Lead-Free Soldering in Inverter Manufacturing: Progress & Challenges

JUL 22, 2025 |

In the ever-evolving world of electronics manufacturing, the shift towards more environmentally friendly practices has gained significant momentum. One area where this is particularly evident is in the production of inverters, where lead-free soldering has become an industry standard. This transition not only aligns with global environmental regulations but also poses its own set of challenges and benefits. In this article, we will explore both the progress that has been made and the hurdles that remain in the adoption of lead-free soldering within inverter manufacturing.

**The Push for Environmental Compliance**

The drive for lead-free soldering in inverter manufacturing is primarily motivated by the need to comply with stringent environmental regulations. The European Union's Restriction of Hazardous Substances Directive (RoHS), which limits the use of certain hazardous materials, including lead, in electrical and electronic equipment, has been a significant catalyst. Similar regulations have been adopted in various countries worldwide, pressuring manufacturers to seek alternative soldering materials that do not contain lead.

**Advancements in Lead-Free Solder Technology**

Manufacturers have made notable strides in developing lead-free solder materials that meet the necessary mechanical and thermal requirements for inverter applications. Alloys such as SAC (Tin-Silver-Copper) have emerged as popular alternatives due to their favorable properties. These materials offer excellent thermal fatigue resistance and mechanical strength, essential for the reliability and performance of inverters.

In addition to alloy development, advancements in soldering techniques have also played a crucial role. Manufacturers are investing in research to optimize soldering processes, ensuring that lead-free alternatives can be seamlessly integrated into existing production lines without compromising the integrity of the final product.

**Challenges in Implementation**

Despite these advancements, the transition to lead-free soldering is not without its challenges. One of the primary concerns is the higher melting temperature of lead-free solders compared to traditional leaded solders. This necessitates modifications in the manufacturing process, including adjustments in soldering equipment and techniques, which can be costly and time-consuming.

Another challenge lies in the reliability of lead-free solder joints over time. While significant progress has been made in improving the durability of these joints, concerns about long-term reliability under harsh operating conditions persist. Manufacturers must rigorously test and validate these joints to ensure they meet the high standards required in inverter applications.

**Economic Considerations**

The shift to lead-free soldering also involves economic implications. The initial investment in new materials, equipment, and training can be substantial, particularly for smaller manufacturers. However, the long-term benefits, including compliance with global regulations and improved market competitiveness, often outweigh these initial costs. Moreover, as lead-free technology becomes more widespread, economies of scale are likely to reduce these expenses over time.

**Future Outlook**

The future of lead-free soldering in inverter manufacturing holds promise. Continued research and development efforts are expected to yield even more advanced solder alloys and techniques that address current challenges. Furthermore, as the industry collectively moves towards more sustainable practices, manufacturers who embrace lead-free soldering early on are likely to gain a competitive edge.

In conclusion, while the journey to lead-free soldering in inverter manufacturing presents several challenges, it is a necessary step towards a more sustainable future. The progress made so far is encouraging, and with ongoing innovation and adaptation, the industry is well-positioned to overcome the remaining hurdles and fully embrace this environmentally responsible technology.

As solar technology races ahead—from perovskite cells to tandem architectures, from anti-reflective coatings to transparent electrodes—staying on top of fast-moving innovation has become a strategic imperative.

