Infrared Thermography: Drone-Based vs. Handheld Inspection Efficiency

JUL 22, 2025 |

Infrared thermography is a powerful technology used to detect and visualize temperature variations across surfaces. By capturing infrared radiation emitted by objects, it allows inspectors to identify thermal anomalies that could indicate issues such as energy inefficiencies, structural defects, or electrical faults. With advancements in technology, infrared thermography has found applications in various industries, including building diagnostics, electrical inspections, and maintenance of mechanical systems. Two prominent methods that leverage this technology are drone-based and handheld inspections. In this article, we will explore the efficiency of these two approaches and consider their advantages and limitations.

Drone-Based Infrared Thermography

Drone-based infrared thermography has become increasingly popular due to its ability to cover large areas quickly and efficiently. Equipped with high-resolution infrared cameras, drones can access hard-to-reach areas and capture detailed thermal images from a bird’s-eye view. This method is particularly advantageous for inspecting extensive infrastructures such as solar farms, power lines, and large commercial buildings.

One of the primary advantages of drone-based inspections is speed. Drones can cover vast areas in a fraction of the time it would take a human inspector to do the same on foot. This efficiency can significantly reduce inspection times and costs, making it a cost-effective solution for large-scale projects.

Additionally, drones can operate in hazardous environments or over difficult terrain, reducing the risk to human inspectors. This capability is especially important in industries where safety is a top priority, such as in the inspection of wind turbines or high-voltage power lines. Furthermore, the aerial perspective provided by drones can offer unique insights that are not possible with ground-based inspections.

However, there are certain limitations to be considered. Drone operations can be affected by adverse weather conditions such as high winds or rain, which can limit their usability. Additionally, regulatory restrictions and airspace limitations may pose challenges, requiring operators to obtain necessary permissions and adhere to local regulations.

Handheld Infrared Thermography

Handheld infrared thermography remains a widely used and versatile method for conducting detailed inspections. Handheld infrared cameras allow inspectors to get up close and personal with the target objects, providing the ability to capture high-resolution images and conduct thorough analysis on-site. This method is particularly effective for inspecting smaller areas or specific components where detailed analysis is required.

One of the key advantages of handheld inspections is the level of control and precision they offer. Inspectors can adjust camera settings on-the-fly and focus on specific areas of interest, making it easier to identify subtle differences in temperature that might indicate potential issues. This level of detail is especially beneficial in industries such as electrical inspections, where pinpointing exact hotspots is essential for maintenance and repair.

Furthermore, handheld inspections do not face the regulatory and weather-related limitations that drone operations might encounter. Inspectors can work indoors or in confined spaces without the need for special permissions, and their work is not hindered by inclement weather conditions.

However, handheld inspections can be time-consuming, especially for large areas or multiple components. The need for physical access to each inspection point can result in longer inspection times, which may be a disadvantage for extensive projects.

Comparing Efficiency: Drone-Based vs. Handheld

When it comes to efficiency, the choice between drone-based and handheld infrared thermography largely depends on the specific requirements of the inspection task. For large-scale inspections where speed and coverage are paramount, drone-based thermography is often the more efficient choice. Its ability to quickly scan vast areas and provide a comprehensive overview makes it ideal for inspecting solar farms, pipelines, and large buildings.

On the other hand, for detailed inspections that require precise analysis and control, handheld thermography offers the advantage. It allows inspectors to focus on specific areas and conduct a more thorough examination, which is crucial for identifying precise faults in electrical systems or mechanical components.

Conclusion

Both drone-based and handheld infrared thermography have their unique strengths and limitations. While drones offer rapid coverage and access to hard-to-reach areas, handheld devices provide detailed analysis and are not constrained by weather or regulatory issues. The choice between the two methods should be guided by the specific needs of the inspection task, the scale of the project, and the level of detail required. As technology continues to advance, the integration of both methods may provide the most comprehensive solutions, combining the strengths of each to optimize inspection efficiency.

