How to Design Fault-Tolerant Power for Semiconductor Fabs?

JUN 26, 2025 |

In the highly sophisticated world of semiconductor fabrication, maintaining an uninterrupted power supply is paramount. Semiconductor fabs—where integrated circuits are manufactured—demand precision and consistency. Even the slightest power interruption can lead to defects, production delays, and significant financial loss. Therefore, designing a fault-tolerant power system is essential to ensure continuous operation and high product yield.

**The Basics of Fault Tolerance in Power Systems**

Fault tolerance refers to the ability of a system to continue functioning correctly, even in the event of a component failure. For semiconductor fabs, this means creating a power system that can withstand disruptions without affecting the production process. This involves not only redundancy but also smart architecture that can automatically bypass failed components and reroute power as needed.

**Key Components of a Fault-Tolerant Power System**

1. **Redundant Power Sources:** At the core of a fault-tolerant power system is the use of multiple power sources. This includes the integration of primary utility power with secondary sources such as diesel generators, uninterruptible power supplies (UPS), and renewable energy systems like solar panels. The redundancy ensures that if one source fails, others can immediately take over without any disruption.

2. **Advanced UPS Systems:** Uninterruptible Power Supplies serve as a critical buffer during power transitions. Modern UPS systems are designed with high battery capacity and advanced electronics that can seamlessly kick in during a power outage, providing a continuous power supply until backup generators are activated.

3. **Smart Grid Technologies:** Implementing smart grid technologies allows for real-time monitoring and management of power distribution. These systems can predict potential failures, balance loads effectively, and switch between power sources automatically to maintain stability.

4. **Power Distribution Redundancy:** Designing redundant power distribution paths ensures that if one path fails, power can be rerouted through an alternative path. This often involves separate power lines, transformers, and switches capable of handling the full load independently.

**Design Considerations for Semiconductor Fabs**

1. **Load Analysis and Management:** Understanding the power requirements of various fab processes is crucial. This involves a detailed analysis of load characteristics and ensuring that all components—ranging from etching machines to cleanroom HVAC systems—are supported by the power infrastructure.

2. **Environmental Controls:** Semiconductor fabs are sensitive to environmental changes. The power system must support not only the production equipment but also the extensive environmental control systems that maintain cleanroom conditions.

3. **Regular Testing and Maintenance:** Regular testing and preventative maintenance are critical to ensure that all power components are functioning as expected. Routine checks can identify potential issues before they lead to failures.

4. **Scalability and Flexibility:** As semiconductor technology evolves, fabs will require more power. Designing a power system that can scale with future growth while maintaining fault tolerance is essential. This might involve modular UPS systems or expandable power distribution networks.

**Implementing a Comprehensive Monitoring System**

A comprehensive monitoring system is vital for dynamic fault management. Utilizing sensors and IoT devices, fab managers can gain insights into power consumption patterns, predict potential weak points, and automate responses to power anomalies. Advanced software can help track performance metrics, automate reporting, and facilitate rapid decision-making during power events.

**Conclusion: Ensuring Continuous Operation in Semiconductor Fabs**

Designing a fault-tolerant power system for semiconductor fabs is a complex but necessary task. By incorporating redundancy, smart technologies, and rigorous planning, fabs can mitigate the risks associated with power failures. These systems not only protect the high-value manufacturing process but also contribute to the overall efficiency and sustainability of semiconductor production. Embracing these strategies ensures that fabs remain resilient and competitive in the fast-paced tech industry.

Stay Ahead in Power Systems Innovation

From intelligent microgrids and energy storage integration to dynamic load balancing and DC-DC converter optimization, the power supply systems domain is rapidly evolving to meet the demands of electrification, decarbonization, and energy resilience.

In such a high-stakes environment, how can your R&D and patent strategy keep up?

