Grounding Design Changes for NEC Article 250 Compliance

JUN 26, 2025 |

The National Electrical Code (NEC) is a cornerstone of electrical safety and design in the United States, and Article 250 specifically addresses grounding and bonding requirements. Grounding is essential for safety, protecting people and equipment from electrical faults by providing a path for fault current to travel safely to the earth. It is crucial for engineers, electricians, and designers to understand the changes related to grounding requirements as specified in NEC Article 250 to ensure compliance and enhance safety.

Key Changes in NEC Article 250

The NEC undergoes periodic revisions to incorporate new safety requirements and technological advancements. Recent changes to Article 250 have introduced modifications affecting grounding system designs. One significant addition is the requirement for grounding electrode systems to include at least one supplemental electrode, such as ground rods or metallic water pipes, to ensure redundancy and reliability in grounding.

Another notable change involves adjustments in sizing grounding electrode conductors. The NEC now specifies more detailed criteria for determining the appropriate size based on the type of grounding electrode used. This ensures that the conductor can carry fault current safely without overheating or breaking.

Design Considerations for Grounding Systems

To design a compliant and effective grounding system, several essential considerations must be addressed. First, it is important to identify all available grounding electrode sources present at the site. Common options include metal underground water pipes, building steel, and ground rods. Each of these options must be evaluated for its conductivity and durability to serve as a reliable grounding electrode.

Next, designers need to consider the path of grounding electrode conductors, making sure they are as straight and short as possible to minimize impedance. The reduction in impedance is crucial for ensuring that fault currents are rapidly and effectively diverted to the earth.

Lastly, the proper materials for grounding conductors and connections must be selected. Corrosion-resistant materials such as copper and aluminum are preferred, as they ensure long-term functionality and compliance with NEC requirements. Additionally, all connections should be tested for continuity and mechanical stability to verify that they meet code requirements and provide a secure path for fault current.

Safety and Compliance: The Role of Inspections and Testing

Regular inspections and testing are integral to maintaining compliance with NEC Article 250. Following the installation of a grounding system, thorough testing should be conducted to measure the resistance of grounding electrodes. This testing verifies that the resistance is within acceptable limits, ensuring the system can effectively handle fault currents.

Periodic inspections should be scheduled to identify any potential issues such as corrosion, damage, or loosened connections that may compromise the grounding system's effectiveness. Addressing these issues promptly is vital for maintaining a safe electrical environment.

Conclusion: Embracing NEC Article 250 for Safer Designs

NEC Article 250 serves as a crucial guide for designing grounding systems that protect both people and equipment from electrical hazards. By understanding recent changes and incorporating them into grounding designs, engineers and electricians can enhance safety and ensure compliance. Regular testing and inspections further solidify the reliability of these systems, safeguarding against potential electrical faults. As the electrical industry continues to evolve, staying informed about NEC updates will remain a key responsibility for all professionals involved in electrical design and installation.

Stay Ahead in Power Systems Innovation

From intelligent microgrids and energy storage integration to dynamic load balancing and DC-DC converter optimization, the power supply systems domain is rapidly evolving to meet the demands of electrification, decarbonization, and energy resilience.

In such a high-stakes environment, how can your R&D and patent strategy keep up?

