Marine Shore Power Systems (Cold Ironing) Explained

JUN 26, 2025 |

Understanding Marine Shore Power Systems

Marine shore power systems are designed to supply electrical power to a vessel from an onshore source while it is docked. These systems involve the integration of several components, including shore-side electrical infrastructure, onboard conversion equipment, and standardized connections to ensure safety and reliability. The process of supplying power from the shore to the vessel is commonly referred to as "cold ironing" because, once the ship’s engines are turned off, it becomes “cold.”

The fundamental purpose of these systems is to enable vessels to access cleaner energy sources while stationary. Shore power can be provided from the local electricity grid or renewable sources such as wind or solar, thereby reducing the reliance on ship-generated power that is less efficient and more polluting.

Benefits of Cold Ironing

One of the primary benefits of cold ironing is the reduction in air pollution. Ships at berth typically rely on diesel-powered auxiliary engines, which emit sulfur oxides (SOx), nitrogen oxides (NOx), and particulate matter. By connecting to shore power, emissions are significantly reduced, benefiting both the local environment and the health of port city residents.

Another advantage is noise reduction. Harbor areas often experience high levels of noise pollution from ship engines and generators. Cold ironing enables ships to turn off these engines, leading to a quieter and more pleasant environment for both port workers and nearby communities.

Additionally, cold ironing can lead to cost savings for ship operators. With rising fuel prices and increasing environmental regulations, utilizing shore power can be more economical in the long run. It also reduces engine wear and tear, potentially lowering maintenance costs.

Challenges in Implementation

Despite the numerous benefits, the implementation of marine shore power systems faces several challenges. The initial cost of installing shore power infrastructure can be high, both for ports and for ships that need to be retrofitted with compatible equipment. This requires significant investment and coordination between various stakeholders, including port authorities, ship operators, and local governments.

Standardization is another challenge. Ships and ports around the world have different electrical systems, voltages, and frequency requirements. This necessitates the development of international standards to ensure compatibility and interoperability across various locations.

Moreover, the availability of sufficient electricity supply at ports can be an issue, especially in areas where the local grid is already under strain. Ensuring a stable and sufficient power supply that can meet the demands of multiple ships docking simultaneously requires careful planning and infrastructure development.

Future Prospects of Marine Shore Power Systems

The future of marine shore power systems is promising, largely driven by increasing environmental regulations and a global push towards sustainability. As more ports and shipping companies recognize the benefits of cold ironing, investment in infrastructure is expected to increase, further facilitating the adoption of these systems.

Technological advancements also hold the potential to make cold ironing more efficient and cost-effective. The development of smart grids and renewable energy integration at ports can enhance the feasibility and attractiveness of shore power solutions. Furthermore, as international standards become more widespread, issues related to compatibility will likely diminish.

In conclusion, marine shore power systems represent a crucial step towards a greener maritime industry. By reducing emissions and noise pollution, they contribute to healthier port cities and a cleaner planet. While challenges remain, the combined efforts of industry stakeholders, technological innovation, and supportive policies will likely pave the way for widespread adoption of cold ironing in the coming years.

Stay Ahead in Power Systems Innovation

From intelligent microgrids and energy storage integration to dynamic load balancing and DC-DC converter optimization, the power supply systems domain is rapidly evolving to meet the demands of electrification, decarbonization, and energy resilience.

In such a high-stakes environment, how can your R&D and patent strategy keep up?