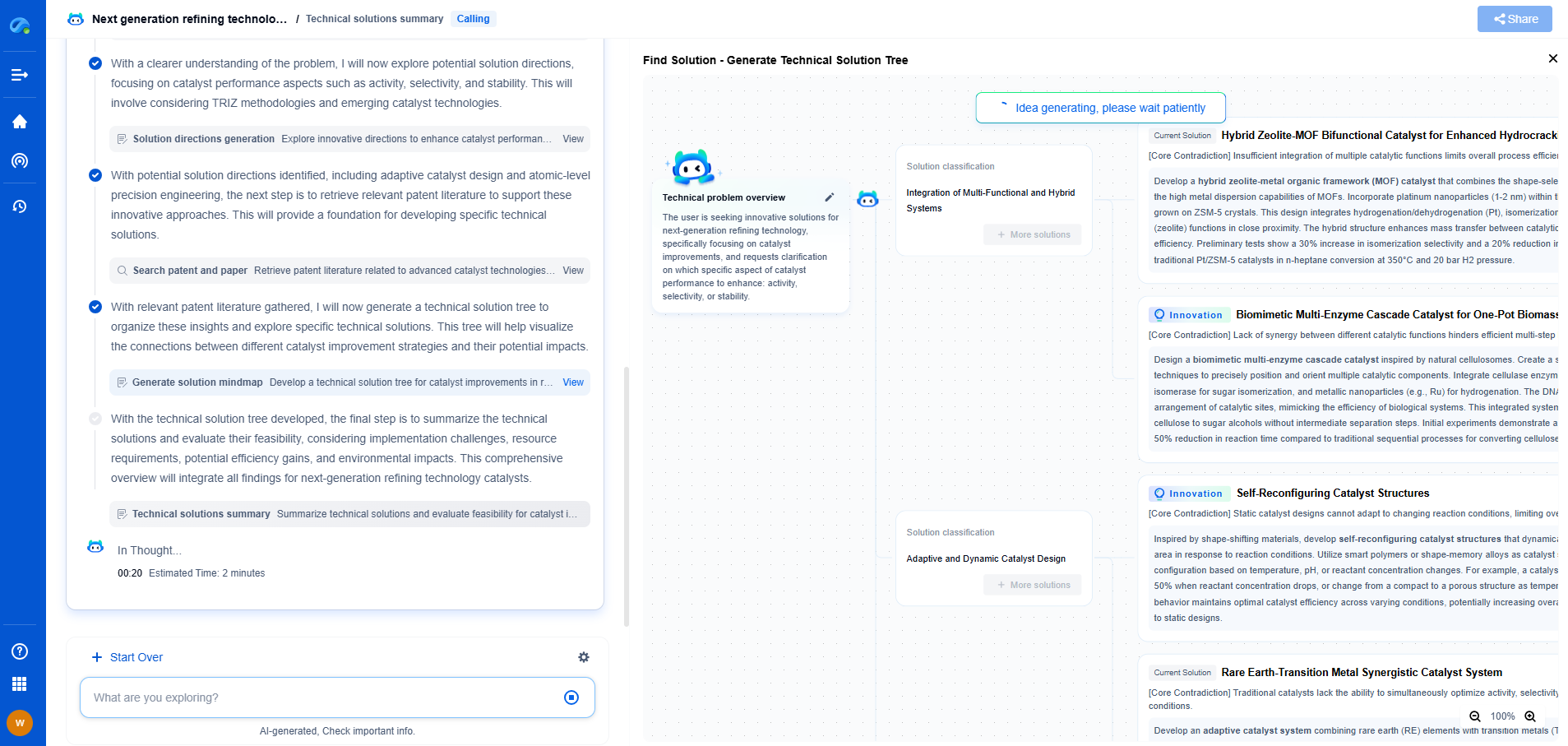

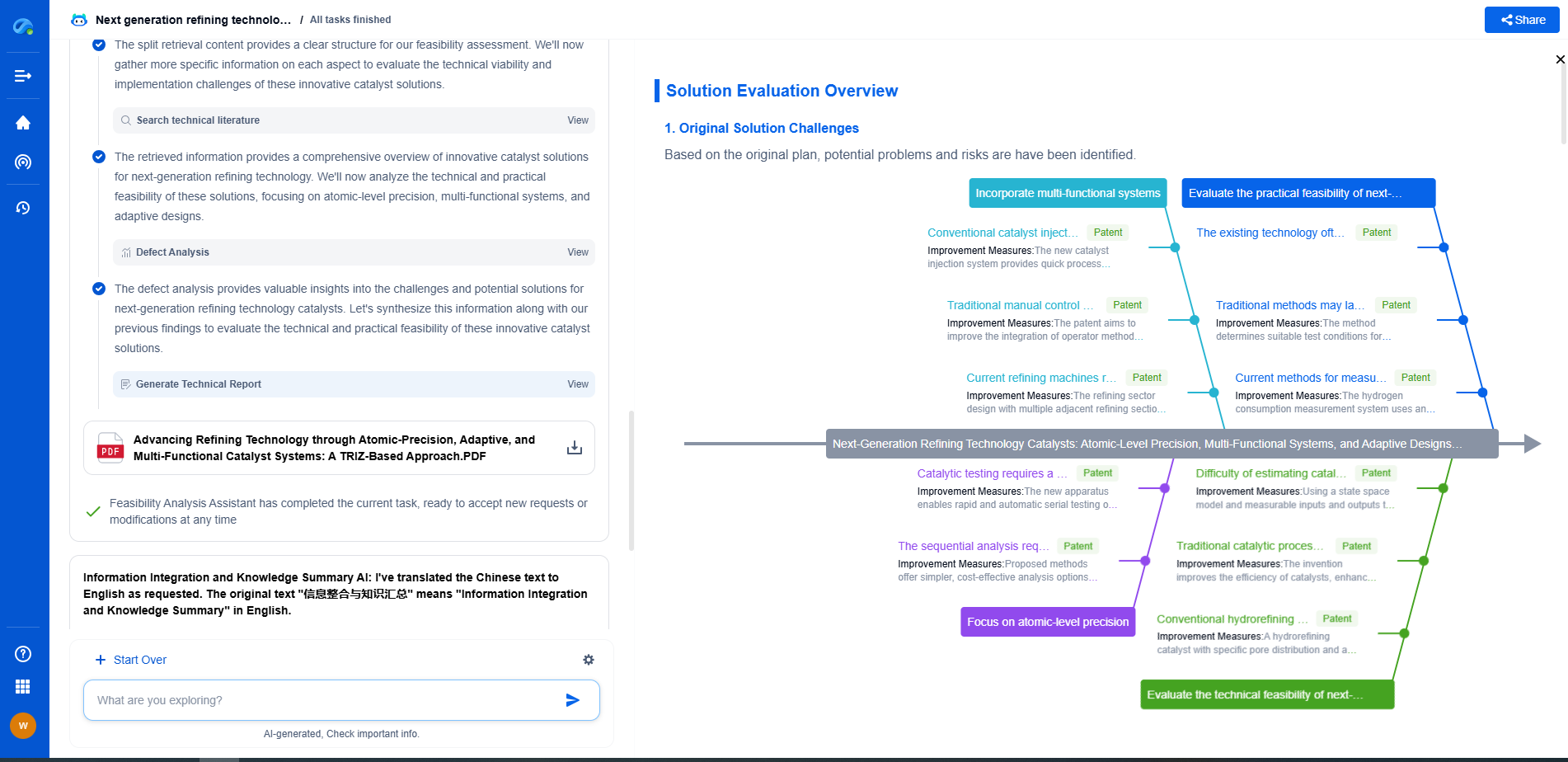

As solar technology races ahead—from perovskite cells to tandem architectures, from anti-reflective coatings to transparent electrodes—staying on top of fast-moving innovation has become a strategic imperative.

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

⚡ Ready to accelerate your solar innovation journey? Try Patsnap Eureka today and let AI help you harness the full power of the sun—and your IP strategy.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com