Leica Cameras in Machine Vision: High-Precision Industrial Inspection

JUL 10, 2025 |

In the realm of industrial inspection, precision and reliability are paramount. Machine vision systems have become an integral component of quality control processes across various industries. At the heart of many high-performance machine vision systems are cameras that capture images with exceptional clarity and detail. Leica cameras, renowned for their optical excellence and innovative technologies, have increasingly found a place in machine vision applications, particularly in high-precision industrial inspection.

The Role of Cameras in Machine Vision

Machine vision systems rely on cameras to capture images of products or components, which are then analyzed by software to detect defects, measure dimensions, or verify positioning. The quality of the captured images directly affects the system's ability to perform accurate inspections. Therefore, choosing the right camera is crucial for achieving optimal results.

Leica Cameras: A Legacy of Optical Precision

Leica has a long-standing reputation for producing cameras with superior optics and imaging capabilities. Founded over a century ago, the company has consistently pushed the boundaries of optical engineering. Leica's expertise in lens design and manufacturing is reflected in their cameras, which deliver sharp, high-resolution images with minimal distortion. This makes them ideal for machine vision applications where precision is essential.

Why Leica Cameras for Industrial Inspection?

1. Exceptional Image Quality

Leica cameras are equipped with high-quality lenses and sensors that capture images with remarkable detail and clarity. This is particularly important in industrial inspection, where even the smallest defect can have significant consequences. The ability to capture high-resolution images ensures that defects are detected early in the manufacturing process, reducing waste and improving product quality.

2. Advanced Imaging Technologies

Leica continually invests in research and development to incorporate the latest imaging technologies into their cameras. Features such as autofocus, high dynamic range (HDR), and low-light sensitivity enhance the performance of Leica cameras in diverse industrial environments. These technologies enable machine vision systems to perform reliable inspections under varying lighting conditions and in challenging scenarios.

3. Robust and Reliable Design

Industrial environments can be harsh, with factors such as dust, vibration, and temperature fluctuations posing challenges to equipment reliability. Leica cameras are designed to withstand these conditions, ensuring consistent performance over time. Their robust construction and high-quality components make them a dependable choice for industrial inspection applications.

4. Integration and Compatibility

Leica cameras are designed with integration and compatibility in mind. They can be easily incorporated into existing machine vision systems, providing seamless operation alongside other components. This adaptability makes it easier for businesses to upgrade their inspection capabilities without overhauling their entire system.

Applications in High-Precision Industrial Inspection

Leica cameras are employed in a wide range of industrial inspection applications, including:

- **Automotive Manufacturing**: Ensuring that components such as engine parts and body panels meet strict quality standards.

- **Electronics Production**: Inspecting circuit boards and semiconductor components for defects that could affect performance.

- **Pharmaceuticals**: Verifying the integrity and labeling of packaging to comply with regulatory requirements.

- **Food and Beverage**: Ensuring product consistency and package integrity to maintain consumer safety and brand reputation.

Conclusion

In the world of high-precision industrial inspection, the choice of camera can significantly impact the effectiveness of machine vision systems. Leica cameras, with their unparalleled image quality, advanced technologies, and robust design, offer a compelling solution for industries seeking to enhance their inspection processes. As technology continues to evolve, Leica remains at the forefront, providing the tools needed to meet the ever-increasing demands of quality assurance and industrial efficiency.

