Industrial Plant Power Distribution: High-Voltage vs. Low-Voltage Systems

JUN 26, 2025 |

In the realm of industrial plants, efficient power distribution is crucial for ensuring smooth operations, minimizing downtime, and maximizing productivity. One of the fundamental considerations in designing an industrial power distribution system is the choice between high-voltage and low-voltage systems. Each of these systems has its unique advantages and challenges, and the decision often hinges on the specific needs and characteristics of the facility in question. This article delves into the key differences between high-voltage and low-voltage systems and explores their respective roles in industrial power distribution.

Understanding High-Voltage Systems

High-voltage systems are typically employed in industrial settings where there is a need to transmit electricity over long distances or when heavy electrical loads are involved. These systems operate at voltages greater than 1,000 volts and are essential for supplying power to large-scale industrial plants, manufacturing facilities, and other energy-intensive operations.

One of the primary advantages of high-voltage systems is their ability to efficiently transmit electricity over long distances with minimal power loss. This is particularly important for industries located far from power generation sources. By stepping up the voltage, power can be transmitted more efficiently, reducing the current and, subsequently, minimizing energy loss due to resistance in the transmission lines.

Another advantage is that high-voltage systems can handle large electrical loads, making them suitable for heavy machinery and equipment that require significant power to operate. This capability is vital for industries such as steel manufacturing, chemical processing, and mining, where equipment demands substantial electrical input.

However, high-voltage systems come with their own set of challenges. The installation and maintenance of high-voltage infrastructure are typically more complex and costly compared to low-voltage systems. Specialized equipment, stringent safety measures, and trained personnel are necessary to manage these systems safely and effectively.

Exploring Low-Voltage Systems

Low-voltage systems, operating at voltages less than 1,000 volts, are commonly used in situations where the electrical demand is moderate, and the distance for power transmission is relatively short. They are prevalent in industries such as food processing, textiles, and small manufacturing units.

One of the key benefits of low-voltage systems is their relative ease of installation and maintenance. The equipment required is generally less expensive, and the safety risks associated with handling low voltage are significantly reduced. This makes low-voltage systems an attractive option for facilities with budget constraints or those with less complex power distribution needs.

Moreover, low-voltage systems offer greater flexibility in terms of modifications and expansions. As industrial plants grow or change, it is often easier to adapt a low-voltage system to meet new demands without significant overhauls.

Despite these advantages, low-voltage systems are not suitable for all industrial applications. They are less efficient for transmitting power over long distances and may not handle heavy electrical loads as effectively as high-voltage systems. This limitation can lead to higher energy losses and increased costs in certain scenarios.

Key Considerations in Choosing Between High-Voltage and Low-Voltage Systems

When deciding between high-voltage and low-voltage systems, several factors must be considered to ensure the optimal choice for a given industrial plant. These include:

1. Load Requirements: Assessing the electrical demand of the facility is crucial. High-voltage systems are generally better suited for large loads, while low-voltage systems are ideal for moderate electrical needs.

2. Distance of Power Transmission: The proximity of the power source to the facility plays a significant role. Long-distance transmission favors high-voltage systems due to their efficiency in reducing power loss.

3. Budget Constraints: High-voltage systems typically involve higher initial investment and maintenance costs. If budget limitations are a concern, low-voltage systems may be more feasible.

4. Safety Considerations: High-voltage systems require stringent safety measures and trained personnel. The facility's ability to manage these aspects is critical in the decision-making process.

5. Flexibility and Future Expansion: The potential for future growth and changes in the facility should be taken into account. Low-voltage systems offer greater adaptability in this regard.

Conclusion

In conclusion, the choice between high-voltage and low-voltage power distribution systems in industrial plants depends on a careful analysis of the specific requirements and constraints of the facility. Each system has its distinct advantages and limitations, and the decision should align with the facility’s operational goals, budget, and future expansion plans. By understanding the unique characteristics of both systems, industrial plant managers can make informed decisions that optimize power distribution efficiency and contribute to the overall success of their operations.

