How to Protect Semiconductor Devices from ESD Damage

JUN 27, 2025 |

Electrostatic Discharge (ESD) is a sudden flow of electricity between two electrically charged objects caused by contact, an electrical short, or dielectric breakdown. While it might seem like a minor event, ESD can cause significant damage to semiconductor devices, leading to malfunctions, reduced life span, or complete failure of the device. Understanding the nature and potential impact of ESD is the first step in implementing protective measures.

Key Causes of ESD

ESD can occur due to various factors, including friction, direct contact, and induction. In a manufacturing or assembly environment, even a simple action like a worker walking across a carpet can generate thousands of volts of static electricity. When this charge is discharged, it can cause micro-level damage to sensitive semiconductor components. Hence, identifying and mitigating ESD risks is crucial.

Implementing ESD Control Measures

1. **Workplace Design and Materials**

Designing the workspace with ESD in mind is fundamental. Start by using ESD-safe flooring materials and workstation surfaces. Anti-static mats and tiles can dissipate static charges effectively. Additionally, using conductive or static-dissipative materials for benches and workstations can help in minimizing static buildup.

2. **Proper Grounding**

Grounding is one of the most effective methods to prevent ESD damage. All conductive and dissipative items in an ESD-protected area should be at the same electrical potential. This includes workstations, floors, and workers themselves. Using wrist straps, heel grounders, and floor mats connected to the ground can prevent charge accumulation on personnel and equipment.

3. **Antistatic Packaging**

During storage and transportation, semiconductor devices should be kept in antistatic bags or containers. These are specially designed to prevent static buildup and protect sensitive components from ESD. Ensure that all packaging materials meet industry standards for ESD protection.

4. **Humidity Control**

Environmental factors, such as humidity, play a crucial role in ESD events. Low humidity increases the likelihood of static electricity buildup. Maintain a controlled level of humidity in the workplace, ideally between 40-60%, to minimize static discharge risks.

5. **Regular ESD Audits and Monitoring**

Conduct regular ESD audits to identify potential risks and assess the effectiveness of ESD controls in place. Use ESD monitoring equipment like static charge meters and ESD event detectors to track and analyze static levels in real-time. This proactive approach can help in taking timely corrective actions.

Training and Awareness

Educating employees about the dangers of ESD and the measures to prevent it is essential. Organize regular training sessions that emphasize the importance of ESD controls and best practices for handling semiconductor devices. Encourage a culture of safety and awareness where employees are vigilant and proactive in preventing ESD incidents.

Conclusion

Protecting semiconductor devices from ESD damage is crucial for maintaining their functionality and reliability. By understanding the causes of ESD and implementing comprehensive control measures, businesses can safeguard their investment in technology and ensure the longevity of their products. Remember, prevention is the key—investing in ESD protection today can save significant costs and headaches tomorrow.

