How Do Diesel Generators Work as Backup Power Sources?

JUN 26, 2025 |

Diesel generators are essential backup power sources that provide electricity during power outages. They are widely used in various industries, businesses, and residential areas to ensure a continuous power supply. Understanding how diesel generators work can help in maximizing their efficiency and reliability.

The Basic Components of Diesel Generators

Diesel generators consist of several key components that work together to produce electricity. The main components include the diesel engine, alternator, fuel system, voltage regulator, cooling and exhaust systems, lubrication system, battery charger, control panel, and main assembly/frame. Each of these components plays a crucial role in ensuring the generator's optimal performance.

The Diesel Engine

The diesel engine is the core component of a diesel generator. It converts the chemical energy in diesel fuel into mechanical energy through combustion. The engine's size largely determines the generator's power output, with engines ranging from small, single-cylinder units to large, multi-cylinder models. Diesel engines are preferred for their durability, efficiency, and ability to generate large amounts of power.

The Alternator

The alternator is responsible for converting the mechanical energy produced by the diesel engine into electrical energy. It consists of a rotor and a stator. When the engine runs, it spins the rotor, creating a magnetic field that induces an electric current in the stator windings. This process generates the electricity needed to power appliances and equipment.

Fuel System

The fuel system in a diesel generator stores and supplies the diesel fuel necessary for the engine to operate. It typically includes a fuel tank, fuel lines, a fuel pump, and injectors. The fuel pump delivers the fuel from the tank to the engine, while the injectors spray the fuel into the combustion chamber for efficient burning.

Voltage Regulator

The voltage regulator keeps the generator's output voltage stable. It monitors the generator's output and adjusts the excitation current to the alternator's rotor to maintain a consistent voltage level. This ensures that the electrical devices connected to the generator receive a steady and reliable power supply.

Cooling and Exhaust Systems

Diesel generators produce a significant amount of heat during operation. The cooling system helps dissipate this heat to prevent the engine from overheating. It typically includes a radiator, coolant pump, and cooling fans. Simultaneously, the exhaust system safely removes the gases produced during combustion, keeping the generator environment safe and functional.

Lubrication System

The lubrication system ensures that all moving parts of the engine are well-lubricated, reducing friction and wear. It includes an oil pump, oil filter, and oil cooler. Proper lubrication is essential for maintaining the generator’s performance and prolonging its lifespan.

Battery Charger

A battery charger is used to keep the generator's starter battery charged. The battery is crucial for starting the generator, and the charger ensures it remains in optimal condition, ready to start the engine whenever needed.

Control Panel

The control panel is the generator's interface, allowing users to monitor and control various parameters. It typically includes controls for starting and stopping the generator, as well as indicators for parameters such as voltage, current, and frequency. Advanced control panels may offer additional features like remote monitoring and automatic transfer switch integration.

Main Assembly/Frame

The main assembly or frame of the generator houses all the components and provides structural support. It is designed to be robust and durable to withstand the generator's operational stresses and environmental conditions.

How Diesel Generators Work

When the main power supply fails, the diesel generator's automatic transfer switch (if equipped) detects the outage and starts the engine. The engine then drives the alternator, converting mechanical energy into electrical energy. The generated electricity is delivered through the generator's output terminals, ready to power connected devices and systems. Once the main power supply is restored, the generator will shut down, and the transfer switch will revert to the main power source.

Maintenance and Efficiency

Regular maintenance is crucial for ensuring the reliability and efficiency of diesel generators. Routine checks should include inspecting the fuel system, cooling system, and lubrication system, as well as testing the battery and control panel functionalities. Proper maintenance not only ensures optimal performance but also extends the generator's lifespan.

Conclusion

Diesel generators are a reliable and efficient solution for backup power needs. Understanding their components and operation allows users to maximize their benefits and ensure a steady power supply during outages. With proper maintenance and care, diesel generators can serve as dependable sources of electricity when it's needed most.

Stay Ahead in Power Systems Innovation

From intelligent microgrids and energy storage integration to dynamic load balancing and DC-DC converter optimization, the power supply systems domain is rapidly evolving to meet the demands of electrification, decarbonization, and energy resilience.

