How Transparent Conductive Oxides (TCOs) Are Made for Solar Cells

JUL 22, 2025 |

Transparent conductive oxides (TCOs) are a critical component in the production of solar cells, serving as a vital layer that enables both electrical conductivity and optical transparency. This unique combination allows TCOs to facilitate the collection and transmission of light into the solar cell while simultaneously conducting the electric current generated by the photovoltaic process. Understanding how TCOs are made is essential for appreciating their role in enhancing solar cell efficiency and performance.

Materials Used in TCOs

The most commonly used materials for creating TCOs are metal oxides. Among these, indium tin oxide (ITO), zinc oxide (ZnO), and fluorine-doped tin oxide (FTO) are the most prevalent. Each of these materials offers distinct advantages in terms of conductivity, transparency, and cost-effectiveness.

1. Indium Tin Oxide (ITO): Known for its excellent transparency and high conductivity, ITO is widely used in various optoelectronic applications, including solar cells. However, the scarcity and cost of indium have prompted researchers to explore alternative materials.

2. Zinc Oxide (ZnO): ZnO is a more abundant and cost-effective option compared to ITO. It can be doped with other elements like aluminum to improve its conductive properties, making aluminum-doped zinc oxide (AZO) a popular choice.

3. Fluorine-doped Tin Oxide (FTO): FTO is another alternative that offers good optical transparency and stability. It is particularly favored in applications where chemical resistance is essential.

Manufacturing Processes for TCOs

The production of TCOs involves various deposition techniques designed to achieve the desired balance between conductivity and transparency. Here are some of the most common methods:

1. Sputtering: This is a physical vapor deposition (PVD) technique where ions are used to eject material from a target, depositing it onto a substrate. Sputtering allows for precise control over the thickness and composition of the TCO layer, making it a popular choice for large-scale production.

2. Chemical Vapor Deposition (CVD): In CVD, gaseous precursors react or decompose on a substrate surface, forming a solid film. This method is advantageous for its ability to coat complex shapes and provide uniform coverage, which is particularly useful for solar cell applications.

3. Sol-Gel Process: A cost-effective and versatile method, the sol-gel process involves the transition of a solution into a solid gel phase. This technique is typically used for producing thin films and can be easily adapted for different TCO materials.

4. Pulsed Laser Deposition (PLD): PLD uses a high-energy laser beam to ablate a target material, which is then deposited onto a substrate. While this technique can produce high-quality films, it is generally more expensive and less scalable than other methods.

Considerations in TCO Production for Solar Cells

When producing TCOs for solar cells, several factors must be considered to optimize their performance. These include:

1. Thickness: The thickness of the TCO layer is crucial for balancing transparency and conductivity. A thinner layer may increase transparency but reduce conductivity, while a thicker layer might do the opposite.

2. Surface Roughness: A smooth TCO surface enhances the light transmission into the solar cell, improving its efficiency. Techniques such as polishing and annealing are employed to achieve the desired surface quality.

3. Doping Concentration: The level of doping in TCO materials affects their electrical properties. Precise control over doping concentration is essential to optimize the TCO's conductivity without compromising transparency.

Conclusion

Transparent conductive oxides are indispensable in the field of solar energy, providing the necessary conductive pathways while maintaining high levels of transparency. By selecting the right materials and manufacturing processes, TCOs can significantly improve the performance of solar cells. As research continues to advance, the development of new TCO materials and techniques promises to further enhance the efficiency and affordability of solar energy systems, contributing to a more sustainable future.

As solar technology races ahead—from perovskite cells to tandem architectures, from anti-reflective coatings to transparent electrodes—staying on top of fast-moving innovation has become a strategic imperative.

