Implementing Active PFC (Power Factor Correction) Circuits

JUN 27, 2025 |

Power factor correction (PFC) is a crucial aspect of electrical engineering that aims to improve the power factor in electrical systems. The power factor is a measure of how effectively electrical power is converted into useful work output. A low power factor indicates poor efficiency, leading to wasted energy and increased costs. Active PFC circuits are designed to address this issue, enhancing the efficiency of power systems, especially in industrial and commercial settings.

Understanding Active Power Factor Correction

Active PFC is a sophisticated approach to optimizing the power factor, employing electronic control mechanisms to dynamically adjust and correct power usage. Unlike passive PFC, which relies on fixed components like capacitors and inductors, active PFC circuits use semiconductor devices and can handle a wider range of loads and conditions. This adaptability makes active PFC a preferred choice for modern power systems.

Advantages of Active PFC Circuits

Active PFC circuits offer several advantages over passive solutions. They provide better control over the power factor, making them suitable for variable loads and complex power systems. They can significantly reduce harmonic distortion, leading to cleaner power for sensitive electronics. Moreover, active PFC devices improve the overall efficiency by minimizing the reactive power, which in turn reduces energy loss and enhances the reliability of the power system.

Components of an Active PFC Circuit

An active PFC circuit typically consists of several key components. A control unit, usually a microcontroller or an application-specific integrated circuit (ASIC), governs the operation of the circuit. The power switch, often a MOSFET or IGBT, controls the current flow. A boost converter is often used to step up voltage levels, ensuring stable operation across varying input conditions. Additionally, sensors and feedback loops are integral to maintaining precise control over the power factor.

Design Considerations for Active PFC Circuits

Designing an active PFC circuit requires careful consideration of several factors. The type of load and its characteristics must be thoroughly analyzed to determine the appropriate PFC strategy. Ensuring compatibility with existing power systems is vital to avoid complications. Thermal management is crucial, as PFC components can generate significant heat during operation. Efficiency and cost-effectiveness should also be evaluated to achieve the best results.

Implementation Steps for Active PFC Circuits

1. **System Analysis**: Begin by assessing the electrical system, identifying areas where power factor correction is needed. Evaluate the load types and their power consumption patterns.

2. **Component Selection**: Choose suitable components for the PFC circuit, including semiconductors, control units, and passive elements. Ensure components can handle the expected load and conditions.

3. **Circuit Design**: Design the circuit layout, incorporating feedback loops and sensors to provide real-time data for dynamic adjustments. Pay attention to thermal management and component placement.

4. **Simulation and Testing**: Use simulation tools to test the circuit design under various conditions. This helps identify potential issues and optimize performance before physical implementation.

5. **Installation and Integration**: Once tested, install the active PFC circuit in the electrical system. Integrate it with existing components, ensuring seamless operation and minimizing disruptions.

6. **Monitoring and Maintenance**: Regularly monitor the system's performance to ensure the PFC circuit operates efficiently. Conduct routine maintenance to address any wear and tear or component degradation.

Challenges and Solutions in Active PFC Implementation

Implementing active PFC circuits can present challenges, such as high initial costs and the complexity of design. However, these can be mitigated with strategic planning and continuous monitoring. Training personnel in the maintenance and operation of these systems can reduce downtime and enhance overall efficiency. Additionally, advancements in technology continue to lower costs and simplify the implementation process, making active PFC more accessible to a wider range of applications.

Conclusion

Active PFC circuits are essential components in modern power systems, offering significant improvements in efficiency and reliability. By understanding their operation, advantages, and implementation steps, engineers can effectively integrate these circuits into various applications, achieving optimal power factor and minimizing energy waste. As technology advances, active PFC will continue to play a pivotal role in shaping efficient and sustainable power solutions.