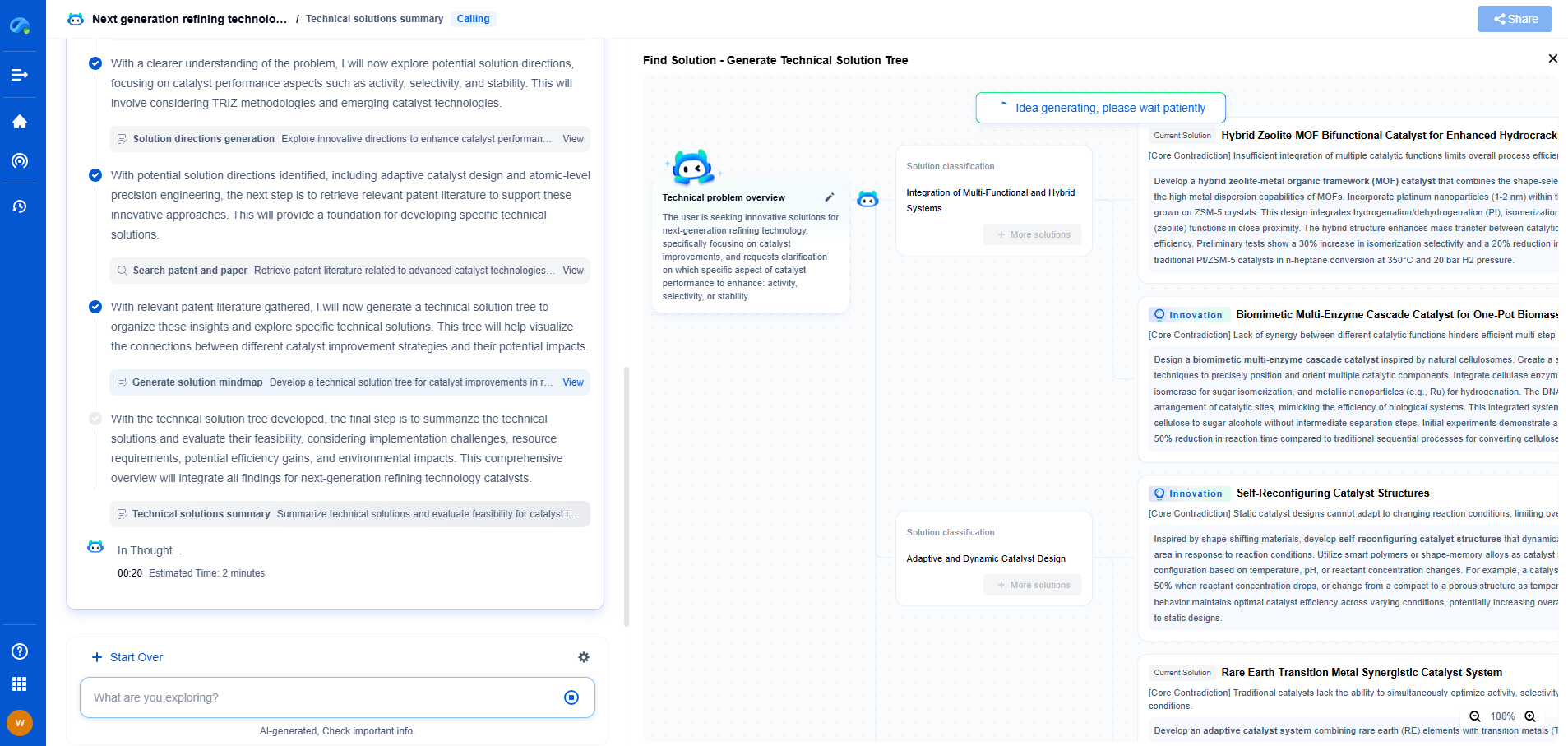

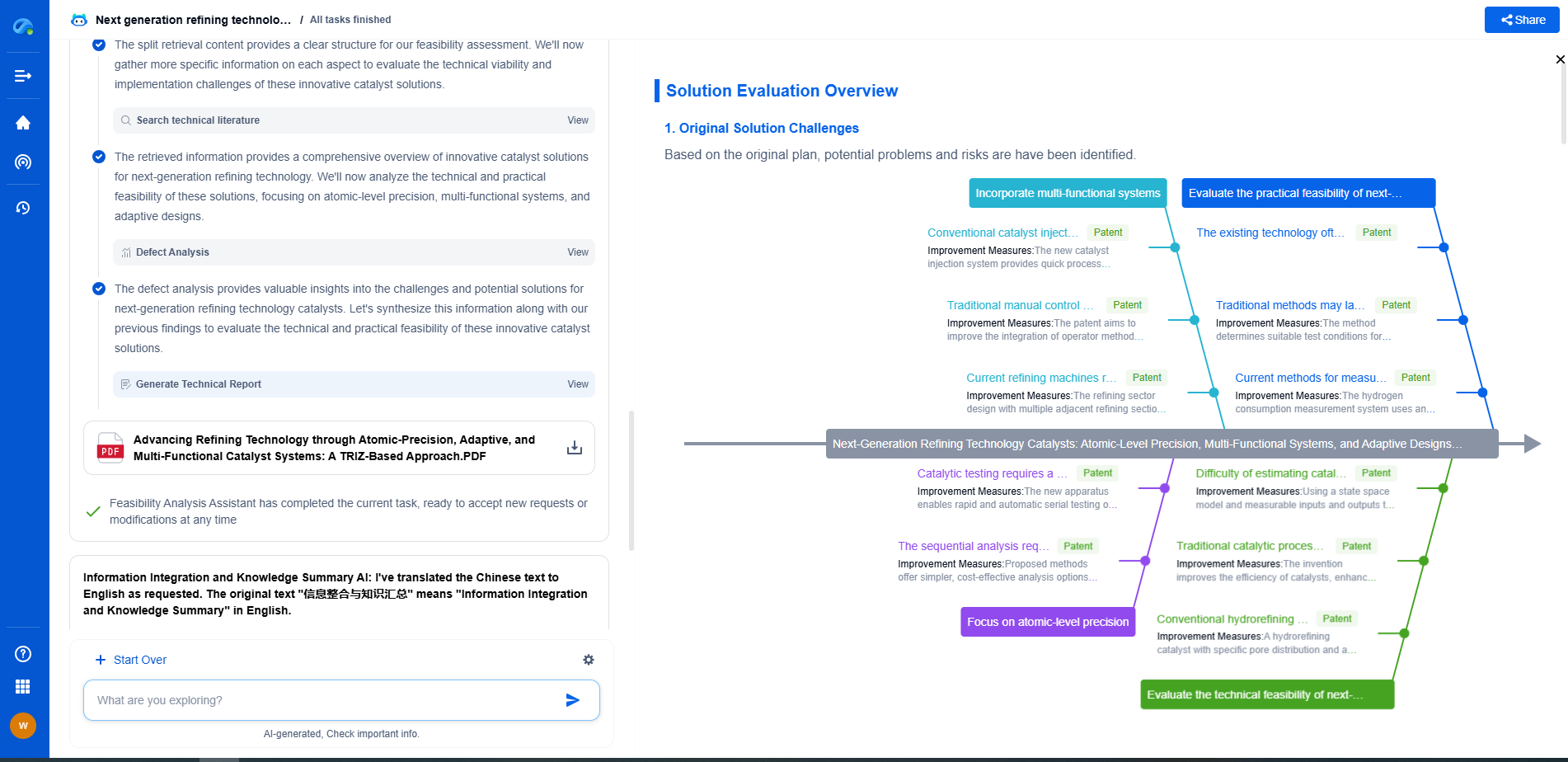

Image processing technologies—from semantic segmentation to photorealistic rendering—are driving the next generation of intelligent systems. For IP analysts and innovation scouts, identifying novel ideas before they go mainstream is essential.

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

🎯 Try Patsnap Eureka now to explore the next wave of breakthroughs in image processing, before anyone else does.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com