How Does EMI Shielding Work in Electronic Devices?

JUN 27, 2025 |

Electromagnetic interference (EMI) is an ever-present concern in the world of electronics. As technology advances and the proliferation of electronic devices continues, managing the noise and interference generated by these devices has become crucial. EMI shielding is a technique used to protect sensitive electronics from external electromagnetic fields and to prevent devices from emitting unwanted electromagnetic radiation. But how does it work, and why is it so important?

The Basics of Electromagnetic Interference

Before diving into the specifics of EMI shielding, it's important to understand what electromagnetic interference is. EMI is a disturbance generated by an external source that affects an electrical circuit. This interference can degrade the performance of the circuit or even lead to complete device failure. EMI can be generated by a variety of sources, including natural phenomena like lightning and man-made sources such as motors, machinery, and other electronic devices.

The Purpose of EMI Shielding

In essence, EMI shielding serves two main purposes: to prevent external interference from disrupting the performance of an electronic device and to stop the device from interfering with other electronics. In both cases, the goal is to maintain the integrity and functionality of electronic systems in environments where various electromagnetic fields are present.

Materials Used in EMI Shielding

EMI shielding is often achieved using materials that can effectively block or attenuate electromagnetic fields. These materials typically have good electrical conductivity and magnetic permeability. Common materials used for EMI shielding include:

1. **Metals**: Metals like copper, aluminum, and steel are widely used because of their excellent conductivity and ability to reflect electromagnetic waves. These materials can be formed into thin sheets or meshes to cover electronic components.

2. **Conductive Plastics**: These are polymers imbued with conductive fillers such as carbon fibers or metal particles. Conductive plastics are lightweight and can be molded into intricate shapes, making them ideal for modern electronics design.

3. **Conductive Fabrics**: These fabrics are woven from threads coated with metals like nickel or silver. They are flexible and can be used to cover irregularly shaped objects or electronic enclosures.

Mechanisms of EMI Shielding

EMI shielding works primarily through three mechanisms: reflection, absorption, and multiple reflections.

1. **Reflection**: This is the most common mechanism and occurs when electromagnetic waves are reflected off the surface of the shielding material. The reflective nature of metals makes them particularly effective at this, as they create a barrier that prevents waves from penetrating.

2. **Absorption**: Some materials absorb electromagnetic waves and convert the energy into heat. The absorbed energy is dissipated before it can affect the protected device. This mechanism is especially useful for shielding against higher-frequency waves.

3. **Multiple Reflections**: When electromagnetic waves encounter a shielding material with a porous or layered structure, they undergo multiple reflections within the material. This causes the waves to lose energy through interaction with the material, ultimately reducing their intensity.

Applications of EMI Shielding

EMI shielding is applied in a wide range of industries and applications, from consumer electronics to aerospace. In consumer electronics, smartphones, laptops, and televisions all incorporate EMI shielding to ensure proper functionality and compliance with regulatory standards. In the automotive sector, EMI shielding is crucial for the safe operation of onboard electronics. In aerospace and defense, reliable EMI shielding ensures the successful operation of communication systems and sensitive equipment in harsh environments.

The Future of EMI Shielding

As electronic devices become more powerful and complex, the challenges associated with EMI are expected to grow. Future advancements in EMI shielding are likely to focus on developing materials that offer better performance while being lighter and more cost-effective. The integration of nanotechnology and advanced composite materials shows promise in achieving these goals.

In conclusion, EMI shielding is an indispensable part of modern electronics design, ensuring that devices operate reliably and without interference. As technology continues to evolve, so too will the methods and materials used to protect against electromagnetic interference.

