Infrared Thermography: Thermal Resistance Network Modeling

JUL 22, 2025 |

Infrared thermography is a fascinating technology that captures temperature distribution across surfaces. By converting thermal radiation into a visible image, it enables the identification of thermal anomalies and inefficiencies in various fields, from electrical inspections to building diagnostics. One of the critical aspects of effectively using infrared thermography is understanding thermal resistance networks, which help model heat transfer within a system.

**Understanding Thermal Resistance Networks**

A thermal resistance network is a conceptual model used to understand and predict the flow of heat through materials and systems. It is analogous to an electrical circuit, where heat is transferred through a series of resistances that can be added or divided based on the configuration—whether in series or parallel. Each segment in the network represents an element of thermal resistance, which is influenced by factors like material properties, thickness, surface area, and temperature gradients.

In practical applications, thermal resistance networks help in identifying heat flow paths and insulation inefficiencies. By modeling the thermal resistances, engineers can predict where heat losses may occur and identify areas that require additional insulation or design changes.

**Key Components of Thermal Resistance Networks**

1. **Conduction Resistance**: This is the resistance to heat flow through a solid material. It is calculated using the material's thermal conductivity, the thickness of the material, and the cross-sectional area. The formula is R_cond = L/(k*A), where L is the thickness, k is the thermal conductivity, and A is the area.

2. **Convection Resistance**: This refers to the resistance to heat transfer between a surface and a fluid, such as air or water, that is in motion. The convective heat transfer coefficient, h, plays a crucial role in determining this resistance. The formula is R_conv = 1/(h*A).

3. **Radiation Resistance**: Radiation resistance accounts for the heat transfer via electromagnetic waves, which occurs even in a vacuum. It depends on factors such as the surface emissivity and the temperature difference between surfaces.

**Applications of Thermal Resistance Networks in Infrared Thermography**

Infrared thermography paired with thermal resistance networks offers a comprehensive approach to diagnosing thermal performance. In building diagnostics, for instance, this combination is used to locate insulation defects and thermal bridges—areas where heat bypasses the insulation layer.

In electronics, thermal resistance networks help in predicting the heat dissipation from components, ensuring that the design maintains operational temperatures within safe limits. By visualizing the temperature distribution with infrared thermography, engineers can validate the thermal model predictions, ensuring reliability and efficiency.

**Challenges and Considerations**

Despite the advantages, using thermal resistance networks with infrared thermography comes with challenges. Accurate material property data is essential for reliable modeling, yet this data can vary with temperature, material age, and manufacturing inconsistencies. Additionally, external conditions such as wind, sunlight, and ambient temperature can affect the infrared thermography readings, making it crucial to account for these factors in the analysis.

Calibration of infrared cameras and consistent maintenance are also critical to ensure accurate measurements. Furthermore, the interpretation of thermographic images requires skill and experience to distinguish between genuine thermal anomalies and apparent temperature differences caused by environmental effects.

**Conclusion**

Infrared thermography combined with thermal resistance network modeling is a powerful tool for understanding and managing heat transfer in a variety of applications. By providing a visual representation of temperature distribution and a theoretical model of heat flow, it allows for the identification and rectification of thermal inefficiencies. As technology advances, the integration of these tools will continue to enhance our ability to design more energy-efficient systems and improve the diagnostic processes across different industries.

