Industrial Visual Inspection: How Cameras Detect Defects in Real Time

JUL 10, 2025 |

The Role of Visual Inspection in Industry

Visual inspection is a crucial step in the manufacturing process. It involves scrutinizing products to ensure they meet quality standards and specifications. Traditionally, this task was performed manually, relying heavily on human operators. However, manual inspection is prone to errors and inconsistencies due to fatigue and subjective judgment. The need for efficient, accurate, and consistent inspection methods has paved the way for automated visual inspection systems powered by cameras.

How Do Cameras Detect Defects?

The process of detecting defects using cameras involves several key components: image acquisition, image processing, and decision-making.

1. Image Acquisition: High-resolution cameras capture images of products as they move along the production line. These cameras are strategically positioned to cover critical areas where defects are most likely to occur.

2. Image Processing: Once images are captured, they are processed using sophisticated algorithms. Machine vision software analyzes these images to identify irregularities or deviations from the norm. Techniques such as pattern recognition, edge detection, and optical character recognition are commonly employed to detect flaws.

3. Decision-Making: After processing the images, the system makes decisions regarding the quality of the product. If a defect is detected, the system can trigger actions such as removing the faulty product from the line or alerting operators for further inspection.

Technologies Empowering Real-Time Inspection

Several technologies play a crucial role in enabling real-time visual inspection:

- Machine Learning and AI: These technologies allow systems to learn from data and improve their accuracy over time. AI algorithms can be trained to recognize specific defects or anomalies, making the inspection process more reliable.

- High-Speed Cameras: Modern industrial cameras can capture images at incredibly high speeds, ensuring that even fast-moving production lines can be monitored effectively.

- 3D Imaging: While traditional systems rely on 2D images, 3D imaging technologies provide a more comprehensive view of the product, enabling the detection of defects that may not be visible in two dimensions.

Benefits of Real-Time Visual Inspection

Real-time visual inspection offers numerous advantages over manual inspection:

- Increased Accuracy: Automated systems reduce the likelihood of human error, ensuring a higher level of consistency and accuracy in defect detection.

- Enhanced Efficiency: With the ability to inspect products at high speeds, these systems can handle large volumes without slowing down production.

- Cost Savings: By identifying defects early in the process, manufacturers can reduce waste and rework, leading to significant cost savings.

- Improved Product Quality: Consistent inspection ensures that only products meeting the highest quality standards reach consumers, enhancing customer satisfaction and brand reputation.

Challenges and Future Prospects

Despite its advantages, real-time visual inspection does face challenges. Complex products with intricate designs can be difficult for current systems to inspect accurately. There is also the ongoing need for better algorithms and faster processing to keep up with ever-increasing production speeds.

Looking to the future, advancements in AI and machine learning promise to make these systems even more sophisticated and capable. Integration with other Industry 4.0 technologies, such as the Internet of Things (IoT), could lead to even more integrated and efficient manufacturing processes.

In conclusion, cameras and automated systems have revolutionized industrial visual inspection, offering unparalleled accuracy and efficiency in defect detection. As technology continues to advance, these systems will become even more integral to maintaining high-quality standards in manufacturing, ensuring that industries can meet the demands of an ever-evolving market.

Image processing technologies—from semantic segmentation to photorealistic rendering—are driving the next generation of intelligent systems. For IP analysts and innovation scouts, identifying novel ideas before they go mainstream is essential.