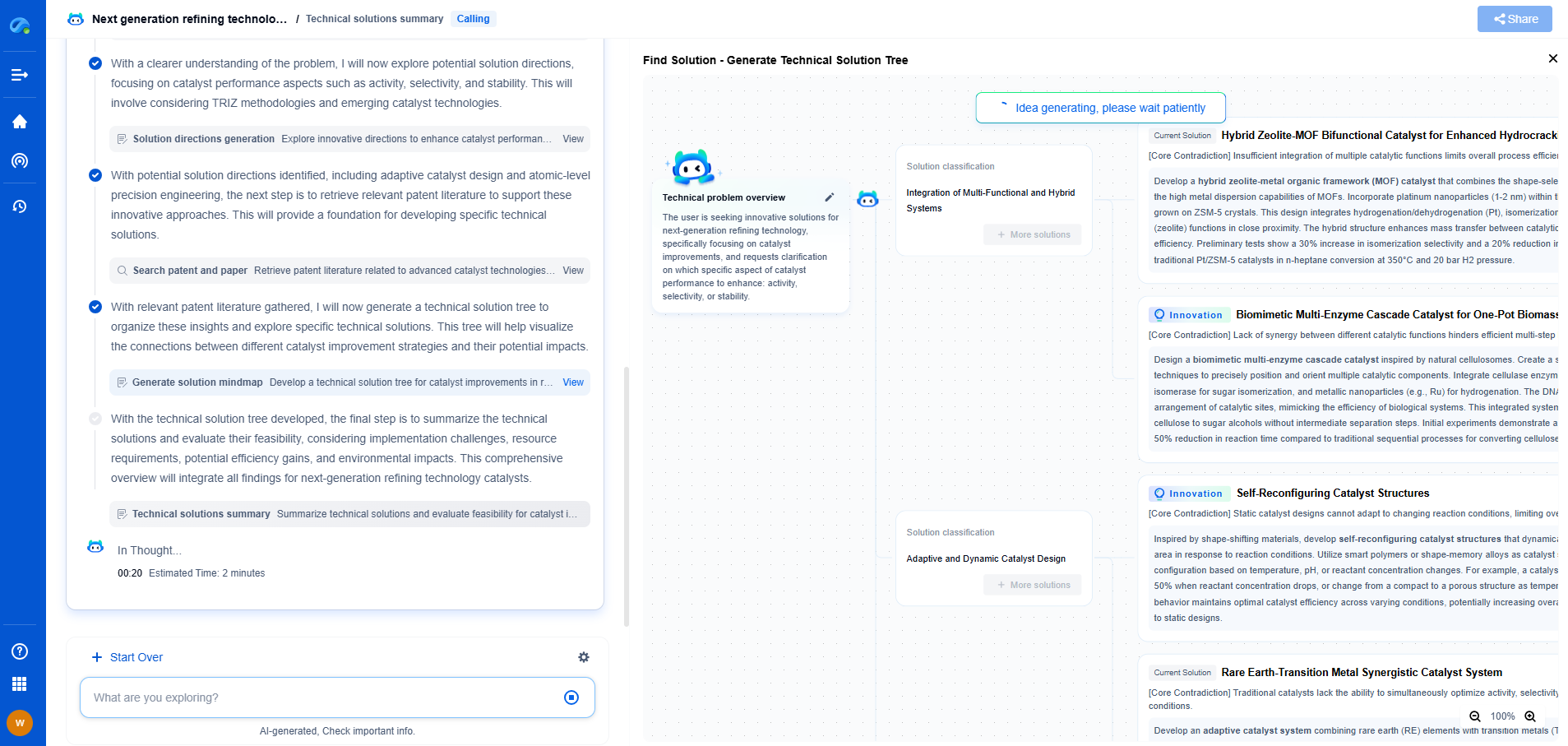

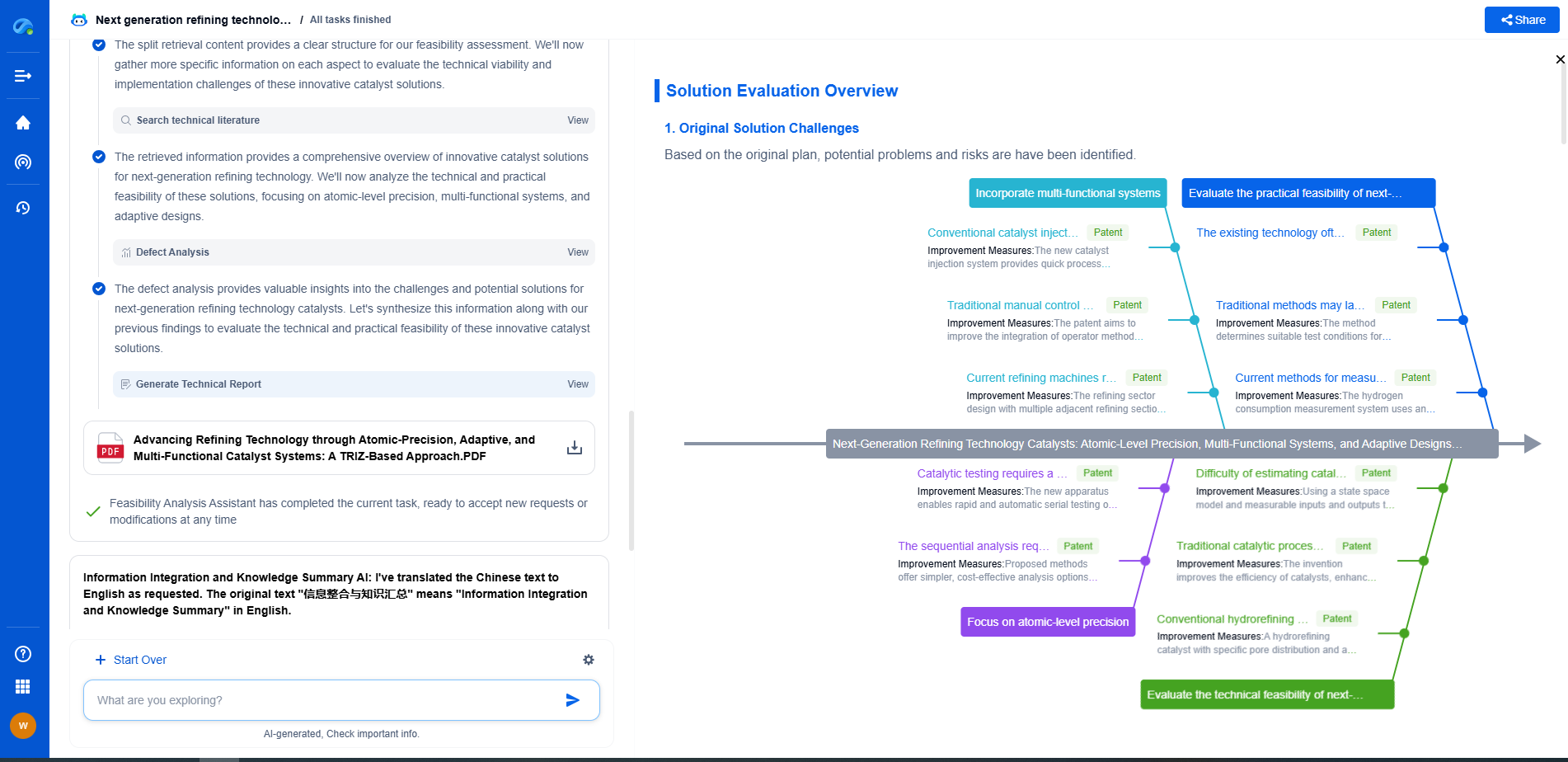

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

⚡ Ready to accelerate your solar innovation journey? Try Patsnap Eureka today and let AI help you harness the full power of the sun—and your IP strategy.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com