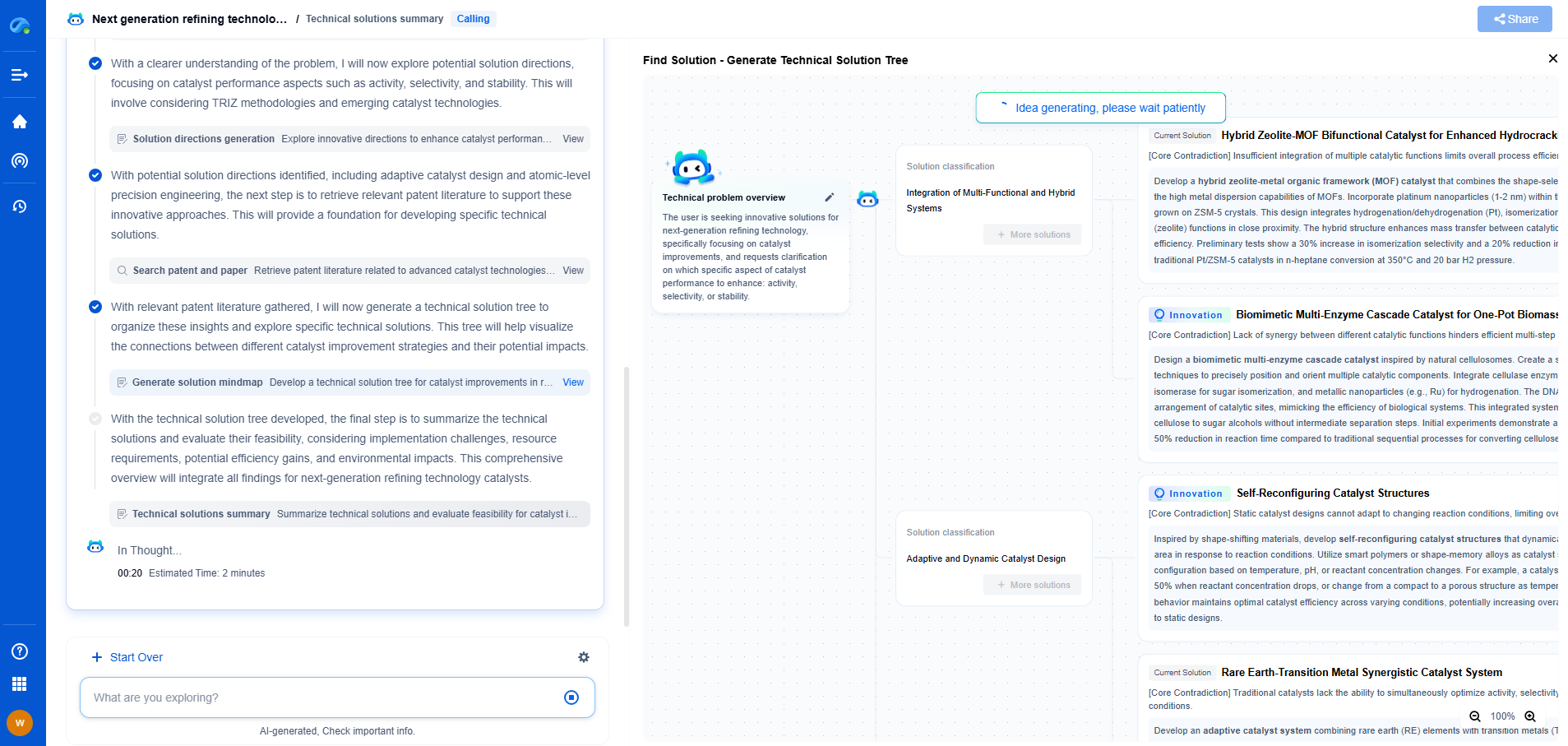

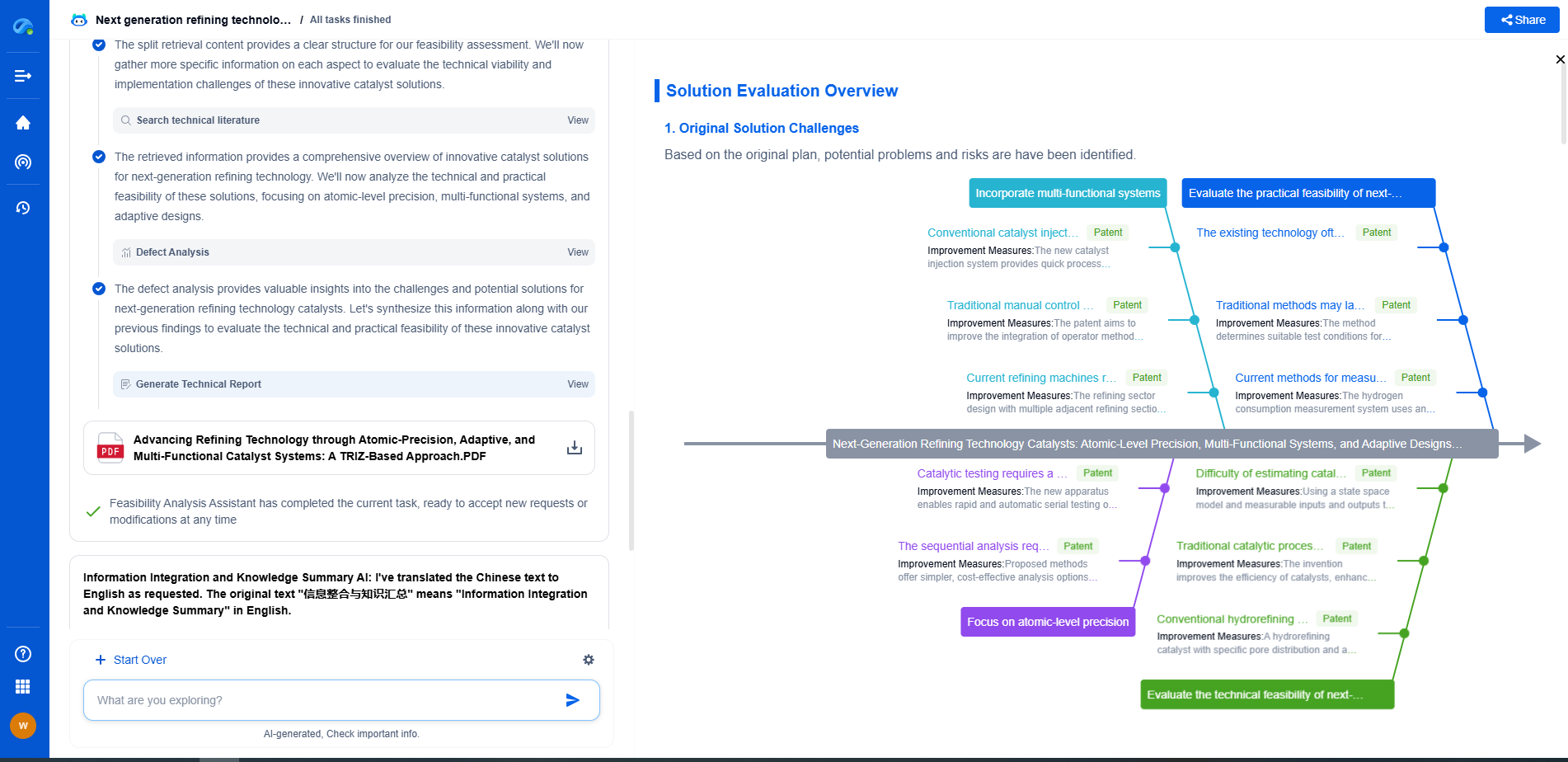

Accelerate Electronic Circuit Innovation with AI-Powered Insights from Patsnap Eureka

The world of electronic circuits is evolving faster than ever—from high-speed analog signal processing to digital modulation systems, PLLs, oscillators, and cutting-edge power management ICs. For R&D engineers, IP professionals, and strategic decision-makers in this space, staying ahead of the curve means navigating a massive and rapidly growing landscape of patents, technical literature, and competitor moves.

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

🚀 Experience the next level of innovation intelligence. Try Patsnap Eureka today and discover how AI can power your breakthroughs in electronic circuit design and strategy. Book a free trial or schedule a personalized demo now.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com