In such a high-stakes environment, how can your R&D and patent strategy keep up?

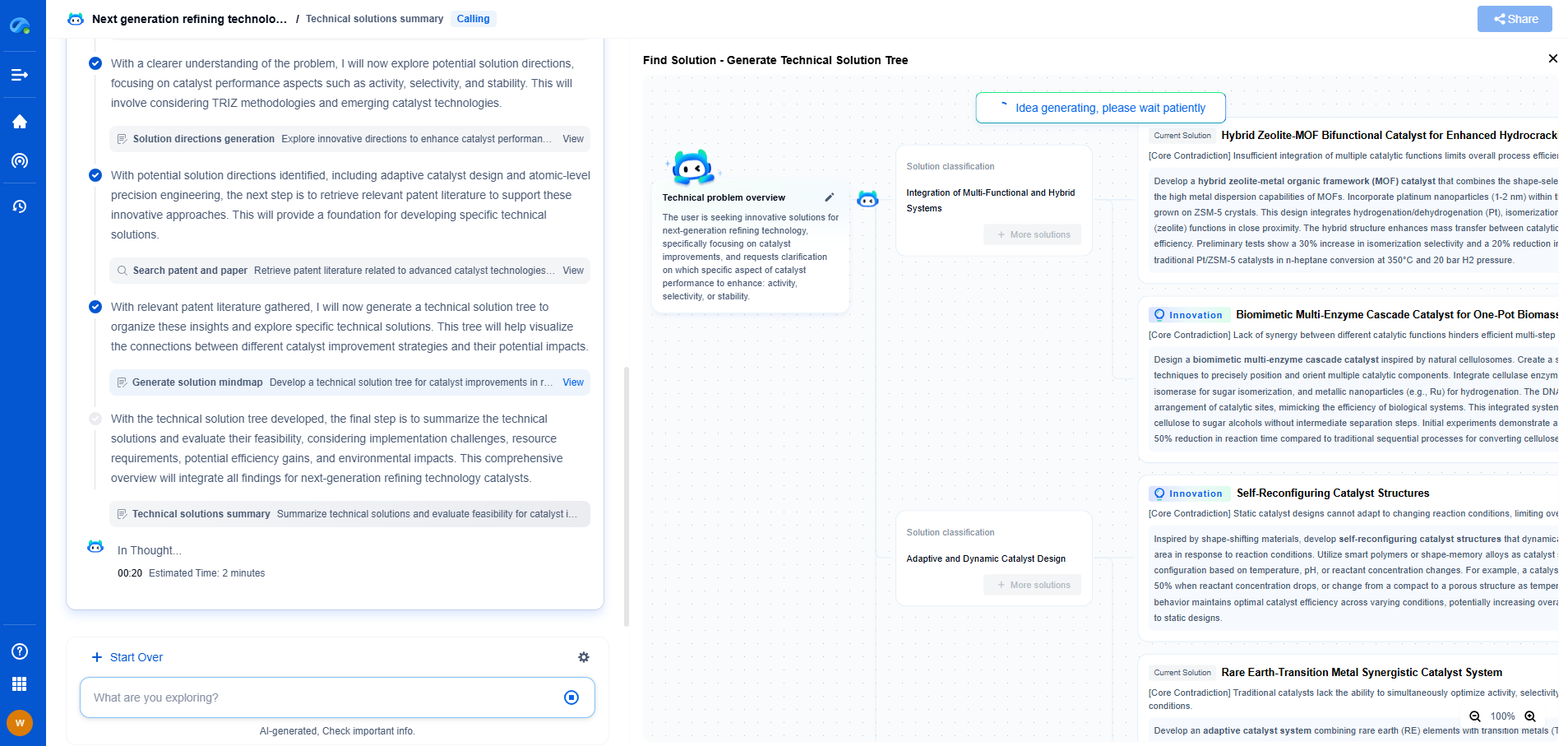

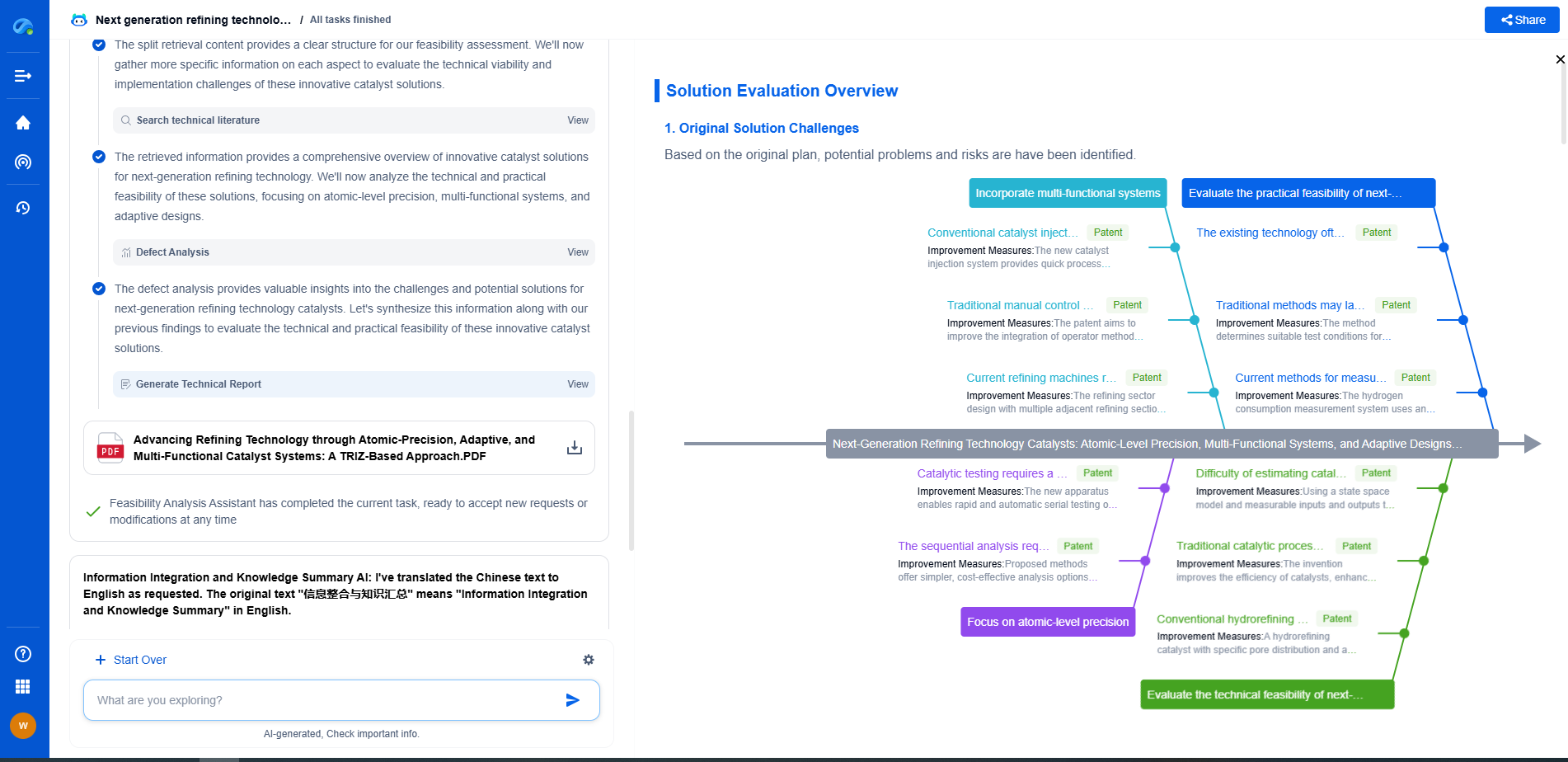

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

👉 Experience how Patsnap Eureka can supercharge your workflow in power systems R&D and IP analysis. Request a live demo or start your trial today.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com