Hydrophobic vs. Superhydrophilic Coatings: Which Wins for Dust Removal?

JUL 22, 2025 |

In the world of surface coatings, two powerful contenders have emerged for maintaining cleanliness: hydrophobic and superhydrophilic coatings. Both possess unique properties that can significantly impact how surfaces handle dust and dirt. As environmental concerns and maintenance costs rise, understanding these coatings' roles in dust removal becomes increasingly vital.

Understanding Hydrophobic Coatings

Hydrophobic coatings are designed with water-repelling properties. By minimizing the surface energy, they create a barrier that makes liquids bead up and roll off the surface with ease. This means that when dust particles land on a hydrophobic surface, they are less likely to stick because there is minimal moisture to help them adhere. The ease of water rolling off can also facilitate the removal of dust when it rains or when the surface is rinsed with water.

However, hydrophobic coatings may not always excel in completely preventing dust accumulation. While they are excellent for repelling water, fine dust and other small particles can sometimes remain, particularly in dry conditions where moisture isn't present to assist in washing the particles away.

Exploring Superhydrophilic Coatings

Contrary to hydrophobic surfaces, superhydrophilic coatings attract water rather than repel it. When water comes into contact with a superhydrophilic surface, it spreads out into an even film rather than forming droplets. This property is particularly advantageous for dust removal because the water film can effectively lift and carry away dust particles.

Superhydrophilic coatings leverage the concept of self-cleaning in a slightly different manner. When it rains or when the surface is washed, the uniform water film can drag dust off the surface more thoroughly than a hydrophobic coating would. This makes superhydrophilic coatings especially useful in environments where cleaning might be sporadic, but rainfall or other water sources are abundant.

Real-World Applications and Limitations

Hydrophobic coatings have found widespread use in industries like automotive, electronics, and construction. They are ideal for situations where preventing water penetration is critical, such as protecting electronic devices or automotive windshields. However, they require occasional maintenance to ensure that their water-repelling abilities remain effective.

Superhydrophilic coatings, on the other hand, are gaining popularity in architectural applications, especially for glass surfaces and solar panels. These coatings are beneficial in urban environments where pollution can lead to excessive dust buildup. They help maintain transparency and efficiency by ensuring that dust is easily washed away with rain or cleaning.

Environmental and Economic Considerations

From an environmental perspective, superhydrophilic coatings offer an advantage by potentially reducing the need for chemical cleaning agents and frequent manual cleaning, thereby lowering the environmental footprint. Additionally, they can contribute to energy savings in applications like solar panels, where maintaining optimal cleanliness directly impacts energy output.

Economically, both coatings offer cost-saving benefits but in different ways. Hydrophobic coatings reduce maintenance frequencies and protect surfaces from water damage, while superhydrophilic coatings minimize the need for cleaning labor and materials.

Conclusion: Which Is Better for Dust Removal?

When it comes to dust removal, the choice between hydrophobic and superhydrophilic coatings is context-dependent. If the primary concern is preventing water damage and minimal dust removal is required, hydrophobic coatings may be the better choice. However, for environments where dust accumulation is a significant issue and water is readily available for cleaning, superhydrophilic coatings provide a compelling solution.

Ultimately, the decision should be influenced by the specific application, environmental conditions, and desired maintenance outcomes. Both coatings have their strengths and can be leveraged to create cleaner, more efficient environments.

