systems, offering a comparative analysis that could guide stakeholders in making informed decisions.

Understanding Flywheel Energy Storage

Flywheel Energy Storage systems store energy in the form of rotational kinetic energy. A flywheel is a rotating mechanical device that is adept at storing rotational energy. When power is supplied to the flywheel, its rotor accelerates, and the energy is stored. Conversely, when the power is extracted, the rotor decelerates, transferring its energy back to the grid.

Response Time

One of the standout features of flywheel systems is their rapid response time. With the ability to respond in milliseconds, flywheels are ideal for applications requiring quick bursts of energy. This responsiveness is attributable to the mechanical nature of energy storage and retrieval, which does not rely on chemical processes or lengthy mechanical operations. This makes flywheels effective in stabilizing frequency and providing short-term grid support.

Efficiency

Flywheel systems boast round-trip efficiencies ranging from 85% to 95%. This high efficiency is due to minimal energy losses during the mechanical energy transfer processes. Although the efficiency can be affected by friction and air resistance, technological advancements, such as the use of magnetic bearings and vacuum environments, have significantly mitigated these losses, enhancing overall system performance.

Exploring Compressed Air Energy Storage

Compressed Air Energy Storage involves compressing air and storing it in underground caverns or large vessels. During peak energy demand, the compressed air is released, heated, and expanded through turbines to generate electricity. CAES systems are particularly well-suited for long-duration energy storage and can store energy for extended periods.

Response Time

The response time for CAES systems is generally slower compared to flywheels. The time required to retrieve energy from CAES can range from a few minutes to several hours, depending on the system configuration and operational readiness. While this response time is not as quick as flywheels, CAES is still valuable for applications where rapid energy deployment is not critical.

Efficiency

The efficiency of CAES systems is typically lower than that of flywheels, with round-trip efficiencies ranging from 40% to 70%. The lower efficiency is primarily due to energy losses during the compression and expansion processes, as well as the need for additional fuel to heat the compressed air. However, innovations such as Advanced Adiabatic CAES are being explored to improve efficiency by recycling the heat generated during compression.

Comparative Analysis: Flywheel vs. CAES

When evaluating flywheel and CAES systems, several factors come into play: response time, efficiency, capacity, and application suitability.

1. Response Time: Flywheels clearly outperform CAES in terms of response time, making them the preferred choice for applications needing instantaneous energy delivery and frequency regulation.

2. Efficiency: Flywheels also generally offer higher efficiency than CAES systems. This makes them more advantageous for applications where high round-trip efficiency is vital.

3. Capacity and Duration: In contrast, CAES systems can store large amounts of energy for longer durations, making them suitable for bulk energy storage and applications requiring sustained energy output over extended periods.

4. Application Suitability: Flywheels are ideal for grid stabilization, frequency regulation, and applications needing rapid energy delivery. CAES, on the other hand, is more suited for load leveling, large-scale energy storage, and balancing intermittent renewable energy sources like wind and solar.

Conclusion

Both Flywheel Energy Storage and Compressed Air Energy Storage offer distinct advantages and drawbacks, shaping their applicability in different energy storage scenarios. Flywheels, with their swift response time and high efficiency, are well-suited for applications requiring rapid energy discharge. CAES, with its large storage capacity, is ideal for longer-term energy supply solutions. As technology continues to advance, both systems will likely play significant roles in the evolving landscape of energy storage solutions, each complementing the other in a balanced energy ecosystem.

Stay Ahead in Power Systems Innovation

From intelligent microgrids and energy storage integration to dynamic load balancing and DC-DC converter optimization, the power supply systems domain is rapidly evolving to meet the demands of electrification, decarbonization, and energy resilience.

In such a high-stakes environment, how can your R&D and patent strategy keep up?

