Industrial Visual Inspection: Defect Detection with Deep Learning

JUL 10, 2025 |

In industrial settings, maintaining high-quality standards is crucial for ensuring customer satisfaction and operational efficiency. Visual inspection is a fundamental aspect of quality control, traditionally carried out by human inspectors who examine products for defects. However, human inspection has limitations, such as fatigue, inconsistency, and high labor costs. To address these challenges, industries are increasingly turning to automated solutions powered by deep learning technologies. This blog will explore how deep learning enhances defect detection in industrial visual inspection, providing greater accuracy and reliability.

The Evolution of Defect Detection

Historically, defect detection relied heavily on manual labor, where inspectors would visually check products for defects such as cracks, scratches, or deformations. While effective to some extent, this method is labor-intensive and prone to human error. The introduction of machine vision systems marked a significant advancement, enabling automated inspection processes. These systems use cameras and image processing algorithms to analyze products, but they still require extensive programming and can struggle with complex or variable defects.

Deep Learning: A Game Changer

Deep learning, a subset of artificial intelligence, has revolutionized many fields, including visual inspection. Unlike traditional machine vision systems, deep learning models can learn from data and improve over time. This ability to learn and adapt makes deep learning particularly effective for defect detection in industrial applications. Convolutional Neural Networks (CNNs) are the backbone of these systems, capable of processing and analyzing visual data with remarkable accuracy.

Advantages of Deep Learning in Visual Inspection

1. **Improved Accuracy and Consistency**: Deep learning models can identify subtle defects that human inspectors might miss. They provide consistent results, unaffected by fatigue or environmental factors, ensuring a high level of quality control.

2. **Scalability and Speed**: Automated inspection systems can operate 24/7, handling large volumes of products without the need for breaks. This efficiency is crucial for industries with high production rates.

3. **Flexibility**: Deep learning models are adaptable and can be trained to recognize new types of defects as they arise. This flexibility reduces the need for constant reprogramming and system updates.

4. **Cost-Effectiveness**: While initial implementation can be costly, the long-term savings from reduced labor costs and minimal errors lead to a favorable return on investment.

Challenges and Considerations

While deep learning offers numerous benefits, there are challenges to consider. One significant hurdle is the need for large datasets to train models effectively. Collecting and labeling sufficient data can be time-consuming and expensive. Additionally, implementing deep learning systems requires technical expertise, which may not be readily available in all organizations. Lastly, ensuring the system's robustness against variations in lighting, orientation, and background can be challenging and requires careful calibration.

Applications in Various Industries

Deep learning-based visual inspection is applicable across diverse industries. In the automotive sector, it is used to detect defects in components and assemblies, ensuring safety and reliability. The electronics industry employs these systems to inspect circuit boards for manufacturing defects. In the food and beverage industry, deep learning helps maintain product quality by identifying foreign objects or packaging defects. These applications demonstrate the versatility and effectiveness of deep learning in enhancing quality control processes.

Future Trends and Developments

The future of industrial visual inspection with deep learning looks promising. As technology advances, we can expect further improvements in model accuracy and speed. The integration of deep learning with other technologies, such as the Internet of Things (IoT) and robotics, will enable even more sophisticated inspection systems. Additionally, the development of unsupervised learning techniques could reduce the need for extensive labeled datasets, making the implementation of these systems more accessible.

Conclusion

Industrial visual inspection has come a long way, from manual checks to sophisticated deep learning systems. By leveraging the power of deep learning, industries can achieve higher accuracy, consistency, and efficiency in defect detection. While challenges remain, the benefits of adopting deep learning-based visual inspection systems are undeniable. As technology continues to evolve, these systems will become even more integral to maintaining quality standards across various industries. Embracing this technology not only enhances product quality but also offers a competitive edge in today’s fast-paced market.