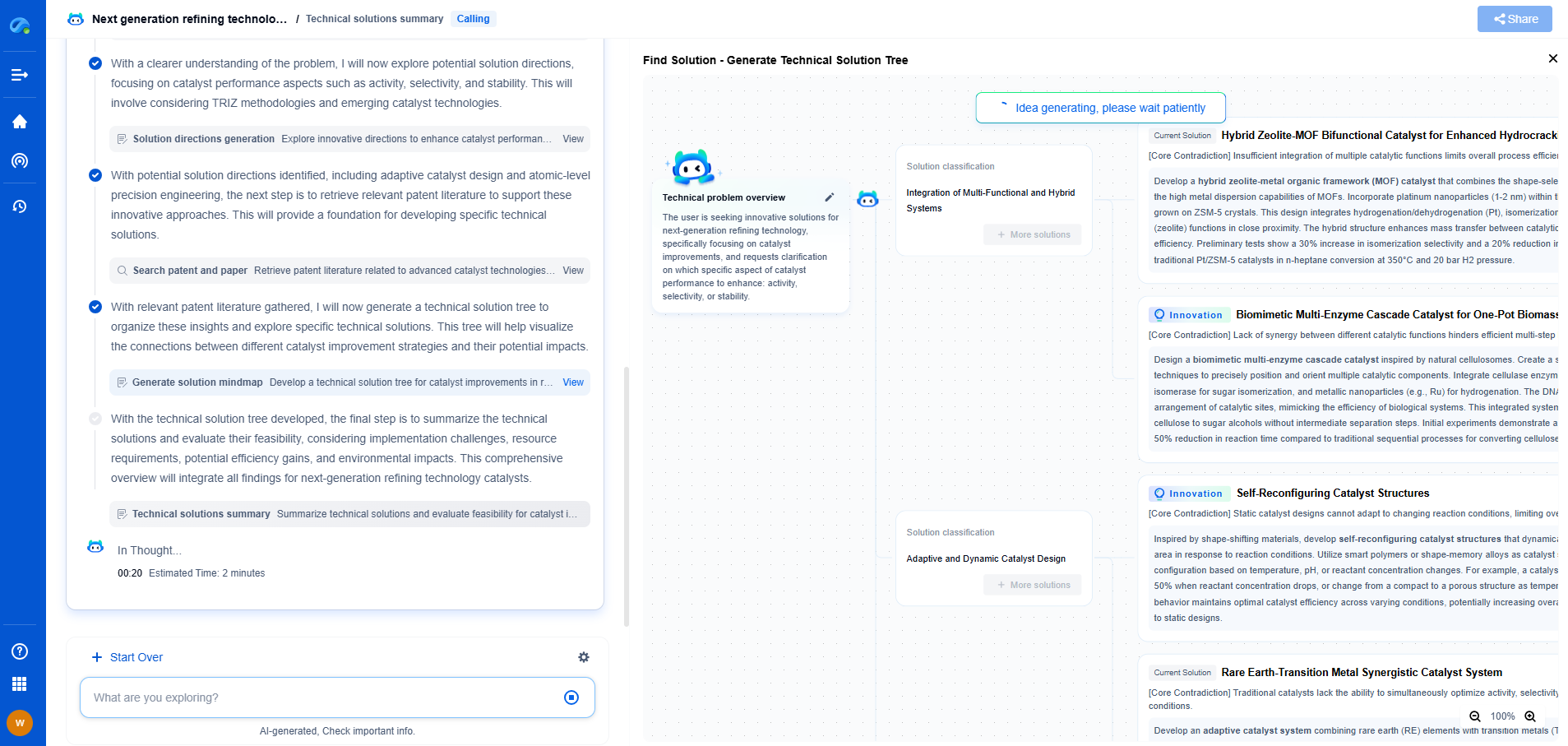

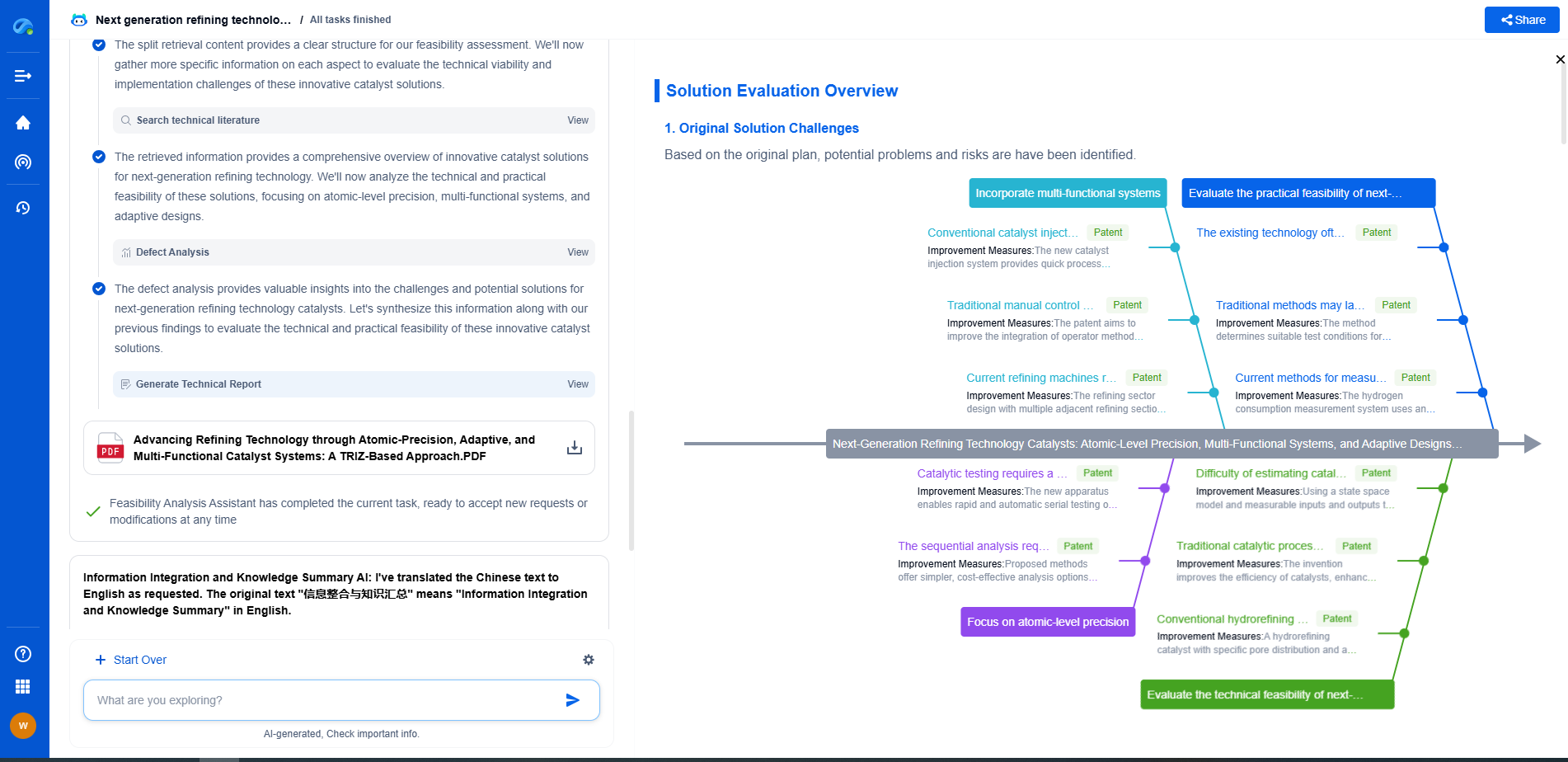

As solar technology races ahead—from perovskite cells to tandem architectures, from anti-reflective coatings to transparent electrodes—staying on top of fast-moving innovation has become a strategic imperative.

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

⚡ Ready to accelerate your solar innovation journey? Try Patsnap Eureka today and let AI help you harness the full power of the sun—and your IP strategy.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com