IEC 61215 vs. UL 1703: Module Qualification Test Differences

JUL 22, 2025 |

In the rapidly advancing field of solar technology, ensuring the reliability and safety of photovoltaic modules is crucial. This is where standards like IEC 61215 and UL 1703 come into play. Both standards serve as benchmarks for testing and certifying solar modules, but they cater to different aspects and regions. Understanding the differences between these two can help manufacturers, installers, and consumers make informed decisions.

Purpose and Scope of IEC 61215

IEC 61215 is an international standard developed by the International Electrotechnical Commission (IEC) for the design qualification and type approval of terrestrial photovoltaic modules. It primarily focuses on ensuring the long-term performance and environmental endurance of solar panels. This standard is critical for assessing how well a module can withstand prolonged exposure to the elements, including factors like temperature fluctuations, humidity, wind, and mechanical loads.

Key Tests in IEC 61215

The IEC 61215 standard includes a series of rigorous tests to determine the durability of solar modules. These tests include:

1. Thermal Cycling Test: Modules are subjected to repeated temperature cycles to simulate day-night temperature variations and assess their ability to withstand thermal stress.

2. Humidity-Freeze Test: This test evaluates a module's resistance to combined humidity and freezing conditions, which can lead to moisture ingress and subsequent degradation.

3. Mechanical Load Test: Modules are tested for their ability to endure mechanical stresses, such as those caused by snow loads or high winds.

4. Damp Heat Test: This assesses a module's resistance to long-term exposure to high levels of humidity and temperature.

5. UV Light Test: The impact of ultraviolet radiation on the module's components is evaluated to ensure longevity and performance.

Purpose and Scope of UL 1703

UL 1703, on the other hand, is a standard developed by Underwriters Laboratories (UL) primarily used in North America. It focuses on the safety and electrical performance of flat-plate photovoltaic modules. UL 1703 addresses the construction, performance, and safety aspects to ensure that solar panels can be safely integrated into the power grid and residential or commercial installations.

Key Tests in UL 1703

The UL 1703 standard encompasses a variety of tests, including:

1. Fire Safety Test: Modules are subjected to tests that assess their fire resistance and the propagation of flames, ensuring they do not pose a fire hazard.

2. Electrical Safety Test: This includes assessing the module's insulation, grounding, and resistance to electrical shock to prevent electrical hazards.

3. Impact Resistance Test: The ability of a module to withstand impacts, such as hail, is evaluated to ensure safety and durability.

4. Temperature Test: Modules are tested to ensure they can operate safely at high temperatures without compromising performance or safety.

Comparative Analysis: IEC 61215 vs. UL 1703

While both IEC 61215 and UL 1703 aim to ensure the reliability of solar modules, their focus areas differ significantly. IEC 61215 places a strong emphasis on long-term performance and environmental stress factors, making it essential for modules intended for use in diverse climatic conditions worldwide. Conversely, UL 1703 is more focused on safety, particularly in terms of electrical and fire safety, which are critical for modules installed in the United States and Canada.

For manufacturers aiming to penetrate the global market, adherence to both standards is often necessary. IEC 61215 certification can demonstrate a module's endurance and adaptability to various environmental conditions, while UL 1703 certification ensures compliance with North American safety regulations.

Conclusion

In the solar industry, standards like IEC 61215 and UL 1703 play a pivotal role in ensuring modules are both effective and safe. Understanding the nuances between these standards can help stakeholders select the right certification for their specific needs. As solar technology continues to evolve, these standards will likely adapt, further enhancing the reliability and safety of photovoltaic modules for consumers worldwide.