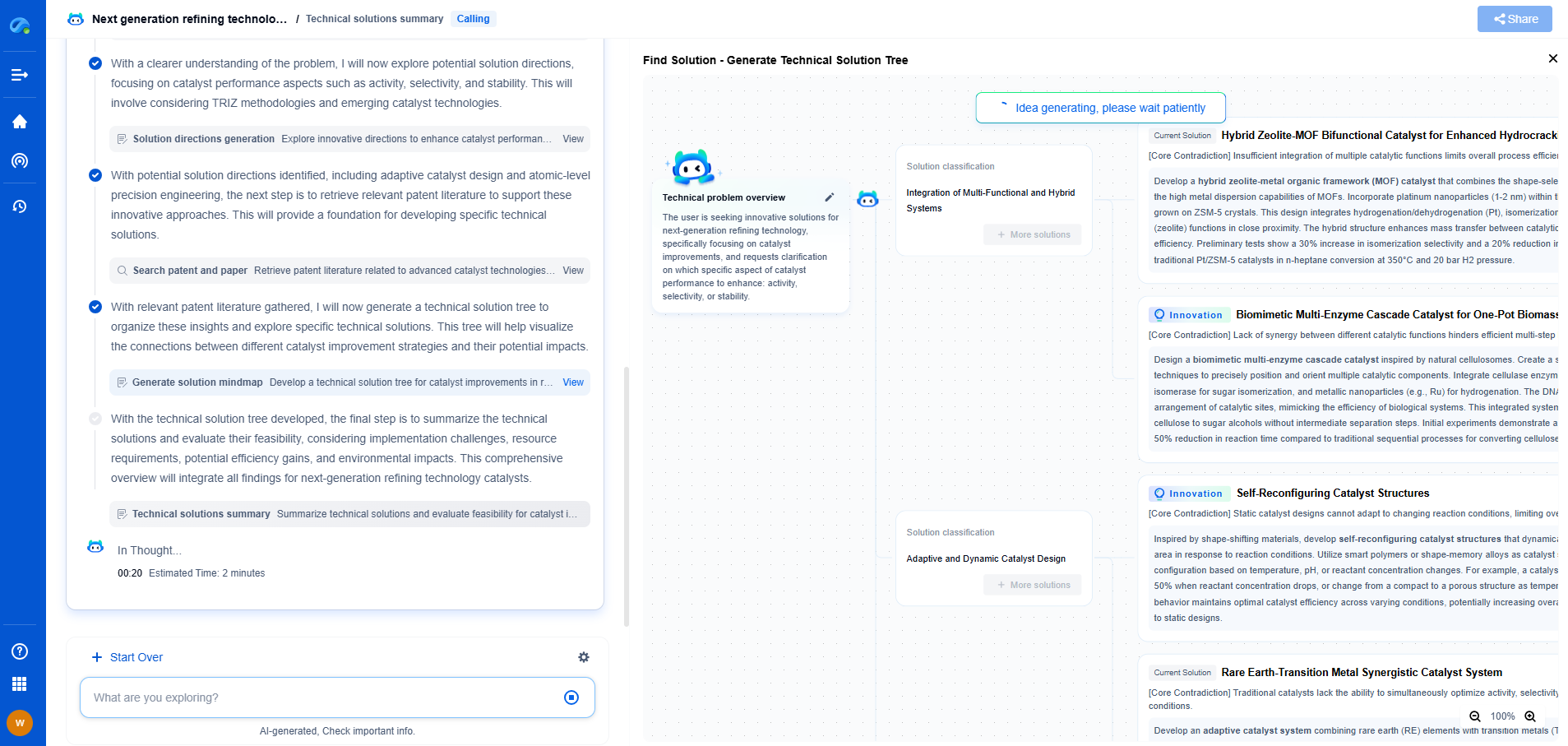

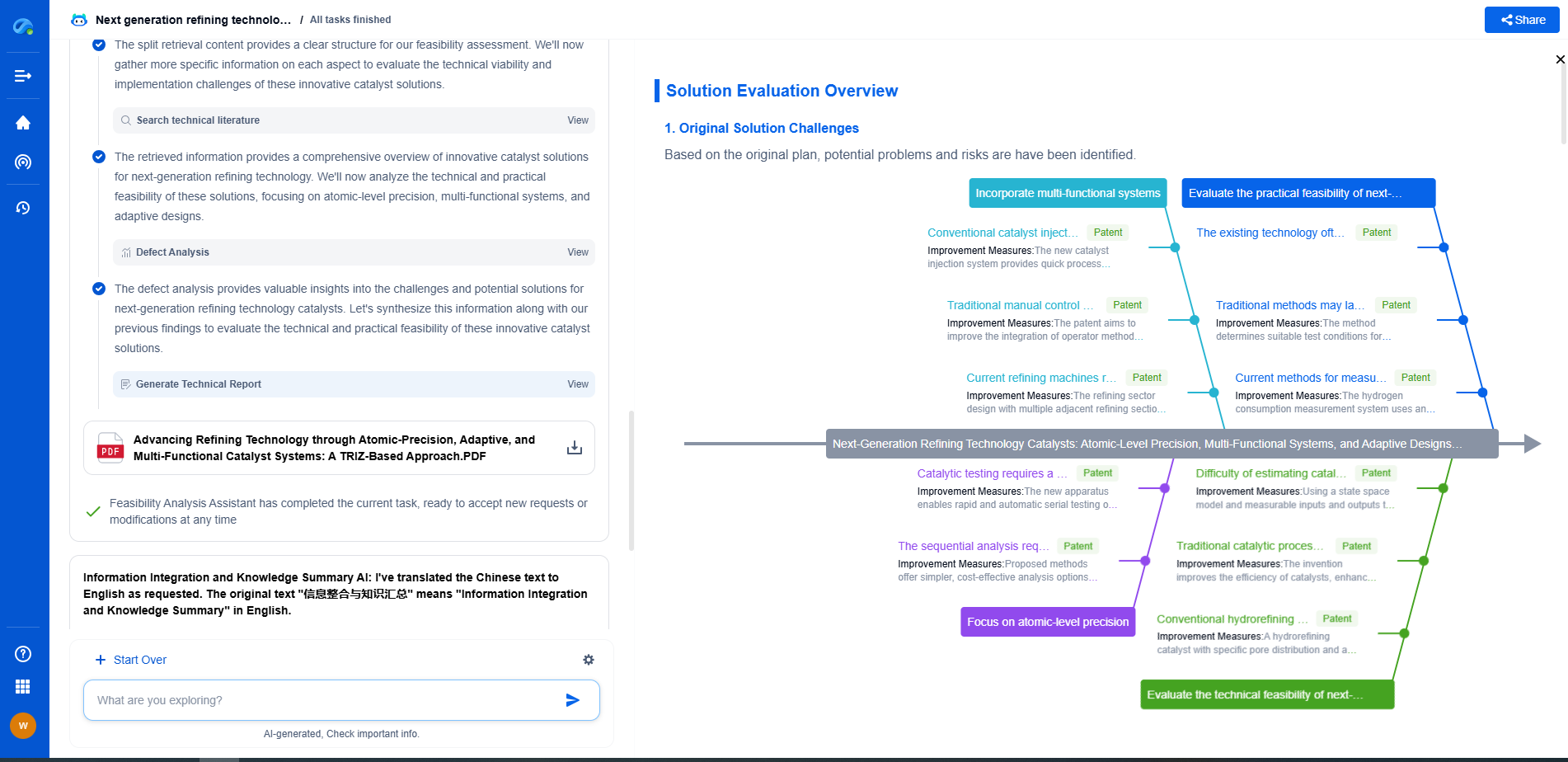

As solar technology races ahead—from perovskite cells to tandem architectures, from anti-reflective coatings to transparent electrodes—staying on top of fast-moving innovation has become a strategic imperative.

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

⚡ Ready to accelerate your solar innovation journey? Try Patsnap Eureka today and let AI help you harness the full power of the sun—and your IP strategy.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com