How to Test Semiconductor Devices Using Multimeter and Curve Tracer

JUN 27, 2025 |

Testing semiconductor devices is a crucial step in ensuring their functionality and efficiency. Whether you're dealing with diodes, transistors, or integrated circuits, understanding how to test these components effectively using a multimeter and a curve tracer can save both time and resources in the long run. This article will guide you through the essential steps and considerations for testing semiconductors.

Using a Multimeter for Semiconductor Testing

A multimeter is an invaluable tool for testing basic semiconductor devices like diodes and transistors. Here’s how you can use it for effective testing:

Testing Diodes

1. **Identify the Diode Terminals**: Determine the anode and cathode of the diode, usually marked by a stripe on the cathode side.

2. **Set the Multimeter to Diode Mode**: Most modern multimeters have a diode testing mode. Select this mode for accurate results.

3. **Perform the Forward Bias Test**: Connect the red probe to the anode and the black probe to the cathode. A good diode will show a voltage drop between 0.6V to 0.7V for silicon diodes and around 0.2V to 0.3V for germanium diodes.

4. **Perform the Reverse Bias Test**: Reverse the probes. The multimeter should show an "OL" reading, indicating no conduction in reverse bias.

Testing Transistors

1. **Identify the Transistor Type and Leads**: Determine whether you have an NPN or PNP transistor and identify the collector, emitter, and base leads.

2. **Set the Multimeter to Diode Mode**: Use this mode to check the junctions.

3. **Test the Base-Emitter and Base-Collector Junctions**: For an NPN transistor, connect the red probe to the base and the black probe to the emitter/collector. You should see a forward voltage. Reverse the probes to see "OL". For a PNP transistor, reverse the probe connections.

4. **Ensure No Short Circuits**: Test between the collector and emitter with different probe polarities and confirm there is no conduction.

Utilizing a Curve Tracer for Advanced Testing

A curve tracer provides a more detailed analysis of semiconductor characteristics by displaying their I-V curves. This tool is particularly useful for more complex components and circuit analysis.

Setting Up the Curve Tracer

1. **Select the Appropriate Test Fixture**: Ensure that the curve tracer has the correct fixture to accommodate your component.

2. **Configure the Display Settings**: Adjust the display settings to properly view the characteristic curves, such as voltage and current scales.

3. **Connect the Device Under Test**: Securely attach your semiconductor device to the test fixture, ensuring correct orientation of terminals.

Interpreting I-V Curves

1. **Observe the Forward Bias Characteristics**: A functional diode will have a curve that rises sharply as the forward voltage increases. For transistors, observe the curve under different base current settings.

2. **Analyze Reverse Bias Behavior**: A good diode should show minimal reverse current until the breakdown voltage is reached. Transistors should exhibit distinct cut-off, active, and saturation regions.

3. **Evaluate Component Performance**: Based on the curves plotted, assess if the device meets its specified parameters. Deviations might indicate faults or degradation.

Precautions and Best Practices

1. **Handle Components Carefully**: Semiconductor devices are sensitive to static electricity; always use anti-static measures when testing.

2. **Ensure Accurate Calibration**: Regularly calibrate your multimeter and curve tracer for precise readings.

3. **Understand the Specifications**: Familiarize yourself with the manufacturer's datasheet to know the expected behavior of the device.

4. **Document Results**: Keep a log of test results for future reference and component comparison.

Conclusion

Testing semiconductor devices with a multimeter and a curve tracer involves a combination of skills, understanding of electronics, and attention to detail. By following the outlined procedures and precautions, you can ensure that the semiconductors you work with are reliable and perform as expected. Whether you're troubleshooting an issue or verifying new components, these tools provide a comprehensive solution for semiconductor testing.

