IGBT vs SiC MOSFET: Power Loss Comparison in Converters

JUN 26, 2025 |

In the realm of power electronics, the choice of semiconductor devices significantly impacts the efficiency, performance, and reliability of converters. Two popular contenders are the Insulated Gate Bipolar Transistor (IGBT) and the Silicon Carbide (SiC) Metal-Oxide-Semiconductor Field-Effect Transistor (MOSFET). As the demand for energy-efficient solutions grows, understanding the power loss characteristics of these devices becomes critical. This blog delves into the power loss comparison of IGBT and SiC MOSFET in converters, providing insights into their respective advantages and limitations.

Understanding Power Loss Mechanisms

Before diving into a detailed comparison, it's essential to grasp the primary power loss mechanisms in semiconductor devices. Power losses in converters typically arise from conduction losses, switching losses, and gate drive losses. Conduction losses occur when the device is in the 'on' state, while switching losses are incurred during the transition from 'on' to 'off' states and vice versa. Gate drive losses are the energy consumed in charging and discharging the gate capacitance.

IGBTs: Pros and Cons

IGBTs are widely used in industrial applications due to their high voltage and current capabilities. They exhibit relatively low conduction losses due to their bipolar nature, which allows them to handle higher currents efficiently. However, one of the main drawbacks of IGBTs is their significant switching losses. The bipolar nature of IGBTs, while advantageous for conduction, results in slower switching speeds compared to MOSFETs, leading to higher energy dissipation during switching events.

In applications where high current handling is critical, and switching frequency is moderate, IGBTs may offer a more cost-effective solution despite their higher switching losses. Additionally, IGBTs have a robust thermal performance, making them suitable for environments where heat dissipation is a concern.

SiC MOSFETs: The Emerging Leaders

SiC MOSFETs, on the other hand, leverage the superior material properties of silicon carbide, offering noteworthy advantages over traditional silicon-based devices. One of the standout features of SiC MOSFETs is their low switching losses. The fast switching capability of SiC MOSFETs reduces the energy lost during transitions, making them ideal for high-frequency applications.

Moreover, SiC MOSFETs exhibit lower conduction losses at high temperatures and voltages, providing enhanced efficiency in demanding environments. The reduced size and weight of passive components, made possible by operating at higher frequencies, further contribute to the overall efficiency and compactness of the power converter design.

Comparative Analysis: IGBT vs SiC MOSFET

When comparing IGBT and SiC MOSFETs, the application-specific requirements play a crucial role. For applications demanding high switching frequencies, such as renewable energy systems and electric vehicles, the low switching losses of SiC MOSFETs often outweigh their higher cost. This translates to reduced energy consumption and improved overall system efficiency.

Conversely, in applications where cost constraints are more critical, and the switching frequency is moderate, IGBTs may still hold a competitive edge. Their ability to handle high currents at lower costs can be advantageous in industrial motor drives and power distribution systems.

Efficiency and Thermal Management

The efficiency gains offered by SiC MOSFETs also translate into improved thermal management. Lower power losses result in less heat generation, reducing the need for extensive cooling systems. This aspect is particularly significant in compact or portable systems, where space and weight are critical factors.

Conclusion

In conclusion, both IGBT and SiC MOSFETs have their unique strengths and weaknesses, with the choice largely dependent on the specific application requirements. While IGBTs provide a cost-effective solution for high current applications with moderate switching frequencies, SiC MOSFETs offer superior efficiency in high-frequency, high-temperature environments. As technology advances and the cost of SiC devices continues to decrease, their adoption is likely to expand across various industries, driving the quest for more energy-efficient power electronic solutions.

Stay Ahead in Power Systems Innovation

From intelligent microgrids and energy storage integration to dynamic load balancing and DC-DC converter optimization, the power supply systems domain is rapidly evolving to meet the demands of electrification, decarbonization, and energy resilience.

In such a high-stakes environment, how can your R&D and patent strategy keep up?