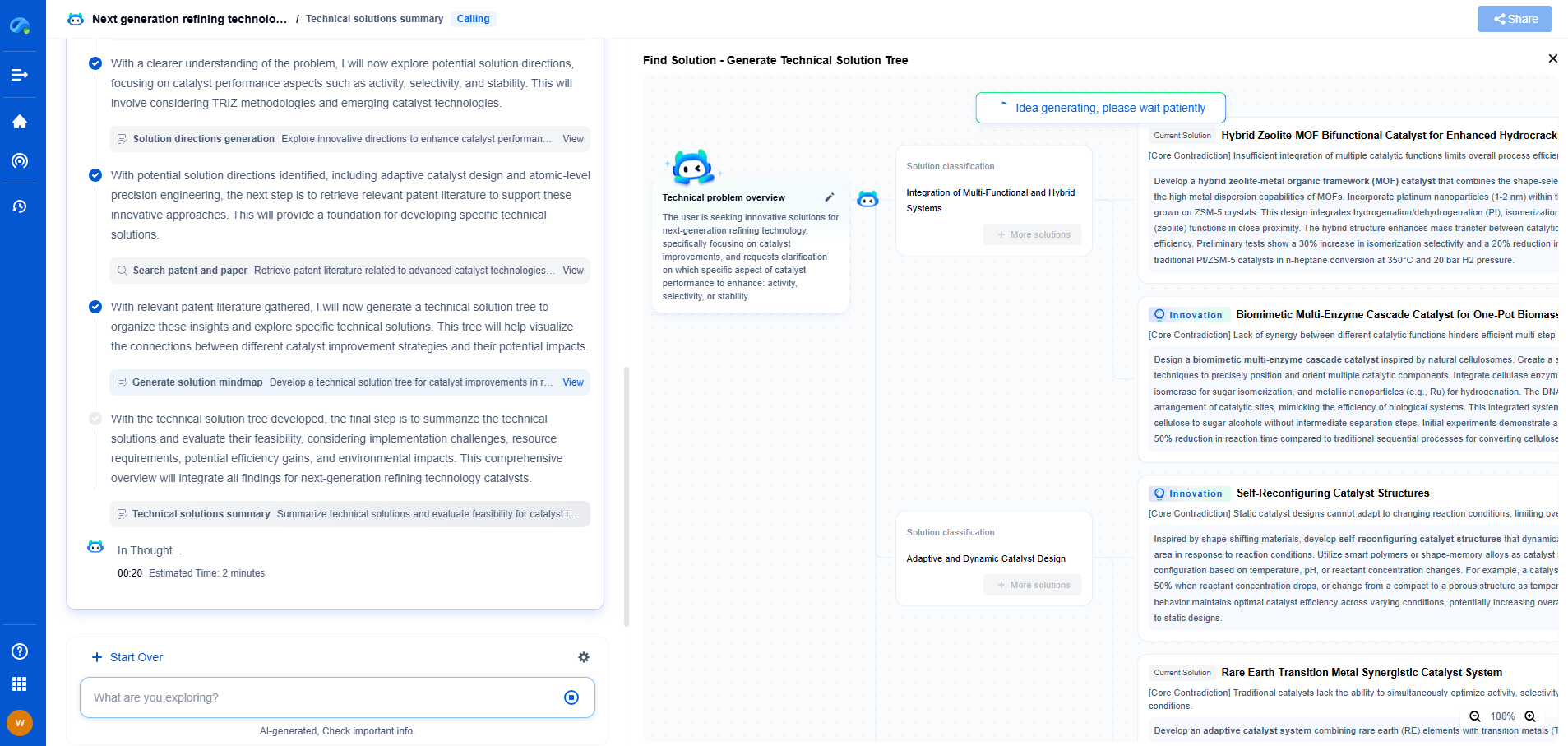

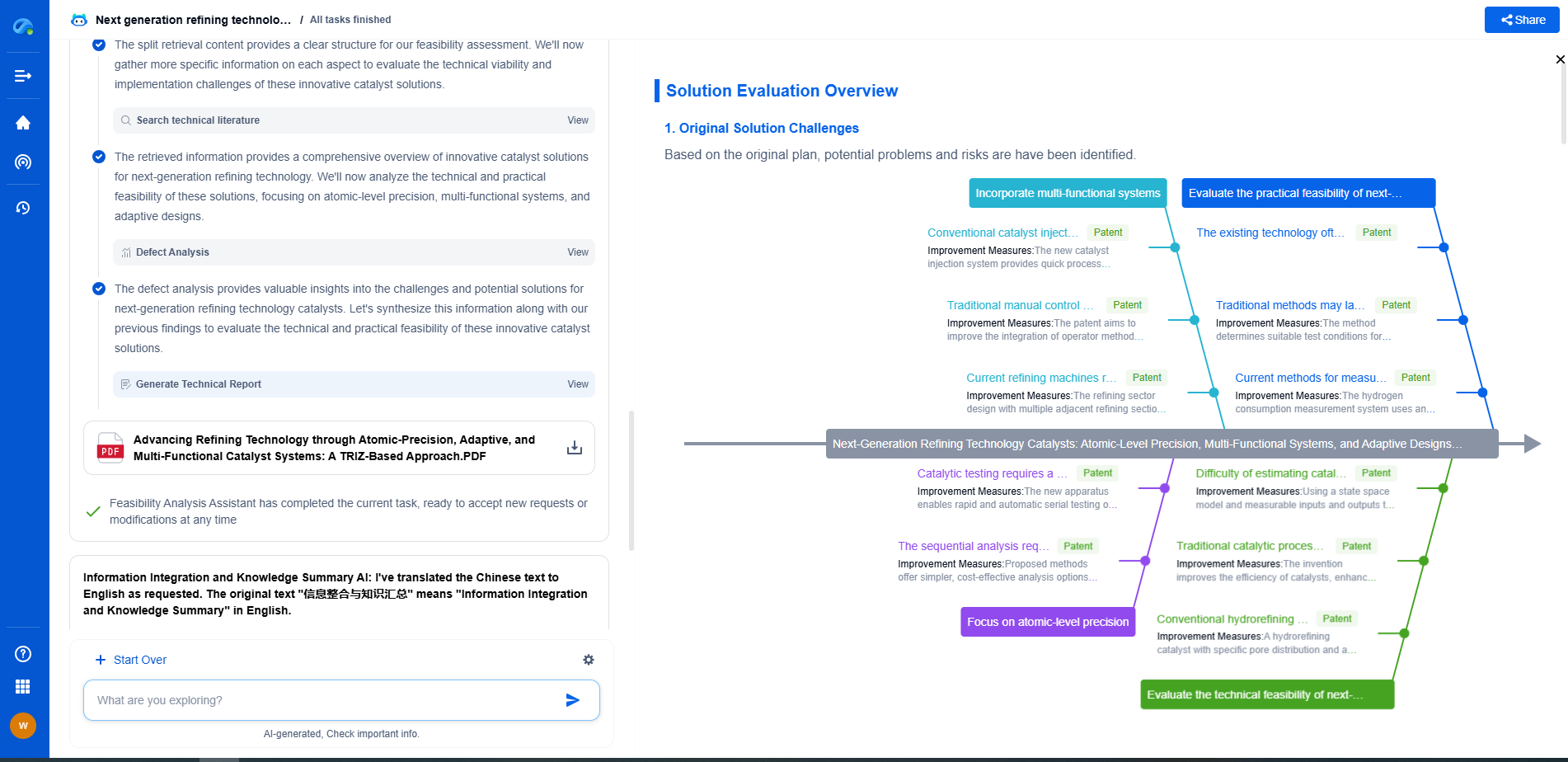

Image processing technologies—from semantic segmentation to photorealistic rendering—are driving the next generation of intelligent systems. For IP analysts and innovation scouts, identifying novel ideas before they go mainstream is essential.

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

🎯 Try Patsnap Eureka now to explore the next wave of breakthroughs in image processing, before anyone else does.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com