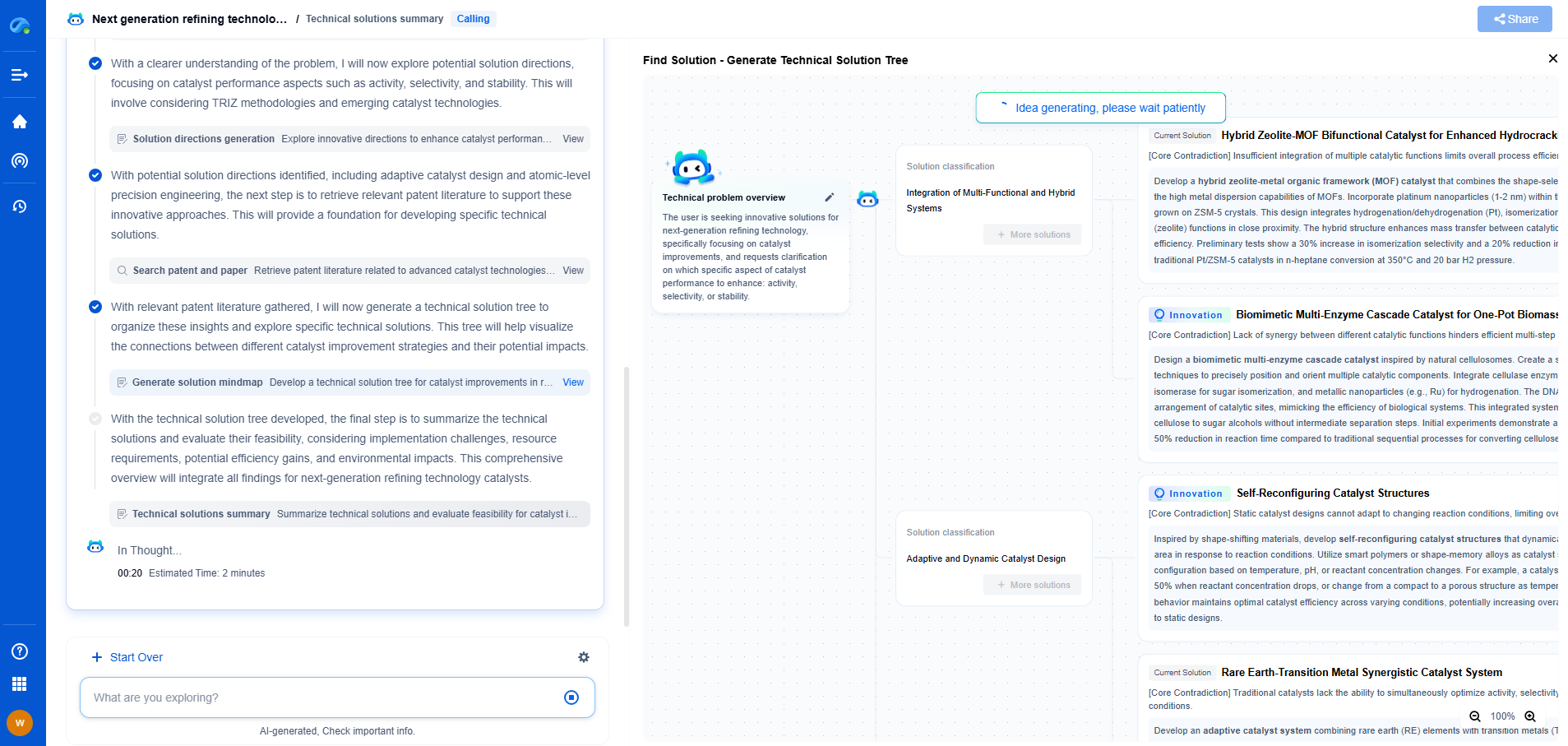

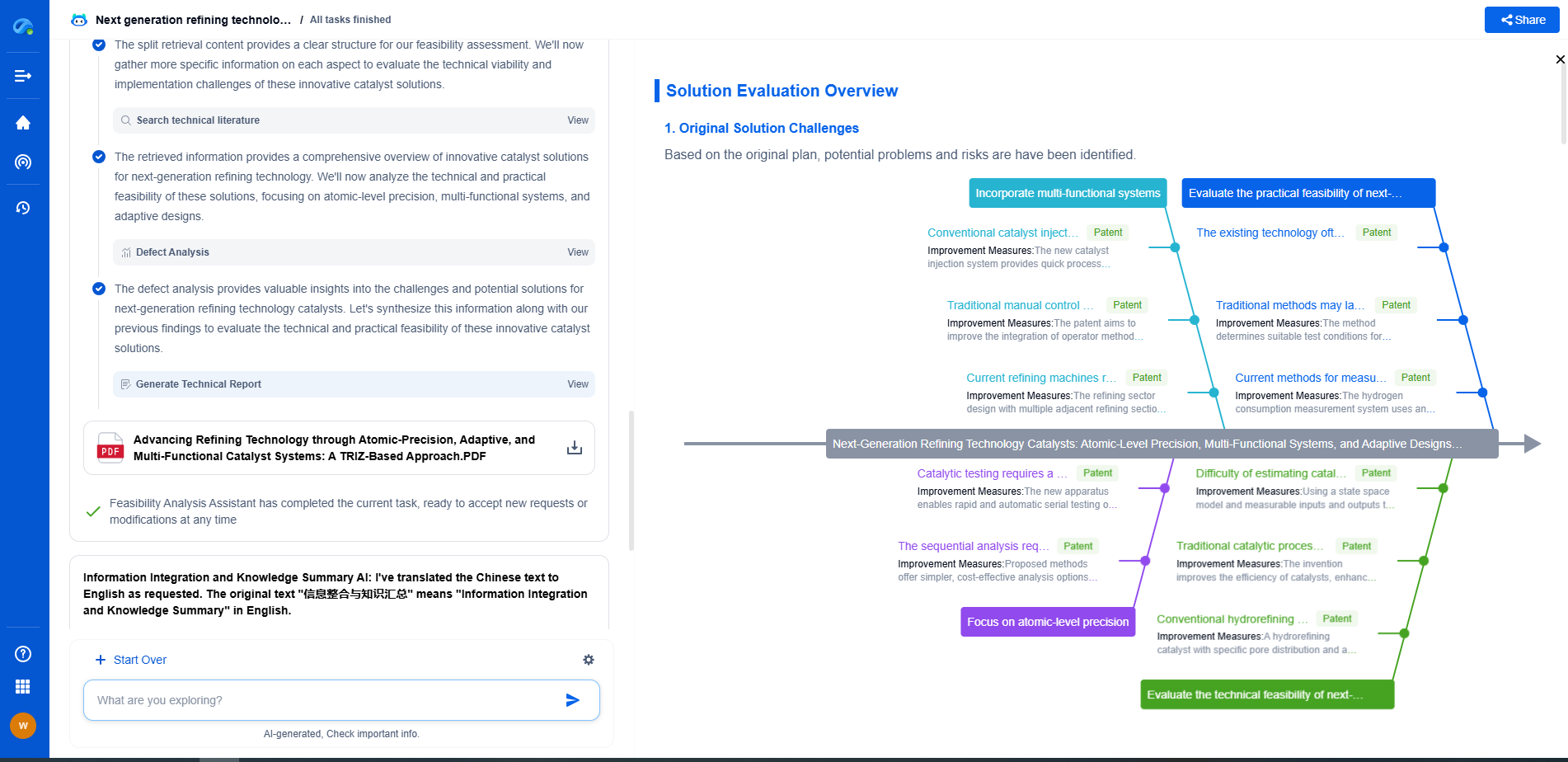

Accelerate Electronic Circuit Innovation with AI-Powered Insights from Patsnap Eureka

The world of electronic circuits is evolving faster than ever—from high-speed analog signal processing to digital modulation systems, PLLs, oscillators, and cutting-edge power management ICs. For R&D engineers, IP professionals, and strategic decision-makers in this space, staying ahead of the curve means navigating a massive and rapidly growing landscape of patents, technical literature, and competitor moves.

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

🚀 Experience the next level of innovation intelligence. Try Patsnap Eureka today and discover how AI can power your breakthroughs in electronic circuit design and strategy. Book a free trial or schedule a personalized demo now.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com