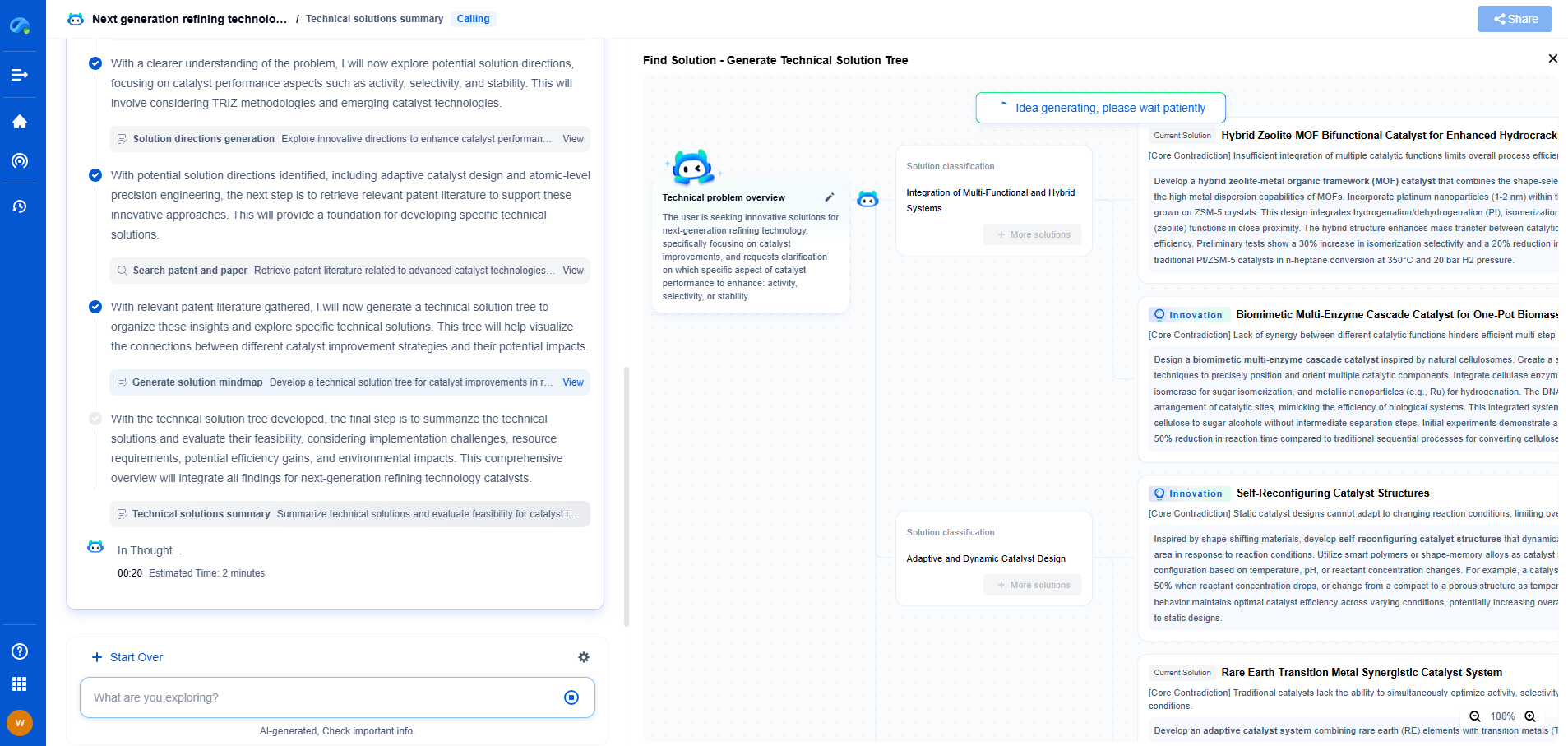

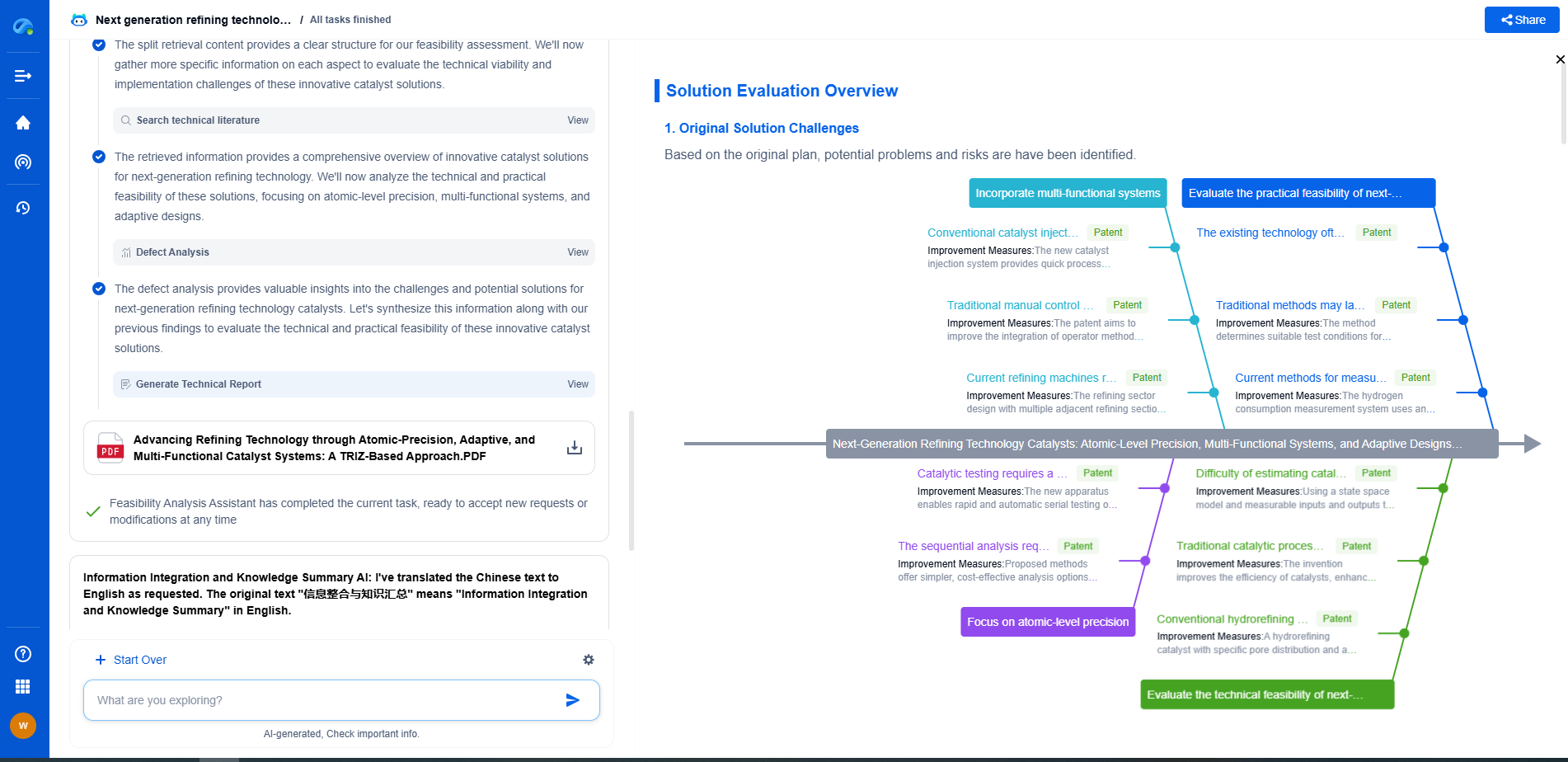

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

🎯 Try Patsnap Eureka now to explore the next wave of breakthroughs in image processing, before anyone else does.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com