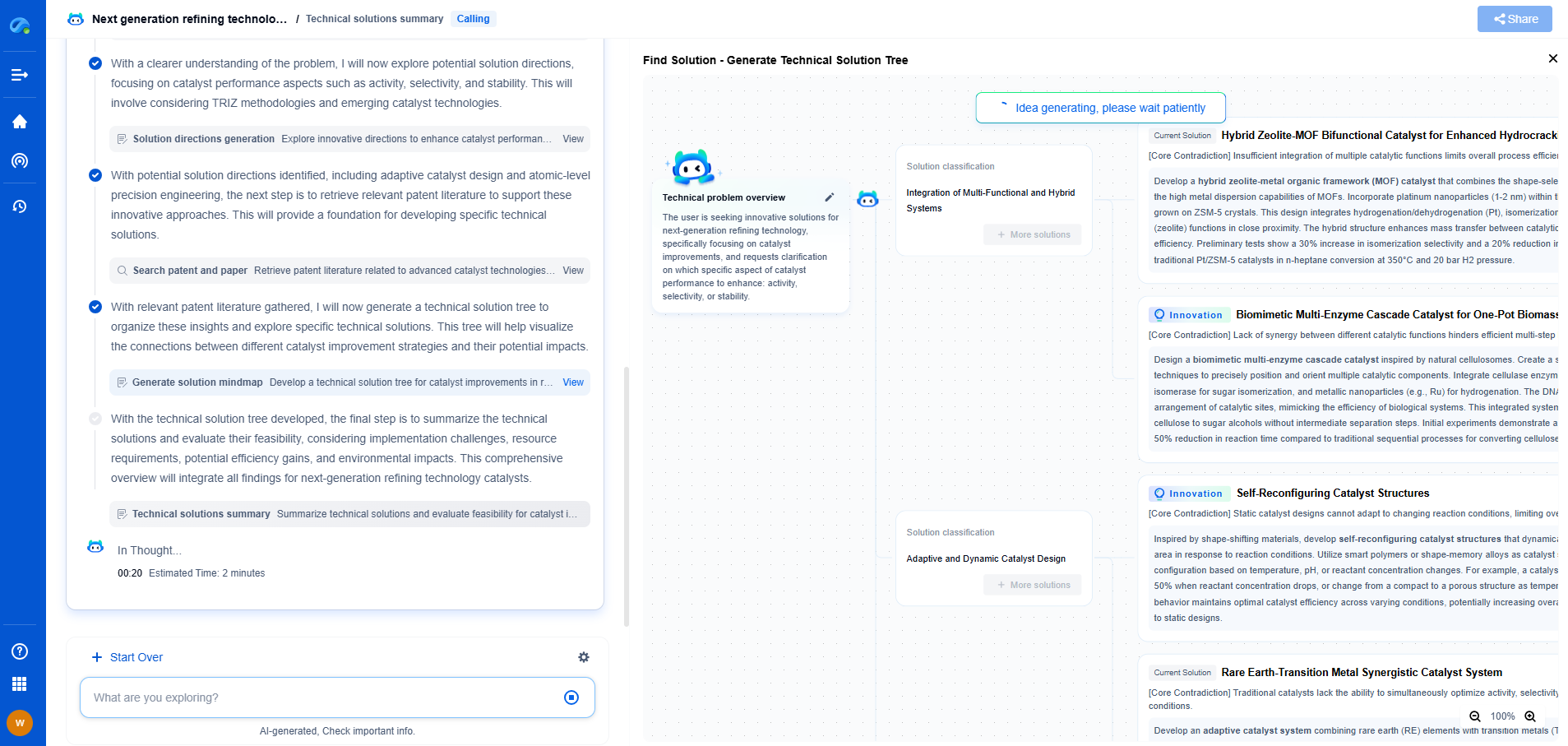

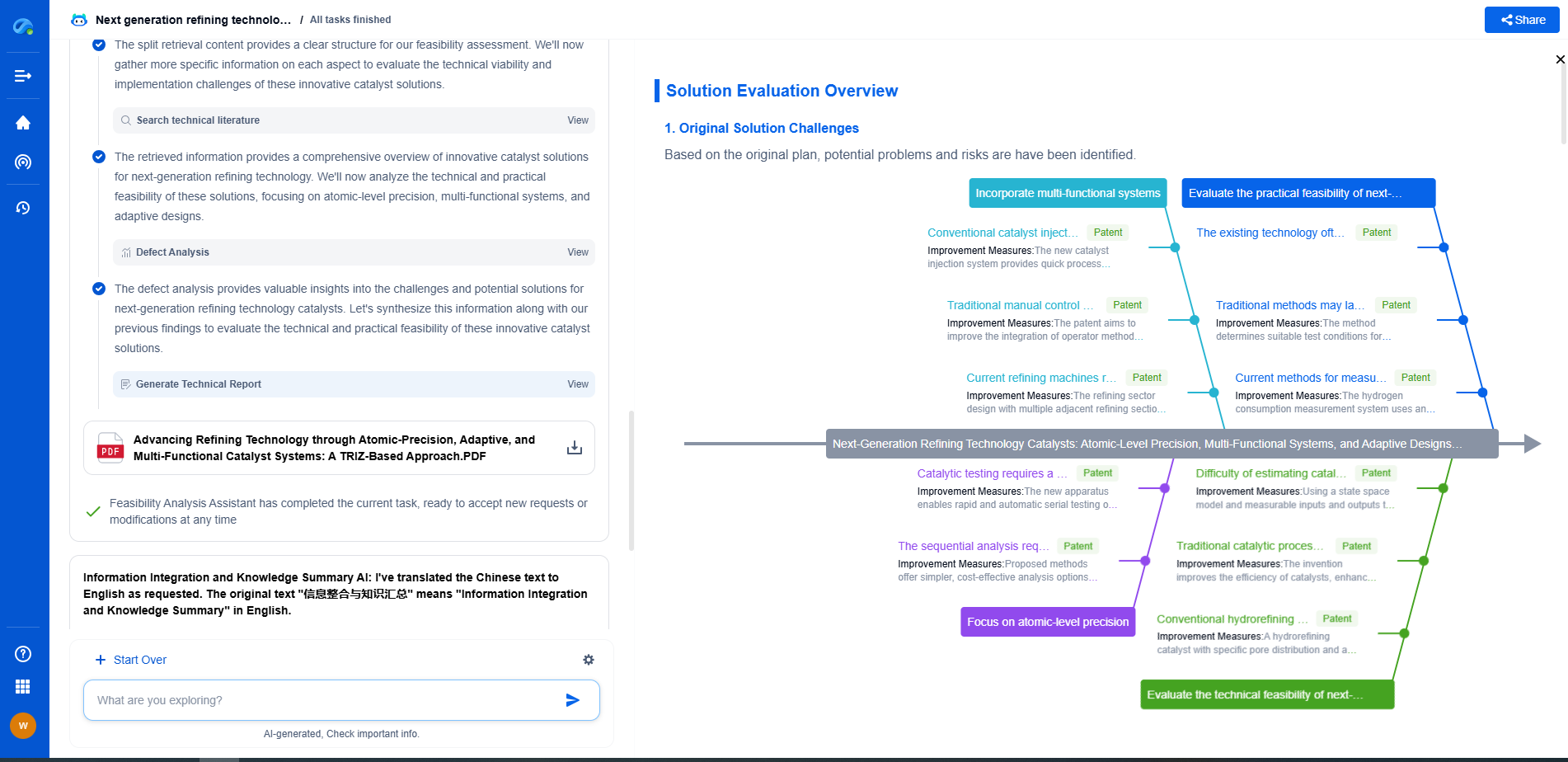

As solar technology races ahead—from perovskite cells to tandem architectures, from anti-reflective coatings to transparent electrodes—staying on top of fast-moving innovation has become a strategic imperative.

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

⚡ Ready to accelerate your solar innovation journey? Try Patsnap Eureka today and let AI help you harness the full power of the sun—and your IP strategy.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com