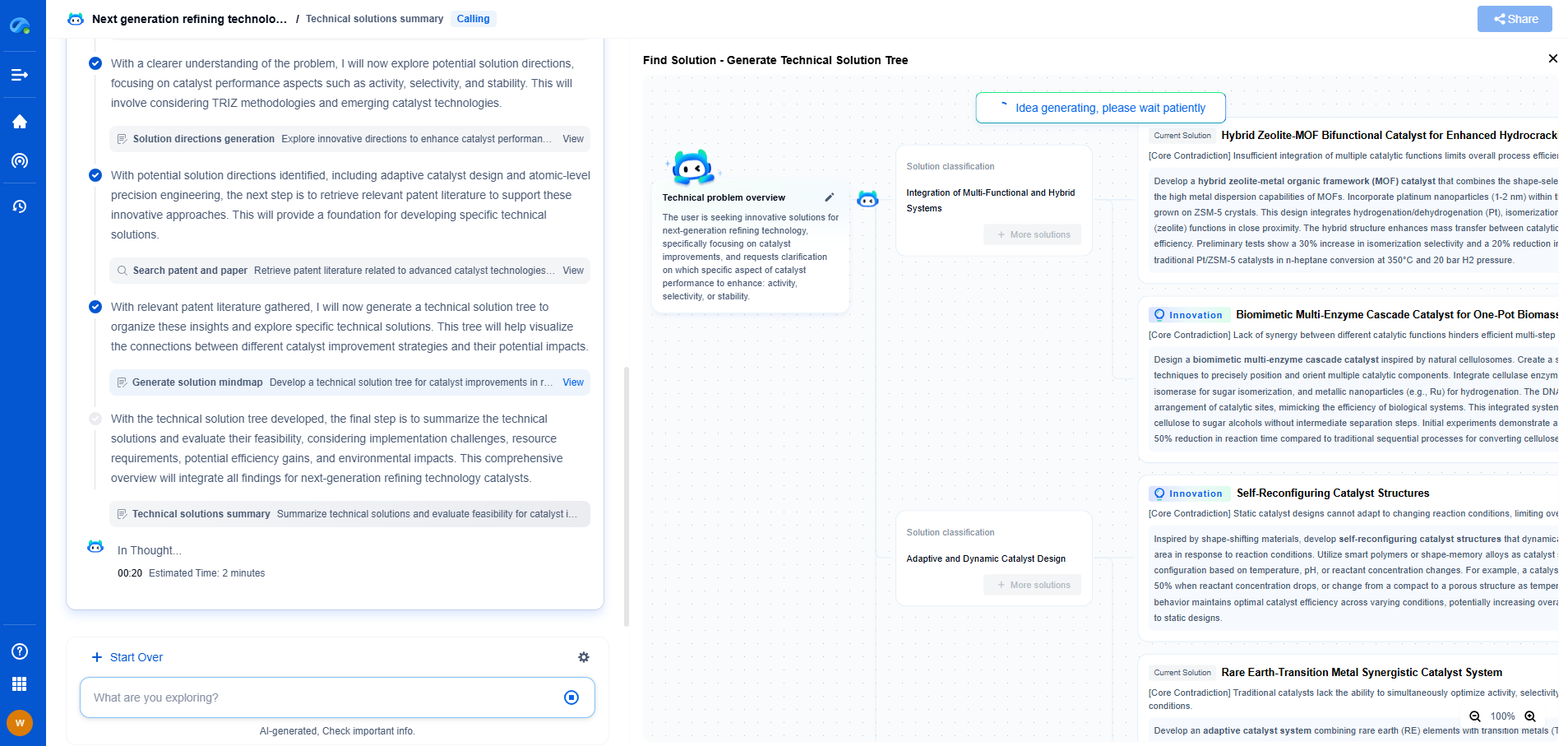

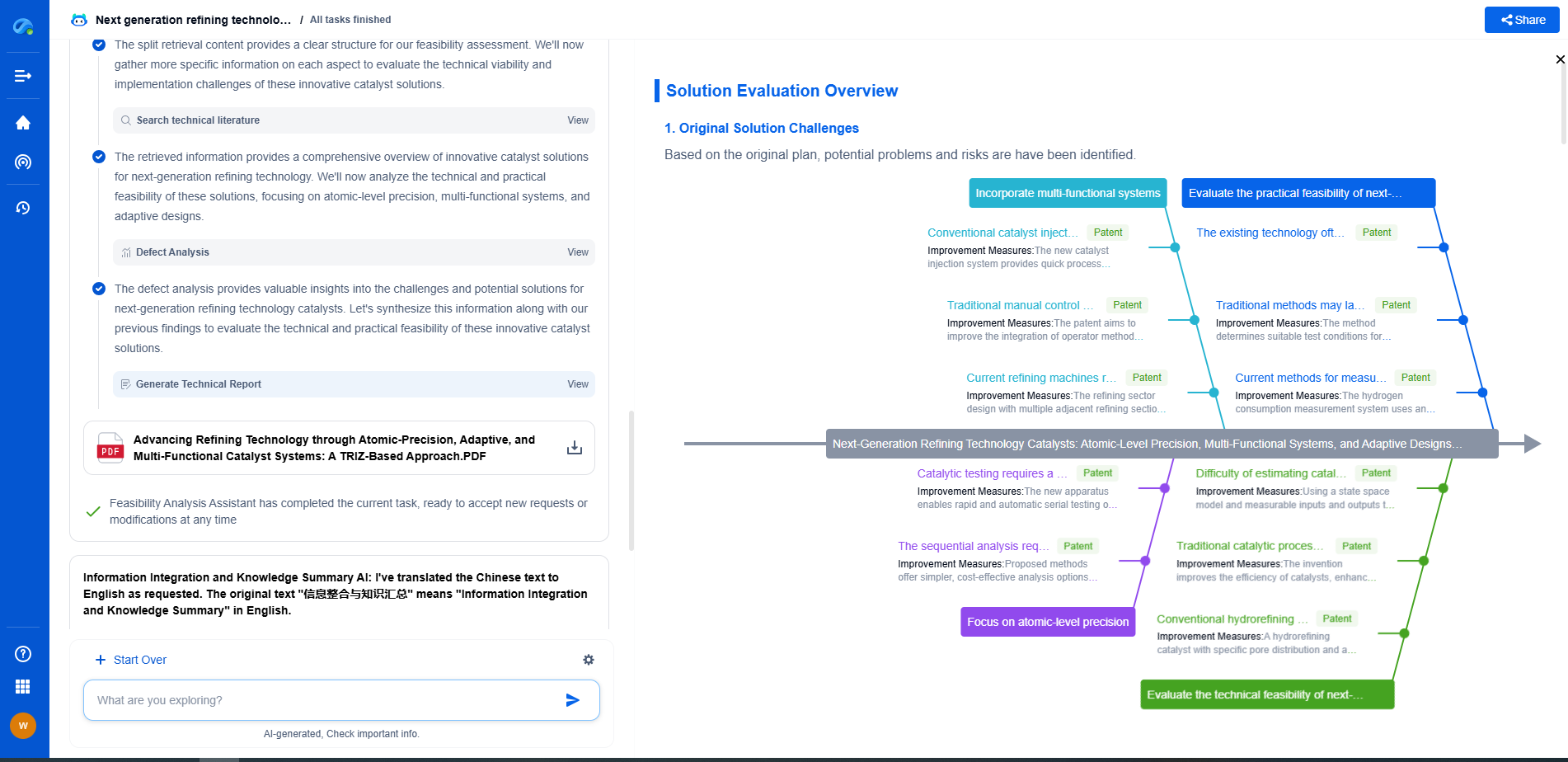

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

👉 Experience how Patsnap Eureka can supercharge your workflow in power systems R&D and IP analysis. Request a live demo or start your trial today.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com