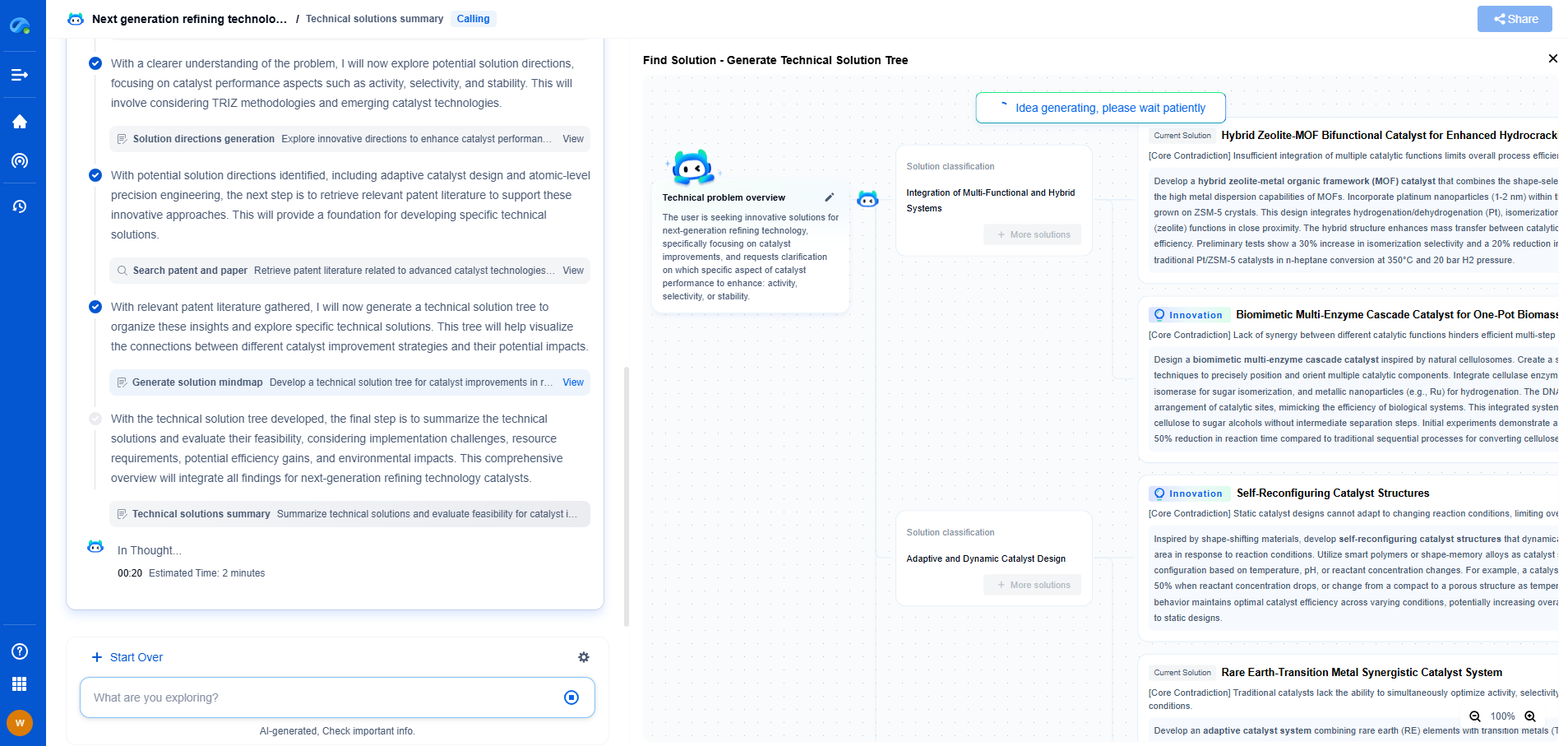

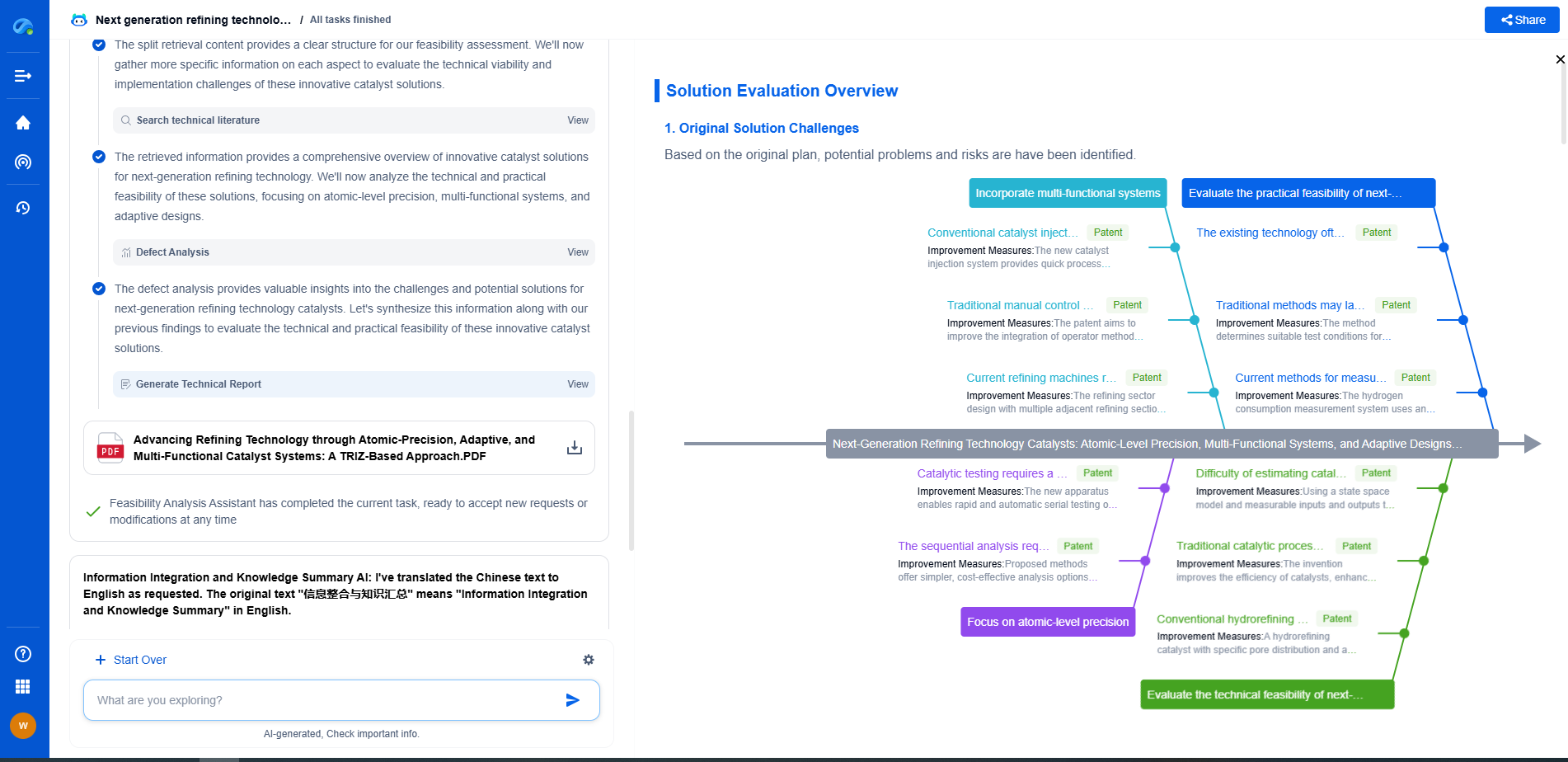

Stay Ahead in Power Systems Innovation

From intelligent microgrids and energy storage integration to dynamic load balancing and DC-DC converter optimization, the power supply systems domain is rapidly evolving to meet the demands of electrification, decarbonization, and energy resilience.

In such a high-stakes environment, how can your R&D and patent strategy keep up?

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

👉 Experience how Patsnap Eureka can supercharge your workflow in power systems R&D and IP analysis. Request a live demo or start your trial today.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com