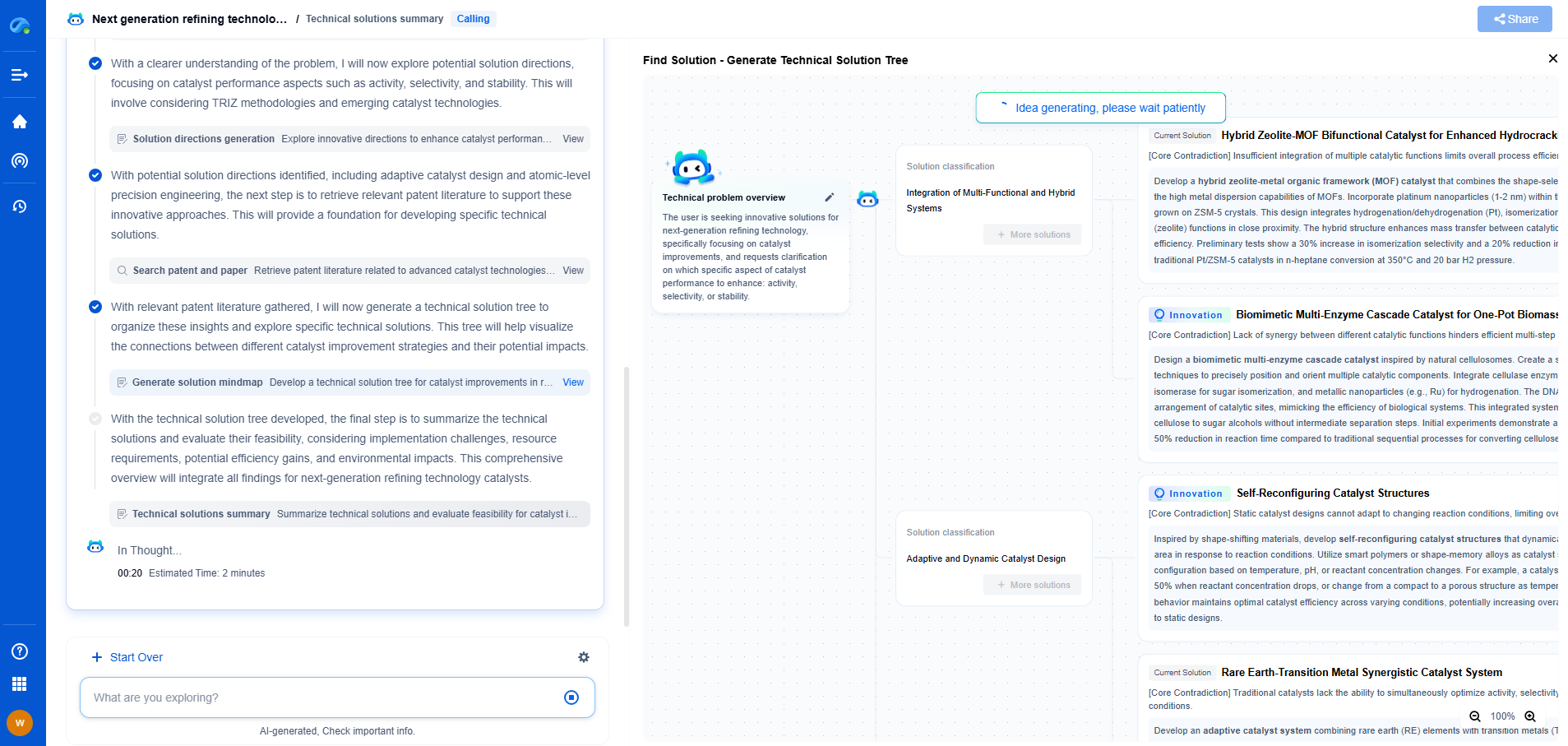

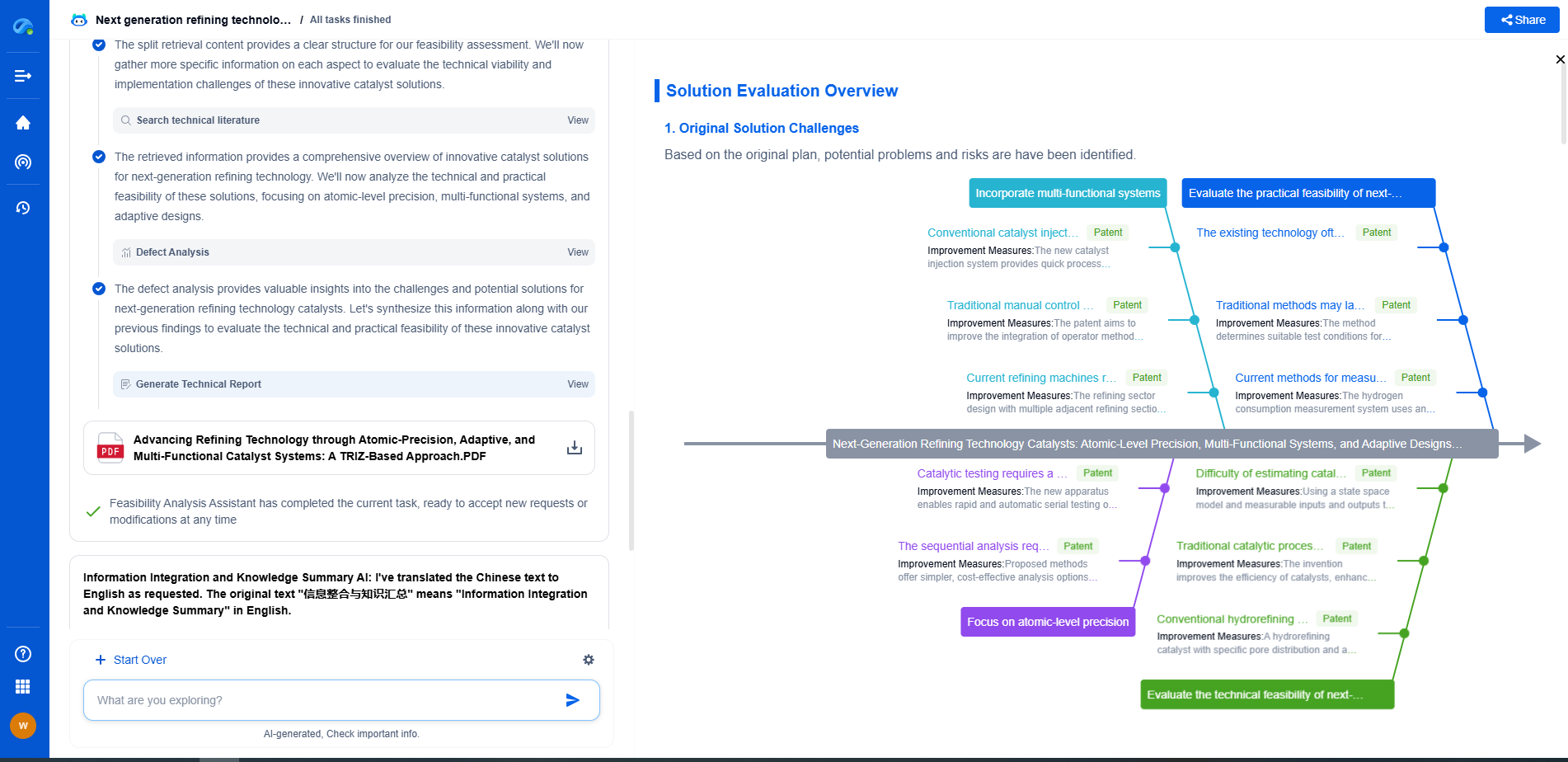

Accelerate Electronic Circuit Innovation with AI-Powered Insights from Patsnap Eureka

The world of electronic circuits is evolving faster than ever—from high-speed analog signal processing to digital modulation systems, PLLs, oscillators, and cutting-edge power management ICs. For R&D engineers, IP professionals, and strategic decision-makers in this space, staying ahead of the curve means navigating a massive and rapidly growing landscape of patents, technical literature, and competitor moves.

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

🚀 Experience the next level of innovation intelligence. Try Patsnap Eureka today and discover how AI can power your breakthroughs in electronic circuit design and strategy. Book a free trial or schedule a personalized demo now.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com