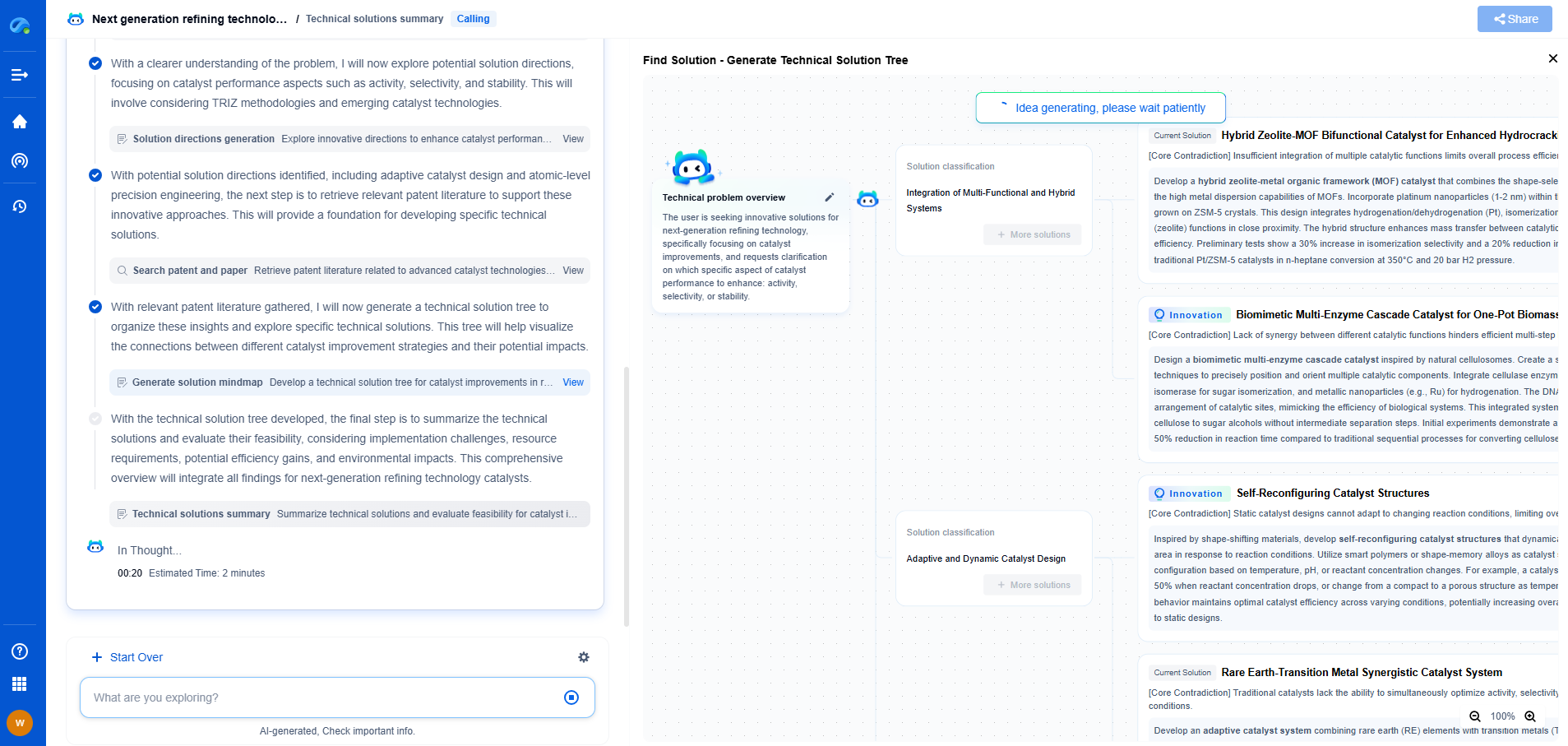

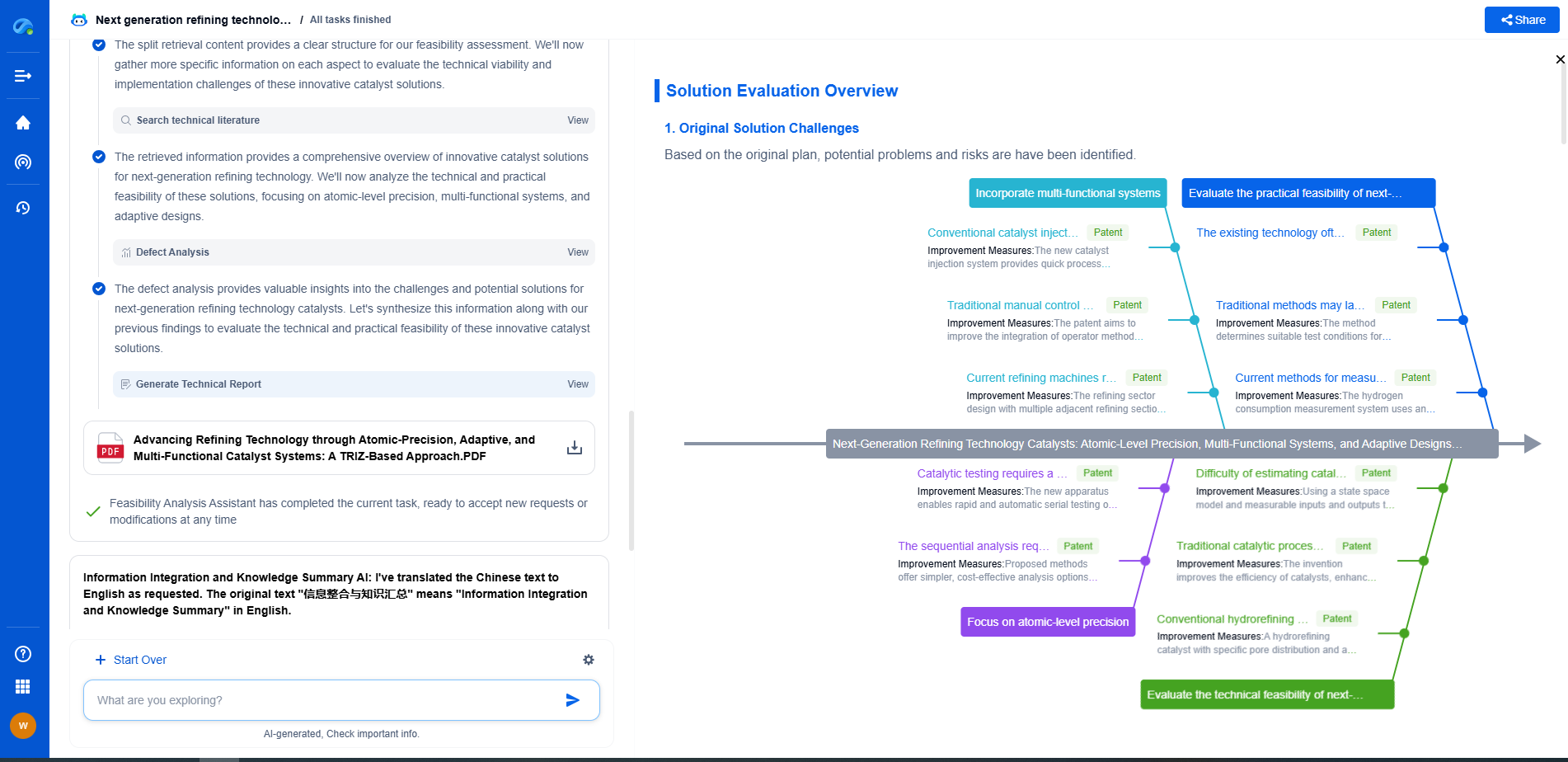

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

⚡ Ready to accelerate your solar innovation journey? Try Patsnap Eureka today and let AI help you harness the full power of the sun—and your IP strategy.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com