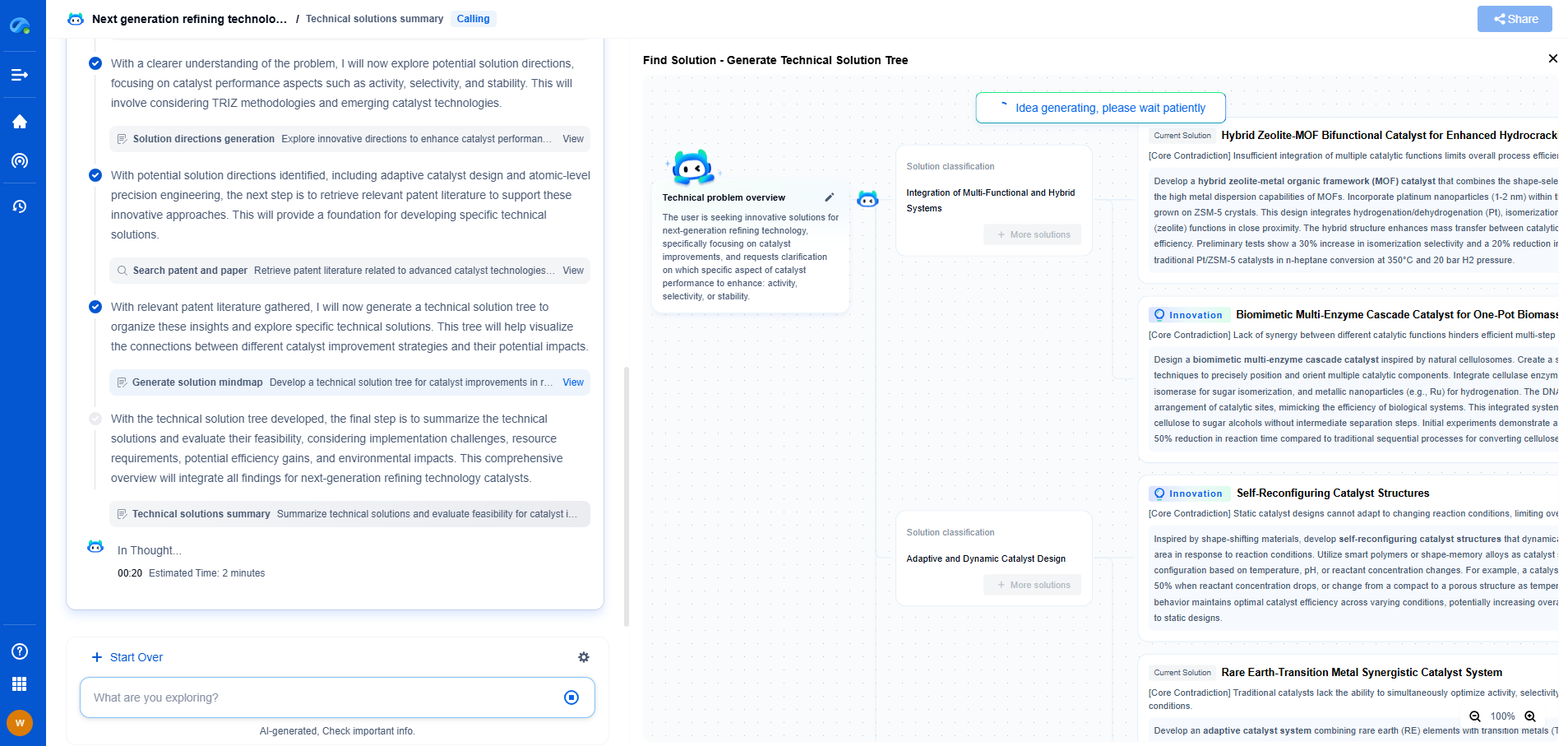

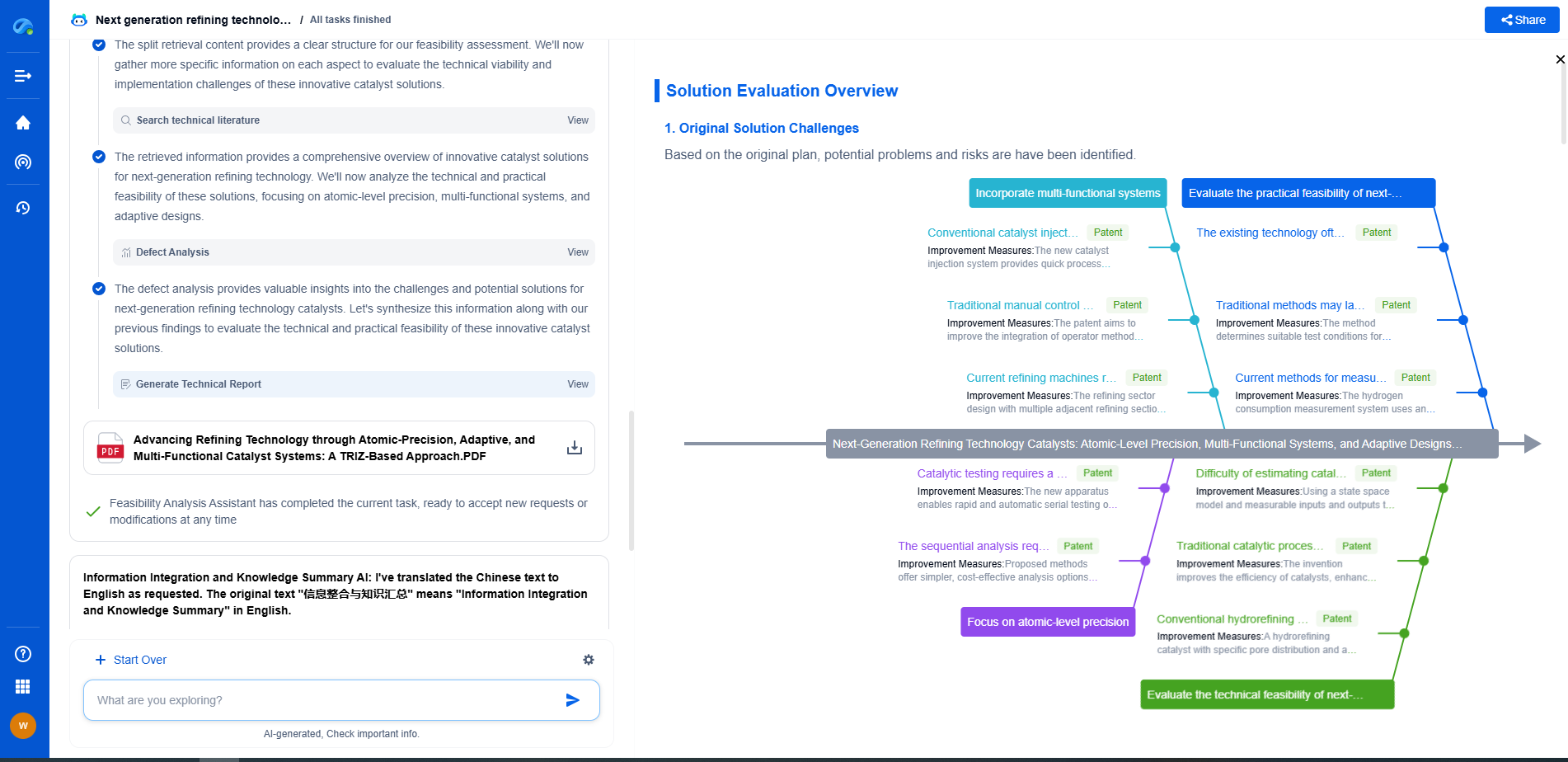

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

👉 Experience how Patsnap Eureka can supercharge your workflow in power systems R&D and IP analysis. Request a live demo or start your trial today.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com