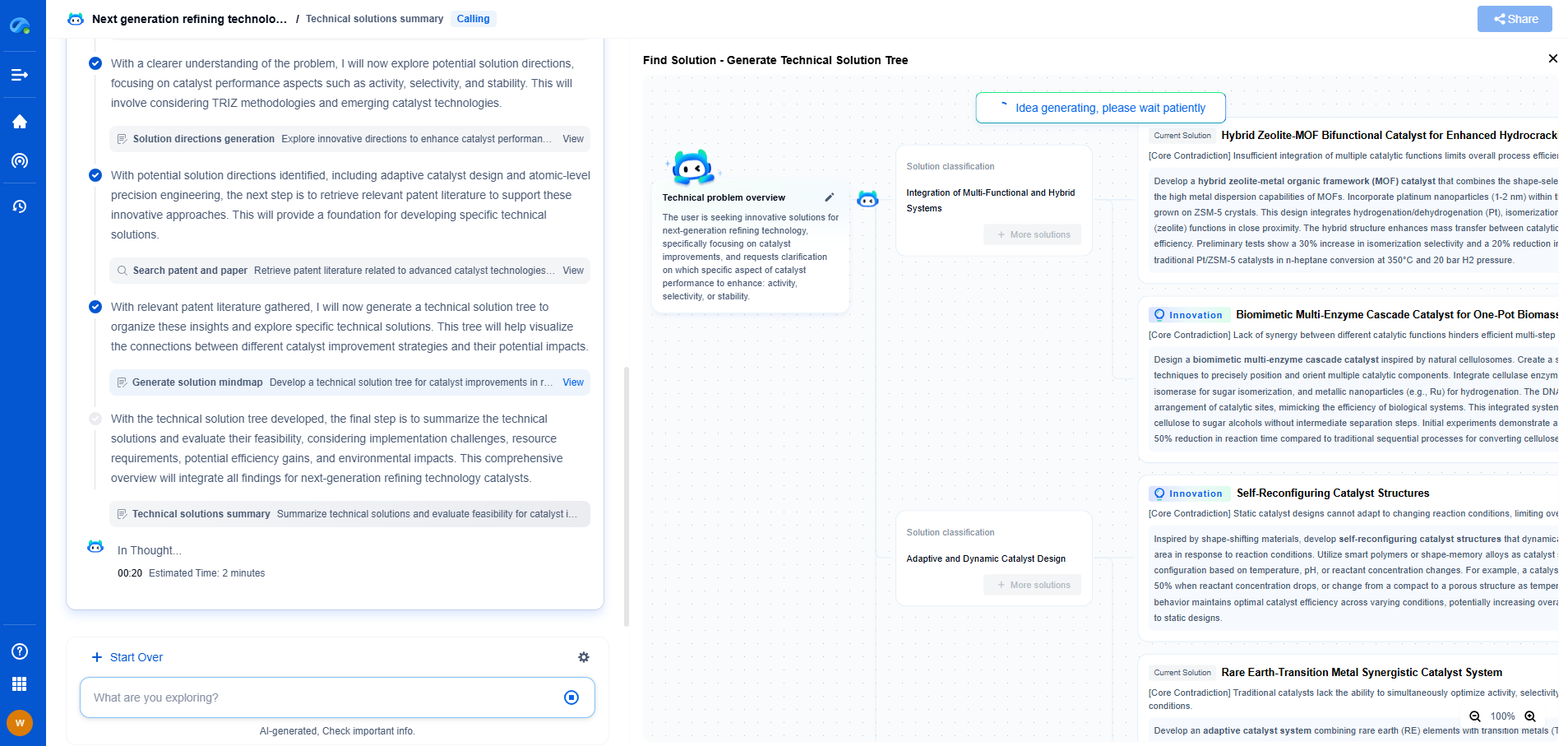

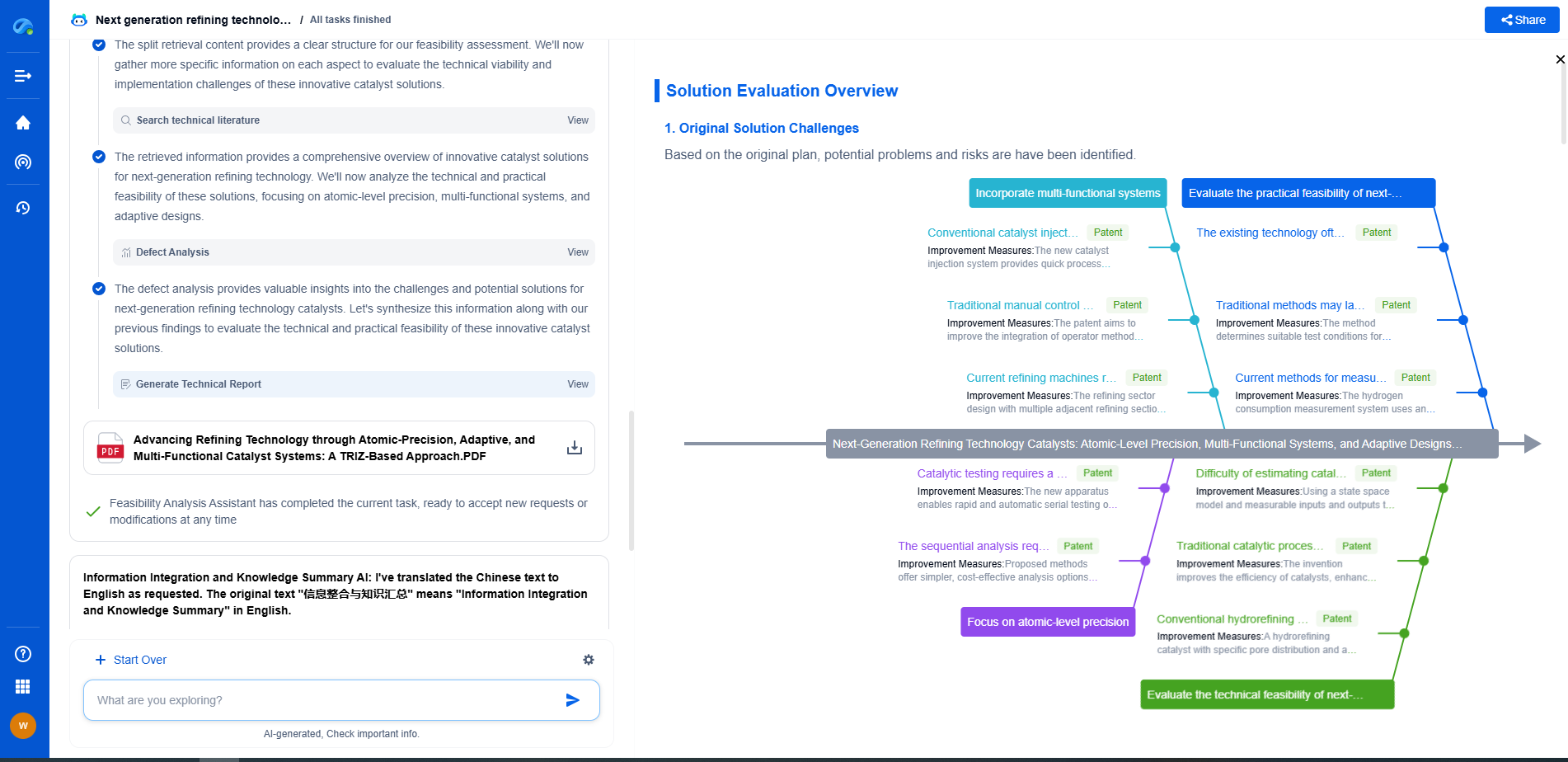

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

👉 Experience how Patsnap Eureka can supercharge your workflow in power systems R&D and IP analysis. Request a live demo or start your trial today.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com