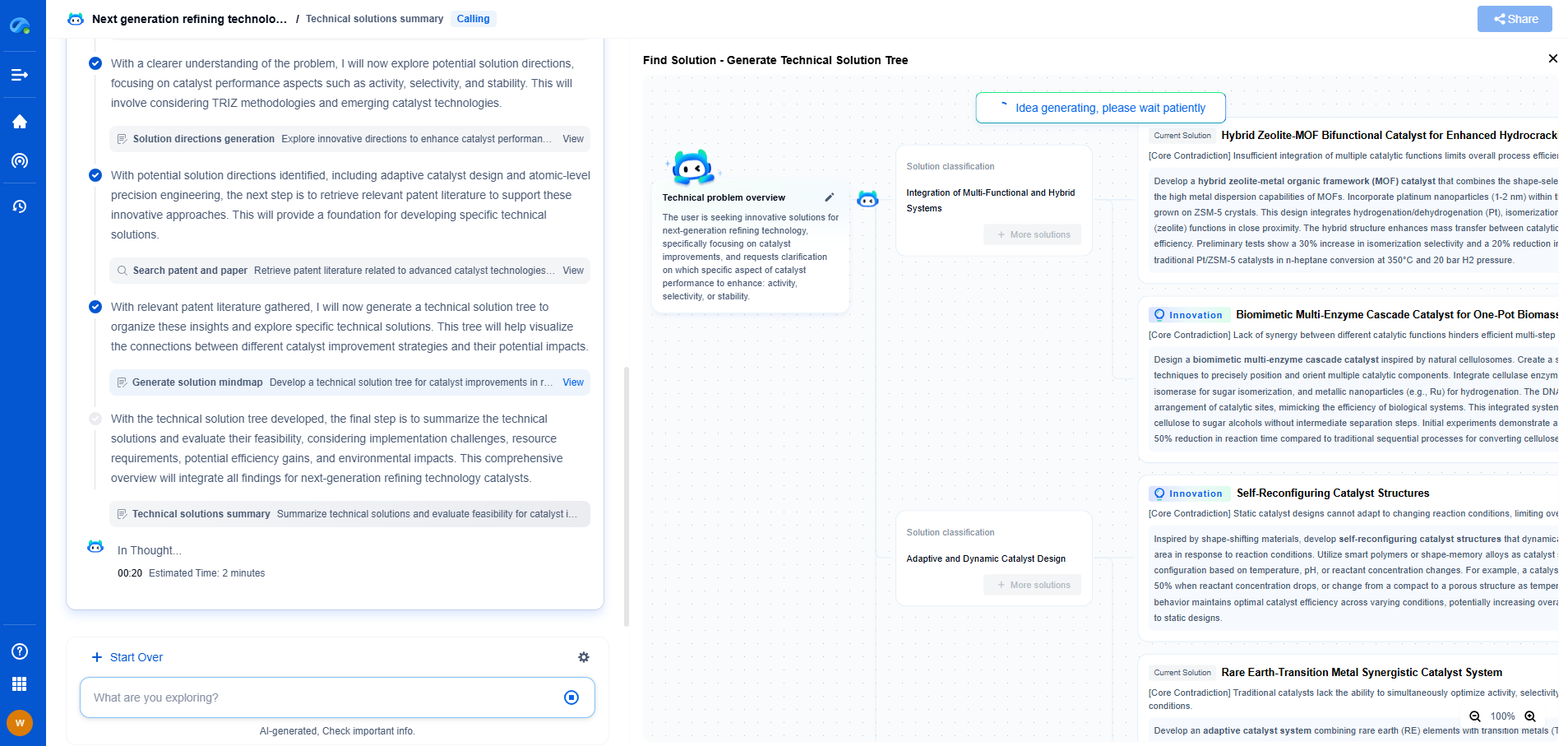

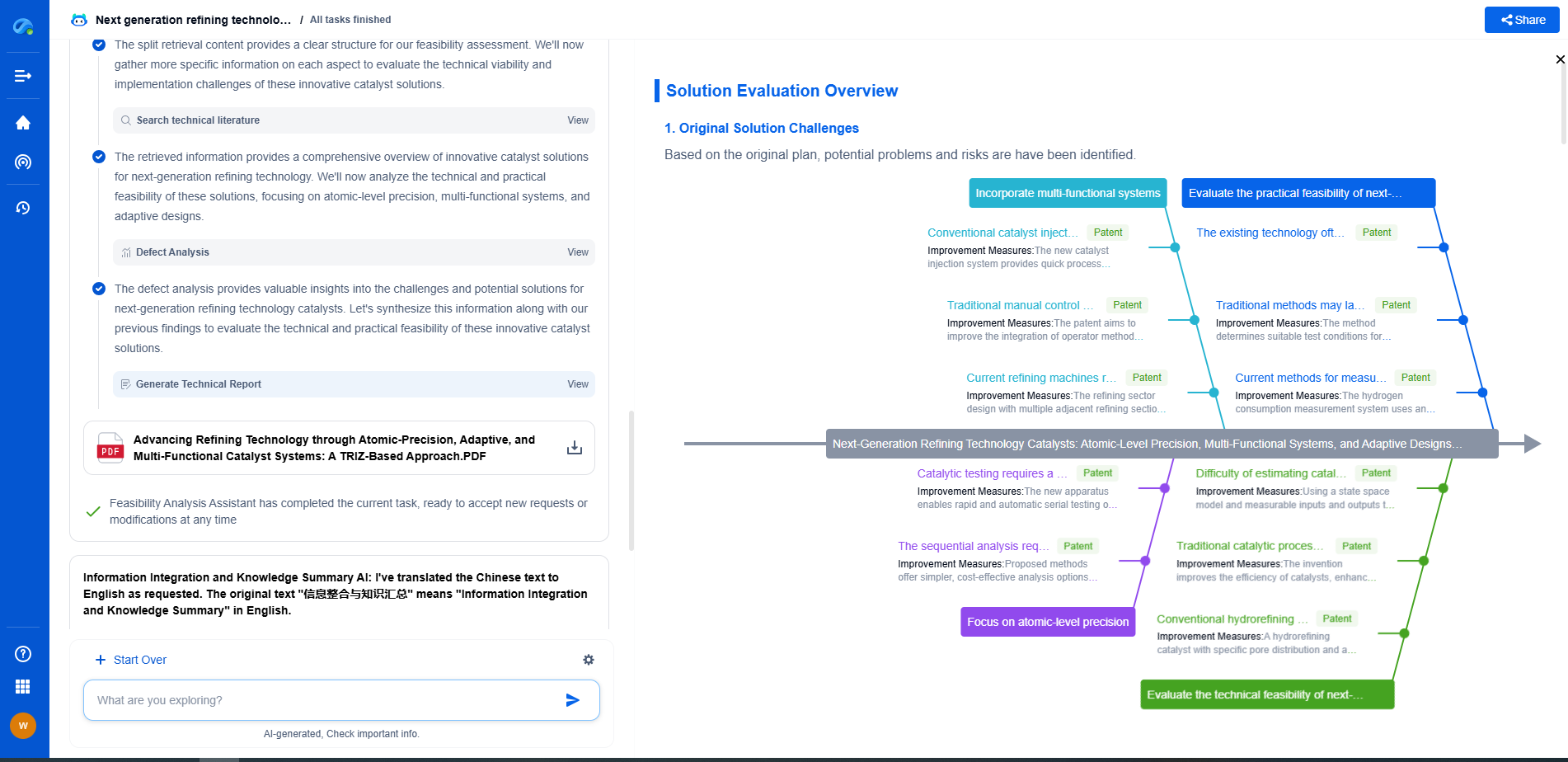

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

👉 Experience how Patsnap Eureka can supercharge your workflow in power systems R&D and IP analysis. Request a live demo or start your trial today.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com