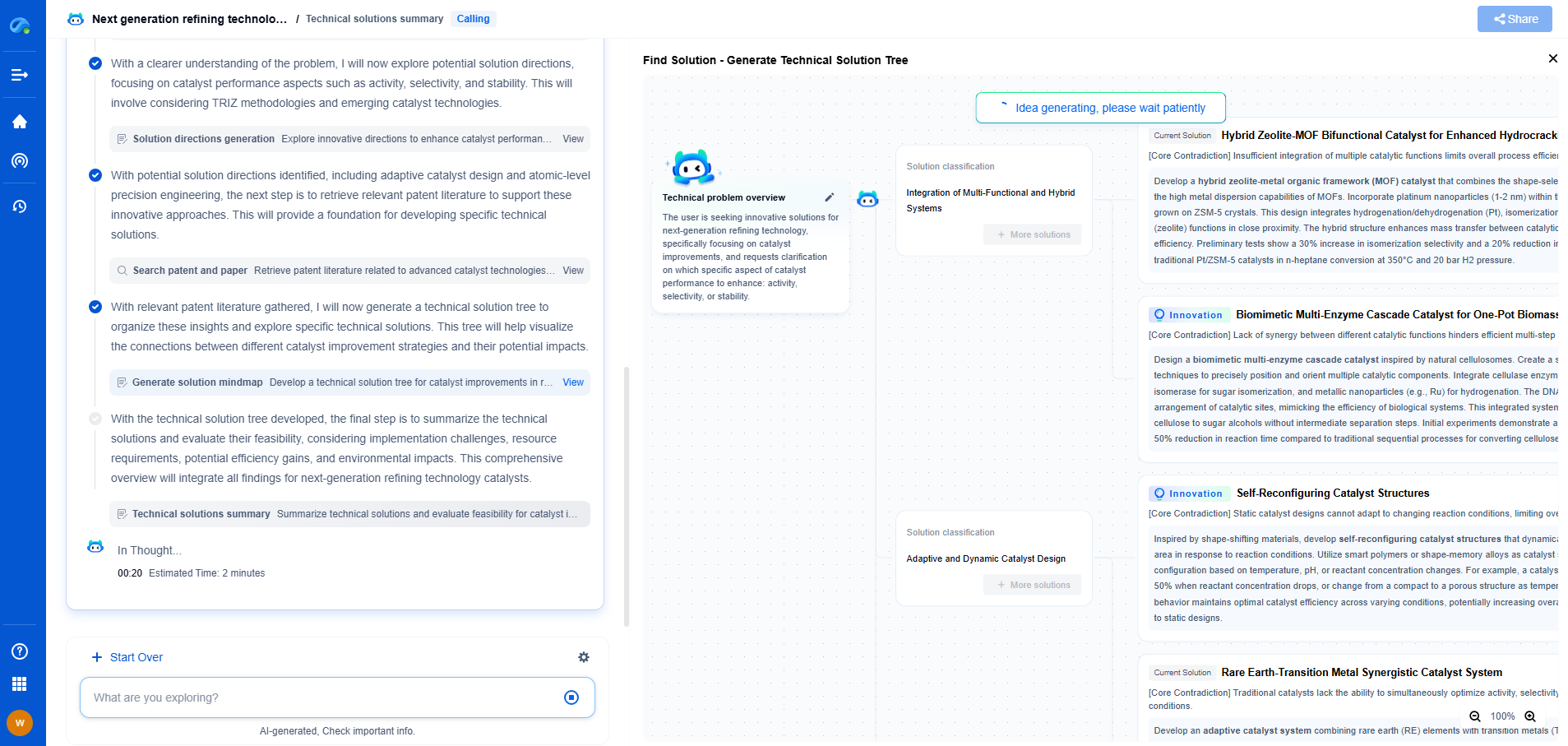

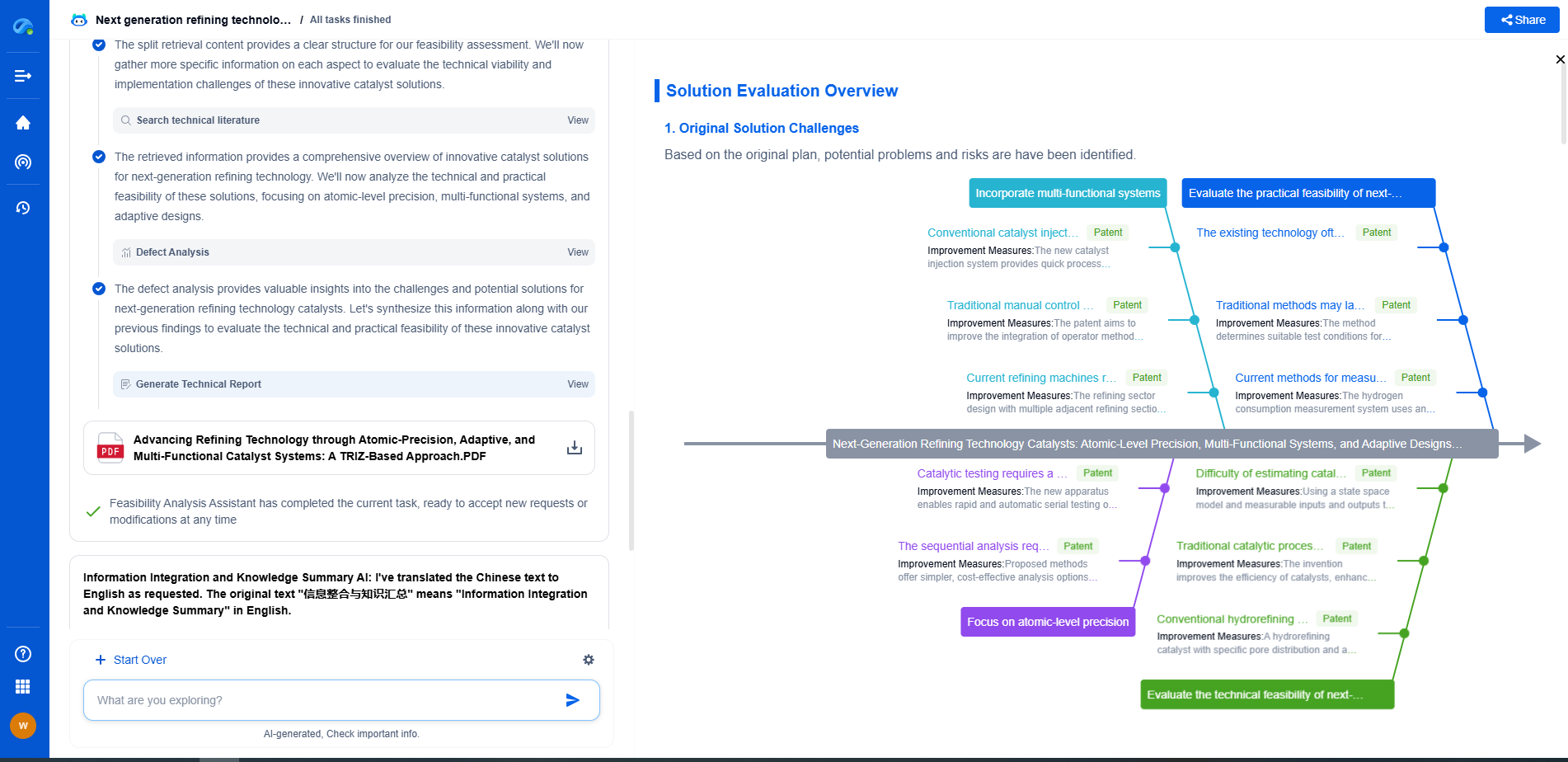

Accelerate Electronic Circuit Innovation with AI-Powered Insights from Patsnap Eureka

The world of electronic circuits is evolving faster than ever—from high-speed analog signal processing to digital modulation systems, PLLs, oscillators, and cutting-edge power management ICs. For R&D engineers, IP professionals, and strategic decision-makers in this space, staying ahead of the curve means navigating a massive and rapidly growing landscape of patents, technical literature, and competitor moves.

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

🚀 Experience the next level of innovation intelligence. Try Patsnap Eureka today and discover how AI can power your breakthroughs in electronic circuit design and strategy. Book a free trial or schedule a personalized demo now.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com