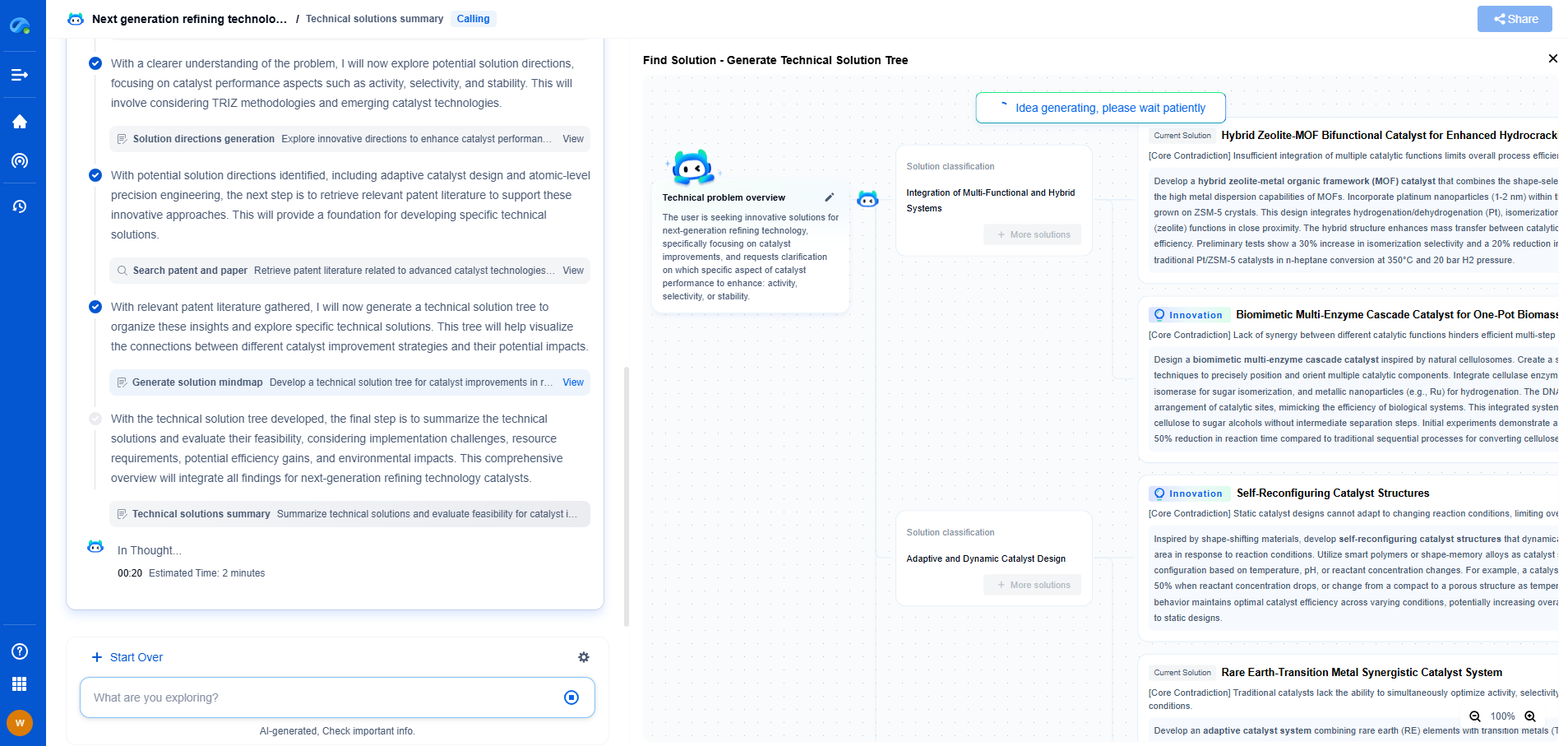

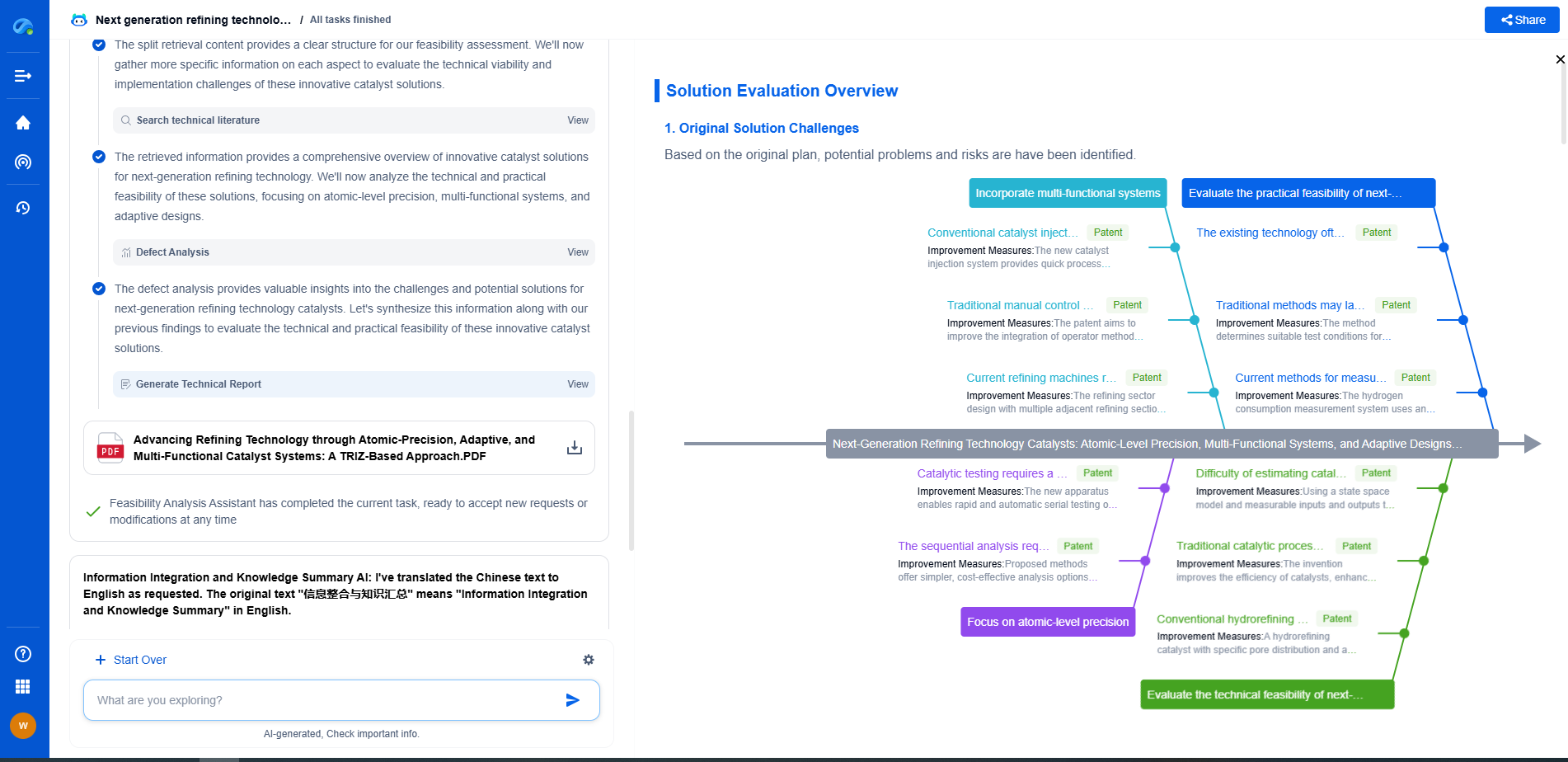

Patsnap Eureka, our intelligent AI assistant built for R&D professionals in high-tech sectors, empowers you with real-time expert-level analysis, technology roadmap exploration, and strategic mapping of core patents—all within a seamless, user-friendly interface.

👉 Experience how Patsnap Eureka can supercharge your workflow in power systems R&D and IP analysis. Request a live demo or start your trial today.

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com